Understanding the structure and connections within mechanical tools is crucial for maintaining performance and extending their lifespan. Having detailed insight into how individual elements fit together ensures smooth operation, especially when it comes to complex machinery. This guide aims to simplify the process of identifying key elements and their placement.

Every component plays a vital role in the proper functioning of the system, whether it’s related to movement, control, or safety mechanisms. When technical issues arise, knowing the specific layout can help pinpoint the source of a problem and streamline repairs. Accurate alignment of these elements also minimizes downtime, promoting efficiency and reliability.

This section serves as a resource for identifying assemblies and individual parts, providing clarity on their arrangement. With a well-organized overview, even intricate systems can be easily understood, ensuring you have the necessary knowledge to maintain, repair, or upgrade components effectively.

Understanding Key Components of This Classic Machine

Maintaining reliable operation requires a solid understanding of how various elements within the machine work together. Each component plays a vital role, contributing to the overall performance and longevity of the equipment.

From mechanical assemblies to electrical systems, every section is interconnected. Proper upkeep ensures smooth functionality, whether through timely replacements or efficient troubleshooting. Awareness of these elements makes it easier to identify wear and tear, minimizing potential downtimes.

Regular inspections help catch issues early, preventing costly repairs. With the right knowledge, owners can optimize the machine’s efficiency, keeping it running smoothly for years to come.

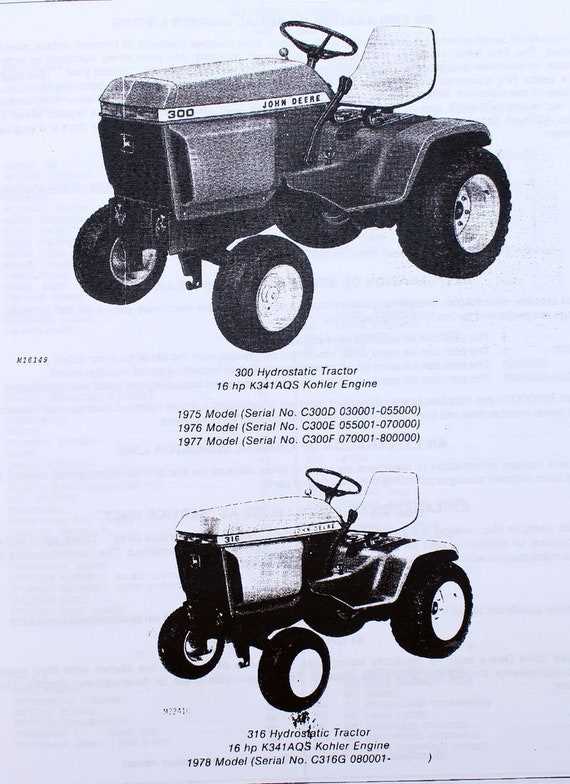

Overview of John Deere Models

Across decades, agricultural and industrial machines have evolved to meet the needs of diverse applications. Various product lines are tailored to specific tasks, offering a blend of performance, reliability, and innovation. These machines are recognized for their adaptability in both small-scale and large-scale operations, making them essential tools for land management, farming, and landscaping.

Classification by Purpose

Each series is designed to serve a unique purpose. Compact units focus on light work, including gardening and property maintenance, while heavy-duty variants tackle demanding activities like plowing and excavation. The balance between size, power, and versatility allows users to select equipment optimized for their needs.

Generational Progress and Technology

Over time, new releases incorporate advanced technologies, enhancing fuel efficiency and user comfort. Hydraulic systems and power steering have become standard features in many models, ensuring smooth

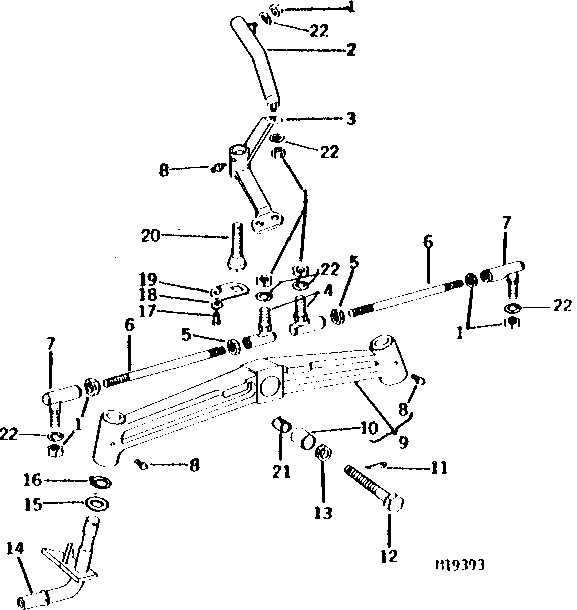

Importance of Parts Diagrams

Detailed visual references play a crucial role in maintaining and repairing mechanical systems. They provide a structured view of components, helping users understand how elements connect and function within larger assemblies. With these references, troubleshooting and identifying specific components becomes much more efficient.

