When maintaining agricultural machinery, it is crucial to have a clear understanding of its structure. This knowledge allows for more efficient repairs and improvements, ensuring that the equipment remains reliable over time. Each mechanical system within these machines plays a vital role, and knowing how various components connect and function together can make a significant difference in performance.

Exploring the individual mechanisms within farming equipment helps you identify key areas that may require attention. Whether addressing routine maintenance or troubleshooting issues, having a clear map of the internal layout is essential. The connections between various systems and their detailed functions will provide the insight needed to keep your machinery in peak condition.

By examining the internal arrangement and focusing on essential mechanical elements, you can better plan repairs and ensure proper operation. This overview will serve as a

Understanding the Components of the 4230

To fully grasp the working of this versatile machine, it’s crucial to become familiar with the essential elements that allow it to perform its tasks efficiently. Each section plays a vital role, working together to ensure smooth operations, optimal performance, and long-lasting durability. Let’s delve into the key elements that contribute to the overall functionality.

- Engine: The power source responsible for driving all the essential functions of the equipment.

- Hydraulic System: Provides the necessary force to lift and maneuver various attachments, ensuring smooth operation.

- Transmission: A vital mechanism that transmits power from the engine to the wheels, allowing movement and speed control.

- Cooling System: Maintains optimal operating temperature, preventing overheating during extended use.

- Electrical Components: Manage essential tasks such as starting the engine, lighting, and powering other electronic systems.

By understanding the role each part plays, you can better appreciate how they interact to maintain the machine’s efficiency

Engine Structure and Functionality

The internal mechanisms responsible for power generation play a crucial role in the overall performance of agricultural equipment. A deep understanding of how the engine components interact helps in maintaining smooth operation and extending the machinery’s lifespan.

Core Elements of the engine consist of several interdependent parts, including the fuel system, pistons, and cooling mechanisms. These elements work in unison to convert energy into mechanical force, ensuring the machine operates efficiently under various conditions.

Maintaining these systems is essential to optimize functionality and avoid potential breakdowns. Regular inspections and timely adjustments can help keep the equipment in peak condition, allowing it to handle demanding tasks with minimal effort.

Transmission Mechanism Overview

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring the smooth operation of the vehicle. It allows for the regulation of speed and torque, adapting to varying driving conditions. By facilitating the efficient distribution of energy, this mechanism enhances both performance and fuel efficiency.

At its core, the system consists of various interconnected components that work together to shift gears and manage power distribution. Whether operating in high or low gears, the seamless interaction between these parts is vital for maintaining control and stability during movement.

Proper maintenance and understanding of the transmission structure are essential for ensuring longevity and preventing potential issues. Regular inspections and timely adjustments can significantly improve the system’s reliability and overall functionality.

