In the realm of modern farming, the efficiency of machinery plays a crucial role in enhancing productivity. Understanding the intricacies of various devices allows operators to optimize their performance and maintain smooth operations. This section aims to explore the essential elements that contribute to the functionality of a specific type of agricultural implement, ensuring users can troubleshoot and repair with confidence.

Familiarizing oneself with the layout and interconnections of mechanical components is vital for effective maintenance. By delving into the arrangement of key elements, users can identify potential issues and execute repairs with greater ease. This knowledge empowers farmers to keep their equipment in peak condition, reducing downtime and improving overall efficiency.

Moreover, a comprehensive grasp of how different sections work together not only aids in resolving immediate concerns but also fosters a deeper appreciation for the technology that drives contemporary agriculture. Whether one is a seasoned operator or a novice, understanding these components is integral to successful farming practices.

Understanding John Deere 457 Baler

This section provides an overview of a specific model designed for efficient crop handling. These machines are integral for modern farming practices, enabling farmers to optimize their workflow while maintaining high-quality production standards. The functionality and durability of this equipment make it a valuable asset in agricultural operations.

Key Features: The design incorporates advanced technology aimed at enhancing performance. Operators can benefit from improved ease of use, enabling them to manage various tasks seamlessly. With features that support consistent output, this model stands out in its category.

Maintenance Considerations: Regular upkeep is essential for maximizing longevity and efficiency. Understanding the components and their interactions allows for better maintenance practices, ultimately leading to reduced downtime. Familiarity with the assembly and function of various elements aids in quick troubleshooting and repair.

Overall, investing time in comprehending this equipment ensures optimal use and enhances productivity on the farm, allowing for a more streamlined and effective approach to crop management.

Key Components of Round Balers

Understanding the essential elements of these machines is crucial for effective operation and maintenance. Each part plays a significant role in ensuring the smooth functioning of the equipment, allowing for efficient harvesting and packaging of materials.

- Feed System: This component gathers the crop and directs it into the compression chamber.

- Compression Chamber: Here, the material is tightly compacted into bales, a critical phase for achieving the desired density.

- Wrapping Mechanism: This part secures the bales with twine or netting, preventing them from unraveling.

- Pickup System: It effectively collects the cut material from the ground, facilitating a seamless feed into the baling process.

- Drive System: Powers the machine, ensuring all components operate in harmony for optimal performance.

By delving into each of these elements, operators can gain a deeper understanding of their equipment and enhance productivity.

Importance of Maintenance for Balers

Regular upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to diminished efficiency, increased downtime, and costly repairs. A proactive approach to servicing equipment not only enhances productivity but also safeguards the investment made in such machinery.

Effective maintenance practices encompass various tasks, from routine inspections to replacing worn components. Understanding the key aspects of upkeep can help operators achieve the best results in their operations.

| Maintenance Task | Description | Frequency |

|---|---|---|

| Inspection | Check for wear and tear, ensuring all parts are functioning correctly. | Weekly |

| Lubrication | Apply grease to moving parts to reduce friction and prevent overheating. | Monthly |

| Cleaning | Remove debris and build-up to maintain optimal operation. | After each use |

| Component Replacement | Replace any damaged or worn parts to prevent breakdowns. | As needed |

By prioritizing maintenance, operators can ensure their machinery remains reliable and efficient, ultimately enhancing the overall productivity of their agricultural activities.

Identifying Common Replacement Parts

Maintaining agricultural machinery is crucial for optimal performance and longevity. Understanding the components that may require replacement helps ensure smooth operation and reduces downtime. Familiarity with these essential elements empowers operators to make informed decisions during maintenance and repairs.

One frequently replaced component is the cylinder. This element is vital for compressing material and may wear out over time due to extensive use. Regular inspection can help identify signs of damage, allowing for timely replacement.

Another critical item is the chain, which facilitates movement and power transmission. Chains are subject to wear and tension changes, making it important to check their condition regularly. If they show signs of excessive stretching or damage, replacing them promptly can prevent further issues.

Rollers play a significant role in guiding materials through the machine. They can experience wear due to constant friction, leading to inefficiencies. Keeping an eye on their condition and replacing them as needed ensures optimal functionality.

Additionally, belts are essential for connecting various components. Over time, they can stretch or crack, necessitating replacement to maintain proper operation. Regular monitoring of belt condition can prevent unexpected breakdowns.

By being aware of these common components, operators can enhance their maintenance routines and ensure their equipment remains in peak working condition.

