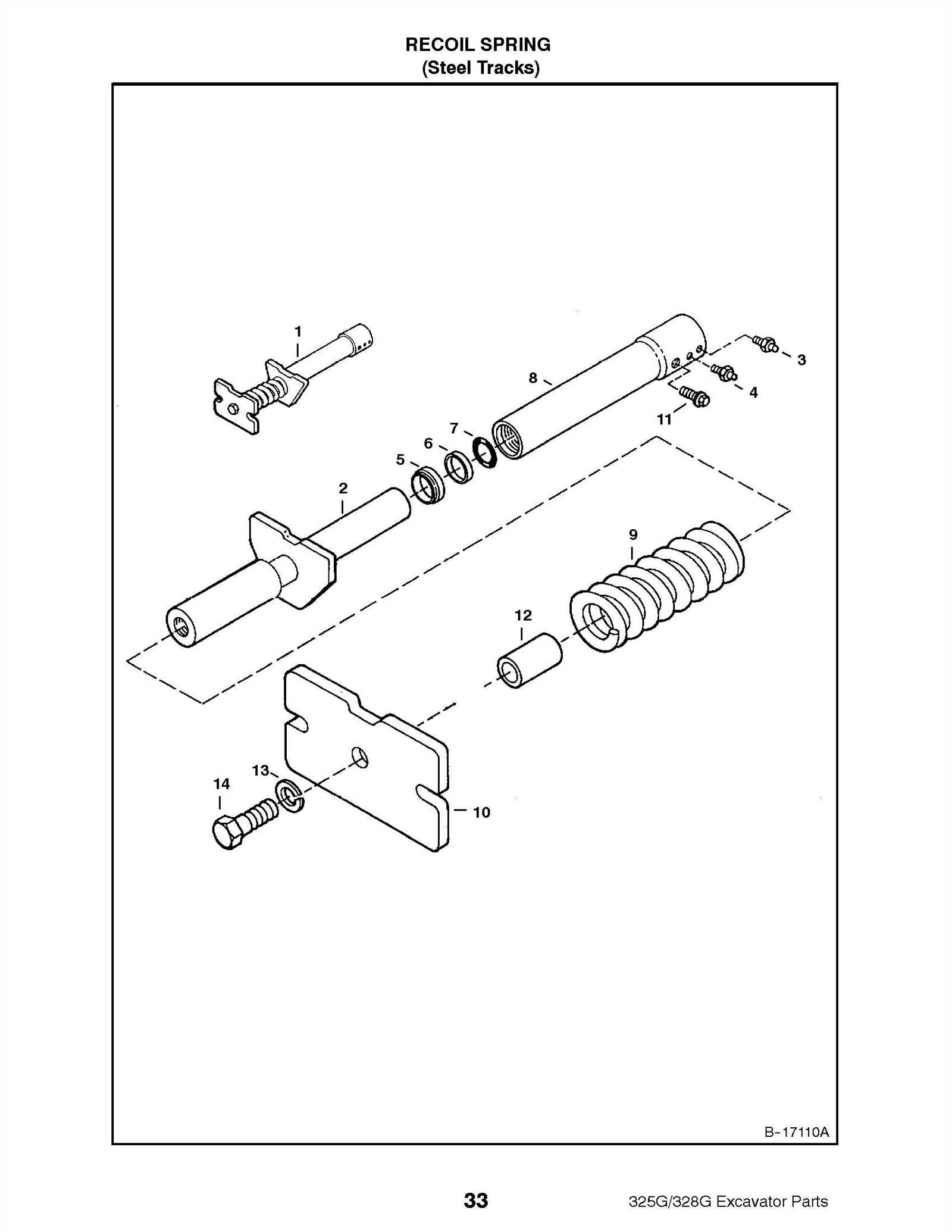

Understanding the intricacies of heavy machinery requires a closer look at the arrangement and functionality of its individual elements. This knowledge is essential for maintenance, repairs, and enhancements. By delving into the structured visual representations of these components, operators and technicians can effectively identify and manage each piece.

Such illustrations serve as invaluable tools, allowing users to navigate the complex network of machinery with confidence. Recognizing how each part interacts not only aids in troubleshooting but also fosters a deeper appreciation for the engineering behind robust construction equipment. This exploration equips users with the insights necessary for optimal performance.

In the following sections, we will examine the various elements of the equipment in detail, providing clarity on their respective roles and interconnections. A comprehensive understanding of these diagrams empowers users to maintain and operate their machinery efficiently, ensuring longevity and reliability in the field.

Understanding the John Deere 325G

The compact equipment in question is a remarkable example of modern engineering, designed for versatility and efficiency in various tasks. Its robust construction allows it to tackle a wide range of applications, making it a preferred choice for professionals in construction, landscaping, and agriculture.

