Understanding the various elements that make up outdoor machinery is crucial for ensuring smooth operation and proper maintenance. Each component plays a vital role in the overall functionality of the device, and knowing their positions and interactions can significantly improve efficiency.

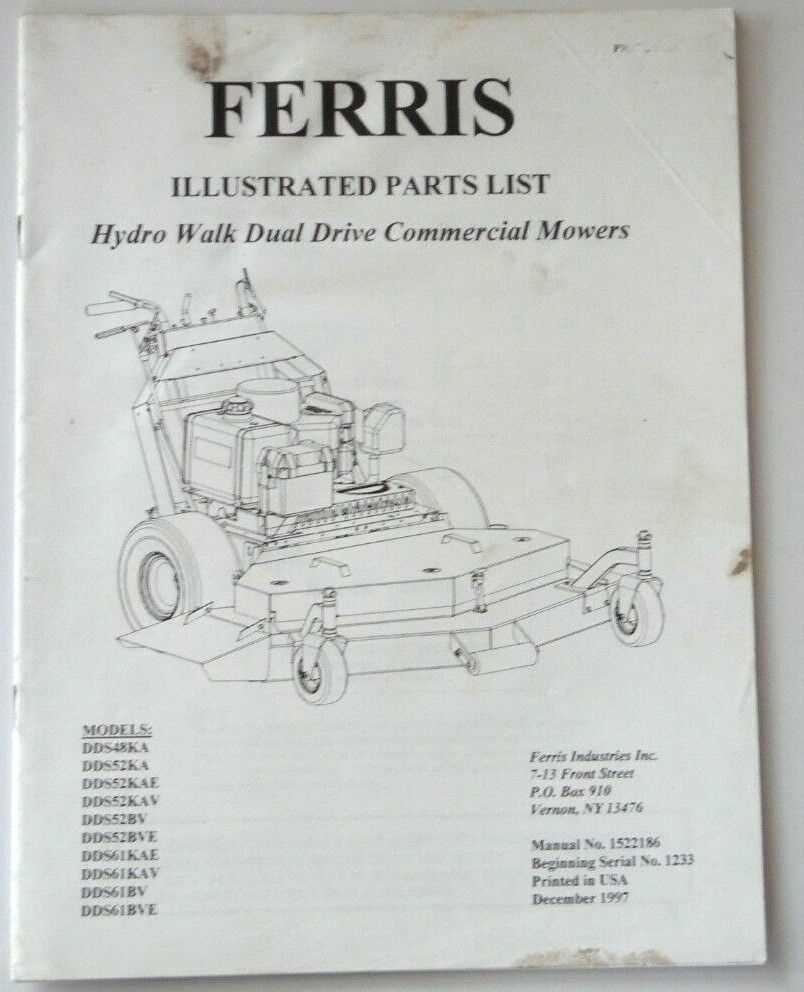

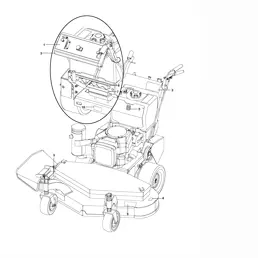

This section provides a detailed look into the arrangement and key structural elements of a popular equipment model. By examining these details, users can gain a better understanding of the core structure and its essential elements, helping them maintain and repair it effectively.

Whether you’re maintaining the equipment or troubleshooting, having a clear visualization of the internal structure is invaluable. This guide breaks down the essential components, offering insights into their specific roles within the machinery.

