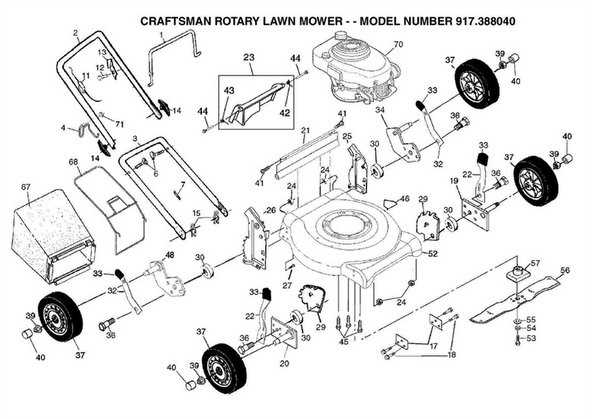

Maintaining your outdoor machinery is essential for achieving the best results in your gardening tasks. Familiarity with the components and their functions can significantly enhance your efficiency and prolong the lifespan of your equipment. This section will provide a comprehensive overview of the intricate structure that supports your lawn maintenance efforts.

Identifying the elements that make up your machinery is crucial for troubleshooting and repairs. Each segment plays a vital role in the overall performance, ensuring that your tasks are completed smoothly and effectively. Whether you’re performing routine maintenance or addressing specific issues, having a clear understanding of these components will empower you.

Additionally, visual references can simplify the process of locating and recognizing various parts. A well-organized illustration can serve as a valuable tool for both novice users and seasoned professionals. By mastering the layout of these elements, you’ll be better prepared to tackle any challenges that arise in your lawn care journey.

Craftsman 30 Inch Riding Mower Parts Diagram

Understanding the components of a lawn maintenance vehicle is essential for effective upkeep and troubleshooting. This section provides a comprehensive overview of the various elements that contribute to the functionality and efficiency of these machines. Familiarity with each section enables users to identify issues promptly and perform necessary repairs or replacements.

Key assemblies include the engine, transmission, and cutting mechanism, each playing a vital role in performance. The fuel system ensures optimal operation, while the electrical parts facilitate ignition and functionality of accessories. Additionally, the chassis and wheels support stability and maneuverability across different terrains.

Detailed visual representations can aid in locating specific elements, making maintenance tasks more manageable. Proper understanding of the structure not only enhances the longevity of the equipment but also ensures a well-maintained lawn throughout the seasons.

Understanding the Engine Components of Your Lawn Mower

In this section, we delve into the intricate components that power your lawn mower, illustrating the interconnectedness and functionality of each part. The engine, akin to the heart of the machine, drives the entire operation, converting fuel into mechanical energy through a series of precise processes. Each component plays a vital role in this conversion, from the combustion chamber where fuel ignites to the piston that translates energy into motion.

| Component | Description |

| Combustion Chamber | The central area where fuel mixes with air and ignites, initiating the power cycle. |

| Piston | Moves up and down within the cylinder, converting energy from combustion into mechanical motion. |

| Spark Plug | Creates a spark to ignite the fuel-air mixture in the combustion chamber. |

| Cylinder | Houses the piston and facilitates the combustion process, guiding the piston’s movement. |

| Valves | Regulate the flow of fuel and exhaust gases in and out of the combustion chamber, ensuring efficient operation. |

| Fuel System | Delivers the right amount of fuel to the combustion chamber, optimizing combustion for power generation. |

| Exhaust System | Channels exhaust gases away from the engine after combustion, maintaining environmental standards. |

Each of these components works seamlessly together to harness energy from fuel and propel the mower forward, underscoring the precision engineering required for efficient lawn maintenance. Understanding these engine components empowers users to maintain and troubleshoot their equipment effectively, ensuring longevity and optimal performance.