Equipped with a powerful engine, this machine delivers exceptional performance while maintaining fuel efficiency. The intuitive controls provide ease of operation, ensuring that users can navigate complex tasks with confidence. Furthermore, its compact size allows for maneuverability in tight spaces, making it ideal for urban projects.

Maintenance and repair are streamlined due to a well-organized layout of components. This design philosophy not only enhances accessibility but also contributes to the overall longevity of the equipment. Understanding the intricate details of its components can empower operators to perform routine checks and troubleshoot issues effectively.

In summary, grasping the essentials of this compact machine is crucial for maximizing its potential. By familiarizing oneself with its features and functionalities, users can ensure that they are making the most of their investment, leading to increased productivity and reduced downtime.

Key Components of the 325G

This section delves into the essential elements that contribute to the functionality and efficiency of this machine. Understanding these components allows operators to maximize performance and ensure longevity, making maintenance and repair processes more straightforward.

Main Elements

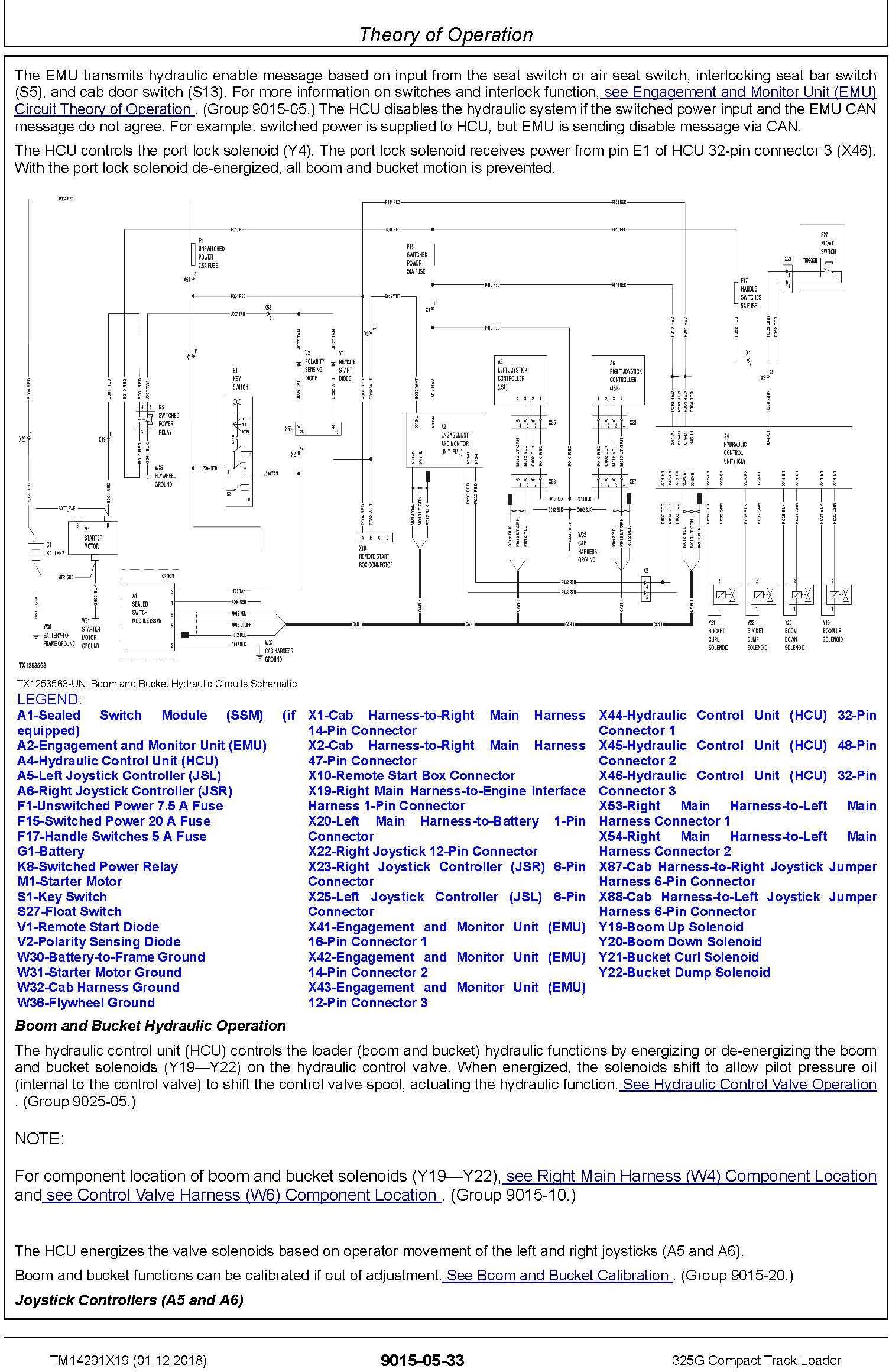

The primary components work together to enhance productivity and maneuverability. Each part plays a critical role in the overall operation, from the engine to the hydraulic systems.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for various tasks, ensuring optimal performance in different conditions. |

| Hydraulic System | Enables smooth operation of attachments and implements, offering precise control and efficiency. |

| Transmission | Facilitates effective power transfer from the engine to the wheels, allowing for seamless movement. |

| Frame | Supports all components and ensures structural integrity, contributing to stability and durability. |