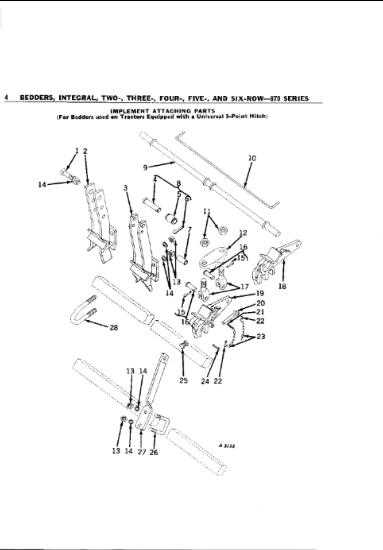

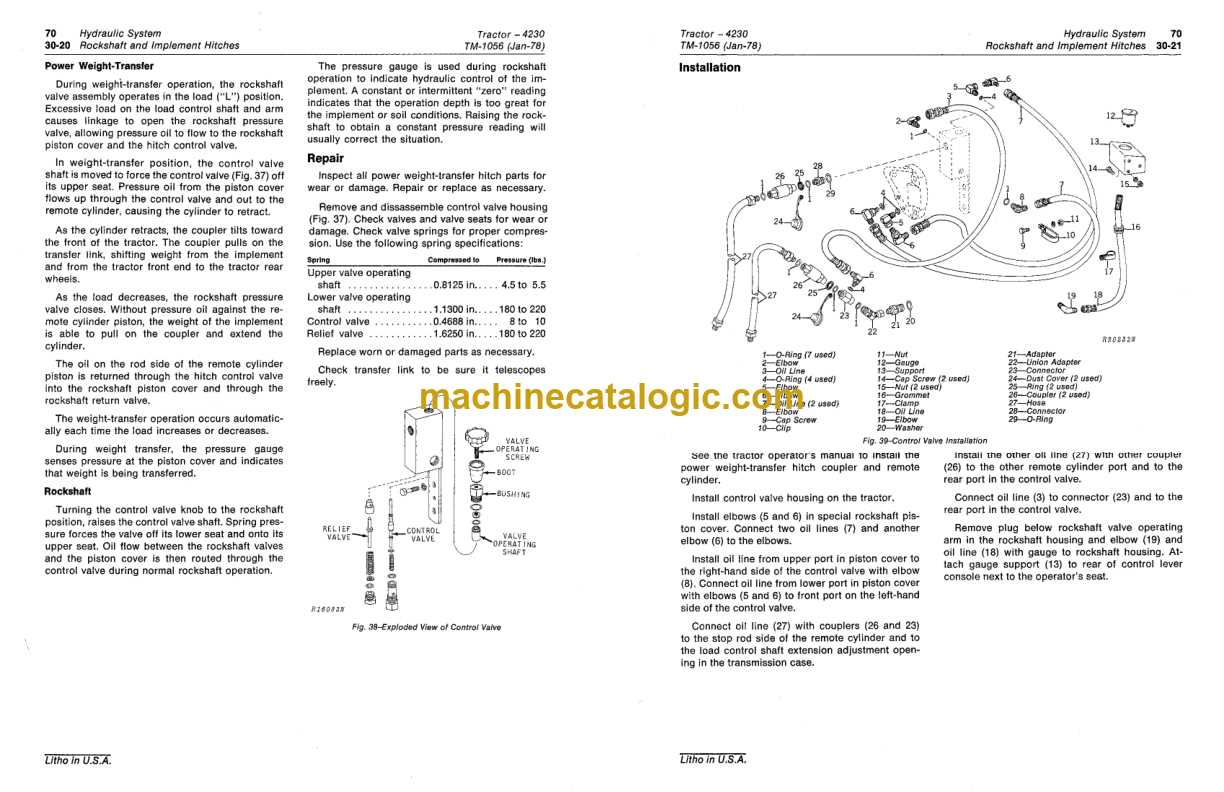

Hydraulic System Components Breakdown

The hydraulic setup of any heavy-duty machinery is a crucial system, responsible for powering various functions. Understanding the individual elements involved allows for better maintenance, diagnosis, and repair. Below is an overview of the key elements typically found in hydraulic assemblies.

- Pump: The pump generates the necessary flow and pressure to drive the system, ensuring smooth operation of different components.

- Reservoir: This component stores the hydraulic fluid, maintaining adequate levels for optimal performance and preventing overheating.

- Control Valves: These are essential for directing the flow of fluid to specific areas, enabling precise control over movements and functions.

- Hoses and Lines: Responsible for transporting the hydraulic fluid between different parts of the system, these must be well-maint

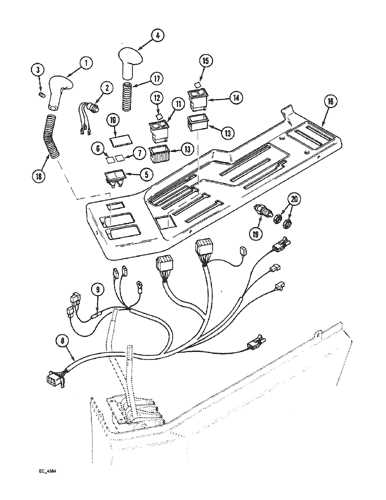

Electrical System Key Parts

The electrical system is essential for ensuring that various functions operate smoothly and reliably. It plays a critical role in powering essential components and managing the flow of energy throughout the entire machine.

Main Power Source

The heart of the electrical system is the power supply, which is responsible for generating and distributing energy. This includes the battery and related elements that provide electricity to key systems, allowing for proper functioning even in demanding conditions.

- Battery: Supplies energy to start the engine and run auxiliary systems.

- Alternator: Recharges the battery while the engine is running, ensuring continuous operation.

