When working with advanced machinery, having a clear understanding of its structure and individual elements is crucial. Every piece of equipment is composed of multiple interconnected units that ensure its smooth operation. Knowing how these elements interact can help in identifying potential issues and maintaining optimal performance.

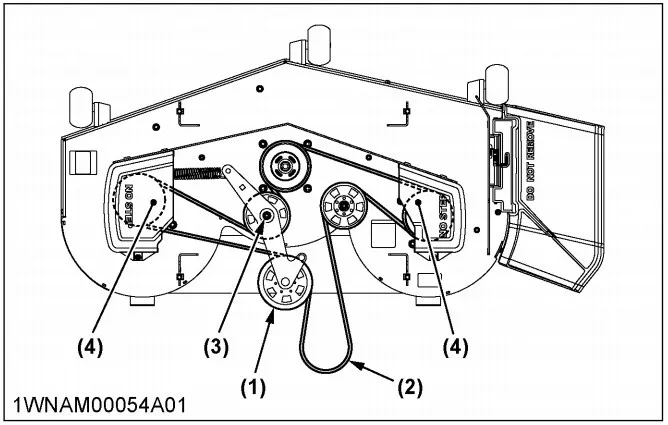

Detailed visual representations of the internal structures are invaluable resources for anyone involved in maintenance or repair. They offer insights into the precise placement and role of various components, making troubleshooting and servicing more efficient.

In addition to aiding in repairs, these representations also enhance the understanding of the equipment’s overall functionality. This comprehensive knowledge can significantly extend the operational lifespan of the machinery, ensuring reliability and efficiency in daily use.

Key Components Overview

This section highlights the essential mechanical and structural elements that define the functionality and performance of a high-quality lawn maintenance machine. These elements contribute to durability, efficiency, and precision during operation, ensuring smooth handling and extended service life.

Engine and Power System

The core of the machinery lies in its robust power source. A well-engineered engine provides the necessary horsepower to tackle demanding tasks, supporting a wide range of operational speeds and maintaining fuel efficiency. This system is complemented by reliable transmissions that ensure smooth power delivery and adaptability to various terrains.

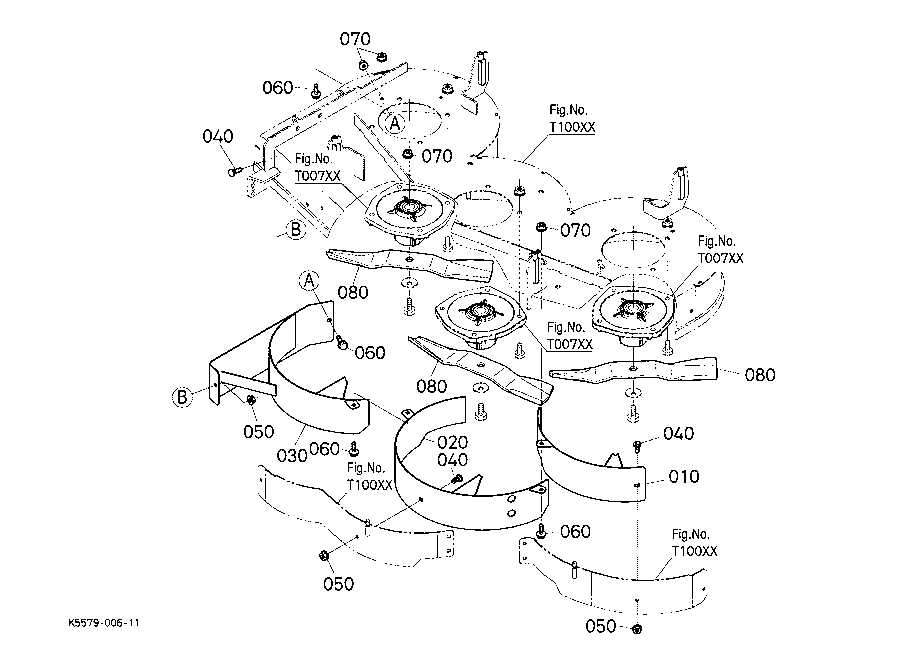

Cutting Deck and Blades

The cutting mechanism is another crucial feature, designed to deliver precise and consistent results. Its sharp, durable blades are housed within a sturdy deck, which offers adjustable height settings to accommodate different grass lengths. This system promotes even cutting across large areas, minimizing effort while maximizing output.

