In the realm of agricultural machinery, a comprehensive grasp of the various components is essential for efficient operation and maintenance. By familiarizing oneself with the intricate details of each section, operators can ensure optimal performance and longevity of their machines. This knowledge not only aids in routine upkeep but also empowers users to tackle any unexpected challenges that may arise during usage.

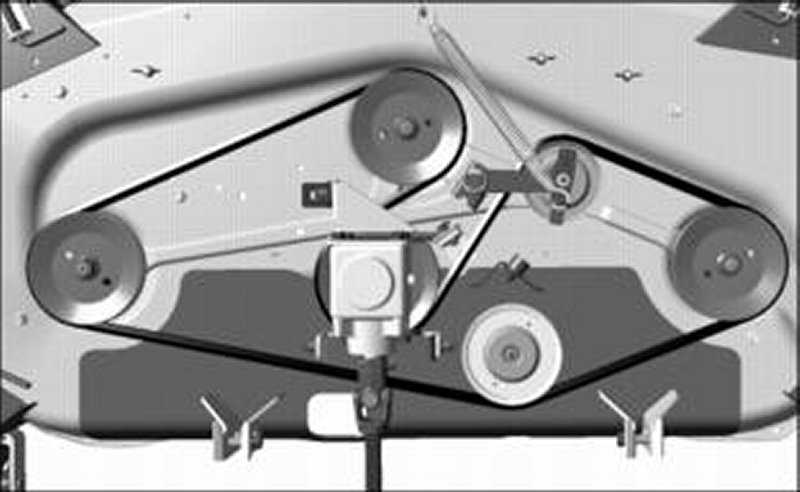

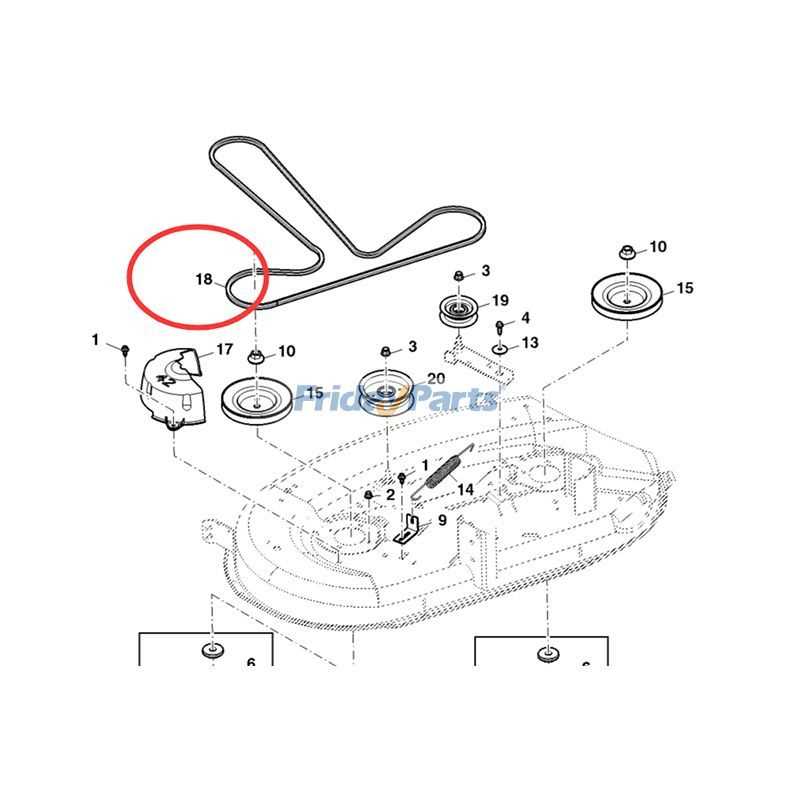

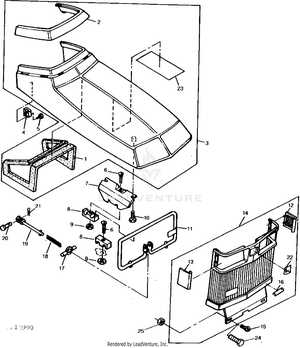

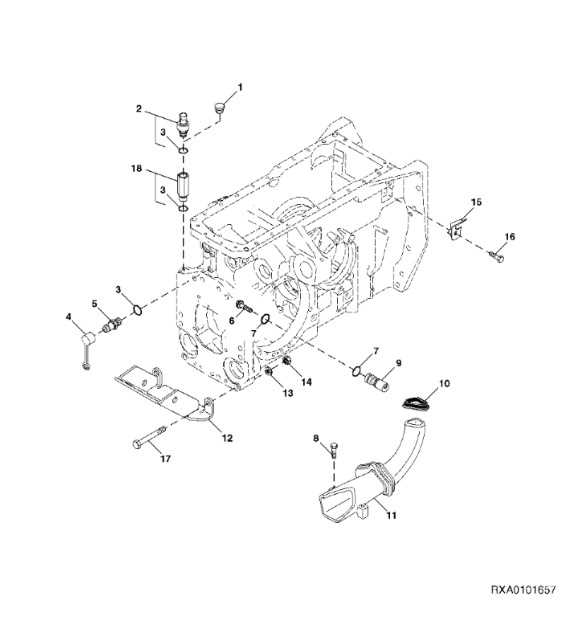

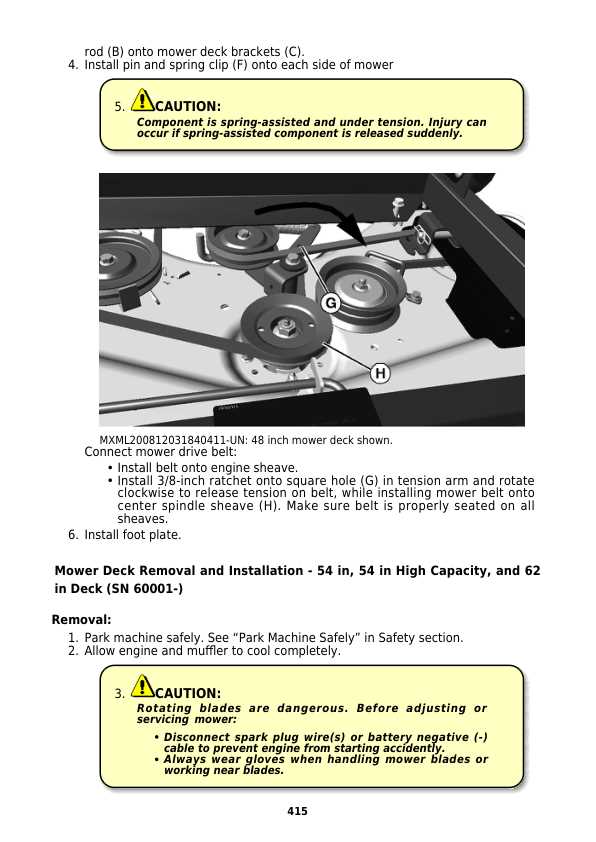

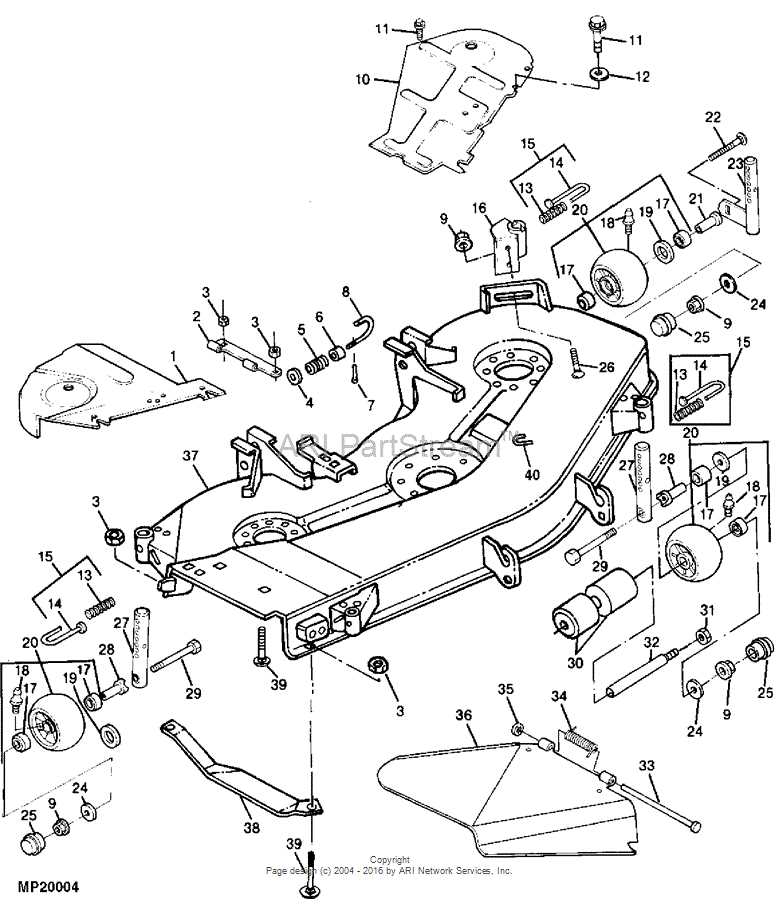

For those seeking clarity, visual aids can serve as invaluable tools. Diagrams illustrating the assembly of essential elements provide a clear overview, simplifying the often complex relationships between different parts. This approach not only enhances understanding but also aids in identifying potential issues before they escalate into more significant problems.

Whether you’re a seasoned professional or a newcomer to the field, having access to well-organized information about machinery components can significantly enhance your workflow. Engaging with these resources equips individuals with the confidence to maintain their equipment effectively, ensuring a smoother operation and greater productivity in the long run.

Understanding John Deere 445 Components

In the realm of agricultural machinery, a comprehensive grasp of individual elements is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance, enhancing productivity, and prolonging the lifespan of the equipment.