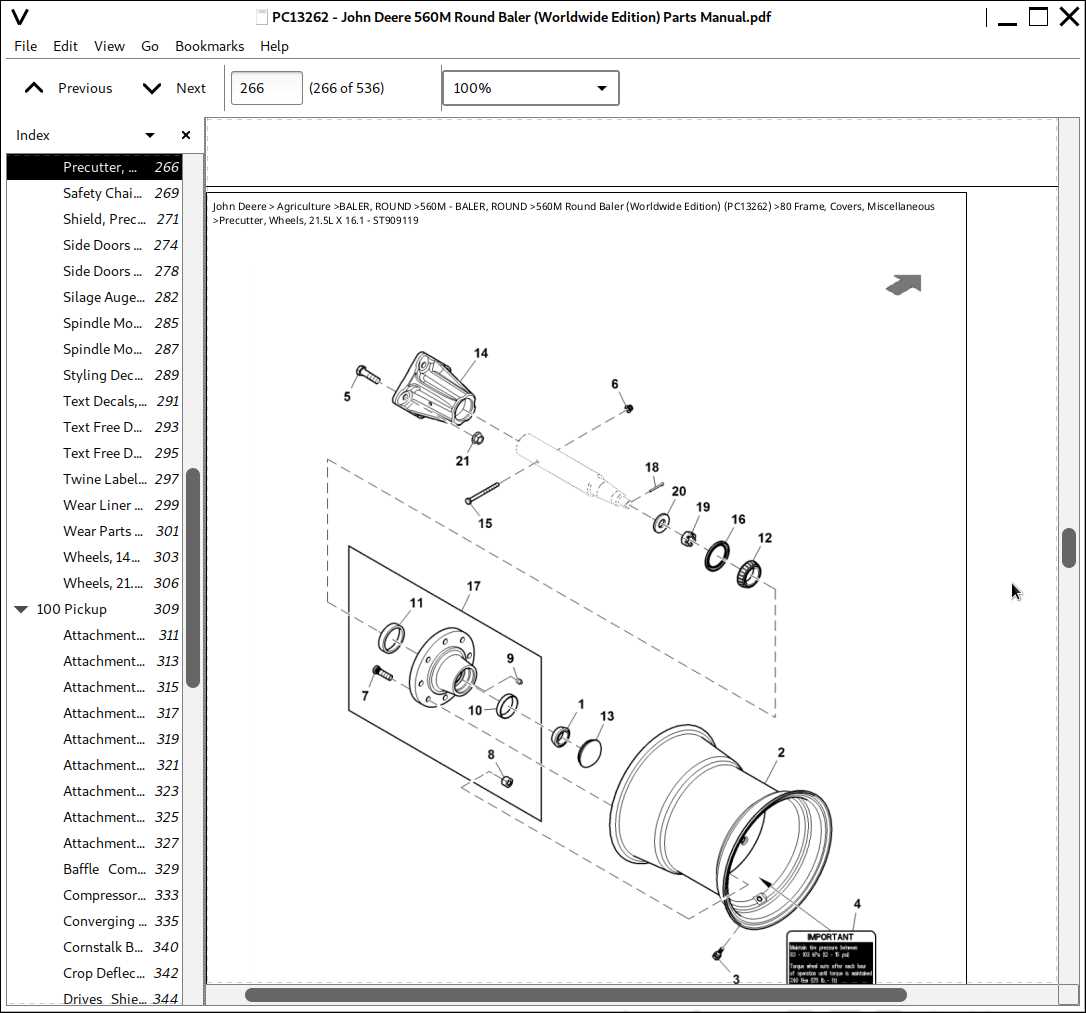

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as a guide to identify various elements and their relationships within machinery.

Key Elements to Focus On

- Labels: Ensure you check for clear designations that correspond to specific parts.

- Numbering: Follow any numerical identifiers that may indicate assembly order or grouping.

- Legend: Refer to any accompanying legend that explains symbols and color codes used in the illustration.

Steps to Interpret the Visuals

- Start by examining the overall layout to get a sense of the assembly.

- Identify the main components before diving into details.

- Cross-reference with a parts list if available for a deeper understanding.

Resources for Finding Parts

Locating components for agricultural machinery can often be challenging. However, there are numerous avenues available to assist operators in acquiring the necessary items efficiently. Utilizing a combination of online platforms, local dealers, and specialized resources can streamline the process significantly.

Online Platforms

The internet provides a wealth of resources for sourcing machinery components. Various websites cater specifically to agricultural equipment, offering catalogs and search functions to find required items. Additionally, forums and community groups can provide valuable insights and recommendations.

Local Dealerships

Visiting nearby dealerships is another effective approach. Many authorized sellers maintain comprehensive inventories and can offer expert advice on compatibility and performance. Establishing a relationship with local suppliers can also yield benefits such as timely service and potential discounts.

| Resource Type | Description |

|---|---|

| Online Retailers | Websites that specialize in agricultural equipment and parts. |

| Community Forums | Platforms for discussion and advice from fellow equipment users. |

| Local Dealers | Authorized sellers with direct access to manufacturer inventories. |

Troubleshooting Common Baler Issues

When operating a harvesting machine, various challenges can arise that may hinder performance. Identifying and resolving these problems promptly is crucial for maintaining efficiency and productivity in the field. This section will explore typical complications encountered during operation and provide insights into effective solutions.

