In the realm of agricultural equipment, comprehending the intricate arrangements of various elements is crucial for effective maintenance and operation. A thorough grasp of these structures allows operators to identify and resolve issues swiftly, ensuring optimal performance and longevity of their machinery.

Visual representations of these intricate systems serve as invaluable tools for both seasoned technicians and newcomers alike. By examining the layout of individual components, users can better understand their interrelations, facilitating more informed decisions during repairs or upgrades.

Moreover, having access to comprehensive visual aids can enhance the overall efficiency of repair processes. This not only minimizes downtime but also empowers users to conduct their maintenance with confidence and precision. The following sections will delve into essential insights and resources that illuminate these complex configurations.

Understanding John Deere JA62 Parts

This section provides insight into the components of a specific agricultural machine, highlighting their roles and significance in maintaining efficiency. Grasping the function of each element is crucial for optimal performance and longevity.

Key Components

Among the vital elements, the engine, transmission, and cutting system stand out. Each plays a fundamental role in ensuring the overall effectiveness of the equipment. Familiarity with these components can lead to better maintenance practices.

Maintenance and Replacement

Regular upkeep and timely replacements are essential to avoid costly repairs. Understanding when to service or substitute components can significantly enhance the machine’s lifespan. Knowing the signs of wear can help in making informed decisions for ultimate performance.

Importance of Accurate Parts Diagrams

Having precise illustrations for machinery components is crucial for effective maintenance and repair. These visuals serve as essential guides, enabling users to identify and locate individual elements, ensuring that every task is performed efficiently.

Enhanced Efficiency

Clear representations of components facilitate quicker troubleshooting and assembly. Technicians can easily pinpoint issues, reducing downtime and boosting overall productivity. This efficiency translates to cost savings and improved operational performance.

Improved Safety

Accurate schematics are vital for safety, as they provide essential information on correct assembly and disassembly procedures. This minimizes the risk of accidents and injuries, protecting both personnel and equipment.

Common Issues with JA62 Components

In any machinery, certain elements may encounter frequent problems that can hinder overall performance. Identifying and addressing these issues is crucial for maintaining efficiency and longevity. Users often report a range of concerns that can arise from wear and tear, improper maintenance, or compatibility with other systems.

One prevalent challenge involves electrical components, where connections can become loose or corroded, leading to intermittent functionality. Additionally, mechanical parts may experience excessive wear, resulting in decreased efficiency or even complete failure if not addressed promptly. Regular inspections and preventive measures can mitigate these risks.

Another common issue pertains to hydraulic systems, where leaks can develop over time. This not only affects performance but also poses safety risks if not managed appropriately. Ensuring proper sealing and routine checks can help in avoiding such complications.

Lastly, users often face challenges with wear components that may require replacement more frequently than expected. Monitoring these elements closely and adhering to maintenance schedules can ultimately enhance reliability and performance.

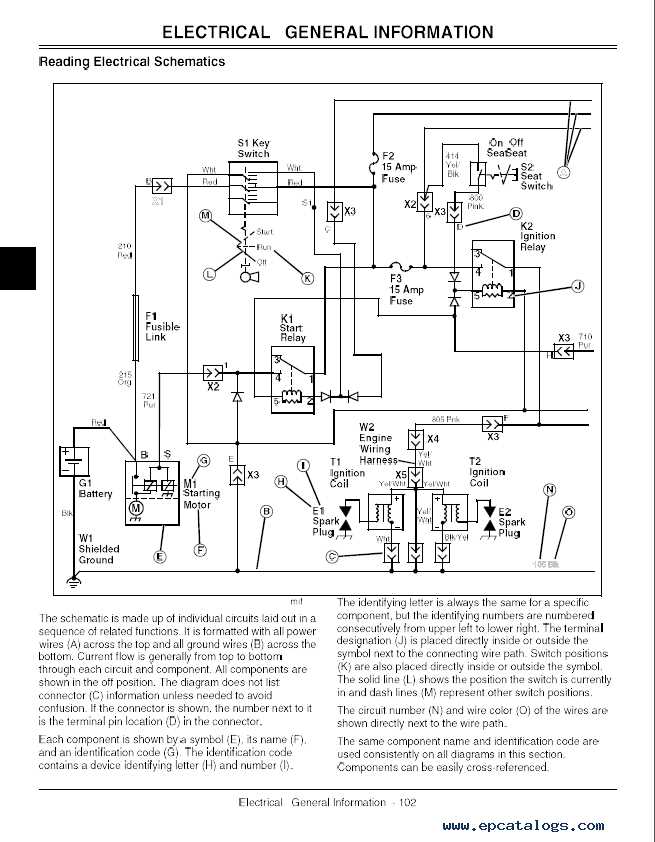

How to Read Parts Diagrams Effectively

Understanding visual representations of mechanical components is essential for anyone involved in maintenance or repair tasks. These illustrations provide a detailed overview of the assembly, allowing you to identify various elements and their relationships. Mastering the art of interpreting these visuals can significantly enhance your efficiency and accuracy during troubleshooting or replacement procedures.

