Modern agricultural equipment relies on intricate systems that work together to ensure efficient and reliable performance. Understanding how various elements are arranged and connected is crucial for optimal use, maintenance, and troubleshooting. By familiarizing yourself with the internal structure and layout of such systems, you can better handle adjustments, repairs, and upgrades, contributing to both productivity and longevity of the equipment.

This section provides a detailed look at the essential components and how they interconnect, offering insights into effective maintenance and servicing. With a focus on supporting enhanced functionality and seamless operation, this guide aims to clarify component relationships and placement. Discovering these details helps operators and technicians achieve smoother workflows, even in challenging conditions.

Here, you’ll find valuable information on positioning and connections, guiding you through each key aspect of assembly. Whether you are a technician, farmer, or machinery enthusiast, this exploration serves as a useful reference, enabling you to better manage the equipment and keep it in prime working condition.

Understanding the Equipment for Efficient Crop Planting

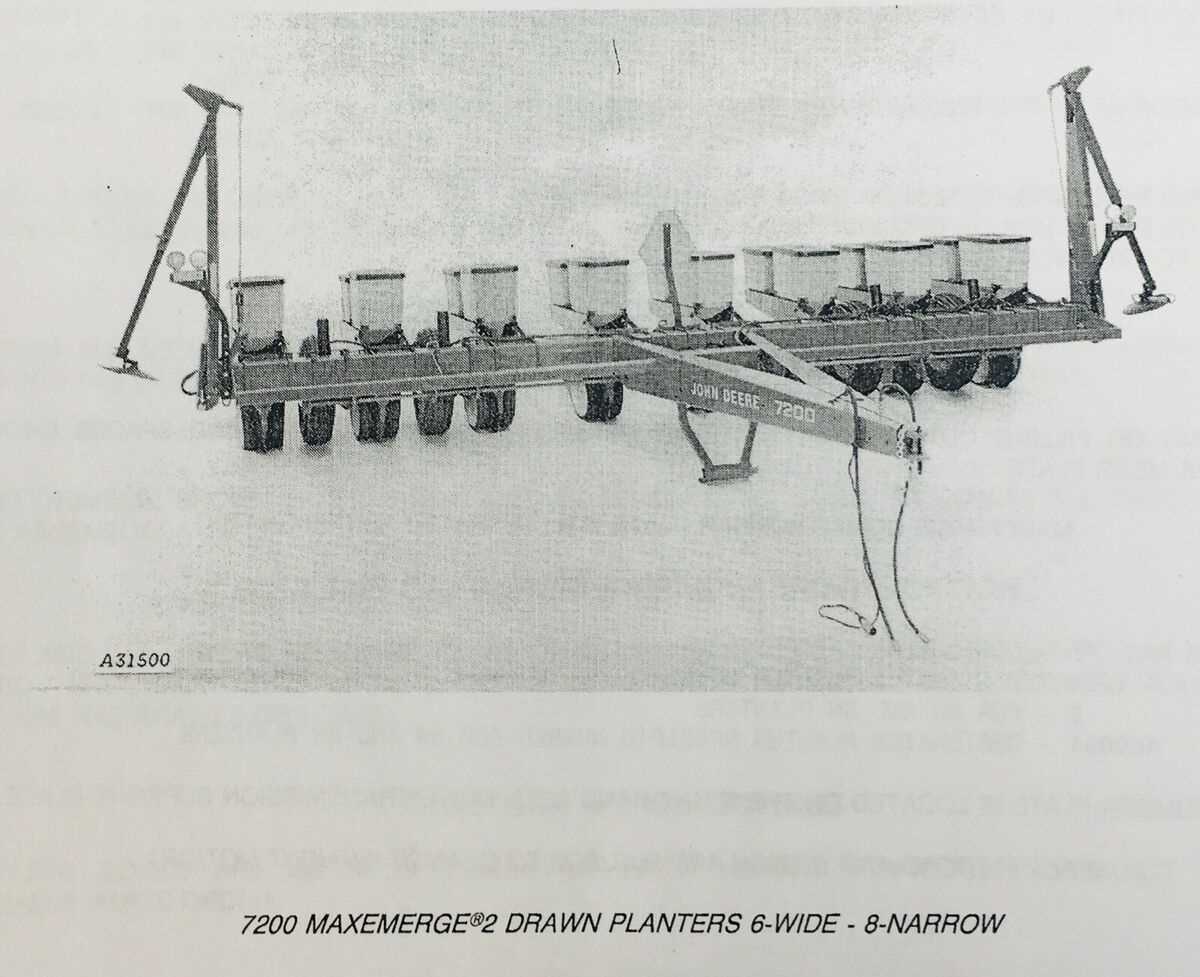

This section provides an overview of a widely recognized planting tool designed to enhance efficiency and consistency in agricultural tasks. It is a versatile choice among farmers due to its reliable performance and adaptability in varying soil and crop conditions. The model includes numerous features that optimize seed placement, maximize crop yields, and minimize downtime in the field.

Key Functionalities and Components

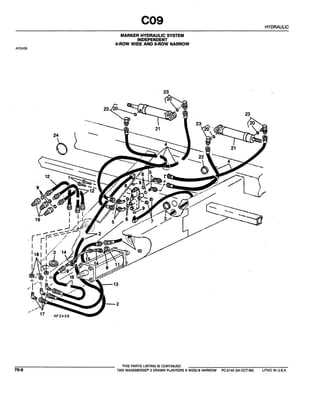

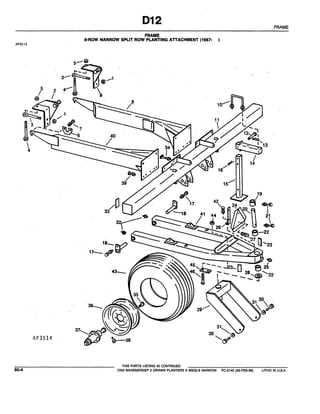

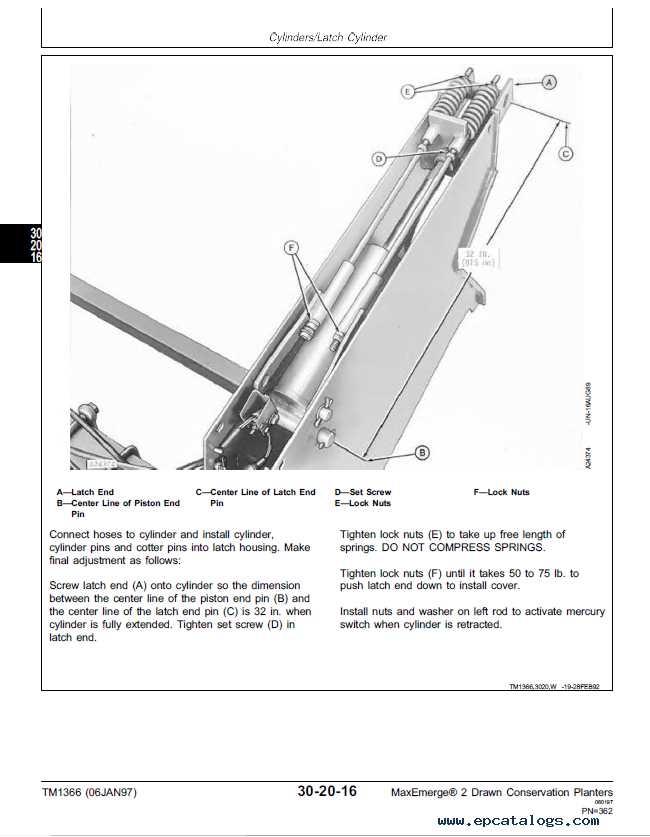

Built to handle diverse planting needs, this machine is equipped with multiple row units and mechanisms for precise seed distribution. The planting tool incorporates advanced systems for spacing, depth adjustment, and row alignment, which help ensure seeds are placed accurately and uniformly across fields. Its modular design allows for easy maintenance and replacement of parts, making it a practical choice for large-scale farming operations.