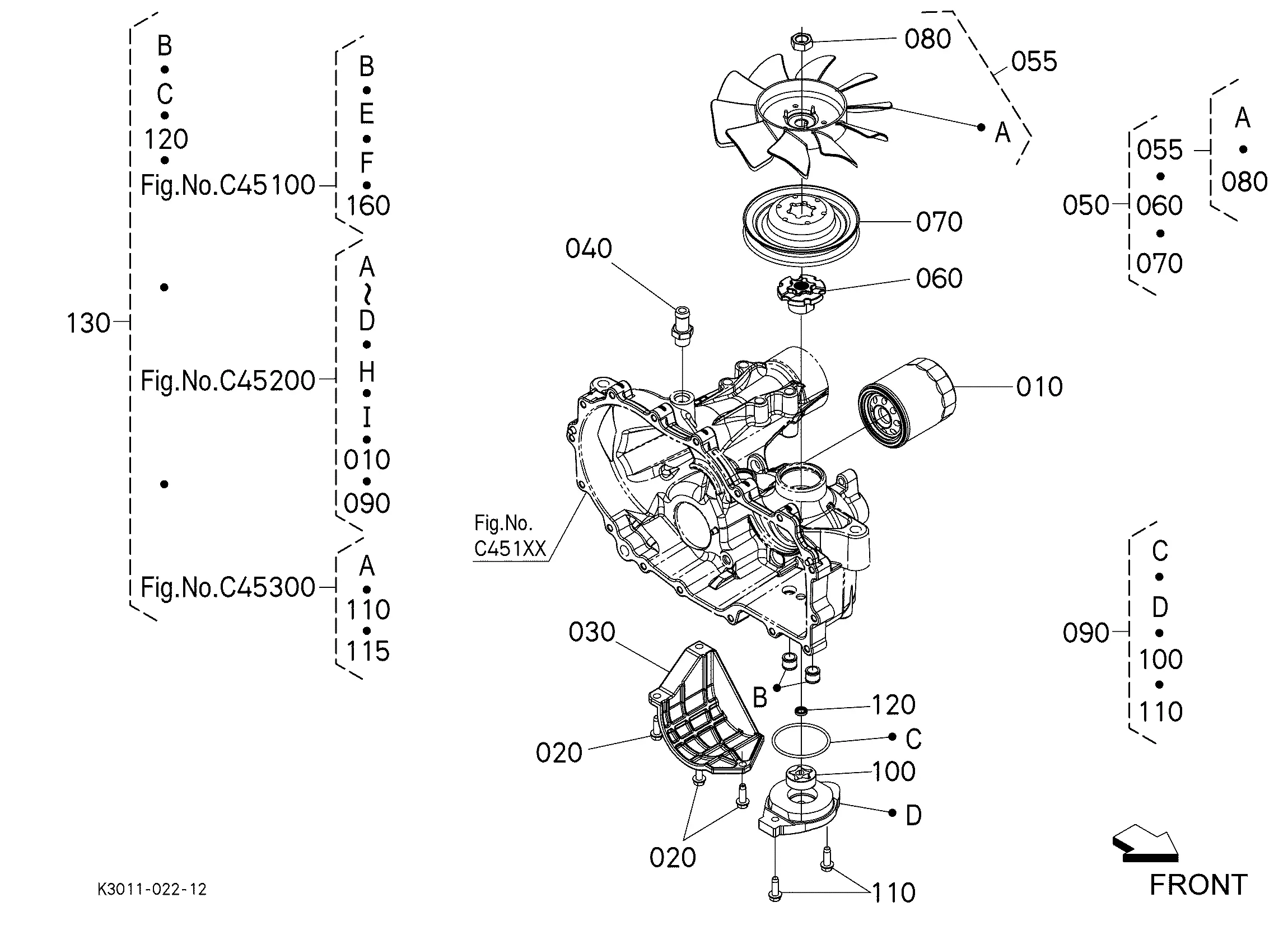

Engine Parts and Their Functions

Understanding the components that make up an engine is essential for anyone looking to maintain or repair it. Each element plays a crucial role in the engine’s overall performance and efficiency, contributing to how smoothly it operates. Below, we’ll explore key components, describing their roles in the system.