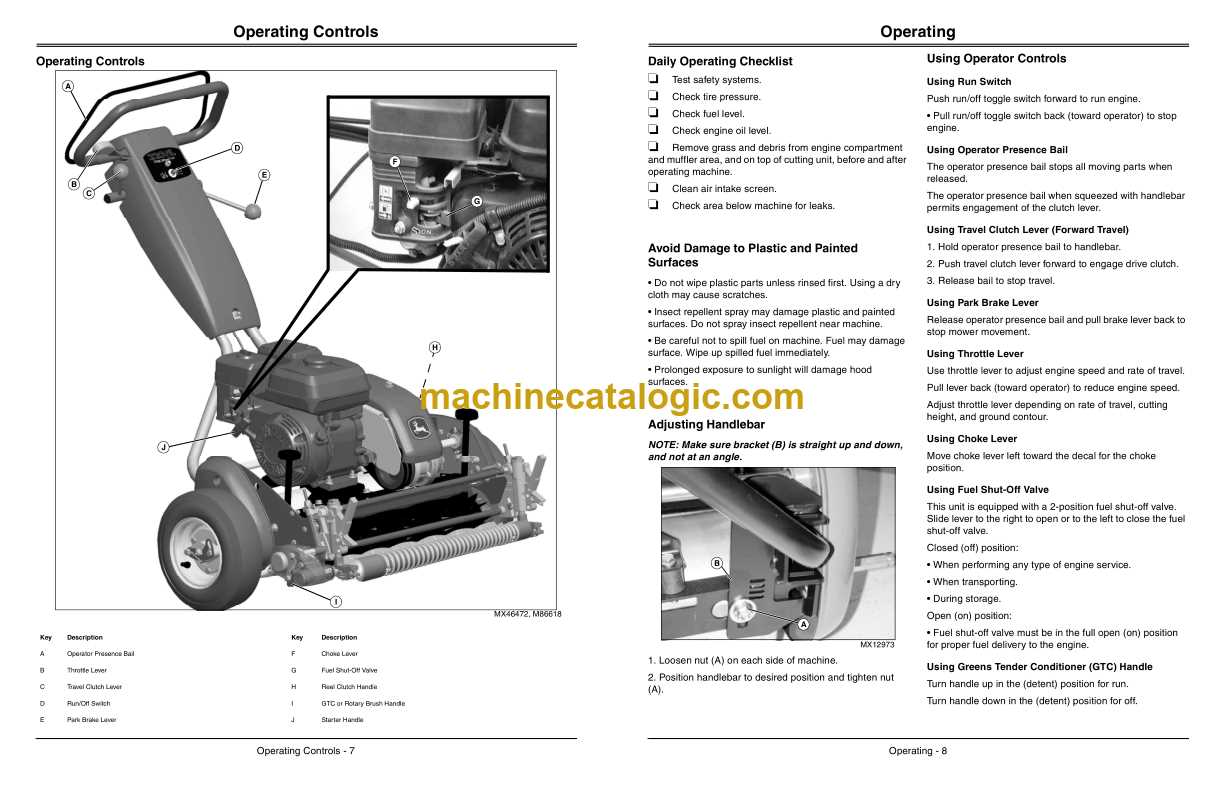

Understanding the Components of Lesco 48 Mower

The efficient operation of outdoor cutting equipment relies on the intricate design and assembly of various mechanical elements. Familiarizing yourself with these elements will help you maintain and repair the machine more effectively. Below is an overview of the key sections and their functions.

Main Framework

The structure holds everything together, ensuring stability during use. It consists of several interlocking sections that provide both strength and flexibility to the machine.

- Chassis – provides the foundation for other components.

- Wheels – support movement and steering on various terrains.

- Handles – allow the operator to control the machine with ease.

Cutting Mechanism

At the core of the equipment’s performance is the cutting system, which delivers the desired results on the grass. Understanding its operation is crucial for optimizing performance.

- Blades – respons

Key Features of the Lesco Mower Design

Understanding the core elements of the cutting equipment’s build provides insight into its efficiency and durability. This section highlights the essential components that contribute to its reliable performance in both commercial and residential settings.

Engine Performance and Power

The engine is designed to deliver consistent power output, ensuring smooth operation even under challenging conditions. Its fuel efficiency allows for extended usage, making it ideal for large areas. The robust structure also minimizes wear, adding to the machine’s longevity.

Cutting Efficiency

With a precise cutting mechanism, the device achieves clean and even results with each pass. Adjustable height settings offer versatility, allowing users to manage varying terrains with ease. The reinforced blades contribute to superior cutting action, reducing the need for frequent maintenance.

