Exploring the intricacies of machinery used in agriculture reveals a fascinating world of interrelated elements that ensure optimal functionality. Each segment plays a crucial role in the overall performance, making it essential for operators and enthusiasts to grasp how these pieces work together. A comprehensive overview of these components provides valuable insights for maintenance and repair.

When delving into the specifics, one can appreciate the design and engineering behind these implements. Knowledge of each individual item not only enhances operational efficiency but also aids in troubleshooting potential issues. This understanding empowers users to maximize their equipment’s potential, ensuring reliability in the field.

Ultimately, recognizing how these elements interact leads to more informed decisions regarding upkeep and upgrades. Whether for professional farming or personal projects, a solid grasp of machinery components is indispensable for anyone seeking to excel in agricultural practices.

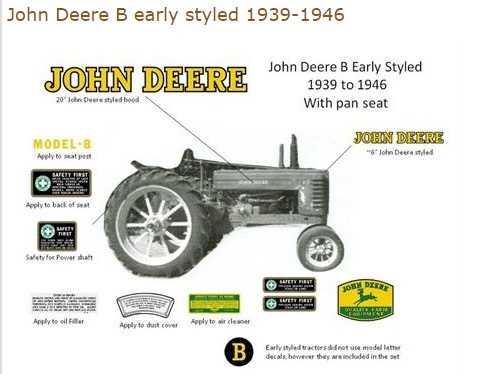

Understanding John Deere B Models

The legacy of a particular line of agricultural machinery is marked by its robust engineering and reliable performance. These models, known for their versatility and durability, have played a crucial role in transforming farming practices over the decades. Their design reflects a commitment to functionality, ensuring that operators can efficiently tackle various tasks in the field.

Each variant within this series is distinguished by unique features that cater to different agricultural needs. Engine specifications and power output have evolved to meet the demands of modern farming, while maintaining the simplicity that users appreciate. Additionally, the integration of advanced technology has further enhanced usability, making these machines indispensable on the farm.

Understanding the various configurations and enhancements available within these models allows users to make informed decisions regarding maintenance and upgrades. This knowledge is essential for optimizing performance and extending the lifespan of these valuable assets. By exploring the intricacies of this equipment, operators can better appreciate its role in supporting agricultural productivity.

Key Components of John Deere B

This section provides an overview of the essential elements that contribute to the functionality and performance of a classic agricultural machine. Understanding these components is vital for effective maintenance and operation.

Engine System

- Power Unit: The heart of the machine, responsible for converting fuel into mechanical energy.

- Cooling Mechanism: Ensures optimal operating temperatures by dissipating heat produced during engine operation.

- Fuel Delivery: System that transports fuel from the tank to the engine for combustion.

Transmission and Drive Train

- Gearbox: Facilitates speed and torque adjustments for various tasks.

- Axles: Connect the wheels and enable movement, supporting the weight of the machine.

- Clutch: Engages and disengages power from the engine to the drive system, allowing for smoother operation.