Wiring and Connections

Wiring serves as the network that transmits electricity to different areas, making sure all components receive the power they need. Quality connections and cables are vital for reducing energy loss and preventing malfunctions.

- Circuit Breakers: Protect electrical circuits from overload or short circuits.

- Fuses: Safeguard the system by interrupting the flow in case of excessive current.

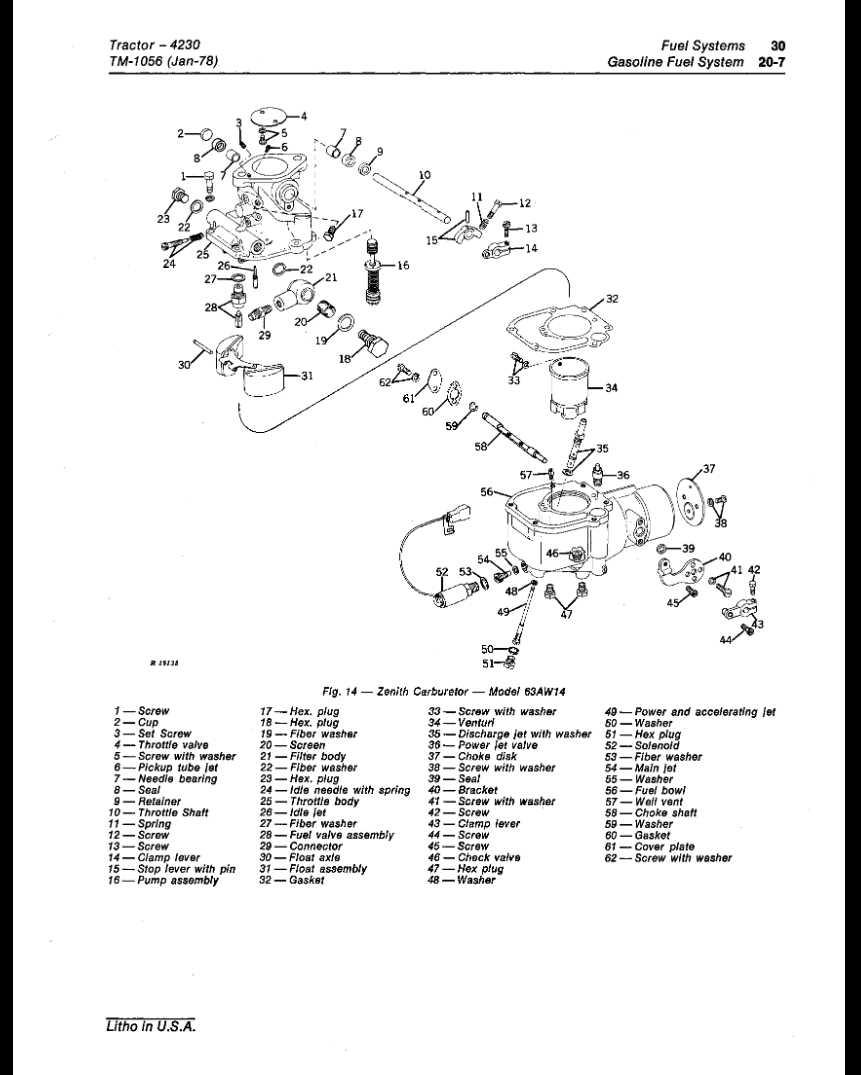

Fuel System Design and Operation

The design and functionality of the fuel delivery system play a crucial role in the overall performance of any agricultural machinery. This system is engineered to ensure that fuel is efficiently transported from the tank to the engine, optimizing combustion and maintaining operational efficiency. Understanding the components and their interactions is essential for effective maintenance and troubleshooting.

Key Components of the Fuel Delivery System

The fuel delivery system typically consists of several vital elements, including the fuel tank, pump, filters, and injectors. Each component serves a specific purpose:

- Fuel Tank: Stores the fuel, ensuring a steady supply for the engine.

- Pump: Moves fuel from the tank to the engine under pressure.

- Filters: Remove impurities and contaminants from the fuel, protecting the engine.

- Injectors: Atomize fuel for efficient mixing with air in the combustion chamber.