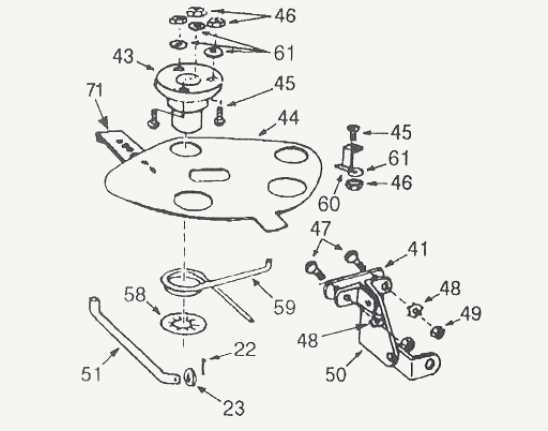

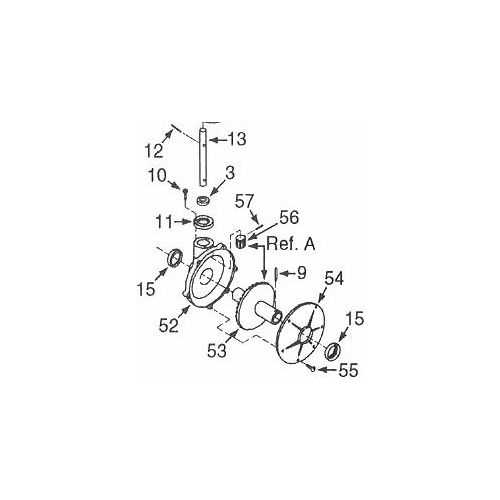

Blade Assembly and Its Functionality

The blade assembly plays a critical role in the overall operation of any cutting equipment. It is responsible for ensuring precise cutting and smooth performance during use. This section explores the structure and purpose of the blade assembly, highlighting its importance in maintaining efficient functionality.

Main Components

- Blade – The primary cutting element, designed to slice through materials with efficiency.

- Spindle – Supports the blade and ensures stable rotation for consistent performance.

- Bolts and Fasteners – Secure the blade in place and keep the assembly tight and functional.

How It Works

When the equipment is activated, the spindle rotates the blade at high speeds. This rotation allows the blade to create a clean and even cut. Proper alignment and sharpness of the blade are essential for optimal performance, reducing strain on the machine and improving results.

- Ensure that the blade is securely fastened to avoid any imbalance.

- Regularly inspect the sharpness to maintain efficiency.