- Cylinder Block: The central structure of the engine, housing various components and acting as the backbone of the entire system.

- Pistons: These move up and down within the cylinder, converting fuel into mechanical power by creating pressure through combustion.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, driving other parts of the engine and ultimately powering the machine.

- Camshaft: Regulates the timing of opening and closing of the valves, ensuring proper air and

Understanding the Electrical System Layout

The electrical system in any machine plays a crucial role in ensuring seamless operation. It includes various interconnected components that manage the flow of power, ensuring that all essential systems function efficiently. Understanding how these components are arranged and how electricity flows through the system is key to troubleshooting potential issues and ensuring optimal performance.

Main Components of the Electrical System

The layout generally includes a battery, wiring, relays, fuses, and key switches. Each of these elements works together to manage the electrical current, from powering the engine to operating auxiliary features. Knowing the placement of each part can help in routine maintenance and repair work.

Power Distribution and Safety Features

Another essential aspect is the distribution of power across the system, controlled through relays and fuses. These safety mechanisms are designed to protect the system from overloads and prevent damage. Regular inspection of

Hydraulic System Components Explained

The hydraulic system is an essential part of machinery, enabling the transfer of energy through fluid pressure. By converting mechanical power into hydraulic energy, this system allows for efficient movement of different components. Understanding the key elements involved helps ensure proper maintenance and functionality.

Main Components

The hydraulic system consists of several crucial elements working together. These include pumps, actuators, valves, and reservoirs, all of which contribute to generating and regulating the fluid pressure needed to perform various mechanical tasks. Below is a detailed breakdown of each component:

Component Function Pump Generates fluid flow and pressure by converting mechanical energy into hydraulic energy. Actuator Chassis and Frame Structure Details