Specifications and Adjustment Features

The equipment is built with robust materials and includes adjustable settings for row spacing, depth control, and application rates. This flexibility allows farmers to tailor operations based on crop type, soil composition, and planting conditions. Detailed adjustments and calibrations are made possible by various levers, springs, and gauge wheels, ensuring

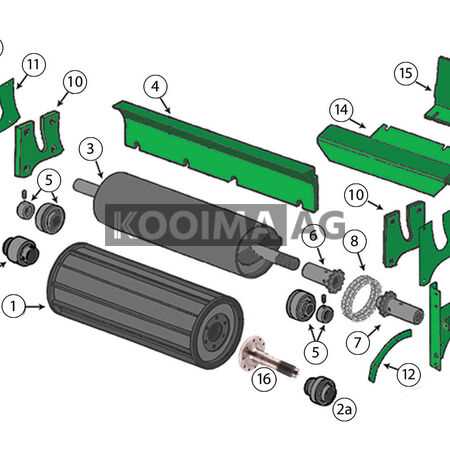

Components of the 7200 Planting Machine

Understanding the key elements of this planting system helps operators maintain efficiency in fieldwork and ensures proper functionality. This machinery includes various mechanisms designed to deliver seeds accurately while maintaining soil health and promoting optimal growth conditions. Each component plays a unique role in preparing, planting, and managing the soil for each cycle.

Seed Delivery Mechanism: The central system responsible for placing seeds in the soil with precision. Its components ensure consistent seed distribution, adjusting to different soil types and field conditions to achieve ideal spacing.

Soil Preparation Tools: These parts work to break up the ground, remove debris, and create the ideal planting environment. Equipped to handle various terrains, they adjust to specific soil types, enhancing ground readiness for planting.

Depth Control System: This component regulates the planting depth, crucial for ensuring seeds are placed where they can access moisture and nutrients effectively. Adjustments in this system enable compatibility with different crop needs.

Downforce Adjusters: These mechanisms maintain the necessary pressure on the ground to achieve consistent depth and prevent the machinery from bouncing or skipping, leading to uniform growth results across the field.

Seed Metering Apparatus:

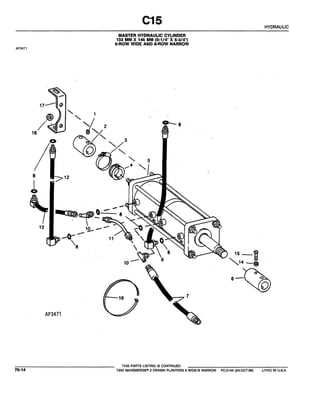

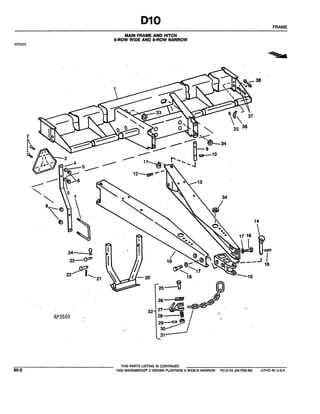

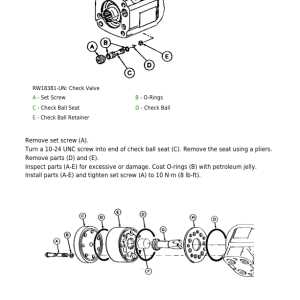

Importance of Parts Diagrams

Visual guides that map out the components and connections in equipment play a crucial role in understanding how each element contributes to the overall function. Such resources provide clarity on complex systems, highlighting the relationship between each component and ensuring efficient operation and maintenance.

Benefits of Using Component Schematics

- Efficient Troubleshooting: Well-organized schematics allow for quick identification of specific elements, enabling users to locate issues accurately and streamline repairs.

- Enhanced Maintenance: Regular upkeep is simplified with clear component layouts, as users can better understand wear points and critical areas requiring frequent inspection.

- Improved Part Replacement: When a replacement is needed, these visual maps eliminate confusion by clearly indicating each component’s role and location within the system.

