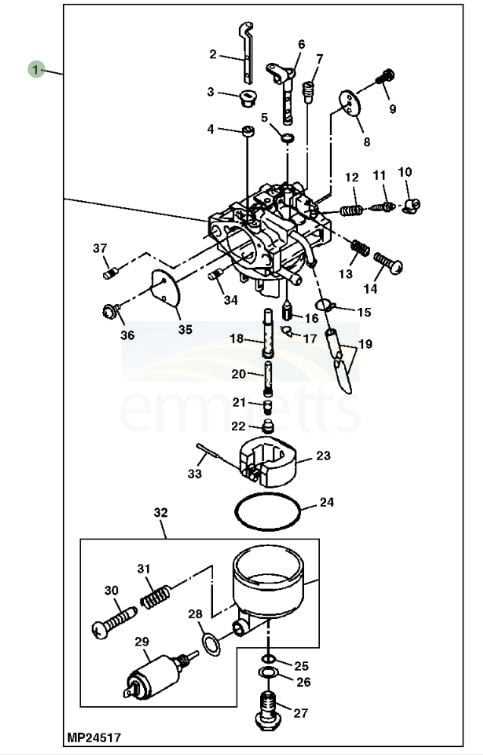

The intricate design of modern landscaping machines involves a myriad of essential components that work in harmony to achieve ultimate efficiency. Familiarity with these elements is crucial for maintenance and repair, ensuring that every piece functions optimally. By grasping the configuration of these parts, users can enhance their overall experience and prolong the lifespan of their equipment.

For enthusiasts and professionals alike, diving into the specifics of machinery layouts provides invaluable insights. Recognizing how each element interrelates not only facilitates smoother operation but also aids in troubleshooting issues as they arise. A clear visual representation of these structures becomes a vital resource for anyone aiming to achieve peak performance in their outdoor tasks.

As we explore the detailed arrangement of components, it becomes apparent that understanding their roles is fundamental. This knowledge empowers users to tackle repairs confidently, ensuring that their machines remain reliable allies in maintaining beautiful outdoor spaces. With a closer look at the intricate schematics, users can truly appreciate the engineering behind these powerful tools.

John Deere Z915E Parts Diagram: Understanding Your Mower

Gaining a clear comprehension of your mowing machine is essential for efficient maintenance and optimal performance. Knowing the components and their functions enables you to troubleshoot effectively and ensure longevity.

Key Components to Familiarize

- Engine

- Transmission

- Cutting Deck

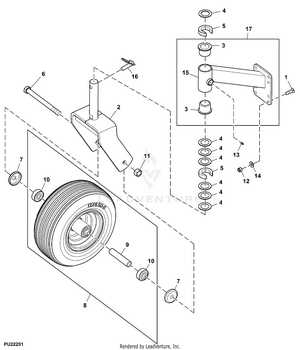

- Wheels and Tires

- Control System

Maintenance Tips

- Regularly inspect belts and blades for wear.

- Check fluid levels frequently.

- Clean air filters to promote efficiency.

- Keep all connections secure to avoid malfunctions.

Understanding these elements not only enhances your mower’s performance but also maximizes its lifespan, providing the ultimate value for your investment.

The Importance of Understanding Parts Diagrams

Comprehending the visual representation of components within machinery is crucial for effective maintenance and repair. These illustrations serve as essential tools, enabling users to identify and locate individual elements swiftly. By grasping the layout and relationship between different parts, operators can enhance their troubleshooting skills and optimize the overall functionality of their equipment.

Having a clear understanding of these visual aids allows for more efficient repairs, minimizing downtime and reducing costs associated with prolonged malfunctions. Additionally, familiarity with the configuration of various components fosters a deeper appreciation of the machinery’s design and engineering.

Furthermore, engaging with these representations encourages a proactive approach to maintenance. By knowing what to look for, operators can perform regular checks and replacements before minor issues escalate into significant problems. Ultimately, mastering the intricacies of component visuals contributes to a smoother operation and longevity of the equipment.

