In the realm of outdoor maintenance, having a comprehensive understanding of your machinery is crucial for optimal performance and longevity. Knowing the individual components and their functions can significantly enhance your efficiency while tackling various landscaping tasks. This section will delve into the intricate details of a specific model, providing valuable insights into its assembly and operation.

Every piece of equipment consists of numerous elements, each playing a vital role in ensuring smooth functionality. By familiarizing yourself with these parts, you not only empower yourself to perform basic repairs and maintenance but also enhance your overall experience with the machine. Clarity in understanding how these components interrelate can prevent mishaps and extend the lifespan of your investment.

In the following segments, you will discover an organized representation of the machinery’s various elements, elucidating their positions and interconnections. This exploration aims to equip you with the knowledge needed to manage your lawn care responsibilities effectively, ultimately leading to a healthier and more vibrant outdoor space.

Overview of John Deere Z920M

The subject of this section is a versatile and efficient machine designed for those who seek precision and reliability in lawn care. This equipment stands out for its exceptional performance, making it a preferred choice among professionals and enthusiasts alike. With a focus on user-friendly features and robust construction, it delivers an optimal mowing experience.

Equipped with advanced technology, this model ensures superior cutting efficiency while minimizing downtime. The durable components contribute to its longevity, allowing users to tackle various landscaping tasks with confidence. Additionally, the ergonomic design enhances comfort during operation, making it suitable for extended use.

Maintenance is straightforward, ensuring that operators can keep the machine in peak condition with minimal effort. Overall, this piece of equipment represents a blend of innovation and practicality, making it an invaluable asset for maintaining pristine outdoor spaces.

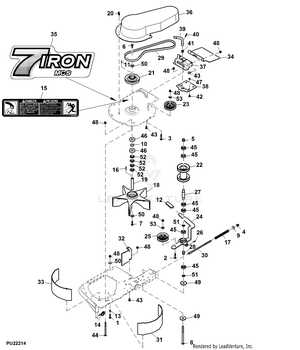

Importance of Parts Diagrams

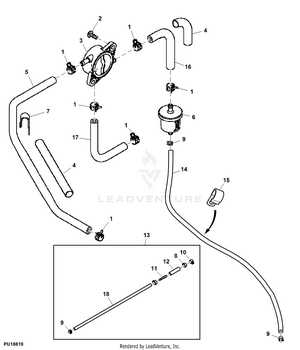

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide an organized view of individual elements, making it easier for technicians and users to identify, locate, and understand each piece’s function. By simplifying complex assemblies, these illustrations enhance communication between professionals and ensure that everyone involved is on the same page.

Moreover, such visuals aid in the efficient ordering and replacement of components. When a specific element needs to be replaced, having a clear guide minimizes confusion and reduces the likelihood of errors during the procurement process. This not only saves time but also helps in maintaining operational efficiency.

In addition, these visual aids serve as educational tools. They allow new operators to familiarize themselves with the equipment’s structure, promoting safer and more informed handling. Understanding how components interact fosters better troubleshooting skills, which is vital for effective maintenance practices.

Ultimately, well-crafted representations are invaluable resources that support both daily operations and long-term upkeep, contributing significantly to the longevity and performance of the equipment.