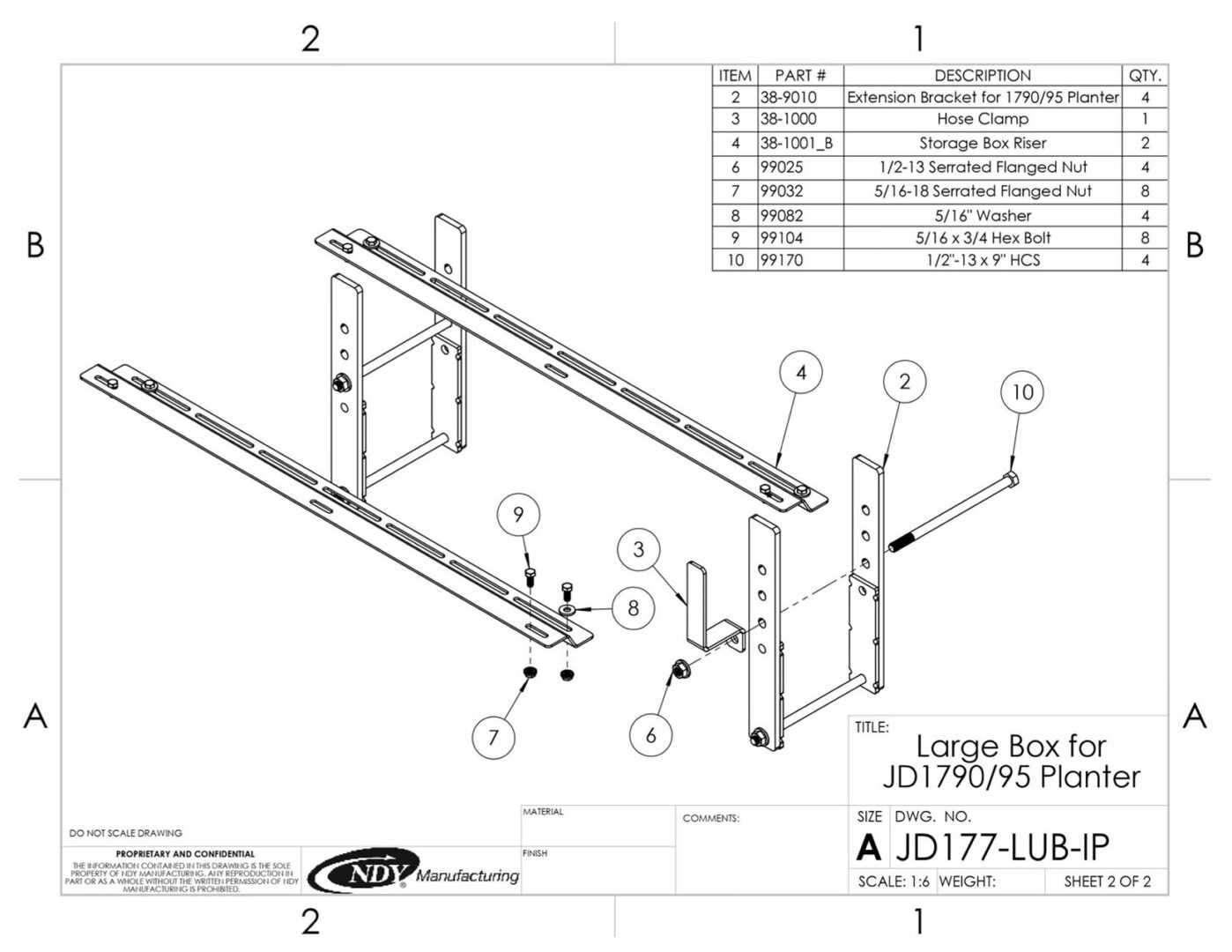

Streamlined Assembly and Installation

For assembly and installation tasks, a clear view of every element’s place within a larger setup helps avoid errors and ensures correct placement. This structured approach minimizes potential mistakes, saving both time and resources during initial setups or replacements.

- Study the schematic carefully to understand the connections between elements.