1. Poor Bale Formation

If the bales are not forming correctly, it can often be attributed to improper tension settings or feed rate issues. Ensure that the tension is adequately adjusted, and monitor the material being fed into the machine for consistent flow. Clogs in the intake area can also disrupt the process, so regular checks are recommended.

2. Twine or Net Wrap Problems

Issues with binding materials can arise from improper threading or misalignment of the wrapping mechanism. Regularly inspect the twine or net wrap for damage and ensure it is loaded correctly. Worn components can also lead to failures, so consider replacing any worn parts as needed.

3. Unusual Noises

Unexpected sounds during operation may indicate underlying mechanical problems. Listen for grinding, knocking, or rattling noises, which can suggest that bearings, gears, or other components require attention. Immediate inspection can prevent further damage and costly repairs.

4. Hydraulic System Issues

If the hydraulic system is not functioning properly, check for leaks, low fluid levels, or air in the system. Regular maintenance and timely fluid changes are essential for optimal performance. Sticking valves or worn hoses can also impact operation, so be vigilant in your checks.

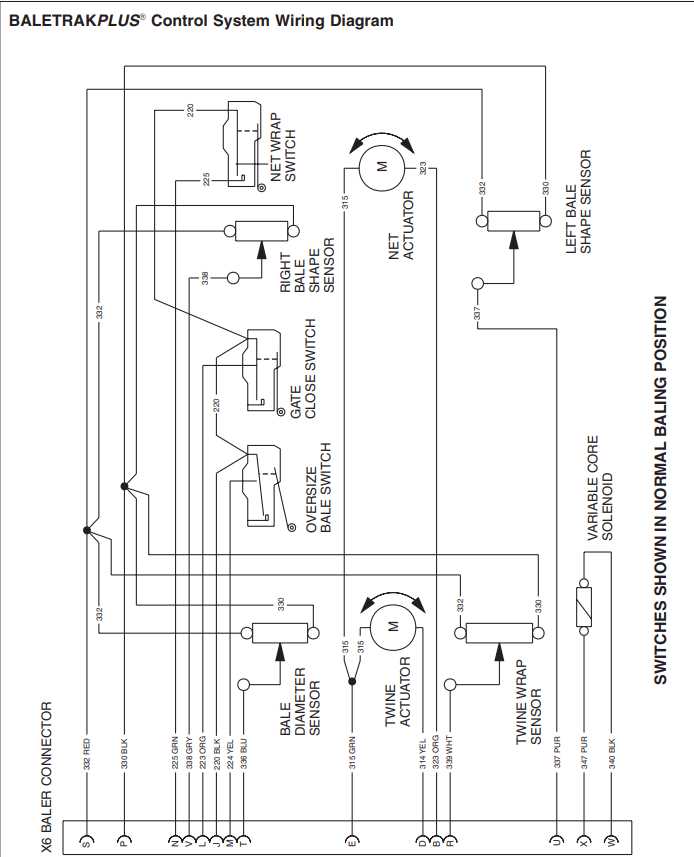

5. Electrical Failures

Electrical components play a vital role in machine functionality. If there are issues with lights, indicators, or control systems, inspect wiring connections and fuses. A thorough examination can often reveal simple fixes that restore proper operation.

By staying vigilant and addressing these common issues promptly, operators can ensure smooth performance and longevity of their machinery. Regular maintenance checks and a proactive approach will significantly reduce the risk of encountering serious problems during harvesting.

Upgrades for Enhanced Performance

To maximize the efficiency and productivity of your agricultural machinery, implementing strategic enhancements can make a significant difference. These upgrades not only improve functionality but also extend the lifespan of the equipment, ensuring a greater return on investment.

Engine Optimizations: Upgrading to a more powerful engine can lead to increased speed and improved fuel efficiency, allowing for quicker field operations.

Advanced Technology: Incorporating modern technology, such as precision monitoring systems, can provide real-time data to enhance decision-making and operational effectiveness.

Improved Components: Replacing outdated components with high-performance alternatives can significantly enhance durability and reduce maintenance costs.

Enhanced Safety Features: Adding upgraded safety mechanisms ensures not only the protection of the operator but also the overall reliability of the equipment in challenging environments.

Overall, these strategic enhancements can transform the functionality of your machinery, making it a vital asset on the farm.

Benefits of Genuine John Deere Parts

Utilizing authentic components for machinery is crucial for maintaining optimal performance and longevity. These original items are designed specifically for seamless integration, ensuring reliability and efficiency in operation.

Quality Assurance

When you opt for genuine components, you benefit from:

- Superior manufacturing standards

- Enhanced durability

- Consistent performance

Long-Term Savings

Investing in authentic parts can lead to significant savings over time through:

- Reduced maintenance costs

- Minimized downtime

- Extended machinery lifespan