In the realm of modern agriculture, the efficiency and functionality of equipment play a crucial role in ensuring successful operations. Familiarity with the intricate mechanisms and individual elements of these machines is essential for optimal performance and maintenance. This knowledge not only enhances productivity but also extends the lifespan of the machinery.

Exploring the various segments and functionalities of these tools allows operators to diagnose issues swiftly and carry out necessary repairs. Visual representations serve as invaluable resources, providing insights into the arrangement and interaction of each component. By grasping these connections, users can navigate challenges with confidence.

As we delve deeper into the subject, it becomes clear that understanding the anatomy of agricultural implements leads to more informed decisions. This ultimate comprehension empowers operators to maintain their equipment effectively and adapt to the evolving demands of farming.

Understanding the MX8 Mower Overview

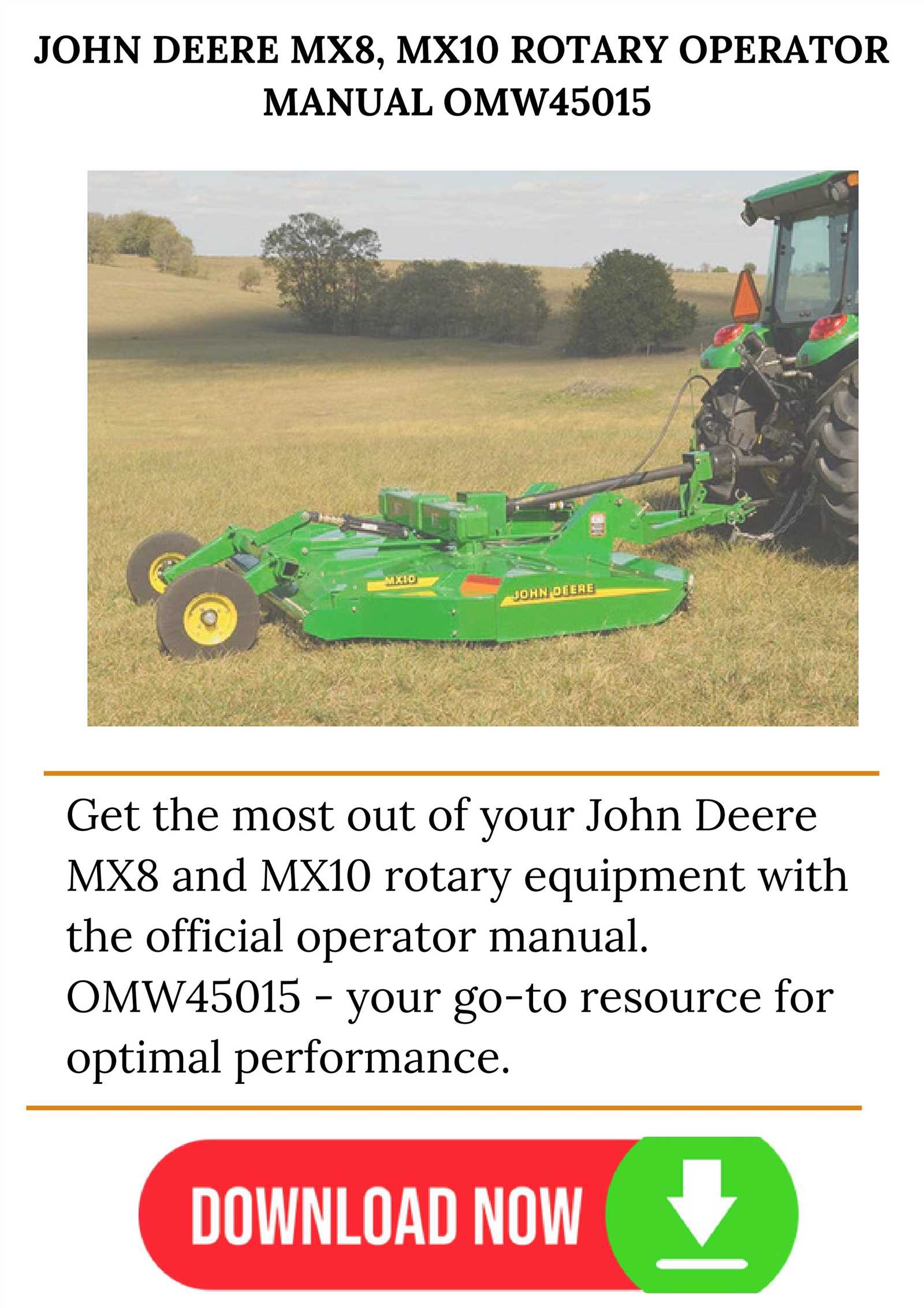

The MX8 mower represents a robust solution designed for efficient lawn care and maintenance. This equipment is engineered to tackle a variety of terrains, making it suitable for both residential and commercial applications. With its sturdy construction and advanced features, it aims to deliver exceptional performance and reliability for users seeking to maintain their landscapes effectively.