- Identify critical areas requiring regular maintenance or potential replacements.

Common Issues with Planter Parts

Understanding frequent challenges with agricultural equipment components can help improve efficiency and prolong operational lifespan. Over time, parts can experience wear, alignment issues, or functional inconsistencies that impact performance. Addressing these common obstacles proactively ensures smoother operations during planting seasons.

Wear and Tear on Moving Components: One of the primary issues involves gradual wear on essential moving elements. Frequent usage, combined with exposure to soil and moisture, can cause these components to degrade faster, leading to reduced accuracy and efficiency. Regular inspections help detect signs of wear early, allowing for timely replacements.

Alignment and Calibration Problems: Another common challenge arises from alignment or calibration inconsistencies. Even slight misalignments can affect planting accuracy, spacing, and depth. Regular checks and adjustments ensure that all elements remain synchronized, reducing the risk of uneven planting.

Soil and Debris Accumulation: Soil, dust

Maintenance Tips for Longevity

Proper upkeep is essential to ensure that agricultural equipment performs reliably over the years. Routine care helps prevent unexpected downtime and can significantly extend the lifespan of machinery. Regularly scheduled inspections and small adjustments can make a big difference in the overall durability and effectiveness of equipment used in the field.

Keep Moving Parts Lubricated

Consistent lubrication of moving components is crucial to avoid wear and tear. Friction can quickly lead to mechanical breakdowns if neglected, so it’s advisable to regularly apply high-quality lubricants as recommended for the specific components. This routine can help reduce the risk of corrosion and ensure smooth operation, particularly during heavy-duty work periods.

Check for Wear and Replace When Necessary

Inspect frequently for signs of wear on essential components. Parts exposed to high-stress conditions may show early indications of degradation, such as cracks or thinning. Replacing worn components proactively can prevent more serious issues and help maintain optimal performance. Having spare parts on hand can also reduce delays when replacement is necessary.

Consistent maintenance not only improves equipment longevity but also supports better productivity. Keeping a log of service dates and tasks performed can help track patterns and anticipate future needs. With

Where to Find Replacement Parts

For those seeking to maintain agricultural equipment and ensure reliable performance, having access to replacement components is essential. The right sources can help keep machinery functioning smoothly and extend its operational lifespan. Whether dealing with wear-and-tear issues or preparing for future maintenance, knowing where to obtain quality replacements can save time and avoid interruptions in farming activities.

Many reliable suppliers offer a range of compatible parts, catering to various needs from mechanical updates to specific hardware replacements. It is often beneficial to look for specialized vendors who focus on agricultural machinery, as they can provide expert advice and help locate the exact components required. Authorized dealers, online marketplaces, and certified repair shops are all effective places to consider.

To find trustworthy options, consider comparing prices, checking product reviews, and confirming compatibility with your specific equipment model. Opting for reputable sources ensures quality and durability, which are key to achieving optimal machine performance and reducing future repair costs.

Upgrading Your Planter Efficiency

Enhancing the performance of your equipment can lead to better field productivity, reduced operating costs, and improved crop yields. By making strategic adjustments, you can ensure that each part of your seeding setup works optimally, adapting to varying soil conditions and crop types with greater precision.

Consider Advanced Monitoring Systems

Integrating modern monitoring systems can provide real-time insights into planting depth, spacing accuracy, and seed flow. These systems offer vital feedback, enabling operators to adjust quickly to any inconsistencies that may impact yield. Monitoring systems today often come with easy-to-use interfaces and can be customized to display the most relevant metrics for your specific setup.