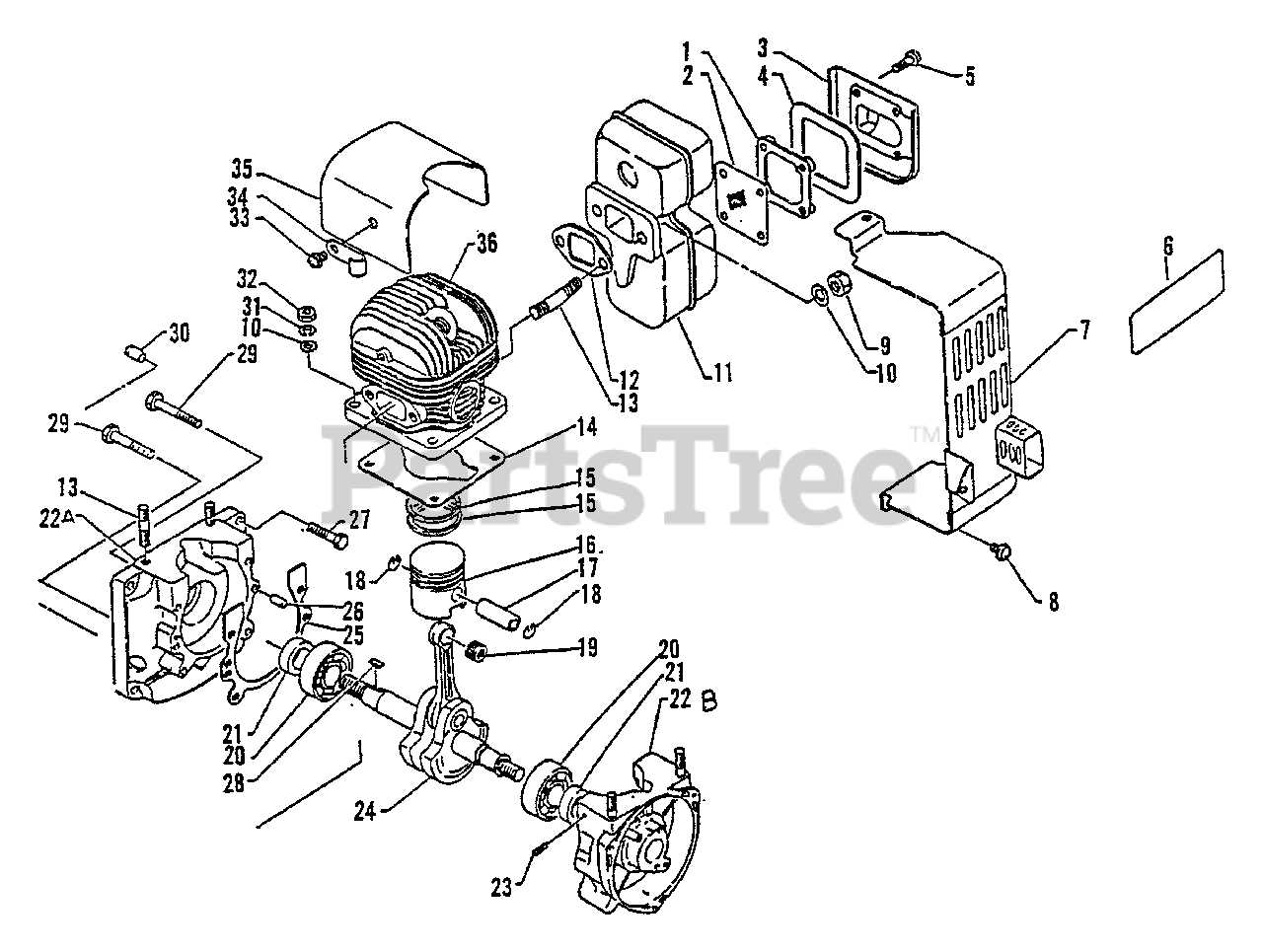

Role of the Engine in Mower Operation

The engine serves as the core power source, ensuring that the entire machine functions efficiently. Its primary role is to convert fuel into mechanical energy, which then drives the cutting mechanism and allows smooth movement across various surfaces. Without a reliable engine, the equipment cannot perform its essential tasks effectively.

Power Generation: The engine generates the necessary energy by combusting fuel. This process creates rotational force, which is transferred to other components to activate the blades and propulsion system.

Efficiency and Performance: A well-maintained engine ensures maximum efficiency, allowing the machinery to handle different terrains and resist wear over time. The overall performance of the equipment is directly tied to the engine’s condition and power output.

In summary, the engine plays a vital role in providing the force needed for both movement and the execution of cutting tasks, making it the heart of the operational system.

Exploring the Drive Belt System

The drive belt system is a crucial component in ensuring smooth operation and efficient power transmission within various types of equipment. By connecting multiple moving parts, it helps transfer energy from the engine to other mechanical components, allowing the machine to perform its intended functions. A well-maintained belt system guarantees longevity and reduces the likelihood of breakdowns.

Main Functions of the Belt System

- Transferring energy between rotating elements

- Maintaining consistent performance under varying conditions

- Providing a flexible and durable connection between components

Common Issues and Maintenance Tips

- Check for wear and tear regularly to avoid unexpected failures.

- Ensure proper alignment of pulleys to reduce friction and belt damage.

- Replace worn or cracked belts promptly to maintain optimal performance.

