When it comes to maintaining your outdoor space, having a comprehensive grasp of your machinery can make all the difference. Familiarity with the various components of your equipment enables you to troubleshoot issues efficiently and ensures optimal performance.

In this section, we will explore the intricacies of essential components used in turf management devices. By delving into the layout and function of each piece, you’ll gain insight into how they work together to achieve the ultimate results.

Whether you are a seasoned gardener or a weekend warrior, understanding the configuration of your tools is crucial. This knowledge not only enhances your maintenance skills but also extends the lifespan of your machinery.

Ariens Riding Mower Overview

This section provides an insightful look into a well-regarded brand known for its exceptional outdoor equipment, designed for efficiency and durability. These machines cater to various landscaping needs, ensuring that users can achieve a pristine lawn with minimal effort.

Key Features

- Robust construction for longevity

- Powerful engines that enhance performance

- User-friendly controls for ease of operation

- Advanced cutting technology for precise results

Maintenance Tips

- Regularly check and change the oil.

- Inspect and replace blades as needed.

- Clean the undercarriage to prevent buildup.

- Ensure tire pressure is at recommended levels.

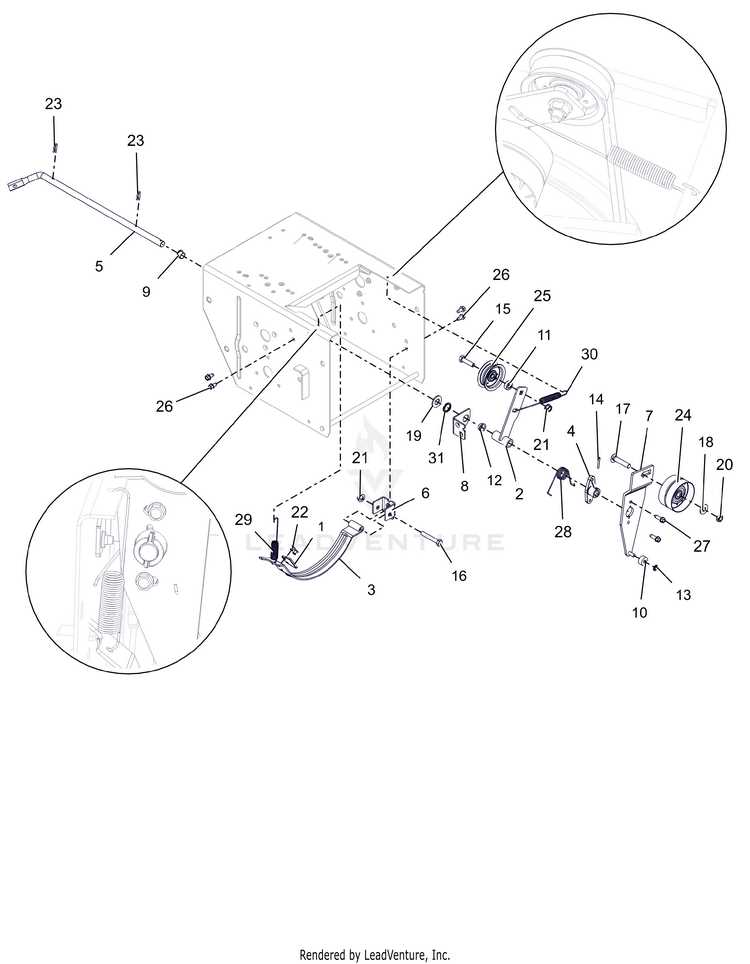

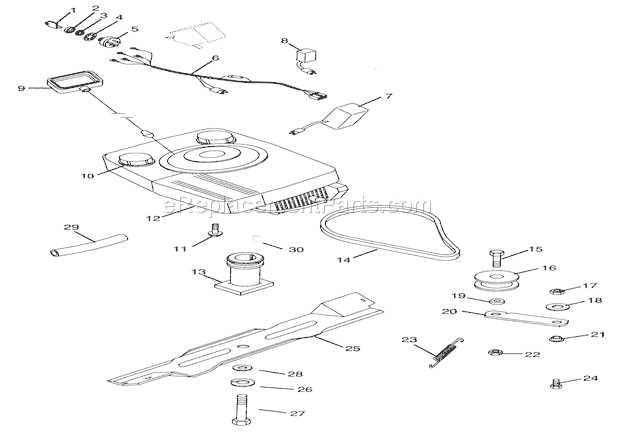

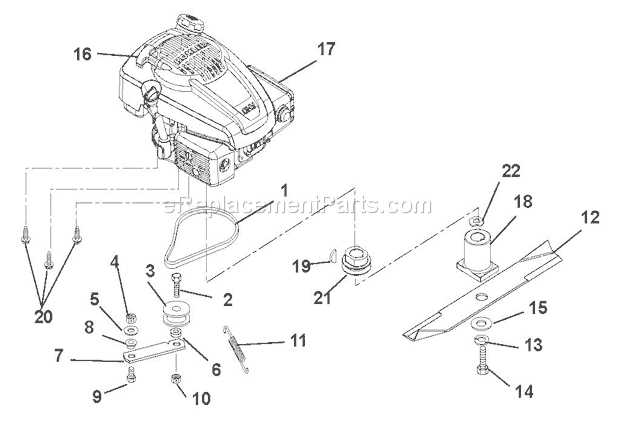

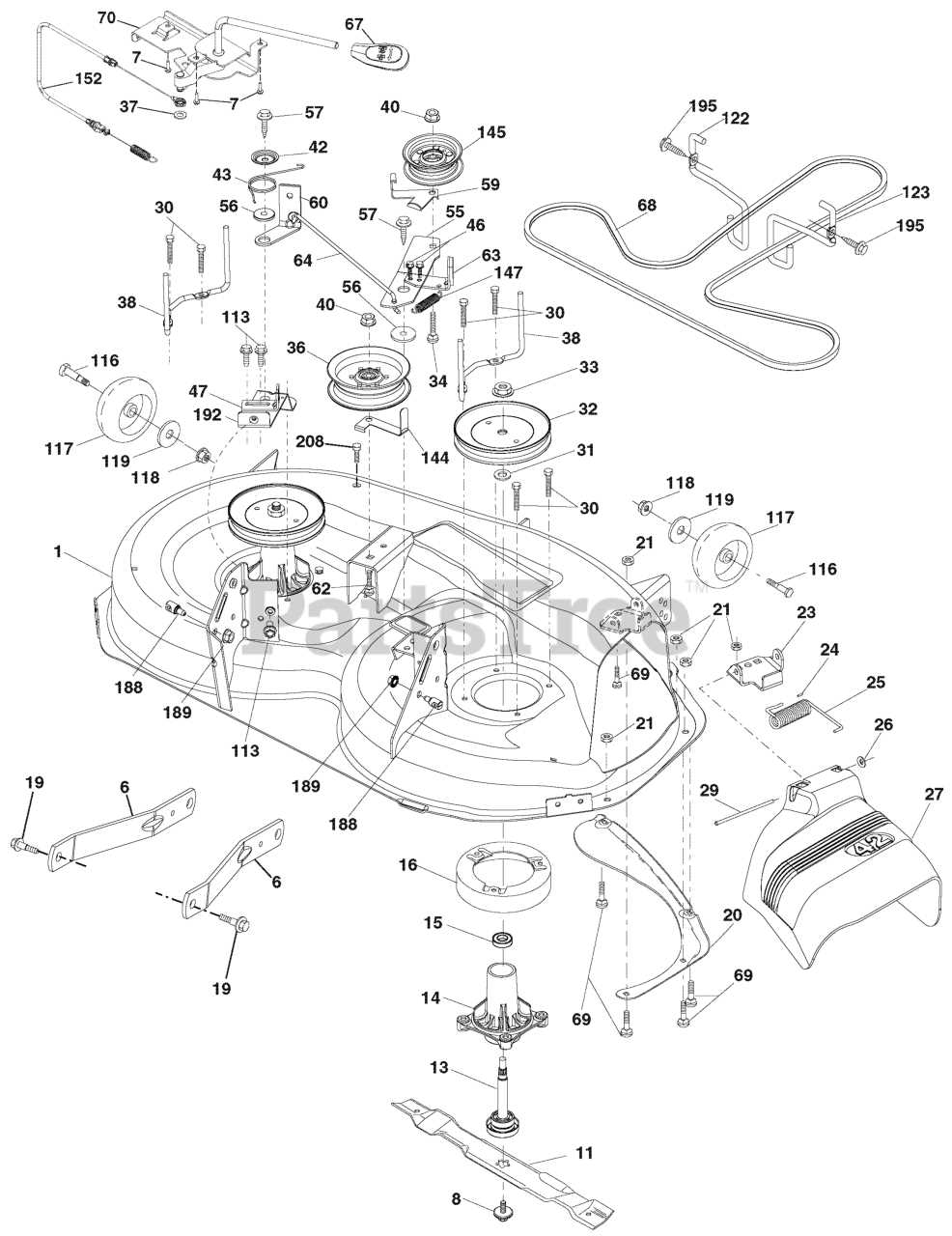

Essential Components of Ariens Mowers

Understanding the vital elements of these machines is crucial for maintaining their performance and longevity. Each component plays a significant role in ensuring efficient operation, from the engine to the cutting mechanism. Familiarity with these key elements allows users to troubleshoot issues and perform necessary upkeep effectively.