Featuring a durable design, this mower is built to withstand the rigors of frequent use. It incorporates innovative technology that enhances cutting efficiency while ensuring ease of operation. Users can expect a machine that not only meets their mowing needs but also provides comfort and control during extended periods of operation.

The versatility of the MX8 allows it to handle different mowing conditions, from flat lawns to uneven grounds. Its capability to adapt to various environments makes it a valuable asset for landscapers and homeowners alike. Understanding its features and functionality can help users maximize their investment and achieve optimal results in their landscaping efforts.

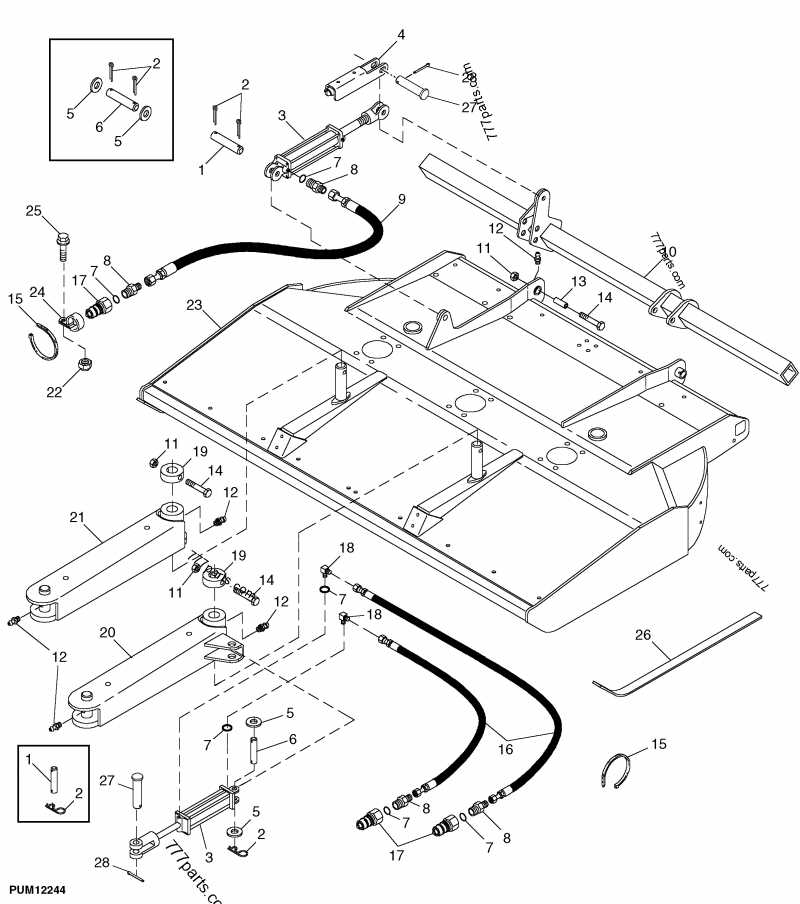

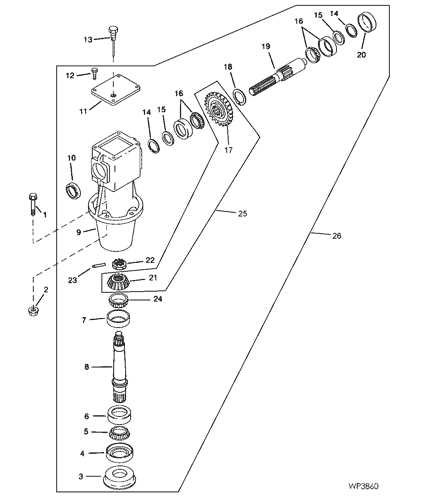

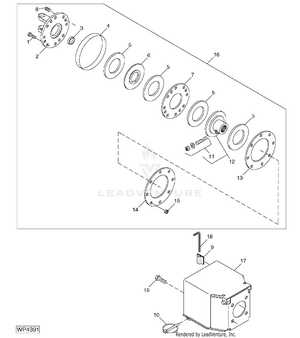

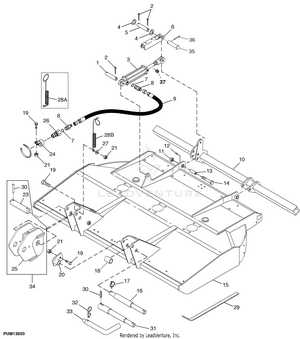

Key Components of MX8 Equipment

This section explores the essential elements that contribute to the functionality and efficiency of this agricultural machinery. Understanding these components can enhance operational effectiveness and maintenance practices.

Drive System

The drive system is crucial for transferring power from the engine to the working parts. It includes gears, belts, and pulleys that work together to ensure smooth operation and optimal performance.