Importance of Maintenance

Regular upkeep of these key parts is vital for ensuring optimal operation and preventing unexpected breakdowns. Routine checks and timely replacements can significantly enhance the machine’s reliability and performance in the field.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for both technicians and operators, allowing for quick identification of elements and their relationships. Such illustrations enhance the overall efficiency of servicing equipment, reducing downtime and preventing costly mistakes.

Enhancing Maintenance Efficiency

Clear visual guides facilitate faster troubleshooting and enable technicians to locate specific components without unnecessary delays. When each element is depicted accurately, it empowers workers to execute repairs swiftly and effectively, ensuring that machinery remains in optimal condition.

Training and Skill Development

Illustrations are invaluable in training new personnel. They provide a visual reference that enhances comprehension and retention of information. Trainees can learn to identify parts and understand their functions, leading to a more knowledgeable workforce and improved operational safety.

| Benefit | Description |

|---|---|

| Quick Identification | Facilitates rapid location of components. |

| Reduced Downtime | Minimizes the time machinery is out of service. |

| Improved Training | Enhances learning and understanding for new workers. |

| Cost Efficiency | Reduces the likelihood of errors during repairs. |

Common Issues with 325G Parts

When dealing with machinery components, various challenges can arise that impact performance and reliability. These difficulties often stem from wear and tear, improper maintenance, or compatibility concerns. Understanding these common issues can aid in timely interventions and enhance the longevity of equipment.

Wear and Tear: Frequent usage can lead to degradation of vital components. It’s essential to monitor signs of fatigue, such as cracks or unusual noises, which may indicate impending failure.

Maintenance Oversights: Neglecting routine checks and service can result in diminished efficiency. Regular lubrication and inspections are crucial to prevent breakdowns and extend the life of each element.

Compatibility Issues: Using incorrect replacements can lead to poor performance and damage. Always ensure that new components match the specifications to avoid complications.

Addressing these common challenges effectively requires vigilance and knowledge, paving the way for optimal machinery operation.

Where to Find Parts Diagrams

Accessing detailed visual guides for machinery components is essential for effective maintenance and repair. These resources provide users with a clear overview of individual elements, helping to identify and order the correct pieces when needed.

Official Manufacturer Resources

One of the most reliable sources for these visual guides is the official website of the manufacturer. Many companies offer online portals where users can download or view comprehensive illustrations specific to various models. These resources often include updated information and part numbers, ensuring accuracy.

Online Retailers and Forums

Another useful avenue is online marketplaces and community forums dedicated to machinery enthusiasts. Retailers often provide breakdowns alongside their inventory, while forums allow users to share insights and resources. Engaging with these communities can lead to discovering rare materials and additional support.

In conclusion, whether through official channels or community-driven platforms, finding accurate visual references for machinery components is vital for effective upkeep and repair.

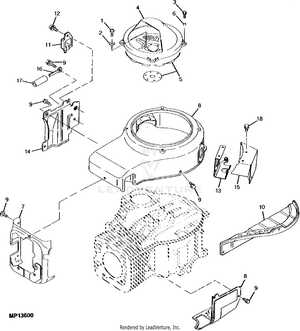

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of the various elements and their interconnections, making it easier to identify and locate specific items when needed. Proper interpretation of such visuals can significantly streamline the troubleshooting process.