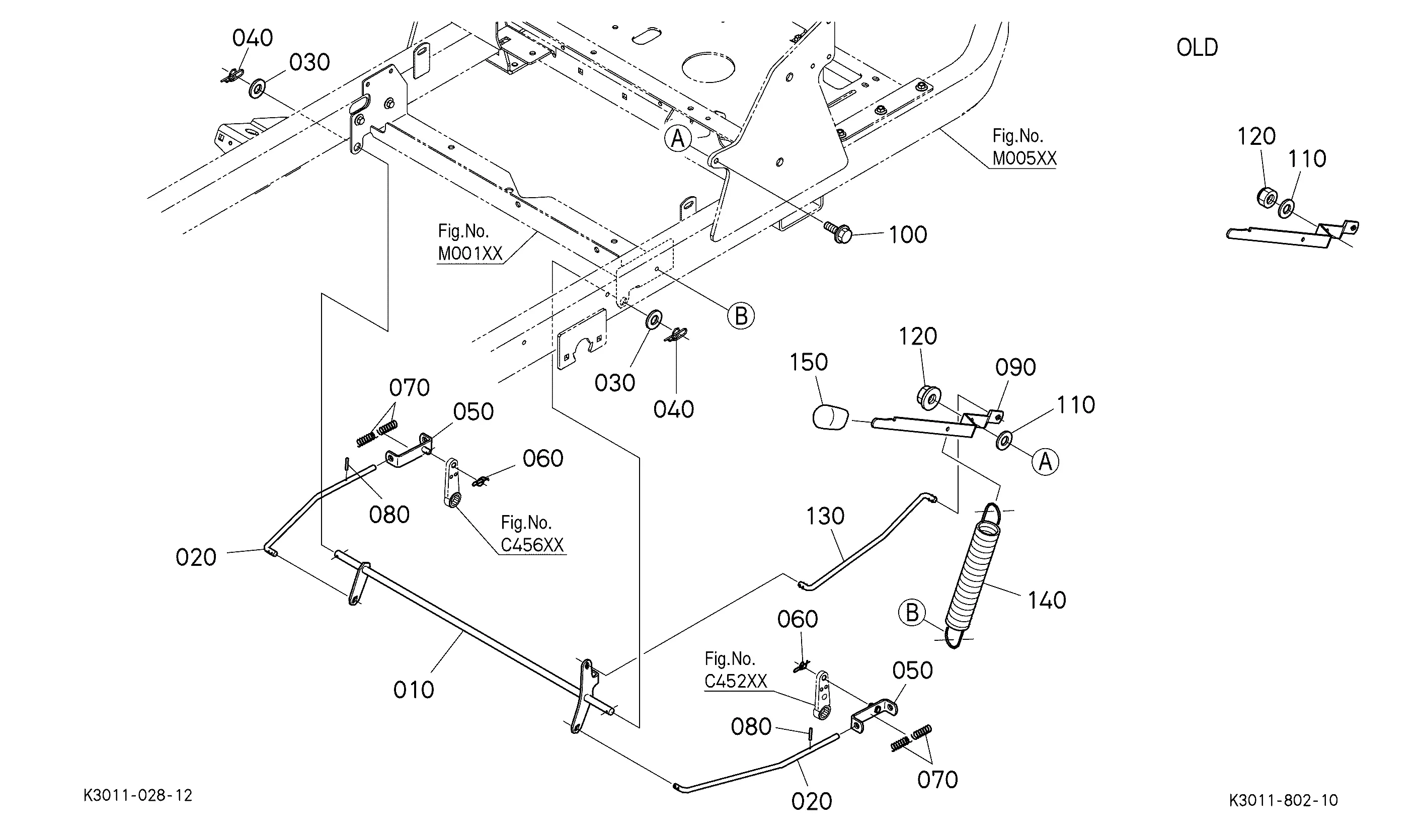

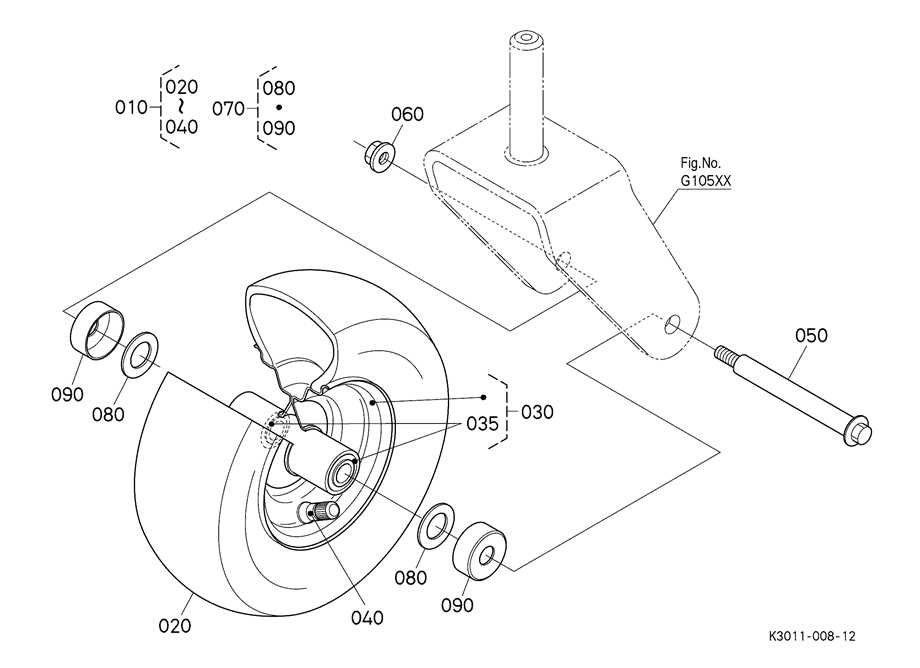

The chassis and frame of any equipment play a crucial role in maintaining stability, durability, and overall structural integrity. Understanding the framework is essential to ensuring proper functionality and long-term resilience under varying operational conditions.

- Foundation: The frame serves as the foundation, providing support to all major components and ensuring they are securely mounted.

- Load Distribution: A well-designed structure ensures that weight is evenly distributed, reducing the risk of stress points that could lead to damage.

- Material Strength: The chassis is typically constructed from reinforced materials, offering both strength and flexibility to withstand mechanical pressure and environmental factors.