Key Components of the Z920M

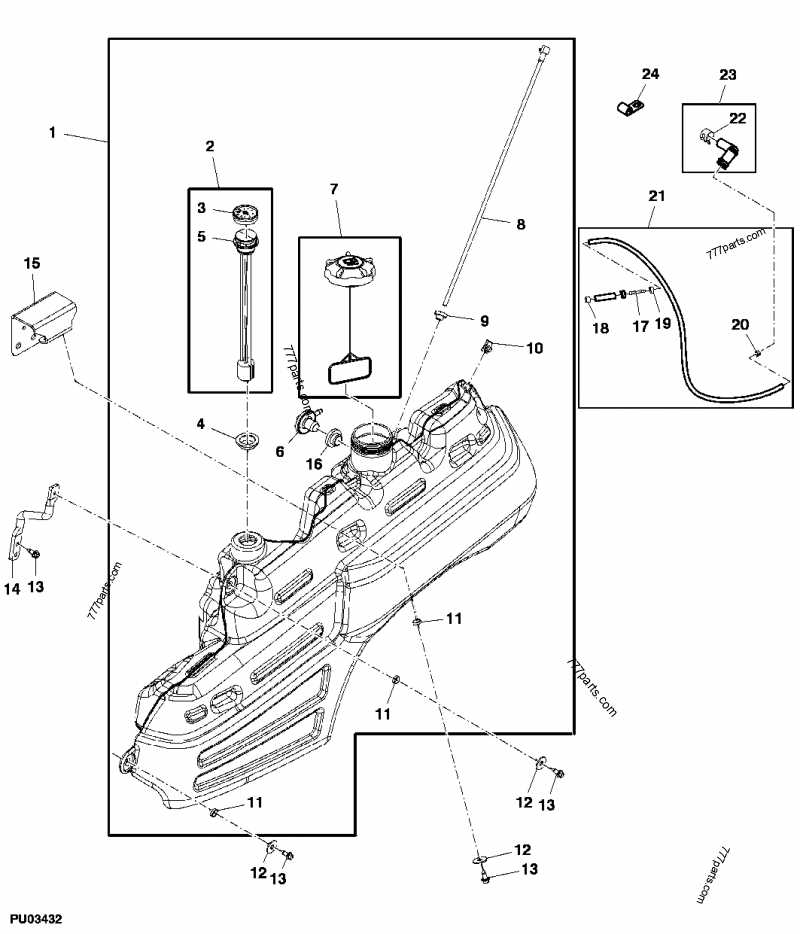

The efficient operation of any mowing machine relies heavily on its essential elements. Understanding the primary features that contribute to performance can enhance both maintenance practices and overall user experience. This section outlines the critical components that define this particular model, emphasizing their roles and functions.