Operational Principles

In operation, the fuel system maintains a consistent flow to support engine requirements. When the engine is activated, the pump draws fuel from the tank and sends it through filters to eliminate debris. Clean fuel is then delivered to the injectors, which precisely meter the amount of fuel injected into the combustion chamber. This process is vital for optimal performance and emissions control, ensuring the machinery operates efficiently under varying loads and conditions.

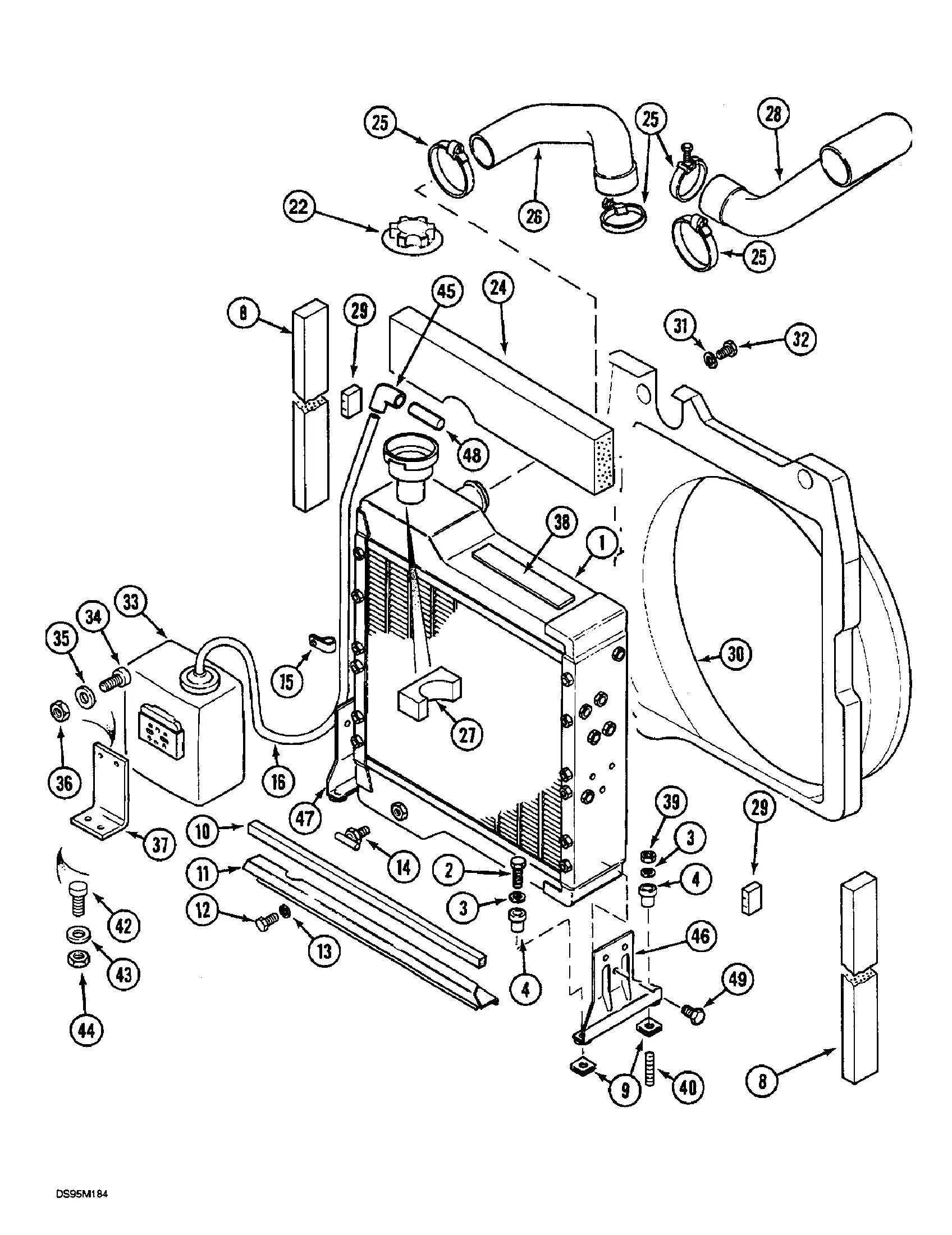

Cooling System and Its Role

The cooling system in agricultural machinery is crucial for maintaining optimal operating temperatures, ensuring efficient performance and longevity of the engine. It is designed to regulate heat dissipation, preventing overheating during extensive use. Understanding the components and their functions within this system is essential for effective maintenance and troubleshooting.