Cutting Mechanism

The cutting mechanism comprises blades and associated assemblies designed for precision and durability. This system is vital for achieving the desired results in various terrain and conditions, making regular inspection essential.

Importance of Maintenance for MX8

Proper upkeep is crucial for ensuring optimal performance and longevity of equipment. Regular attention to components can prevent breakdowns and enhance efficiency, ultimately leading to cost savings and improved productivity. Implementing a structured maintenance routine is essential for maximizing the lifespan of machinery.

Key aspects of maintenance include routine inspections, timely repairs, and regular lubrication. These practices help identify potential issues before they escalate, ensuring smooth operation during usage.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspecting Components | Weekly | Identifies wear and tear early |

| Lubrication | Monthly | Reduces friction and wear |

| Replacing Worn Parts | As Needed | Prevents failures and enhances performance |

Where to Find Parts Diagrams

Locating detailed illustrations of components for various machinery can greatly enhance the repair and maintenance process. These resources provide essential visual guidance, ensuring that users can identify and obtain the necessary items efficiently.

Here are some reliable sources to explore for such visual aids:

- Official Manufacturer Websites: Most producers offer comprehensive online resources, including schematic representations of their equipment. Checking their service or support sections can yield valuable information.

- Online Retailers: E-commerce platforms specializing in machinery often provide access to visual references alongside product listings, helping buyers understand what they need.

- User Manuals: Printed or downloadable guides typically contain illustrations. They can be found on manufacturer websites or directly from the equipment packaging.

- Online Forums and Communities: Engaging with enthusiasts and professionals in dedicated forums can lead to shared resources and personal experiences regarding component identification.

- Local Dealers: Authorized distributors often have physical copies or can assist in locating the necessary resources for your machinery.

Utilizing these avenues can streamline the process of acquiring the correct components, ensuring that your equipment remains in optimal condition.

Common MX8 Repair Issues

In the realm of agricultural machinery, certain challenges frequently arise that can impact performance and efficiency. Understanding these common concerns can aid in timely maintenance and enhance longevity.

Typical Problems

- Hydraulic system leaks

- Worn or damaged cutting blades

- Engine overheating

- Drive belt wear

Preventative Measures

- Regularly inspect hydraulic connections for integrity.

- Replace blades before they become excessively dull.

- Monitor engine temperature during operation.

- Check belts for signs of fraying or cracking.

Tips for Ordering Replacement Parts

When it comes to acquiring new components for your machinery, understanding the process can save you time and money. Knowing what to look for and how to communicate your needs effectively will ensure that you get the right items without unnecessary hassle.

Know Your Model and Specifications

- Identify the specific model and year of your equipment.

- Gather any available manuals or documentation that detail the components.

- Make note of any serial numbers or part codes that can help in locating the correct replacements.

Research Suppliers

- Look for reputable vendors with good reviews and customer feedback.

- Compare prices and availability across different suppliers to find the best deal.

- Consider reaching out to customer service for additional information or clarification on products.

By taking these steps, you can ensure a smoother ordering experience and keep your equipment running efficiently.

MX8 Compatibility with Other Models

Understanding the compatibility of this specific equipment with other similar models is crucial for efficient operation and maintenance. Many users seek to identify which units share components or operational features to optimize their equipment lineup. Compatibility can influence performance, repair costs, and the availability of replacement components.

Several models have been identified as compatible based on shared engineering principles and design features. The following table highlights the key relationships between these units:

| Model | Compatibility Features |

|---|---|

| Model A | Shared drive system, interchangeable attachments |

| Model B | Similar hydraulic configurations, compatible mounting points |

| Model C | Identical control mechanisms, overlapping maintenance schedules |

By exploring these compatibilities, users can enhance the versatility of their machinery and streamline maintenance practices, ensuring more efficient operation across various tasks.

Resources for DIY Repairs and Upgrades

Embarking on do-it-yourself maintenance and enhancements can be both rewarding and cost-effective. With the right information and tools, enthusiasts can tackle various tasks, ensuring their machinery operates smoothly and efficiently. Below are some valuable resources that can assist in the journey of self-repair and improvement.

- Online Forums and Communities:

- Join dedicated groups where experienced users share tips and tricks.

- Participate in discussions to gain insights on common issues and solutions.

- Video Tutorials:

- Search for instructional videos that provide step-by-step guidance.

- Follow along with visual aids to better understand the repair process.

- Manufacturer’s Manuals:

- Refer to official documentation for detailed specifications and maintenance guidelines.

- Use these manuals as a reference for troubleshooting and upgrades.

- Replacement Component Retailers:

- Explore online stores specializing in aftermarket and original components.

- Compare prices and quality to find the best deals for necessary items.

- Local Workshops and Classes:

- Look for community workshops that offer hands-on training in repairs.

- Attend classes to enhance skills and gain practical experience.

Utilizing these resources can empower individuals to confidently perform repairs and upgrades, enhancing the longevity and performance of their equipment.