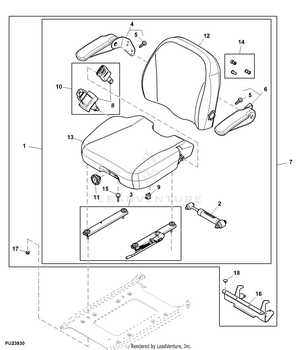

Key Components of the John Deere Z915E

This section explores essential elements that contribute to the functionality and efficiency of a specific mowing machine. Understanding these components enhances the user experience and maintenance practices.

Essential Elements

- Engine: Powers the entire system, ensuring optimal performance.

- Deck: The cutting platform, crucial for achieving precise mowing results.

- Transmission: Facilitates smooth movement and speed control.

- Wheels: Provide stability and maneuverability across various terrains.

Maintenance Considerations

- Regular inspections of the engine for wear and tear.

- Cleaning and sharpening the cutting blades to maintain efficiency.

- Checking the transmission fluid levels to ensure proper operation.

- Inspecting tires for damage and ensuring correct inflation.

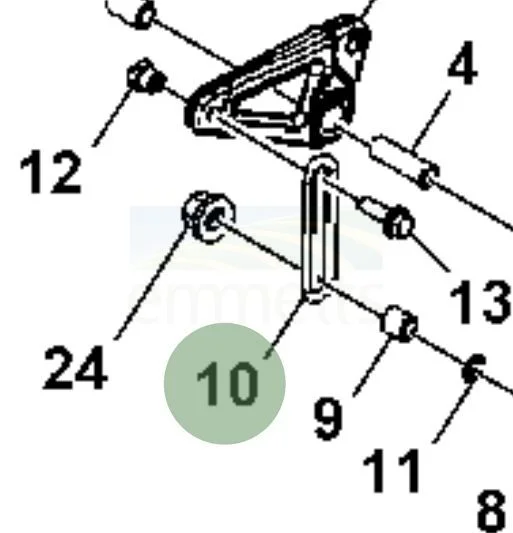

How to Locate and Interpret the Parts Diagram

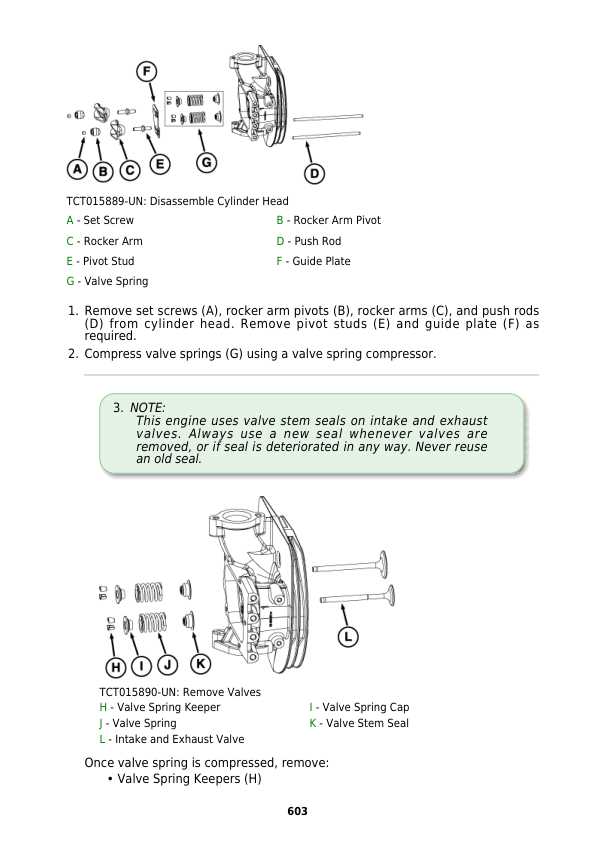

Understanding the components of machinery is essential for effective maintenance and repair. A well-structured visual representation can simplify this process, helping users identify various elements and their functions. This section will guide you on how to find and comprehend these illustrations efficiently.