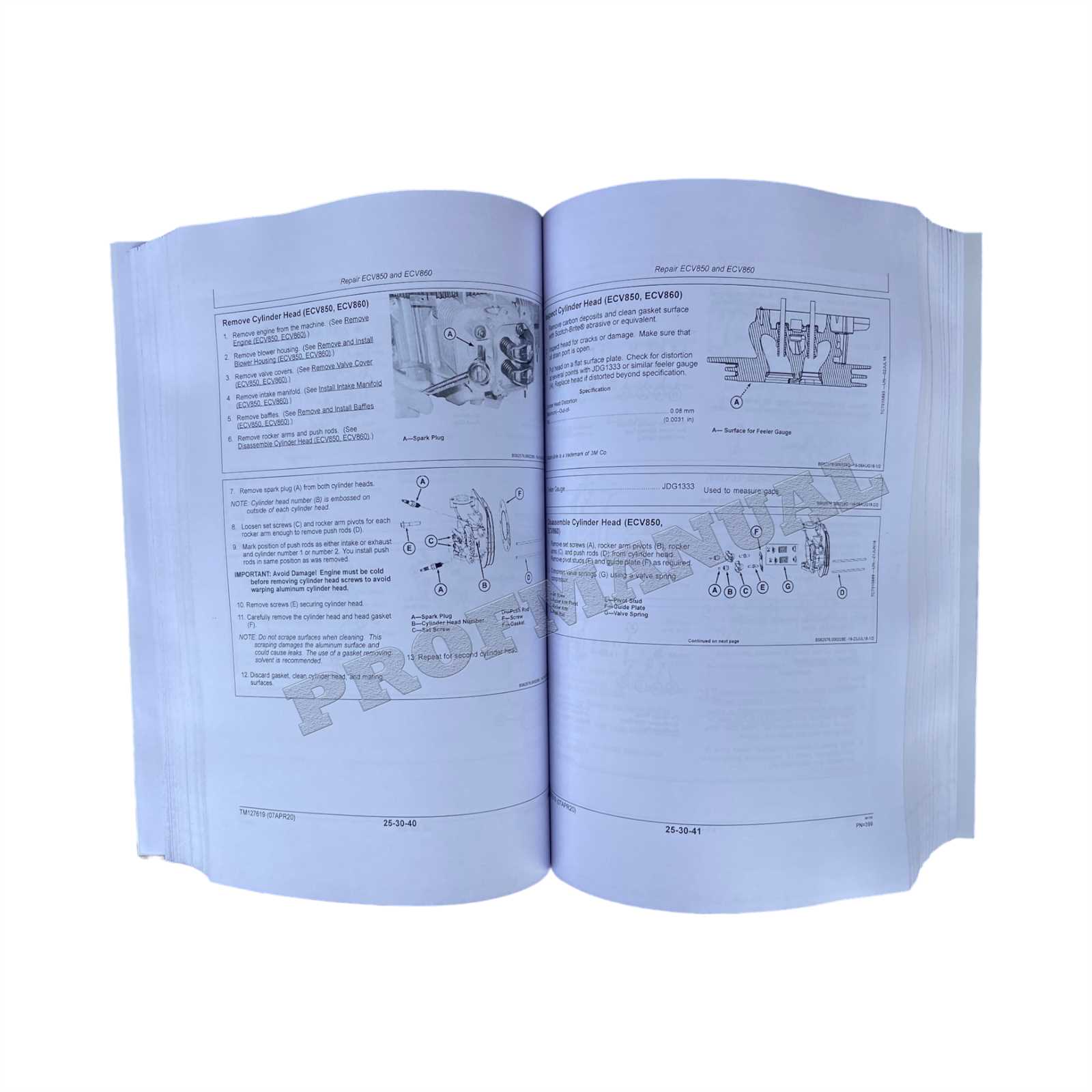

Engine and Powertrain

The heart of the mower is its powerful engine, which drives the machine and ensures smooth operation across various terrains. The powertrain system, which includes the transmission and drivetrain, facilitates seamless power transfer, allowing for optimal speed control and maneuverability. Regular maintenance of these components is crucial for sustaining performance and prolonging the life of the equipment.

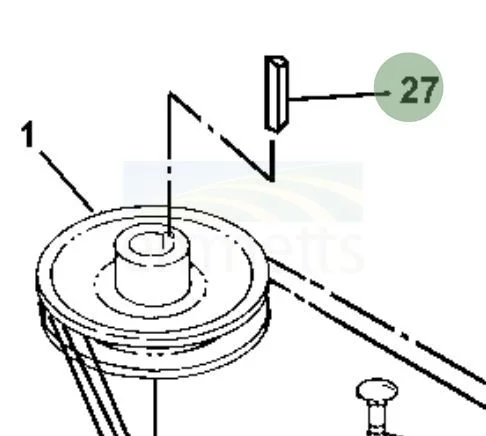

Cutting Deck and Blades

The cutting deck is fundamental to achieving a clean and precise cut. Designed with advanced engineering, it accommodates multiple blade configurations to suit different grass types and conditions. The blades themselves are crafted for durability and sharpness, ensuring efficient grass clipping and minimal strain on the engine. Proper blade care and deck adjustments are vital for maintaining cutting effectiveness.

Common Issues and Solutions

Understanding potential problems and their solutions can significantly enhance the longevity and performance of your equipment. Whether it’s mechanical failure or operational inefficiency, being aware of common challenges allows for timely interventions and effective maintenance strategies.

Frequent Problems

- Engine starting difficulties

- Uneven cutting performance

- Overheating issues

- Battery drainage

- Unresponsive controls

Recommended Solutions

- Engine starting difficulties: Check the fuel level, inspect the spark plug, and ensure the battery is charged.

- Uneven cutting performance: Examine the blade sharpness and ensure it is correctly aligned. Regularly clean the mower deck to prevent debris buildup.

- Overheating issues: Ensure proper airflow by cleaning air filters and radiator fins. Monitor coolant levels and replace when necessary.

- Battery drainage: Inspect the battery connections for corrosion and secure fit. Consider replacing an old battery.

- Unresponsive controls: Verify all electrical connections, inspect fuses, and test the control switches for proper functionality.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires diligent care and regular upkeep. By adopting a systematic approach to maintenance, you can enhance performance and reduce the likelihood of costly repairs. Here are some essential practices to keep your equipment in optimal condition.