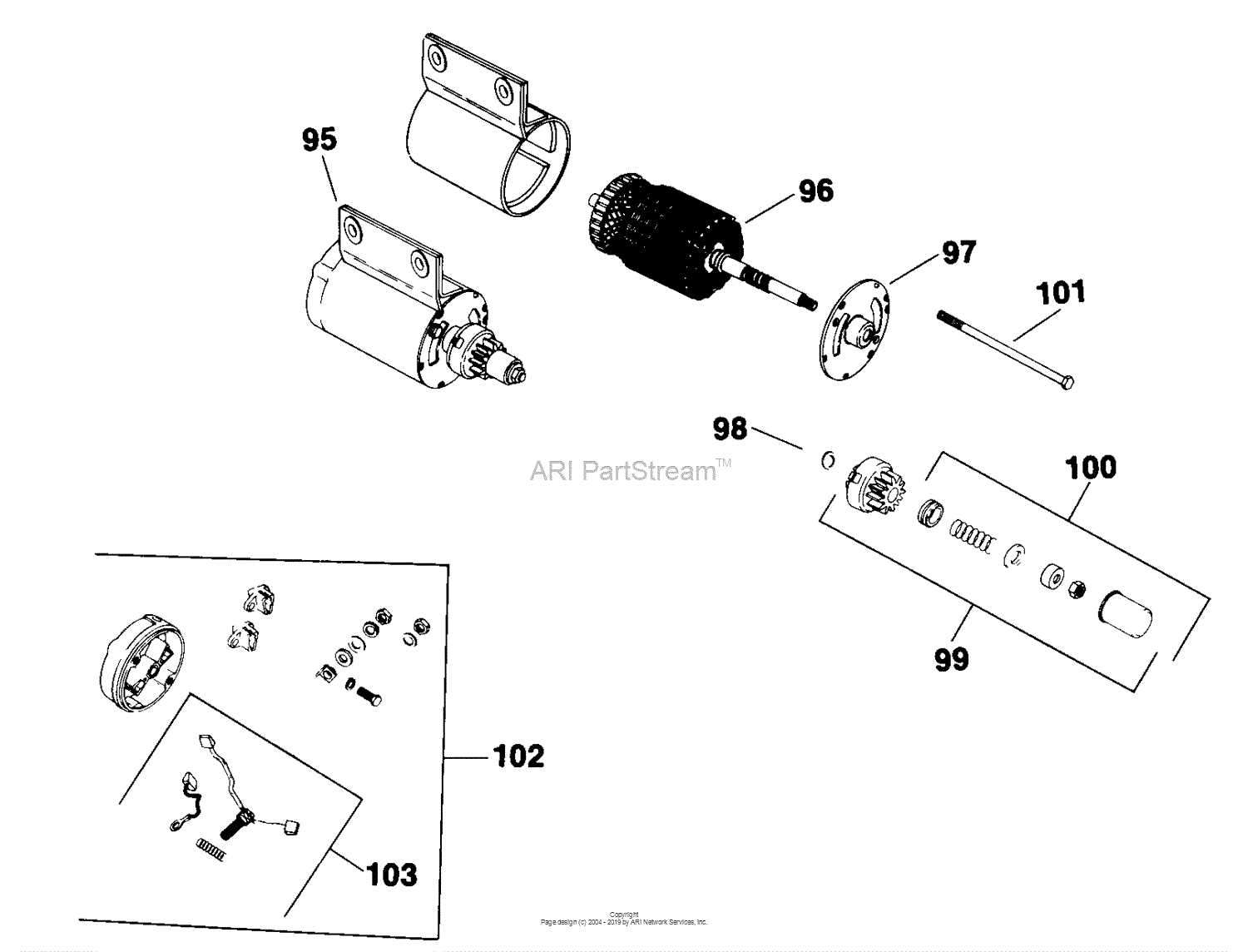

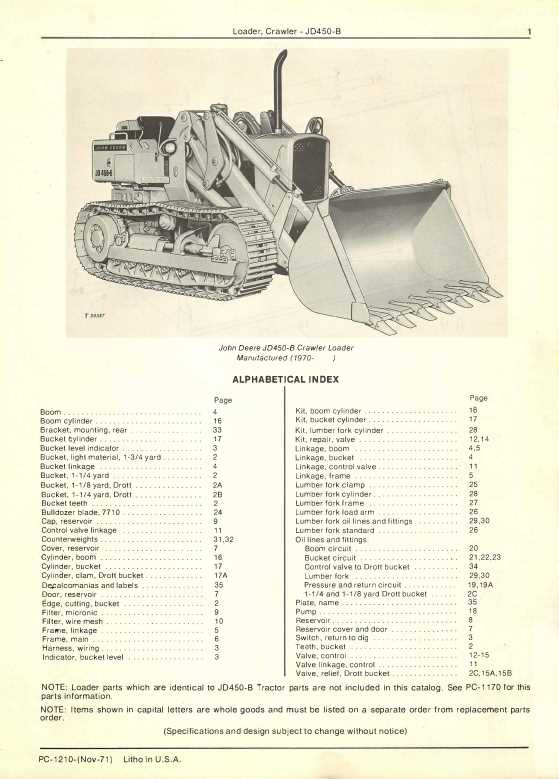

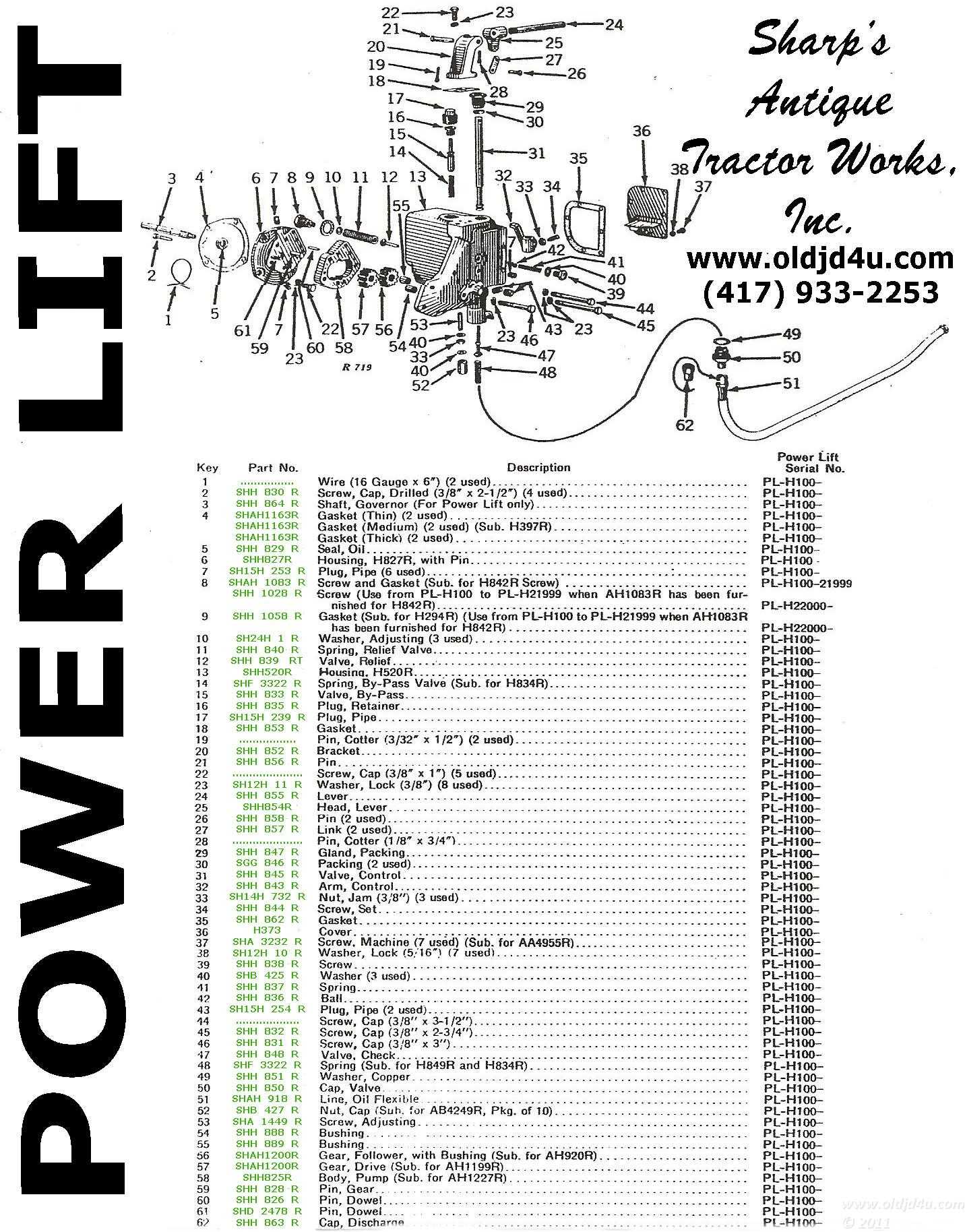

Benefits of Using Parts Diagrams

Utilizing visual representations of components enhances understanding and efficiency during maintenance or repairs. Such illustrations provide clarity, enabling users to identify necessary elements quickly, which ultimately streamlines the process.