To begin, consider the following steps for locating the relevant visual reference:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for categories related to service or technical documents.

- Search for your specific model or series.

Once you have accessed the illustration, interpreting it can seem daunting. Follow these tips to enhance your understanding:

- Familiarize Yourself with Symbols: Each component is often represented by specific icons. Review the legend or key provided.

- Follow the Layout: Diagrams are typically organized in a logical order. Start from one section and move systematically through the layout.

- Cross-Reference with Manuals: Use accompanying documentation for additional context regarding the parts and their functionality.

- Take Notes: Jot down important details or part numbers for future reference, especially if you plan to order replacements.

By utilizing these strategies, you will not only locate the necessary visual resources but also enhance your ability to interpret them accurately, leading to more effective repairs and maintenance tasks.

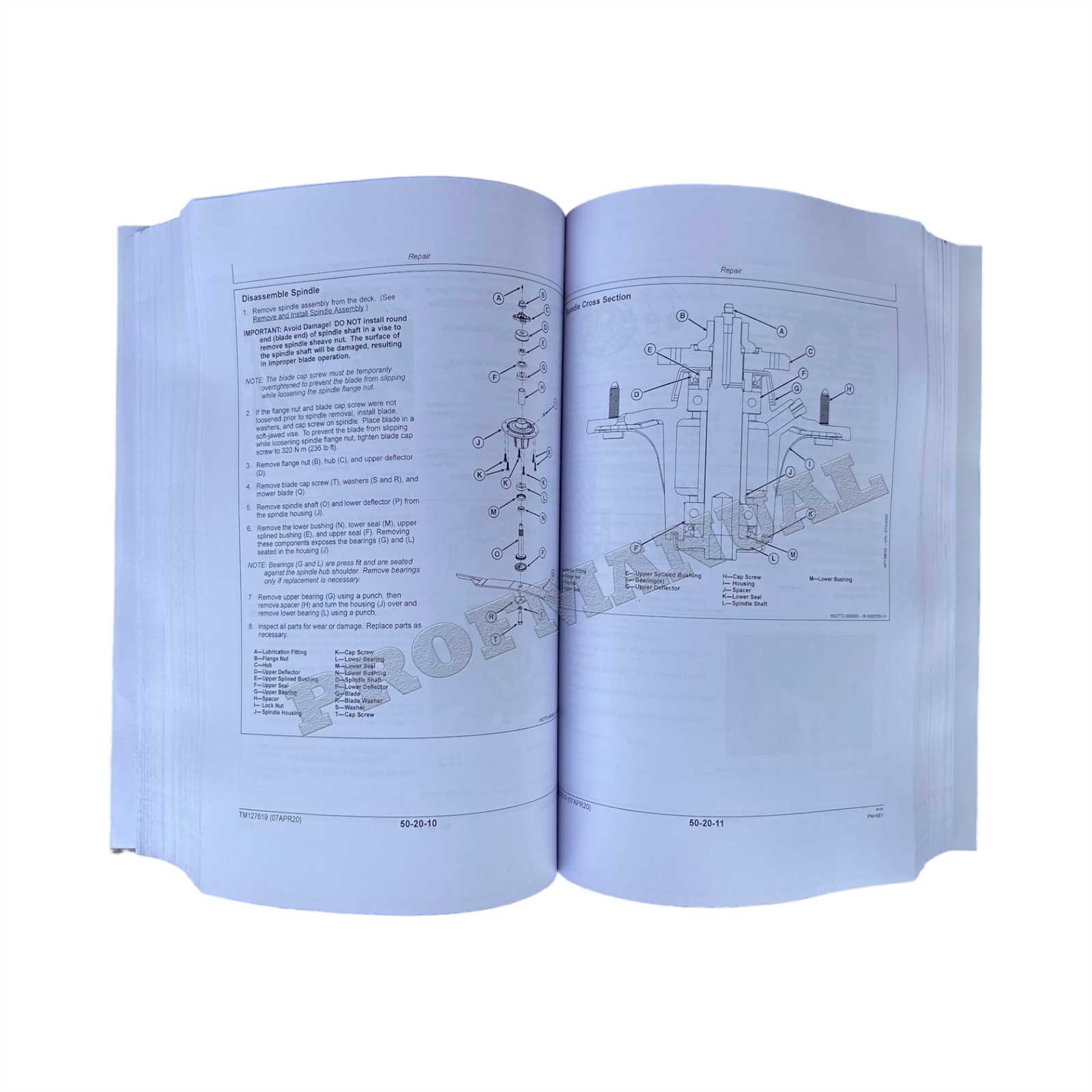

Common Maintenance Tasks and Parts Replacement

Regular upkeep of your machinery is essential for optimal performance and longevity. Understanding key tasks and when to replace specific components can prevent unexpected breakdowns and enhance efficiency. Below are some standard maintenance activities that should be performed periodically.

-

Oil Change:

Routine oil changes help maintain engine health. Check oil levels regularly and replace it according to the manufacturer’s recommendations.

-

Air Filter Replacement:

Replacing the air filter ensures that the engine receives clean air, improving combustion and efficiency. Inspect it frequently and replace it when it appears dirty or clogged.

-

Blade Sharpening:

Sharp blades are crucial for effective cutting. Regularly inspect and sharpen blades to ensure a clean cut and reduce stress on the engine.

-

Tire Maintenance:

Check tire pressure and tread depth regularly. Properly inflated tires enhance traction and ensure a smoother operation.

-

Battery Check:

Inspect the battery terminals for corrosion and ensure that the connections are tight. Test the battery’s charge regularly to avoid starting issues.