- Track depth consistency across rows

- Optimize spacing based on field variations

- Identify potential flow issues immediately

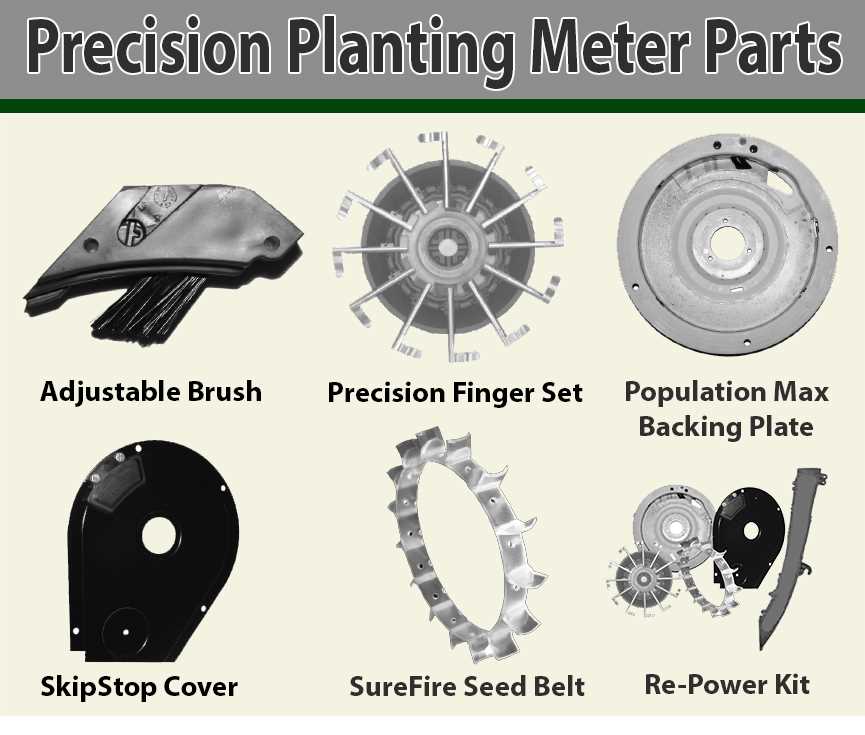

Upgrade Components for Improved Precision

Replacing certain elements with updated versions can enhance control over seed placement and soil interaction. Precision parts offer better durability, consistency, and adaptation to complex terrain. Even small changes, such as in the dispensing or pressure components, can contribute significantly

Comparing 7200 to Other Models

In agriculture, various equipment designs and functionalities are tailored to meet diverse field requirements. When choosing between different models, it’s essential to understand the unique capabilities and differences in performance each one offers. Here, we’ll examine key characteristics that set this model apart from others in its category.

- Row Configuration Options: Many models in this category offer a range of row setup options, allowing operators to select arrangements that suit specific crop types and field layouts. Differences in row-spacing flexibility can significantly impact planting precision.

- Depth Control Mechanisms: Accurate depth management is crucial for ensuring optimal seed placement and growth. Some models incorporate advanced depth regulation technologies, enhancing control and consistency even on uneven terrain.

- Maintenance and Durability: Equipment longevity and ease of upkeep are important for sustained performance. Variations in build quality, material choice, and component accessibility affect each model’s maintenance needs, influencing both cost and time efficiency over seasons.

- Compatibility with Accessories: Modern designs often include compatibility with various add-ons to improve efficiency, such as monitoring systems and nutrient dispensers. These options differ by model, impacting the degree of customization available.

- Efficiency in Larger Fields: Certain models are more suited to expansive plots, offering configurations that support greater coverage per pass. This feature is advantageous for operations on larger fields, optimizing time and fuel usage.

Understanding these factors helps in making an informed decision, ensuring that the chosen equipment

User Experiences and Feedback

Many users find that effective maintenance and familiarity with each component of agricultural machinery can greatly enhance performance and reliability. Sharing insights and real-world observations helps others understand both the capabilities and common challenges that may arise.

One of the most frequently mentioned aspects is the simplicity of setup and daily operation. Users often highlight that well-designed parts contribute to smoother fieldwork and less downtime. Consistent quality and intuitive layouts are some of the factors praised by experienced operators, who find them beneficial for achieving steady results across various conditions.

In addition, feedback often touches on the durability of each element, especially under heavy use. Many users appreciate the robustness, noting that regular upkeep can significantly extend operational life and reduce replacement needs. Those who have experience with these machines often share practical advice on optimizing performance, ensuring both efficient function and minimal interruptions throughout the season.