Familiarize Yourself with the Legend

Most visual schematics come with a legend that explains the symbols and notations used. Before diving into the main illustration, take a moment to review this section. Knowing what each symbol represents will save you time and prevent confusion as you work through the different parts.

Break Down the Components

Instead of viewing the entire illustration at once, focus on smaller sections. Identify key assemblies and their connections. By dissecting the overall image, you can better understand how individual pieces fit together, making it easier to locate specific items when needed.

Where to Find Official Diagrams

Accessing accurate and reliable technical illustrations is crucial for anyone involved in maintenance or repairs. These resources provide essential guidance, ensuring that tasks are performed correctly and efficiently. Understanding where to locate these official materials can significantly enhance your work experience.

Manufacturer’s Website: The primary source for authentic technical illustrations is often the manufacturer’s official website. Many companies offer comprehensive sections dedicated to resources, including user manuals and detailed schematics. Navigating to the support or resources tab typically yields a wealth of information.

Authorized Dealers: Authorized retailers and service centers frequently possess copies of official illustrations. Establishing a relationship with a dealer can grant access to additional resources, including printed manuals and expert advice tailored to specific models.

Online Forums and Communities: Engaging with online communities can be beneficial. Many enthusiasts and professionals share valuable resources, including links to official illustrations. Participating in these forums can lead to discovering hidden gems that might not be widely known.

Technical Publications: Various technical publications and magazines offer in-depth articles, including diagrams for different models. Subscribing to industry-related journals can keep you updated on the latest resources and best practices.

Customer Support: If you encounter difficulty locating specific illustrations, reaching out to customer support can be advantageous. Representatives can often provide direct links or guidance on where to find the required materials.

Maintenance Tips for JA62 Parts

Proper upkeep of machinery components is essential for optimal performance and longevity. Regular attention to key elements can significantly enhance efficiency and prevent unexpected breakdowns. Implementing a structured maintenance routine ensures that each segment functions smoothly and reliably.

1. Regular Inspection: Frequently examine all components for signs of wear or damage. Early detection of issues can save time and resources in the long run.

2. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction, minimizes wear, and promotes smooth operation. Refer to manufacturer guidelines for recommended lubricants.

3. Cleanliness: Keep all areas free from dirt and debris. Accumulation of contaminants can hinder performance and lead to unnecessary strain on the machinery.

4. Tightening Fasteners: Periodically check and tighten bolts and screws to prevent parts from loosening during operation. This simple task can greatly enhance safety and functionality.

5. Follow Manufacturer Guidelines: Always adhere to the specific maintenance recommendations provided by the manufacturer. These instructions are tailored to maximize the lifespan and efficiency of your equipment.

By implementing these practices, you can ensure that your equipment remains in peak condition, allowing for seamless operation and reduced risk of malfunctions.

Identifying Genuine vs. Aftermarket Parts

When maintaining equipment, distinguishing between authentic and alternative components is crucial for performance and longevity. Genuine items typically meet the manufacturer’s specifications, while alternatives can vary in quality and compatibility. Understanding the differences can help ensure optimal functionality and reliability in operations.

Quality and Performance

Authentic components are designed to provide the best performance and durability, often backed by warranties. In contrast, aftermarket options may offer cost savings but can sometimes compromise quality. Assessing materials and construction can reveal significant insights into expected performance.

Packaging and Markings

Another method to identify genuine components is to examine packaging and labeling. Authentic items usually feature consistent branding and high-quality packaging. Look for certifications or manufacturer logos that verify authenticity, as these are often absent in lower-quality alternatives.

Frequently Replaced JA62 Components

In the world of machinery, certain elements tend to require more frequent attention due to wear and tear. Understanding these components is essential for maintenance and efficiency. This section will explore some of the most commonly substituted elements that play a crucial role in overall performance.

Commonly Changed Elements

Filters are among the most regularly replaced items, ensuring the machine operates smoothly by preventing contaminants from affecting its functionality. Regular replacement is vital for optimal operation.

Key Wear Parts

Batteries are another critical component that often needs replacement, especially as they age. Keeping a fresh battery can greatly enhance the reliability and starting power of the equipment.

Resources for Repair and Replacement

When it comes to maintaining and restoring machinery, having access to quality information and materials is essential. Various platforms offer invaluable tools, guides, and components to ensure optimal performance and longevity of your equipment.

Online Communities: Engaging with forums and social media groups can provide insights and firsthand experiences from other users. These platforms often share troubleshooting tips and recommended suppliers.

Manufacturer Websites: Many original equipment manufacturers provide extensive resources, including manuals, schematics, and lists of authorized distributors. These are vital for accurate replacements and repairs.

Local Dealerships: Visiting nearby retailers can yield direct access to essential components and expert advice. Staff members can help identify specific needs and offer personalized service.

Third-Party Suppliers: Numerous independent companies specialize in aftermarket components. They often offer competitive pricing and a wide range of alternatives to suit various requirements.

By exploring these avenues, you can enhance your repair and replacement efforts, ensuring your machinery operates at its best.