In the world of farming, machinery plays a vital role in enhancing productivity and efficiency. Knowing the various elements that constitute these machines is essential for any operator. A thorough grasp of these components not only aids in effective maintenance but also contributes to optimal performance in the field.

The intricate relationships between different machine parts can often be complex. By examining a detailed representation of these components, one can identify how each element functions in unison to achieve the desired results. This knowledge empowers users to troubleshoot issues swiftly and perform necessary repairs, ensuring that their equipment remains operational.

Moreover, understanding the assembly of these mechanisms is crucial for those looking to enhance or upgrade their agricultural tools. Whether you’re an experienced farmer or a novice, having access to clear visual guides can significantly simplify the learning curve and help in making informed decisions regarding maintenance and improvements.

Understanding the John Deere 14T Baler

This section delves into the intricacies of a crucial piece of agricultural machinery designed for efficient hay and straw handling. Recognized for its reliability, this equipment plays a significant role in the harvesting process, enabling farmers to efficiently manage their crops.

Functionality is at the heart of its design. By compressing cut plant material into compact units, it facilitates easier transport and storage. The operational efficiency and innovative mechanisms contribute to minimizing labor and maximizing productivity in the field.

Moreover, maintenance is essential for ensuring longevity and performance. Familiarity with the inner workings and components allows operators to identify potential issues early, keeping the machine in optimal working condition. Regular inspection and timely replacements are key to sustaining its effectiveness over time.

In conclusion, understanding this piece of machinery enhances its operational use and ensures that it remains a vital asset in modern agriculture. Knowledge of its functionality and upkeep can lead to improved yields and streamlined harvesting processes.

Key Components of the Baler

Understanding the essential elements of a harvesting machine is crucial for effective operation and maintenance. These integral parts work together to ensure optimal performance, enabling the efficient collection and compression of agricultural materials. Familiarity with these components not only aids in troubleshooting but also enhances the overall functionality of the equipment.

Feeding Mechanism

The feeding system plays a vital role in directing the crop into the compression chamber. It typically consists of a series of rollers and augers that help to gather and transport the material efficiently. A well-designed feeding mechanism minimizes jams and ensures a steady flow of biomass for processing.

Compression Chamber

This section of the machine is where the actual compacting occurs. The compression chamber utilizes a series of belts and rollers to compact the collected material into defined shapes, such as squares or rounds. The design and capacity of this chamber significantly impact the efficiency of the entire system, influencing both the size and density of the output.

Common Issues with Baler Parts

In the world of agricultural machinery, various components can encounter frequent challenges that affect overall efficiency and performance. Understanding these common difficulties is essential for effective maintenance and troubleshooting. This knowledge enables operators to identify potential problems before they escalate into more significant issues.

One prevalent concern involves wear and tear on essential components due to constant use. Over time, friction and stress can lead to degradation, impacting the functionality of the equipment. Regular inspections can help mitigate this issue, ensuring that parts remain in optimal condition.

Another significant issue arises from misalignment of moving parts. This misalignment can result in uneven operation, causing strain and potential failure of interconnected mechanisms. Operators should regularly check for proper alignment to avoid costly repairs.

Moreover, clogging is a frequent problem that can disrupt workflow. Debris and foreign materials can accumulate, obstructing the flow and causing inefficiencies. Implementing a routine cleaning schedule is vital to minimize this risk and maintain smooth operation.

Lastly, lubrication is crucial in preventing friction-related issues. Inadequate lubrication can lead to increased wear and potential breakdowns. Operators must ensure that all necessary components are properly lubricated according to manufacturer guidelines to prolong the lifespan of the machinery.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of agricultural machinery. Regular attention not only enhances performance but also extends the lifespan of your equipment. Following a few key practices can make a significant difference in maintaining functionality and reliability.

Regular Inspections: Conduct frequent checks to identify wear and tear early. Look for signs of rust, loose components, or unusual noises that may indicate underlying issues. Addressing these problems promptly can prevent costly repairs down the line.

Lubrication: Keeping moving parts well-lubricated is crucial for reducing friction and wear. Use the recommended lubricants for each component and follow the manufacturer’s guidelines regarding intervals and amounts.

Cleanliness: After each use, ensure that the machinery is clean. Remove debris, dust, and residue that can accumulate and lead to operational problems. A clean machine operates more efficiently and reduces the risk of malfunctions.

Storage Conditions: When not in use, store equipment in a dry, sheltered environment to protect it from the elements. Exposure to moisture and extreme temperatures can cause significant damage over time.