In addition to these tasks, always consult your equipment manual for specific guidelines on maintenance intervals and parts replacement to keep your machine running smoothly.

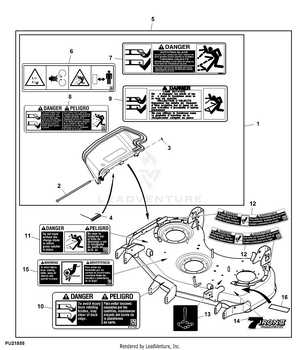

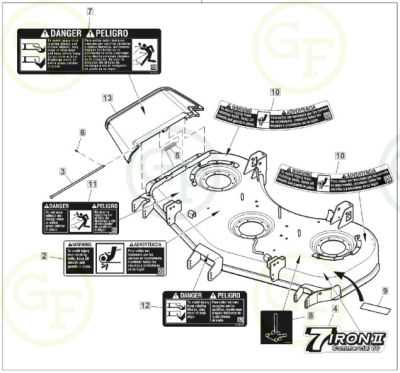

Tips for Efficiently Using the Parts Diagram

Understanding how to navigate a visual representation of components can significantly enhance your maintenance and repair processes. Utilizing these illustrations effectively allows for quick identification of individual elements, streamlining the workflow and minimizing downtime. Here are some strategies to make the most of these resources.

1. Familiarize Yourself with the Layout

Take time to understand the arrangement and symbols used in the visual guide. Knowing how components are grouped and labeled can save you valuable time when searching for specific items. Pay attention to any color codes or markings that indicate categories or functions, as these can further aid in quickly locating what you need.

2. Cross-reference with the Manual

Always have your operational manual on hand while using the visual representation. This allows you to confirm part numbers and specifications, ensuring that you select the correct items for replacements or repairs. Cross-referencing minimizes errors and provides a comprehensive understanding of how each piece interacts with the overall system.

Where to Access and Download the Parts Diagram

Finding detailed visual references for machinery components is crucial for effective maintenance and repairs. Numerous resources are available online that provide access to these essential illustrations. Whether you are a seasoned technician or a DIY enthusiast, knowing where to locate these resources can significantly streamline your projects.

Official manufacturer websites often host comprehensive libraries where you can easily navigate to the specific model you need. Additionally, third-party platforms frequently offer downloadable materials, ensuring you have the most up-to-date information at your fingertips. Online forums and communities can also be valuable, as they often share links and recommendations for reliable sources.