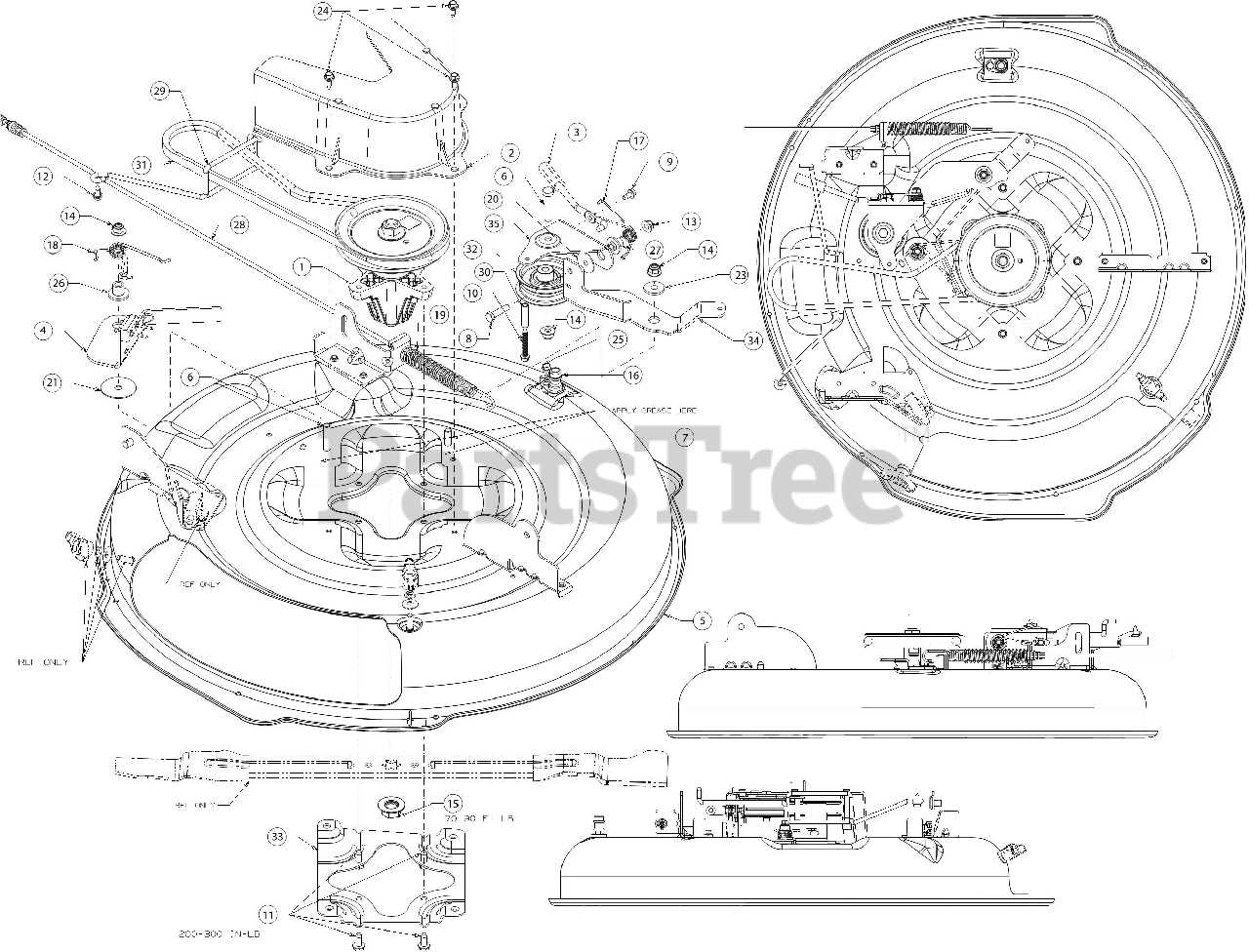

Exploring the Blade System in Detail

The blade mechanism is a vital component of any lawn maintenance machine, contributing significantly to its overall efficiency and performance. Understanding the intricacies of this system can enhance both maintenance practices and operational effectiveness.

The blade assembly typically consists of several essential elements, including blades, spindles, and belts. Each part plays a critical role in ensuring smooth operation and optimal cutting results. Regular inspection and maintenance of these components can prevent wear and tear, ultimately extending the life of the machine.

Blade types vary in design and functionality, with some tailored for specific grass types or cutting conditions. Familiarity with the different styles allows users to select the most suitable option for their particular needs, thus achieving the best performance.

Moreover, adjustments and alignments are crucial for maintaining cutting precision. Ensuring that blades are correctly positioned not only enhances the quality of the cut but also reduces unnecessary strain on the engine, promoting longevity.

In conclusion, a thorough understanding of the blade system enhances overall user experience, making it easier to manage and maintain lawn care tools effectively.

Identifying and Replacing Belt Mechanisms

Belt systems play a crucial role in the functionality of many outdoor machinery, ensuring the smooth transfer of power between various components. Understanding how to identify and replace these mechanisms can enhance the longevity and performance of your equipment. This guide will walk you through the essential steps to recognize when a belt needs attention and how to carry out the replacement process effectively.

Recognizing Signs of Wear

To maintain optimal performance, it is vital to monitor the condition of the belts regularly. Common indicators of wear include visible cracks, fraying, or slipping during operation. Listening for unusual noises can also signal potential issues; any high-pitched squeaks or grinding sounds may suggest that the belt is not functioning as it should. Regular inspections will help you catch problems early and prevent further damage.