Enhanced Clarity

Visual aids help users grasp complex structures easily. By offering a clear view of components, these tools eliminate confusion and reduce the chances of errors during assembly or disassembly.

Improved Efficiency

Having a visual reference accelerates the workflow. Technicians can swiftly locate specific items, minimizing downtime and ensuring tasks are completed promptly, which leads to greater productivity.

Common Repairs for John Deere B

Regular maintenance and timely interventions are crucial for ensuring the longevity and efficiency of agricultural machinery. Understanding common issues and their solutions can significantly enhance performance and reduce downtime. Below are some typical repairs that operators might encounter.

| Repair Type | Description |

|---|---|

| Engine Tune-Up | Regular adjustments and replacements of spark plugs, filters, and fluids to maintain optimal engine performance. |

| Brake System Maintenance | Inspection and replacement of brake pads and fluid to ensure effective stopping power. |

| Fuel System Cleaning | Removing clogs and ensuring the fuel lines and injectors function efficiently for proper combustion. |

| Transmission Repair | Addressing leaks and ensuring smooth gear transitions through fluid changes and part replacements. |

Finding Replacement Parts Online

Locating components for machinery can be a straightforward process when utilizing the internet effectively. Numerous online platforms offer a wide array of options, ensuring that users can find what they need with ease. The key is to navigate these resources strategically to identify reliable suppliers and the correct items.

Start by using specific keywords that describe the item you are looking for, including model numbers and other relevant identifiers. This specificity helps narrow down the search results, making it simpler to locate the exact component required for your equipment. Additionally, consider visiting websites dedicated to machinery and equipment, as they often have extensive catalogs and may provide helpful diagrams or schematics.

When exploring various online retailers, pay attention to customer reviews and ratings. This feedback can provide valuable insights into the quality of the components and the reliability of the seller. Some platforms also offer customer support, which can be beneficial if you have questions or need assistance in making your selection.

Lastly, compare prices across different sites to ensure you are getting the best deal. Many online stores provide discounts or promotions, making it worthwhile to shop around before finalizing a purchase. By leveraging these strategies, you can efficiently find the necessary components to keep your machinery running smoothly.

Identifying Original vs. Aftermarket Parts

When it comes to machinery maintenance, distinguishing between genuine components and alternatives is crucial for optimal performance. Understanding the differences can significantly impact both longevity and efficiency. Many operators seek affordable options, but the implications of choosing the wrong type can be significant.

Genuine components are typically produced by the original manufacturer, ensuring that they meet specific quality and performance standards. These items are designed to fit perfectly and work seamlessly with your equipment, providing reliability and peace of mind.

On the other hand, alternative components often come from third-party manufacturers and may offer a lower price point. However, the quality can vary widely. While some alternatives are engineered to high standards, others may not meet the necessary specifications, potentially leading to suboptimal functionality or even damage over time.

When assessing these options, it is essential to consider factors such as warranty coverage, availability, and compatibility. Researching reviews and seeking advice from experienced users can also guide you in making an informed decision.

Ultimately, understanding the distinctions between these two categories empowers users to choose wisely, balancing cost with quality for the best outcomes in their maintenance efforts.