Streamlined Maintenance and Repairs

Having clear schematics allows technicians to disassemble and reassemble systems with accuracy. These visuals minimize the chances of assembly errors and reduce downtime by ensuring that each component is correctly placed and aligned.

Efficient Ordering and Inventory Management

Well-organized layouts assist in tracking replacement needs and matching items with their corresponding models. This precision avoids ordering mistakes, reducing costs and ensuring the availability of the right components when needed.

| Benefit | Description |

|---|---|

| Error Reduction | Visual aids decrease the likelihood of incorrect assembly or installation. |

| Time Savings | Streamlined repair

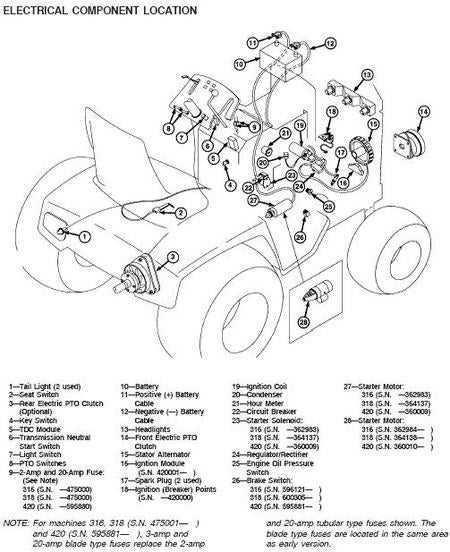

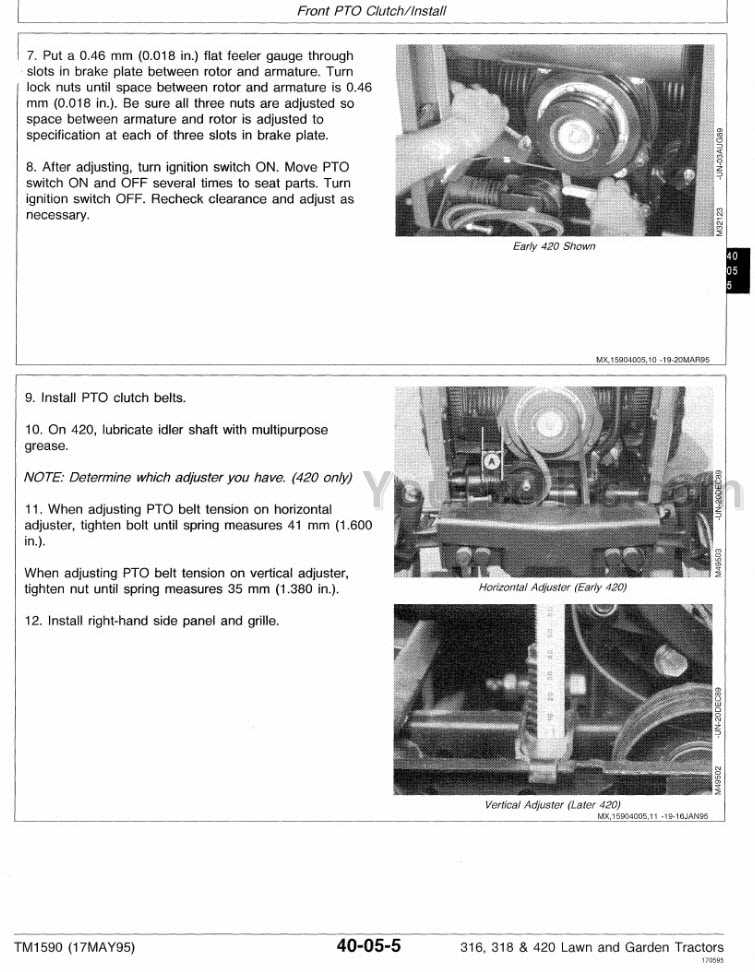

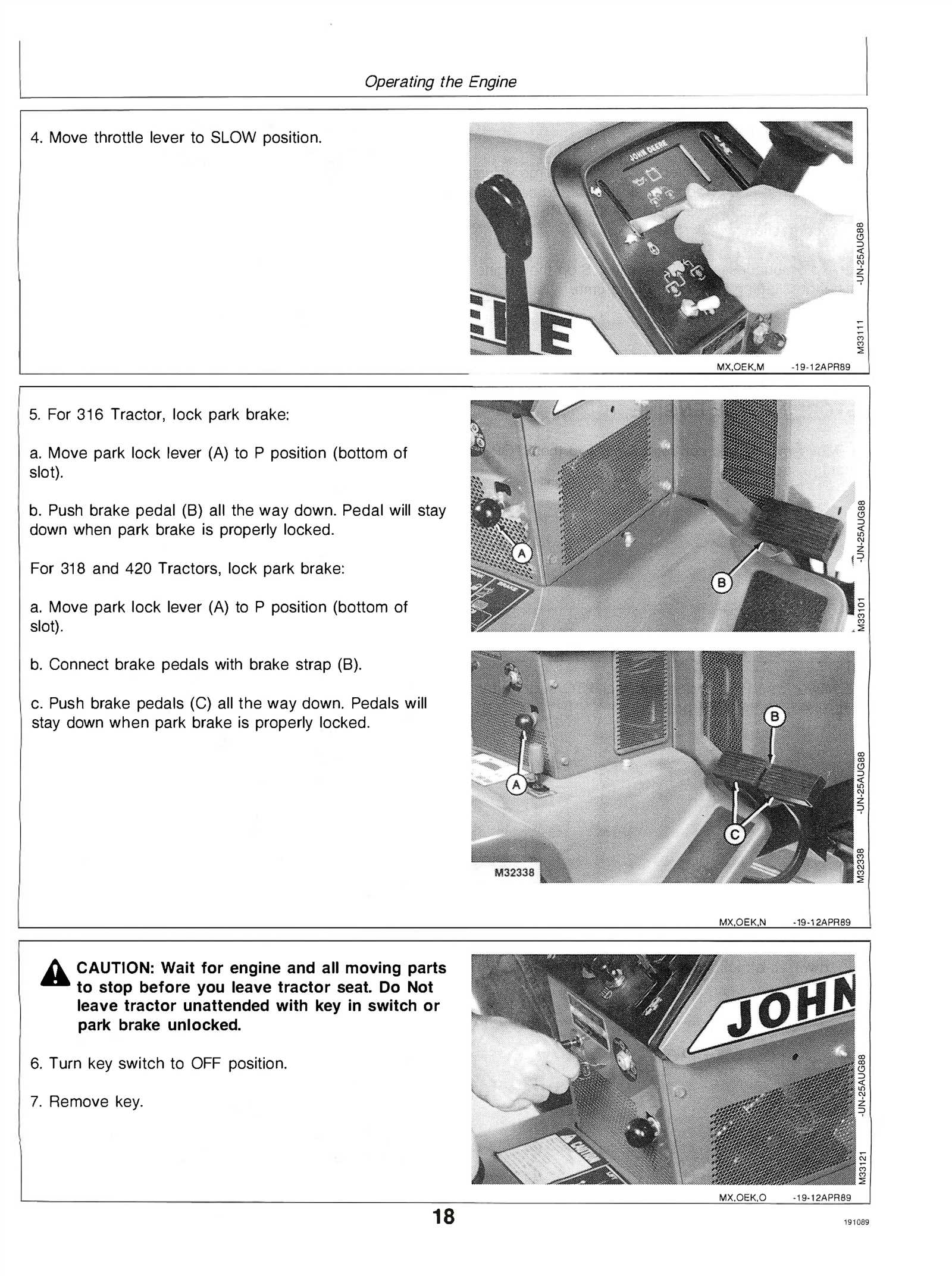

Key Components of the 316 Model

This section provides a focused overview of essential elements that contribute to the performance and reliability of this particular equipment. By understanding the structure and interaction of these core parts, users can ensure smoother operation and extend the lifespan of their machine. Engine and Power SystemThe heart of the machine lies in its robust power system, which delivers consistent energy to drive all functions efficiently. A reliable engine ensures smooth operation, with components such as fuel filters and cooling mechanisms working to maintain stability during intensive tasks. Transmission and Control FeaturesA highly adaptable transmission setup plays a pivotal role in maneuvering, allowing seamless changes in speed and direction. Control levers and pedal-operated systems further enhance usability, providing operators with precision and comfort while handling various workloads. Finding Replacement Parts Easily

Locating suitable components for machinery can feel challenging, especially when dealing with older equipment or niche models. However, the process can be streamlined with the right approach, saving both time and effort. This section offers practical guidance on sourcing alternatives and ensuring compatibility with minimal hassle. Start with the Model Specifications

The first step is to gather all relevant information about the equipment, including its technical specifications and manufacturing details. This data helps in narrowing down potential options and ensures the chosen elements meet the original design requirements. Documentation and online databases are invaluable resources during this phase. Explore Online Platforms and Specialty Dealers

Numerous online marketplaces and specialized retailers offer an extensive selection of compatible components. Searching through these channels allows for comparisons in pricing and availability. Some suppliers also provide cross-referencing tools, making it easier to identify equivalent alternatives even when the original item is out of production. Common Issues and SolutionsIn any complex mechanical system, problems may arise over time due to wear, improper maintenance, or environmental conditions. Identifying typical issues early and applying effective solutions can prolong the lifespan of the equipment and prevent costly repairs. Frequent Mechanical Challenges

Electrical Faults and Remedies

|