Steps for Replacement

Replacing a worn belt requires careful attention to detail. Start by disconnecting the power source for safety. Next, consult the equipment manual to locate the belt’s position and the necessary removal steps. Once the old belt is removed, compare it with the new one to ensure proper sizing. Install the new belt by following the routing guidelines provided in the manual, making sure it fits snugly in its designated path. After installation, reconnect the power and test the equipment to confirm that everything operates smoothly.

By understanding the signs of wear and following the correct replacement procedure, you can ensure your machinery remains in excellent working condition for years to come.

Examining the Electrical Wiring Layout

Understanding the intricacies of electrical connections is crucial for optimal performance and safety. This section will delve into the arrangement and functionality of the various wiring components, highlighting their roles in ensuring smooth operation.

Key Components and Their Functions

The electrical system consists of several essential elements, including the ignition switch, battery, and various sensors. Each component plays an ultimate role in the overall functionality, providing power and control to the machine.

Common Wiring Issues

Frequent problems may arise from wear and tear, leading to malfunctions. Regular inspection of the connections and insulation is vital to prevent potential hazards and ensure the longevity of the equipment.

Locating and Servicing the Fuel System

In the context of maintaining your equipment, understanding the pathways and components that facilitate the delivery of fuel is crucial. This section focuses on identifying and maintaining the components responsible for supplying fuel to your machinery. It encompasses the exploration of routes through which fuel travels, as well as the components that regulate its flow and ensure optimal operation.

Locating these critical elements involves recognizing their positions within the machinery, pinpointing their locations without reliance on external aids. Servicing them necessitates a meticulous approach, ensuring the functionality of every component that constitutes the fuel system’s operation.

By comprehending these aspects, you equip yourself with the knowledge required to maintain and troubleshoot your equipment effectively, ensuring uninterrupted performance in your operational endeavors.

Reviewing Steering and Transmission Parts

This section delves into the essential components responsible for navigation and movement in lawn care machines. Understanding these elements is crucial for maintenance and optimal performance.

Steering Components

The steering mechanism plays a vital role in maneuverability. Key elements include:

- Steering Wheel: Provides the user with control over direction.

- Steering Shaft: Connects the wheel to the mechanism, transmitting movement.

- Rack and Pinion: Translates rotational motion into lateral movement.

- Linkage System: Facilitates the connection between the steering wheel and wheels, ensuring smooth operation.

Transmission Elements

The transmission system is responsible for converting engine power into movement. Key components include:

- Gearbox: Houses the gears that manage speed and torque.

- Drive Belt: Transfers power from the engine to the wheels.

- Clutch: Engages and disengages power flow, allowing for controlled operation.

- Drive Axles: Deliver power to the wheels, enabling movement across various terrains.

Regular inspection and maintenance of these components ensure longevity and reliability, enhancing the overall user experience.

Inspecting the Frame and Chassis Components

Examining the foundational structure and supporting framework of your mower is crucial to ensure its longevity and operational efficiency. By conducting a thorough inspection of the frame and chassis components, you can identify potential areas of wear, stress, or damage that may impact performance over time.

Key Areas to Check

When inspecting the core structure and chassis elements, focus on critical points such as joints, welds, and connection points. These areas often bear the brunt of mechanical stress and environmental exposure, making them prone to corrosion, fatigue, or misalignment.

| 1. | Check for signs of rust, especially in areas exposed to moisture or frequent contact with grass clippings. |

| 2. | Inspect welds for cracks or weakening, which can compromise the structural integrity of the frame. |

| 3. | Examine bolts and fasteners to ensure they are securely tightened, preventing loosening during operation. |

| 4. | Assess the condition of suspension components, if applicable, checking for wear in bushings or shock absorbers. |

Importance of Regular Inspection

Regularly inspecting the frame and chassis components of your mower helps in early detection of issues, allowing for timely maintenance and repair. This proactive approach not only extends the lifespan of your equipment but also enhances safety and operational efficiency during use.

Maintenance Tips for Longevity and Efficiency

Regular upkeep is essential for ensuring optimal performance and extending the lifespan of your equipment. By implementing a consistent maintenance routine, you can prevent potential issues and enhance the overall efficiency of your machinery. This section provides practical tips to keep your device running smoothly.

Routine Checks

Performing regular inspections is vital. Examine the engine oil levels, air filters, and spark plugs to ensure they are clean and in good condition. Replace any worn-out components promptly to avoid further damage. Additionally, keep an eye on the tires, checking for proper inflation and tread wear.

Cleaning and Storage

After each use, it’s crucial to clean your machine thoroughly. Remove debris, grass clippings, and dirt to prevent corrosion and buildup. During off-seasons, store the equipment in a dry, sheltered area to protect it from the elements. Consider using a cover to safeguard against dust and moisture.