Key components of the cooling system include:

- Radiator: Acts as a heat exchanger, dissipating heat from the engine coolant into the air.

- Water Pump: Circulates coolant through the engine and radiator, promoting consistent temperature regulation.

- Thermostat: Monitors coolant temperature and controls its flow to maintain an optimal operating range.

- Cooling Fans: Enhance airflow through the radiator, improving heat dissipation, especially during low-speed operation.

- Coolant Reservoir: Stores excess coolant and allows for expansion and contraction of the fluid during heating and cooling cycles.

Maintaining the cooling system is vital for:

- Preventing engine damage due to excessive heat.

- Enhancing fuel efficiency through optimal engine performance.

- Extending the overall lifespan of the machinery.

Regular inspections and maintenance of the cooling system components can help identify potential issues early, ensuring reliable operation in various conditions.

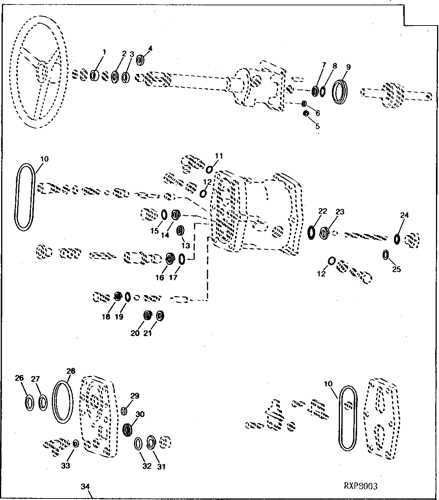

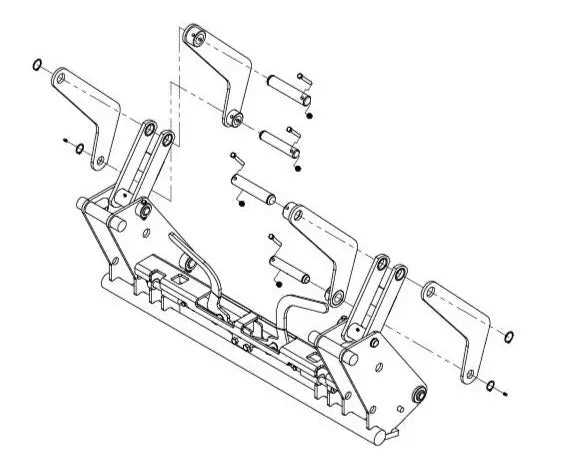

Steering Mechanism and Its Elements

The steering system of a vehicle plays a crucial role in its overall functionality and control. This assembly enables operators to navigate with precision, ensuring that the machine responds effectively to directional commands. Understanding the key components involved in this system is essential for maintenance and repair, as each element contributes to the smooth operation of the machinery.

Key Components

- Steering Wheel: The primary interface for the operator, allowing for manual input of direction.

- Steering Column: Connects the steering wheel to the gear mechanism, facilitating the transfer of movement.

- Gear Mechanism: Converts the rotational motion of the steering wheel into lateral movement of the wheels.

- Linkage: A series of rods and joints that connect the gear mechanism to the wheels, transmitting motion.

- Wheels: The final components that respond to the steering inputs, changing the direction of travel.

Maintenance Considerations

Regular inspection of the steering system is vital to ensure safety and reliability. Key aspects to monitor include:

- Checking for wear and tear on the steering components.

- Ensuring proper lubrication of moving parts.

- Verifying alignment and adjustment of the linkage.

- Inspecting for any loose connections that may affect performance.