- Connection Points: Various mounting points allow for the attachment of key components, ensuring they remain fixed and aligned during operation.

- Corrosion Resistance: Protective coatings or finishes are often applied to prevent rust and other forms of degradation, extending the lifespan of the structure.

Regular

Transmission Parts and Their Roles

The transmission system plays a vital role in the functionality of machinery, enabling the transfer of power from the engine to the wheels. Understanding the components involved in this system can enhance maintenance efforts and improve operational efficiency.

- Gearbox: This unit houses gears that facilitate speed adjustments and torque multiplication, allowing for optimal performance under varying conditions.

- Clutch: Acting as a mediator between the engine and transmission, the clutch engages and disengages power, enabling smooth gear shifts.

- Drive Shafts: These components transmit rotational energy from the gearbox to the wheels, playing a crucial role in the movement of the vehicle.

- Torque Converter: Often found in automatic systems, this device increases torque and allows for smoother acceleration by maintaining engine speed during gear shifts.

- Transmission Fluid: Essential for lubrication and cooling, this fluid ensures that all moving parts within the system operate smoothly and efficiently.

Each component of the transmission system is integral to its overall functionality, and proper understanding can lead to improved maintenance and longevity of the machinery.

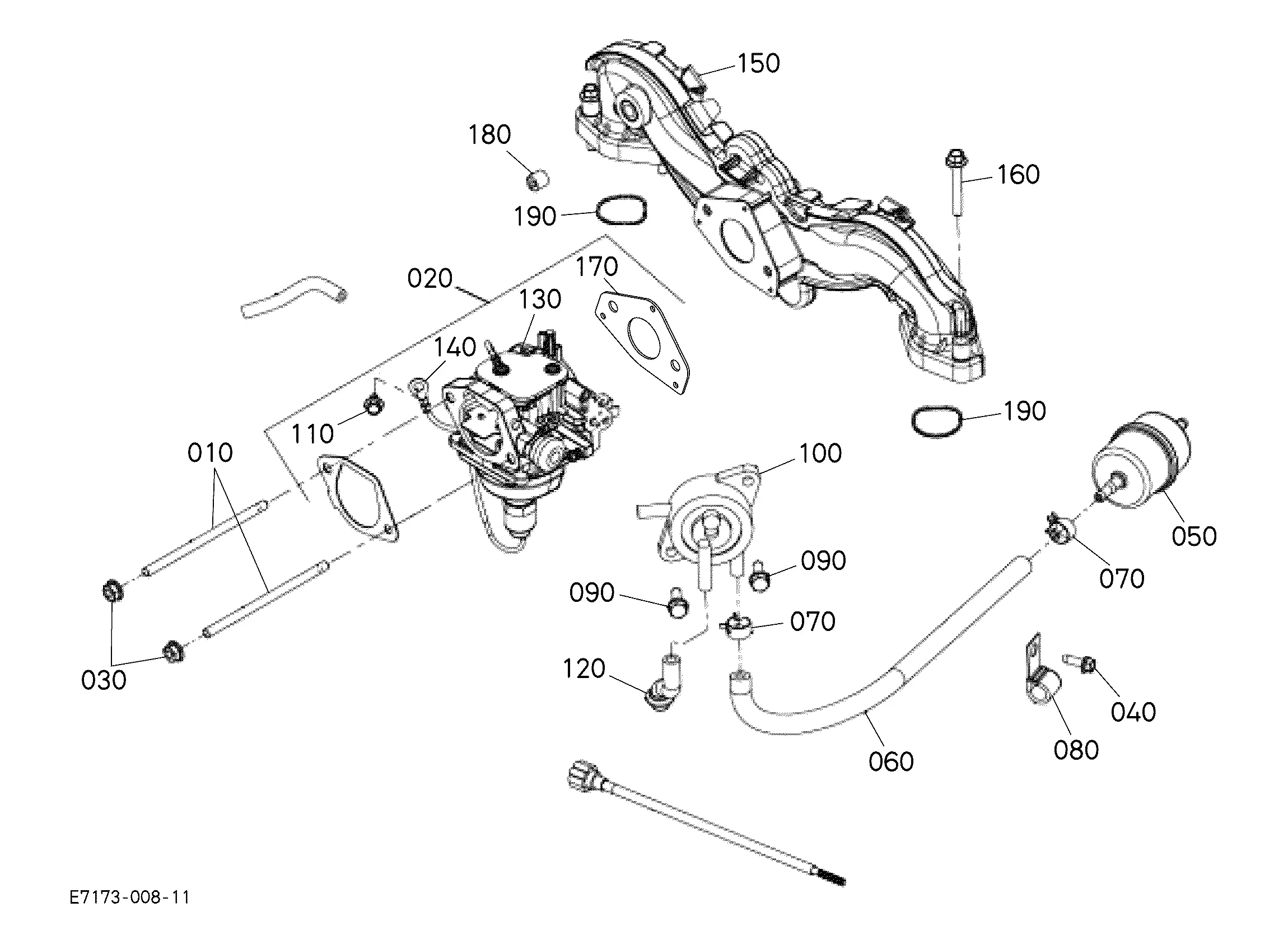

Fuel System Components Breakdown

The fuel system is a critical part of any engine, playing a vital role in delivering the necessary fuel for optimal performance. Understanding the various elements involved helps ensure efficient operation and maintenance of the machinery. Each component contributes to the overall functionality, working in harmony to manage fuel delivery and quality.

Fuel Tank: This is the primary reservoir for storing fuel. It is essential to maintain its cleanliness and integrity to prevent contamination and ensure a steady supply of fuel.

Fuel Pump: Responsible for transporting fuel from the tank to the engine, this component must maintain proper pressure to facilitate efficient flow. Regular checks are necessary to avoid any disruptions in fuel delivery.

Fuel Filter: This part removes impurities and debris from the fuel before it reaches the engine, protecting it from damage. Periodic replacement is crucial to maintain system efficiency.

Fuel Injectors: These devices atomize the fuel, allowing it to mix with air for optimal combustion. Proper functioning of fuel injectors is essential for performance and emissions control.