Regular Inspections

Conduct routine checks to identify any wear and tear before it escalates. Focus on key components such as the engine, blades, and transmission. Monitoring fluid levels, including oil and coolant, is crucial. Address any leaks promptly to prevent further damage.

Cleaning and Storage

After each use, ensure that the equipment is thoroughly cleaned. Removing debris and grass clippings will prevent buildup that can lead to corrosion. Additionally, when not in use, store the machinery in a sheltered environment to protect it from harsh weather conditions. Regular maintenance, along with proper cleaning and storage, can significantly enhance the longevity of your equipment.

Where to Find Genuine Parts

Ensuring the longevity and efficiency of your equipment requires sourcing authentic components. These elements are essential for maintaining optimal performance and safety standards. Finding reliable suppliers is crucial to avoid the pitfalls of counterfeit or substandard alternatives.

Authorized Dealers

One of the most dependable sources for authentic components is through authorized dealers. These establishments are officially recognized and guarantee the quality of their inventory. Working with them not only provides assurance regarding authenticity but also access to expert advice and support.

Online Marketplaces

Reputable online platforms can also be valuable resources. When searching for genuine components, it’s important to check seller ratings and reviews. Look for platforms that specialize in equipment supplies, as they often have a broader selection and competitive pricing. Always verify the authenticity before making a purchase.

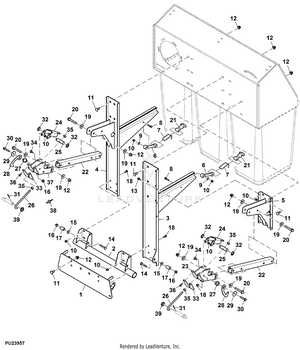

Upgrading Your Z920M Equipment

Enhancing your machinery can significantly improve performance, efficiency, and longevity. Whether you are looking to boost productivity or adapt to new tasks, various options are available to elevate your equipment’s capabilities. This section explores key upgrades that can transform your current setup into a powerhouse of functionality.

Performance Enhancements

One of the most effective ways to improve your equipment is by focusing on performance. Consider investing in advanced engine components or optimizing existing systems. Upgrading filters and fluids can lead to better fuel efficiency and power output. Additionally, exploring enhanced blade options can ensure a cleaner, more precise cut, catering to a variety of terrains and conditions.

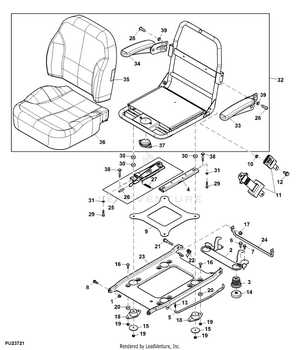

Comfort and Usability Features

Enhancing comfort and usability is essential for long hours of operation. Ergonomic seats, improved control layouts, and sound insulation can make a significant difference. Adding modern technology, such as GPS tracking or automatic terrain adjustment systems, can streamline tasks and reduce operator fatigue, allowing for a more enjoyable working experience.

Benefits of Regular Inspections

Conducting routine evaluations of machinery is crucial for maintaining optimal performance and extending the lifespan of equipment. Regular assessments not only help identify potential issues before they escalate but also ensure that all components are functioning efficiently. This proactive approach can lead to significant savings in repair costs and downtime.

Early Detection of Problems: By performing frequent checks, operators can spot wear and tear or malfunctions early on. Addressing these concerns promptly prevents minor issues from developing into major failures that could disrupt operations.

Enhanced Safety: Regular inspections play a vital role in ensuring the safety of operators and surrounding personnel. By confirming that all safety mechanisms are intact and functional, the risk of accidents and injuries is greatly reduced.

Improved Efficiency: Well-maintained equipment operates more smoothly, leading to better productivity. Routine evaluations allow for adjustments and repairs that enhance overall efficiency, ensuring that tasks are completed in a timely manner.

Cost Savings: Investing time in regular inspections can lead to significant long-term savings. By preventing unexpected breakdowns and costly repairs, organizations can allocate their resources more effectively and avoid interruptions in work schedules.

Increased Equipment Lifespan: Consistent maintenance and inspections contribute to the longevity of machinery. By keeping components in optimal condition, operators can maximize their investment and achieve greater value over time.