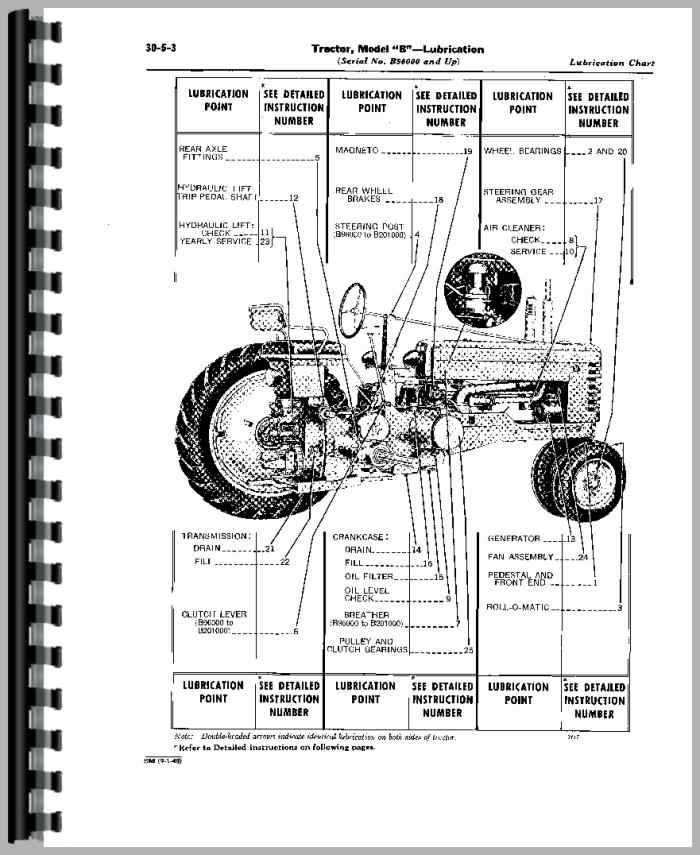

Maintenance Tips for Longevity

Ensuring the durability of machinery requires consistent attention and care. Implementing proper upkeep practices not only enhances performance but also extends the lifespan of equipment. Below are essential strategies to maintain your machinery effectively.

Regular Inspections

- Conduct thorough checks on all components.

- Look for signs of wear and tear.

- Address any issues promptly to prevent further damage.

Proper Lubrication

- Use the recommended lubricants for optimal functionality.

- Regularly check oil levels and replace when necessary.

- Ensure all moving parts are adequately lubricated to minimize friction.

Resourceful Communities for Support

In times of need, the strength of community becomes invaluable. Individuals can find a wealth of knowledge and assistance through local groups, forums, and networks. These resourceful communities foster collaboration and provide a platform for sharing insights and experiences.

Networking with Others can lead to discovering new resources and solutions. Engaging with fellow enthusiasts or professionals allows for the exchange of tips, tools, and strategies that may otherwise go unnoticed.

Additionally, online platforms offer opportunities to connect with a broader audience. By participating in discussions, members can delve into specific challenges and access a treasure trove of collective wisdom, making the pursuit of information more efficient and effective.

Ultimately, the power of community support can enhance problem-solving efforts and encourage continuous learning. Through collaboration and shared resources, individuals can navigate complexities with greater confidence and success.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide a comprehensive view of various elements, aiding in identification and assembly processes. Mastering this skill can streamline workflows and enhance efficiency.

Here are some key tips for interpreting these visuals:

- Familiarize Yourself with Symbols:

- Learn common icons and notations used in the illustration.

- Understand what each symbol represents in terms of function.

- Identify Groups:

- Look for clusters of related items.

- Recognize how different parts interact with one another.

- Reference the Legend:

- Utilize the key that often accompanies the visual.

- Check for color coding or numbering systems that clarify relationships.

- Follow the Flow:

- Trace the sequence of assembly or function as depicted.

- Pay attention to directional arrows indicating movement or connections.

- Consult Additional Resources:

- Look for manuals or guides that provide further explanations.

- Seek online forums or communities for shared insights and experiences.

By mastering these techniques, you’ll enhance your ability to work with mechanical schematics, leading to improved repair outcomes and greater confidence in handling various tasks.