For convenience, consider bookmarking your favorite sites or using dedicated apps that aggregate these references, allowing quick access whenever necessary. With the right tools, you can ensure your equipment remains in optimal condition, ready for any challenge.

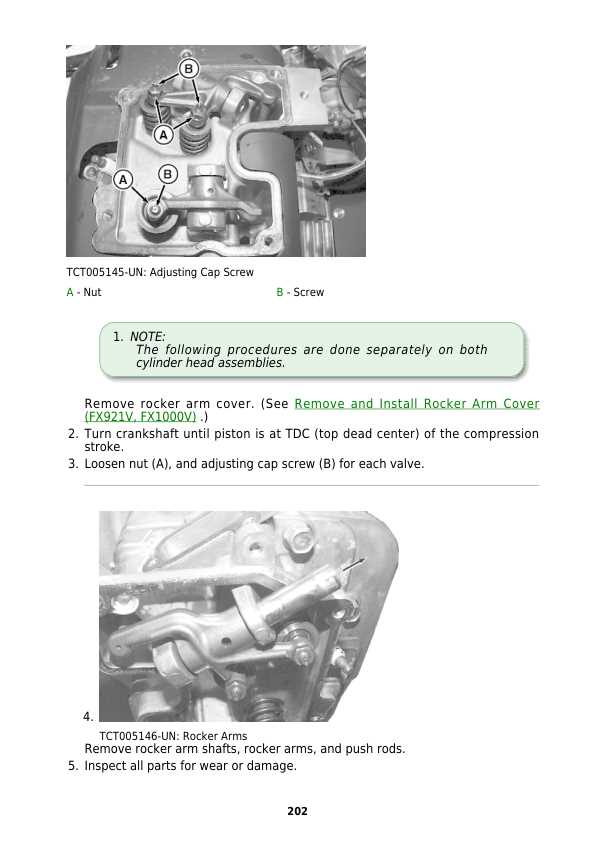

Using the Diagram for Troubleshooting Issues

Utilizing a visual representation of components can significantly aid in identifying and resolving mechanical problems. This approach allows users to pinpoint specific areas of concern quickly and effectively.

When faced with a malfunction, follow these steps to make the most of the visual guide:

- Identify Symptoms: Begin by noting any unusual sounds, vibrations, or performance issues.

- Locate Relevant Sections: Refer to the illustration to find the part that corresponds with the symptoms observed.

- Examine Connections: Check for loose connections or damaged components in the identified area.

- Cross-Reference Specifications: Compare the identified part with the specifications provided to ensure it meets operational standards.

- Document Findings: Keep a record of any discrepancies or issues found during your inspection.

By following these guidelines, users can effectively leverage a visual representation to troubleshoot and address mechanical challenges, ensuring optimal functionality and longevity of the equipment.

Benefits of Regularly Consulting the Parts Diagram

Maintaining equipment in optimal condition requires a thorough understanding of its components. Regularly referencing a schematic that illustrates these elements can lead to numerous advantages for users. This practice not only enhances efficiency but also extends the lifespan of machinery.

- Improved Maintenance: A detailed illustration allows operators to identify parts that need servicing, ensuring timely upkeep and reducing the risk of breakdowns.

- Enhanced Troubleshooting: When issues arise, having access to a visual guide aids in quickly pinpointing malfunctioning components, streamlining the repair process.

- Informed Upgrades: Understanding the arrangement of parts helps users make educated decisions when considering enhancements or replacements, leading to better performance.

- Cost Savings: By accurately diagnosing problems and performing maintenance, users can minimize repair costs and prevent unnecessary expenditures on new equipment.

- Safety Improvements: Familiarity with each component contributes to safer operation, as users can ensure all parts are functioning properly and securely.

Incorporating a routine of consulting these illustrations cultivates a deeper knowledge of machinery, promoting longevity and reliability in operations.