Key Elements of the Machinery

- Engine: The powerhouse that drives all functions.

- Transmission: Facilitates movement and control of speed.

- Hydraulic System: Provides the necessary power for lifting and operating attachments.

- Electrical System: Powers controls and accessories.

- Chassis: The frame that supports the overall structure.

Maintenance Tips for Longevity

- Regularly check fluid levels to prevent overheating.

- Inspect filters and replace them as needed to ensure clean operation.

- Maintain tire pressure for optimal traction and stability.

- Keep the machine clean to avoid buildup of debris that can cause damage.

- Follow the manufacturer’s guidelines for service intervals.

Importance of Accurate Parts Diagrams

Precise visual representations of components are crucial in any mechanical field. They serve as essential tools for technicians and operators, allowing for seamless identification and replacement of elements within complex machinery. By ensuring that every part is accurately illustrated, efficiency and effectiveness in maintenance tasks are greatly enhanced.

Enhancing Repair Efficiency

When individuals have access to clear and detailed illustrations, they can quickly locate the necessary components for repairs. This reduces the time spent on diagnostics and increases the likelihood of resolving issues on the first attempt. Effective schematics minimize the potential for errors, leading to smoother workflows and faster turnaround times.

Improving Understanding of Machinery

Visual aids not only facilitate repairs but also deepen the user’s comprehension of the equipment. By studying the layout of elements, operators can gain insights into the overall functioning of the machine. This knowledge can empower users to perform preventative maintenance, ultimately extending the lifespan of the equipment.

Common Issues with John Deere 445

Understanding typical challenges associated with this model can significantly enhance maintenance and operational efficiency. Many users encounter specific problems that, if addressed promptly, can prolong the machine’s lifespan and performance.

Here are some frequent concerns:

- Starting Difficulties: Many operators report issues with ignition or starting, often linked to battery problems or fuel delivery failures.

- Electrical Failures: Electrical components may malfunction, leading to erratic behavior of lights or the engine.

- Hydraulic System Leaks: Leaks in the hydraulic system can result in reduced efficiency and performance, necessitating immediate attention.

- Cooling System Overheating: Overheating can occur due to clogged radiators or faulty thermostats, affecting overall function.

- Wear and Tear on Belts: Drive belts often experience significant wear, requiring regular inspection and timely replacement.

By being aware of these common issues, operators can take proactive steps to ensure their machinery remains in optimal condition.

How to Locate Replacement Parts

Finding the right components for machinery can be a daunting task, but it is essential for maintaining performance and efficiency. Whether you’re looking for specific elements to enhance functionality or to replace worn-out items, having a structured approach will save time and effort.