Replacement of Worn Parts: Be proactive in replacing parts that show signs of wear. Utilizing high-quality replacements will maintain performance and reliability, ensuring the machinery operates at its best.

Implementing these maintenance strategies will not only optimize performance but also promote a longer service life for your agricultural equipment.

How to Identify Replacement Parts

Identifying components for machinery can be crucial for maintaining optimal performance and longevity. Understanding the specific requirements for your equipment ensures that replacements fit correctly and function as intended. This guide will help you navigate the process of finding the right components.

Steps to Identify Components

- Check the Manual: Refer to the equipment manual for specifications and part numbers.

- Inspect the Existing Component: Look for any identifiable markings or labels on the current part.

- Consult with Experts: Seek advice from professionals or knowledgeable individuals in the field.

- Use Online Resources: Many websites offer detailed catalogs and diagrams for various machinery.

Tips for Accurate Identification

- Measure Dimensions: Use calipers or measuring tape to ensure accurate sizing.

- Note the Model: Keep track of the machine’s model and serial number, as these can be crucial for finding the right match.

- Cross-reference: Compare multiple sources to verify the accuracy of the information you gather.

- Keep Records: Document any findings for future reference, which can simplify the process next time.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can significantly enhance the performance and longevity of machinery. These authentic elements are specifically designed to fit and function seamlessly within their respective systems, ensuring optimal efficiency and reliability.

Quality Assurance

One of the primary benefits of choosing OEM components is the assurance of quality. These items undergo rigorous testing and adhere to strict manufacturing standards, which means they are less likely to fail compared to generic alternatives. When you opt for these original elements, you can trust that they will meet the exact specifications needed for your equipment.

Enhanced Performance

Using authentic components can lead to improved performance of your machinery. These original items are engineered to work harmoniously with other system elements, resulting in better efficiency, reduced downtime, and lower maintenance costs. Investing in quality not only preserves functionality but also contributes to the overall longevity of the equipment.