Cutting Deck: Structure and Maintenance

The cutting deck is a vital component in any grass trimming equipment, playing a crucial role in determining the quality of the cut and overall performance. Its design and upkeep are essential for achieving optimal results, ensuring efficiency and longevity. Understanding the various elements that comprise the cutting deck can greatly enhance its functionality.

Structurally, the cutting deck typically consists of a robust casing that houses the blades, along with mechanisms for height adjustment and debris discharge. The material used in construction often influences durability and performance. Regular inspections of the deck for signs of wear or damage are necessary to maintain its integrity. Cleaning the deck after each use is also recommended, as this helps prevent grass buildup, which can hinder operation.

Maintenance of the cutting deck involves several key practices. Sharpening the blades regularly ensures a clean cut, while checking the alignment of the blades can prevent uneven trimming. Additionally, lubricating moving parts can reduce friction, enhancing overall efficiency. By prioritizing these maintenance tasks, users can ensure that their equipment remains in peak condition, ultimately leading to a more effective trimming experience.

Wheels and Steering Mechanism Overview

The mobility and maneuverability of outdoor equipment play a crucial role in ensuring efficient operation. Understanding the components involved in movement is essential for proper handling and maintenance. This section focuses on the key elements that contribute to the functionality and control of the equipment.

Wheel Design and Functionality

Wheels are fundamental to the movement of any outdoor apparatus. Their design often includes features that enhance traction and stability on various terrains. A robust construction ensures durability, while the tread pattern provides the necessary grip to navigate uneven surfaces. Regular inspection and maintenance of these components are vital for optimal performance.

Steering System Mechanics

The steering mechanism enables the operator to guide the equipment with precision. It typically comprises several interconnected components that facilitate smooth directional changes. This system is designed to respond promptly to user inputs, ensuring seamless navigation. Regular checks and adjustments are recommended to maintain responsiveness and effectiveness.

Fuel System and Efficiency Considerations

The fuel system plays a crucial role in the overall performance and operational efficiency of any outdoor equipment. A well-designed fuel mechanism ensures that the engine receives the optimal amount of fuel for combustion, which in turn affects power output and fuel consumption. Understanding the components involved and their functions can lead to better maintenance practices and improved machine longevity.

Key factors influencing the efficiency of the fuel system include the quality of fuel used, the condition of filters, and the calibration of fuel injectors or carburetors. Regular inspection and replacement of fuel filters are essential to prevent clogging, which can hinder fuel flow and reduce performance. Additionally, using high-quality fuel can help maintain cleaner combustion, resulting in fewer emissions and a smoother operation.

Moreover, the adjustment of fuel-to-air ratios is vital for optimal engine performance. An incorrect mixture can lead to engine strain, excessive fuel consumption, and increased emissions. Therefore, periodic tuning and adjustments are necessary to ensure that the fuel system operates at peak efficiency.

In conclusion, prioritizing the maintenance of the fuel system not only enhances performance but also contributes to the overall efficiency of outdoor equipment. Adhering to recommended practices can lead to significant savings in fuel costs and improved operational reliability.

Electrical Components: Wiring and Safety

The electrical systems of garden equipment play a crucial role in ensuring optimal performance and user safety. Understanding the various components involved, their wiring configurations, and safety protocols is essential for effective maintenance and troubleshooting.

Key Electrical Components

- Battery: Supplies power to the system and requires regular checks for charge and corrosion.

- Ignition System: Responsible for starting the engine and must be in good condition to avoid starting issues.

- Switches: Control the flow of electricity; ensure they function correctly to prevent accidental starts.

- Fuses: Protect the electrical circuit from overloads; replace blown fuses with the correct ratings.

- Wiring Harness: Connects various electrical components; inspect for frays or damage regularly.

Safety Considerations

- Always disconnect the battery before performing any electrical work to avoid shocks or short circuits.

- Use insulated tools when handling electrical components to reduce the risk of accidents.

- Regularly inspect wiring for wear and tear, as damaged insulation can lead to short circuits.

- Follow manufacturer guidelines for installation and maintenance to ensure safe operation.

- Keep all electrical components clean and dry to prevent malfunctions and hazards.