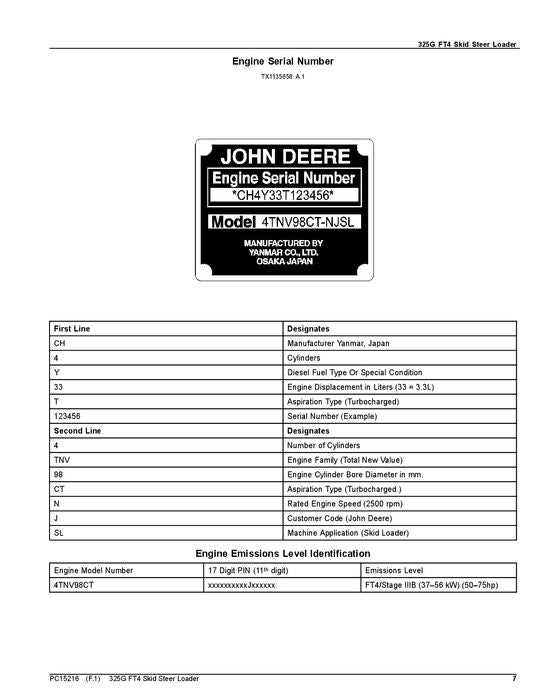

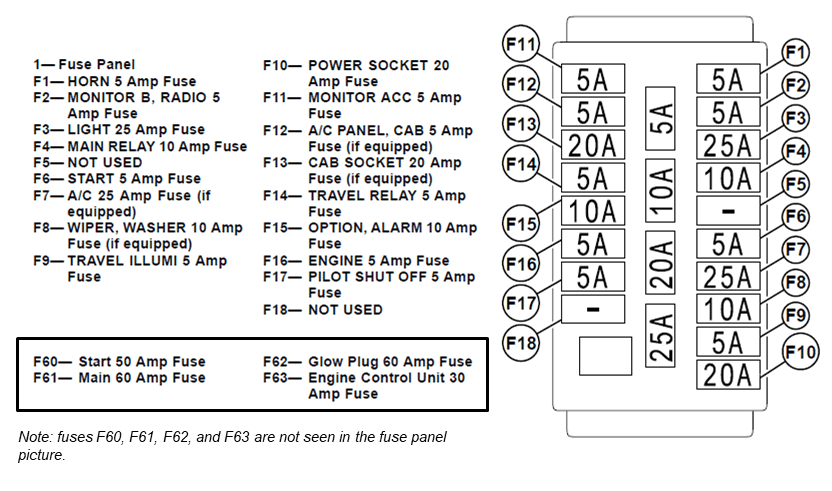

Identify Key Elements

Begin by familiarizing yourself with the main features of the illustration. Look for labels that indicate different components. These tags often include reference numbers or letters, which correlate with a list of items, allowing for quick identification. Pay attention to any color coding or symbols that may highlight particular sections or functions within the system.

Understand Relationships and Functions

Next, observe how the various components are interconnected. Arrows and lines typically represent connections or flow paths, guiding you in understanding how parts interact. Recognizing these relationships is crucial for diagnosing issues and determining what replacements may be necessary. Always refer to the accompanying legend or key, as it provides vital context for interpreting the visual.

Benefits of Genuine John Deere Parts

Utilizing authentic components for machinery offers numerous advantages that can significantly enhance performance and longevity. When opting for these high-quality elements, users can ensure optimal functionality and reliability, ultimately leading to reduced downtime and maintenance costs.

Quality Assurance: Authentic components are manufactured to exacting standards, ensuring they fit perfectly and operate seamlessly within the machine. This precision translates to enhanced efficiency and fewer mechanical failures.

Durability: Genuine items are designed to withstand the rigors of heavy use, providing a longer lifespan compared to generic alternatives. Investing in quality translates to better long-term value, as these items require less frequent replacement.

Warranty Protection: Many genuine components come with manufacturer warranties, offering peace of mind. Should an issue arise, users can take advantage of coverage, reducing potential financial burdens associated with repairs.

Improved Resale Value: Machinery equipped with authentic elements tends to retain higher resale values. Prospective buyers often prioritize well-maintained equipment, particularly when they see quality parts used in its upkeep.

Expert Support: By choosing genuine components, users gain access to comprehensive support and resources from manufacturers. This assistance can be invaluable in ensuring proper installation and maintenance practices, leading to enhanced machine performance.

Overall, opting for authentic components is a prudent choice that supports not only the machinery’s efficiency but also its overall operational integrity.

Maintenance Tips for 325G Owners

Proper upkeep of your machinery is crucial for ensuring optimal performance and longevity. Regular attention to maintenance tasks not only enhances efficiency but also helps prevent costly repairs in the long run. Here are essential practices to keep your equipment in top condition.

First, always consult the manufacturer’s manual for specific maintenance schedules. Adhering to recommended intervals for oil changes, filter replacements, and inspections can greatly extend the lifespan of your machine. Keep a log of maintenance activities to track what has been completed and what is upcoming.

Regularly inspect the hydraulic system for leaks and ensure that all connections are secure. This system plays a vital role in the functionality of your equipment, so any issues should be addressed immediately. Check fluid levels and replace fluids as needed to maintain peak performance.

Pay attention to the undercarriage and tracks. Regular cleaning and inspection will help identify wear and tear early, preventing more significant problems later. Proper tension adjustments are essential to avoid excessive strain on the system.

Lastly, keep your machinery clean. Removing dirt and debris not only improves appearance but also prevents rust and corrosion. Establish a routine for cleaning your equipment after use, focusing on hard-to-reach areas where buildup can occur.