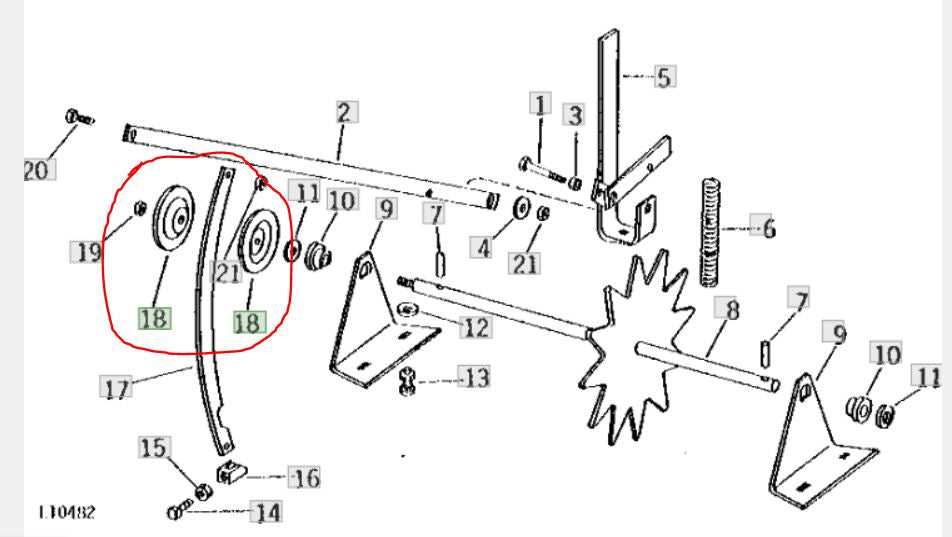

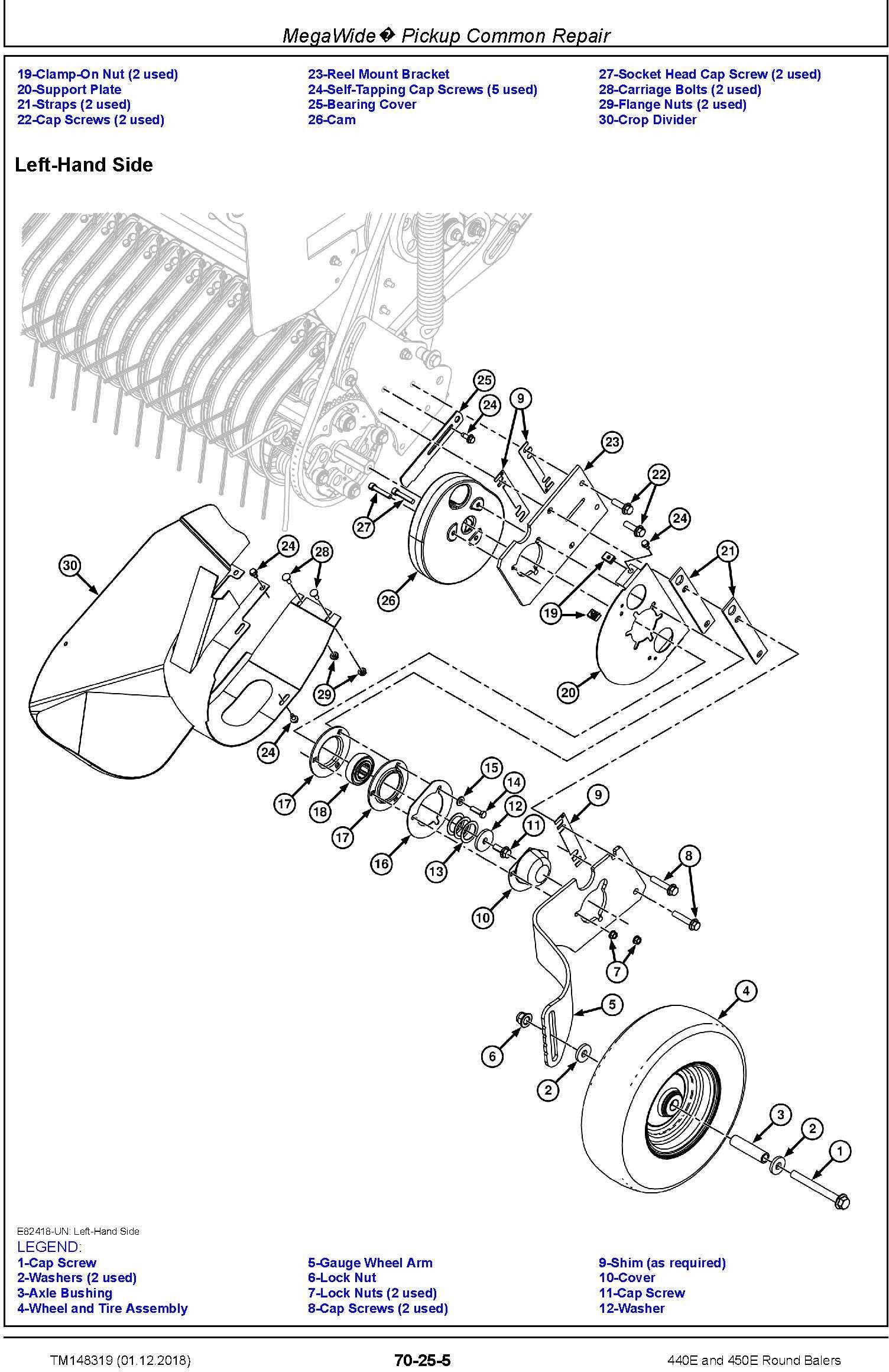

Illustrated Parts Breakdown

This section offers a detailed visual representation of essential components, aiding in understanding their functionality and interconnections. By examining these illustrations, users can gain insights into assembly, maintenance, and troubleshooting processes.

Key features of this breakdown include:

- Clear labeling of each element for easy identification.

- Comprehensive views that highlight both the exterior and interior parts.

- Annotated illustrations that explain the role of each component.

To facilitate better comprehension, the breakdown is organized into several categories:

- Drive System:

- Gear assemblies

- Belts and pulleys

- Feeding Mechanism:

- Rollers

- Chamber components

- Control System:

- Levers and switches

- Safety features

Utilizing this illustrated resource can significantly enhance operational efficiency and simplify maintenance tasks.

Resources for Parts and Diagrams

When it comes to maintaining and repairing agricultural machinery, having access to reliable information and resources is essential. This section provides valuable guidance on where to find detailed schematics and components for efficient equipment management.

Online Resources

- Manufacturer Websites: Official sites often offer downloadable manuals and parts lists.

- Online Retailers: E-commerce platforms frequently provide detailed listings and images of components.

- Forums and Communities: Engaging with online groups can yield helpful insights and shared resources from fellow equipment owners.

Printed Materials

- Service Manuals: Printed guides contain comprehensive diagrams and specifications.

- Catalogs: Supplier catalogs can serve as quick references for identifying necessary items.

- Local Dealerships: Visiting dealerships can provide access to both printed and digital resources, along with expert advice.