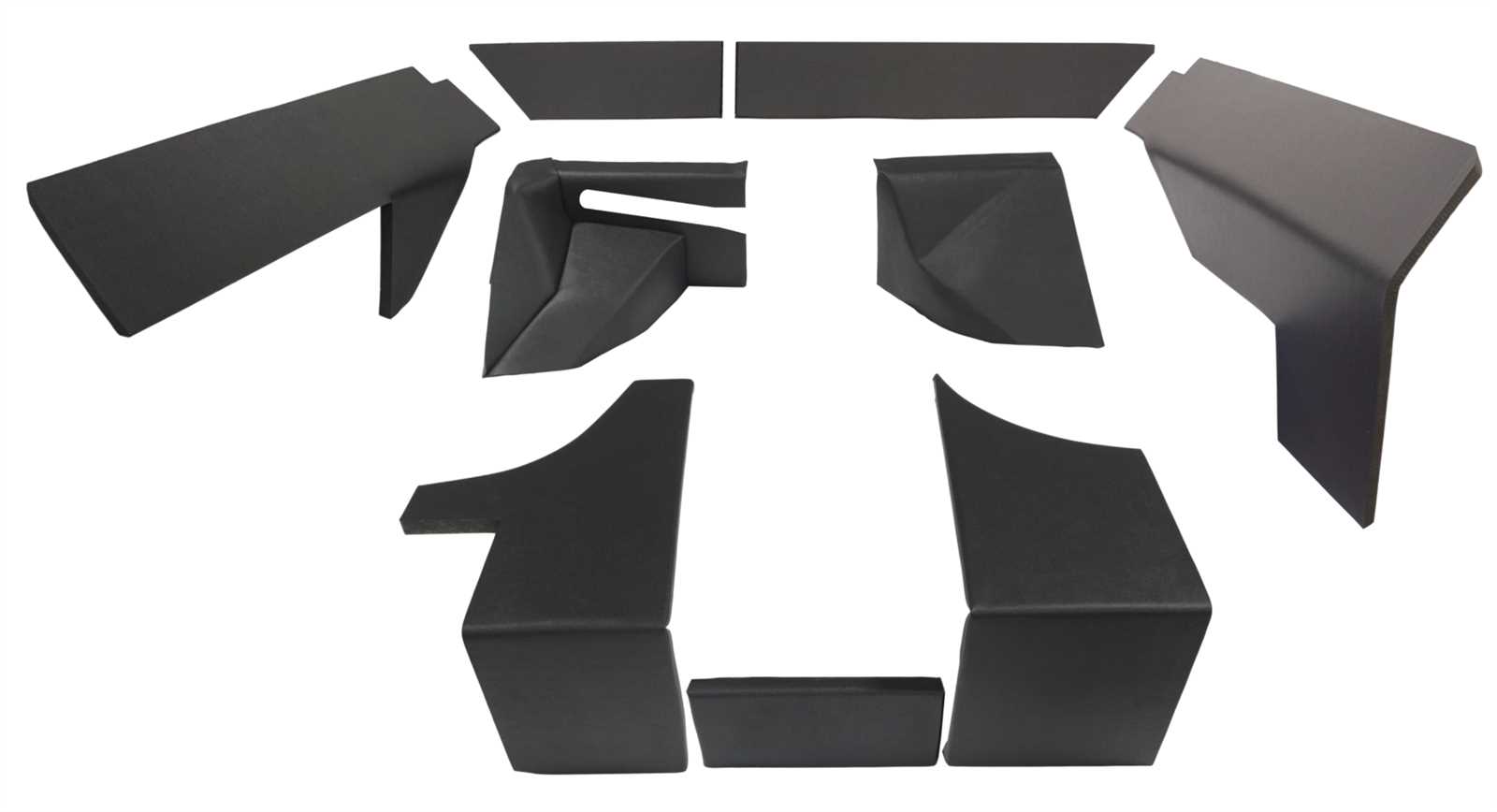

Brake System Parts and Maintenance

The braking mechanism is a crucial component of any machinery, ensuring safe and reliable operation. Regular upkeep and an understanding of the various elements involved in this system are essential for optimal performance. By familiarizing oneself with the essential components and maintenance practices, operators can enhance the longevity and efficiency of their equipment.

Key Components of the Braking Mechanism

Several fundamental elements contribute to the functionality of the braking system. These include the brake pedal, hydraulic lines, calipers, and friction materials. Each component plays a vital role in converting mechanical energy into friction, thereby slowing down or stopping the machinery effectively. Routine checks and timely replacements of worn parts can prevent failures and ensure smooth operation.

Maintenance Practices for Longevity

Regular maintenance of the braking system involves inspecting components for wear and tear, checking fluid levels, and ensuring proper alignment. It is advisable to replace friction materials as needed and to flush the hydraulic system periodically to maintain optimal performance. Keeping the system clean and well-lubricated can significantly extend the lifespan of the braking mechanism and enhance overall safety.