Utilize Manufacturer Resources

One of the best starting points is to check the official resources provided by the manufacturer. Their website often includes catalogs, manuals, and support sections that can help you identify the required components. Additionally, customer service can provide guidance on locating the right items based on model numbers or specifications.

Online Retailers and Marketplaces

Another effective way to find the necessary components is through various online retailers and marketplaces. These platforms typically have extensive inventories, user reviews, and detailed descriptions. Be sure to verify the compatibility of items with your specific machinery to ensure optimal performance.

Benefits of Genuine John Deere Parts

Using authentic components for your machinery ensures optimal performance and longevity. Genuine items are specifically designed to meet the exact specifications of the equipment, providing a perfect fit and reliable operation. This commitment to quality can significantly enhance the efficiency and productivity of your agricultural or industrial tasks.

Quality Assurance

One of the primary advantages of utilizing original components is the assurance of quality. These items undergo rigorous testing and are manufactured under strict guidelines, which guarantees durability and performance. This reduces the risk of breakdowns and costly repairs, ultimately saving time and resources.

Enhanced Performance

Authentic components are engineered to work seamlessly with the machinery they are intended for. This compatibility not only boosts operational efficiency but also ensures that the equipment functions at its best, leading to better results in various applications. When you prioritize genuine items, you invest in the sustained performance of your valuable assets.

DIY Repairs Using Parts Diagrams

Engaging in do-it-yourself maintenance can be both rewarding and cost-effective. Utilizing visual references to understand the components of your equipment simplifies the repair process, allowing for informed decisions and efficient actions. Whether you’re replacing a worn-out element or conducting routine checks, having a clear overview of each part can enhance your confidence and capability.

Visual aids serve as invaluable tools in this endeavor. They break down complex machinery into manageable sections, making it easier to identify the necessary items for replacement or adjustment. By studying these illustrations, you can become familiar with the layout and interconnectivity of various components, leading to more precise repairs.

Moreover, understanding the specific features of your equipment helps prevent unnecessary errors during repairs. With a detailed reference at hand, you can accurately locate components and ensure that you are using the correct replacements. This method not only saves time but also minimizes the risk of damage caused by incorrect handling.

In summary, leveraging visual references for DIY repairs empowers individuals to tackle maintenance tasks with clarity and confidence. Embracing this approach can lead to successful outcomes and a deeper appreciation of the machinery at hand.

Comparing Aftermarket vs. OEM Parts

When maintaining machinery, the choice between original and alternative components can significantly impact performance and longevity. Each option comes with its own set of advantages and considerations that can affect both functionality and budget.

Quality and Performance

Original components are typically manufactured by the equipment’s maker, ensuring that they meet specific standards for quality and compatibility. In contrast, alternative options may vary widely in quality, with some exceeding the original standards while others might fall short. It’s crucial to assess the reputation of the manufacturer when considering alternatives, as this can influence reliability and overall effectiveness.

Cost and Availability

Alternative components often present a more economical solution, appealing to those on a tight budget. However, the potential for lower costs may come with trade-offs in durability. Original components, while generally more expensive, provide peace of mind with their guaranteed compatibility. Availability can also be a factor; original items may take longer to procure, whereas alternatives are often readily accessible.

In summary, the decision between original and alternative components hinges on a balance of quality, cost, and specific needs of the machinery. Careful consideration will ensure optimal performance and value in the long run.

Tips for Maintaining Your Equipment

Proper upkeep of machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps prevent unexpected breakdowns and costly repairs. Adopting a consistent maintenance routine can lead to smoother operations and improved productivity.

Routine Inspections

Conducting regular inspections is vital for identifying potential issues before they escalate. Check fluid levels, filters, and belts frequently. Look for signs of wear or damage, and address any irregularities immediately. Keeping a maintenance log can help track your findings and schedule necessary servicing.

Cleaning and Lubrication

Cleaning equipment after use helps prevent the buildup of dirt and debris, which can lead to malfunctions. Additionally, applying appropriate lubricants to moving parts reduces friction and wear, enhancing performance. Always refer to the manufacturer’s recommendations for the best practices in cleaning and lubrication.