Fuel Lines: These hoses transport fuel between the tank, pump, filter, and engine. Inspecting them for leaks or damage is important to ensure the entire system operates smoothly.

By familiarizing oneself with these key components, operators can enhance their understanding of the fuel system, ensuring their equipment runs efficiently and reliably.

Deck Assembly and Maintenance Tips

The assembly and upkeep of the mowing deck are crucial for ensuring optimal performance and longevity of your lawn care equipment. A well-maintained deck not only enhances cutting efficiency but also contributes to a healthier lawn. Understanding the various components and their functions can significantly improve your maintenance routine.

When assembling the mowing deck, ensure that all parts are securely fastened and aligned correctly. Regularly inspect the blades for wear and tear, as sharp blades are essential for clean cuts. It is advisable to sharpen or replace them as needed to maintain performance.

Additionally, keep the deck free from grass clippings and debris to prevent rust and corrosion. After each use, wash the underside of the deck with water to remove buildup. This practice not only prolongs the life of the components but also enhances cutting efficiency.

Finally, lubricate any moving parts regularly to reduce friction and wear. Following these simple maintenance tips will help ensure that your mowing deck operates smoothly and effectively, providing excellent results for your lawn care needs.

Exploring Safety Features and Controls

Ensuring operator safety is a paramount consideration in the design of modern machinery. This section delves into the essential safety attributes and operational controls that enhance user protection and contribute to efficient functionality.

Among the notable safety mechanisms commonly integrated into equipment are:

- Emergency Shut-Off Switch: A crucial feature that allows for immediate cessation of operations in case of an emergency.

- Safety Guards: Protective barriers designed to shield users from moving parts and potential hazards.

- Operator Presence Controls: Systems that require the operator to maintain contact with controls, ensuring that the machine will stop if they disengage.

- Alert Systems: Visual or auditory signals that notify operators of potential safety issues or operational irregularities.

Furthermore, effective training and familiarization with the control layout significantly enhance safety. Operators should be well-acquainted with:

- The location and function of all safety controls.

- Operational procedures that prioritize safety.

- Regular maintenance checks to ensure all safety features are functioning correctly.

By understanding and utilizing these safety attributes, operators can significantly reduce risks associated with machinery operation, promoting a safer work environment.