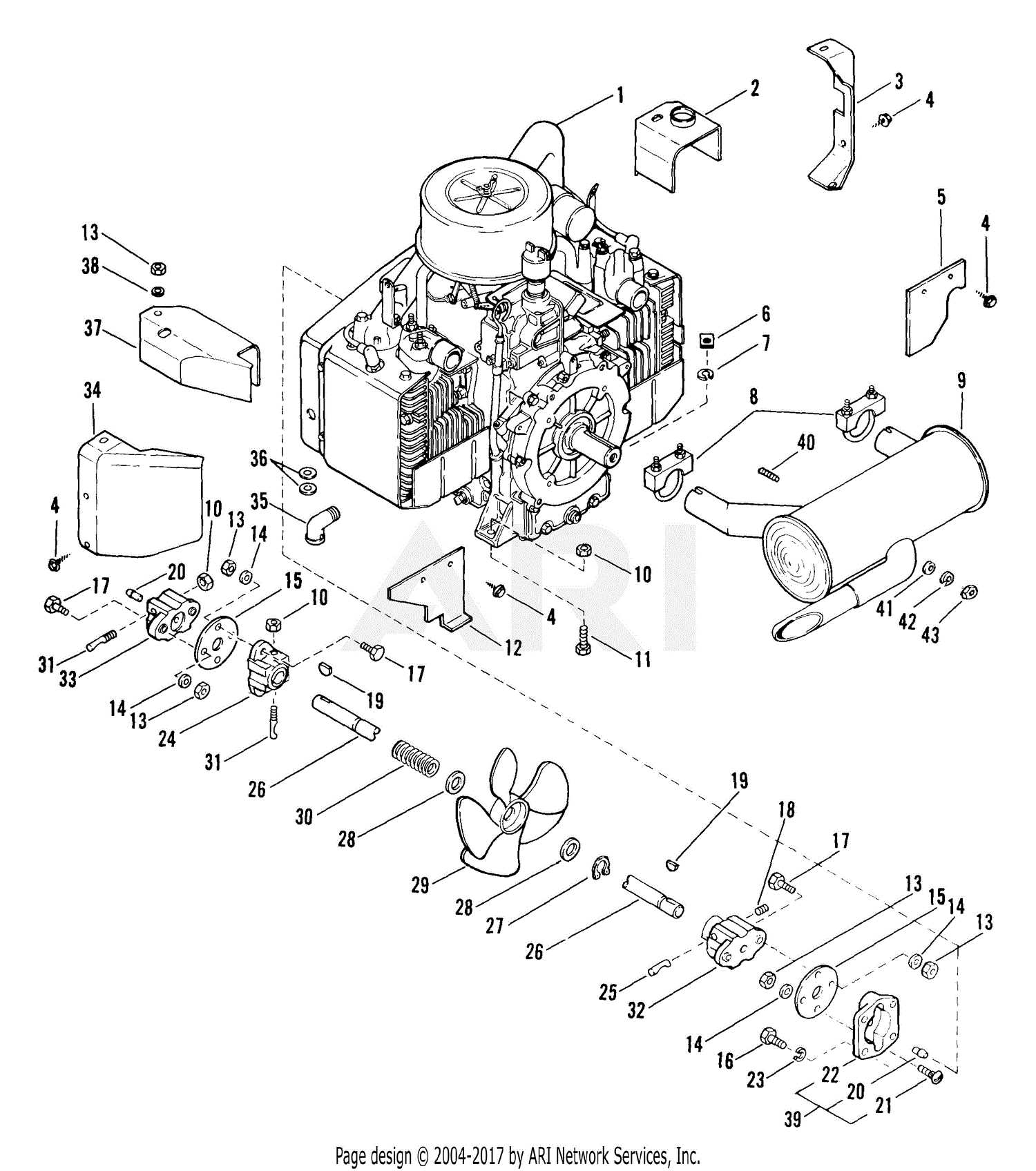

Main Engine Assembly

The heart of any machine lies in its engine assembly, which provides the necessary power for operation. It is designed to deliver optimal performance while ensuring fuel efficiency. Regular inspection and maintenance of this unit are essential for preventing breakdowns and enhancing durability.

The cutting assembly is responsible for delivering a clean and precise cut. Comprised of various blades and related components, it requires regular sharpening and replacement to maintain optimal performance. Ensuring this mechanism is in good condition is crucial for achieving the desired results in lawn care.

| Component | Function |

|---|---|

| Engine | Power source for operation |

| Fuel Tank | Holds the fuel required for engine operation |

| Blades | Responsible for cutting grass and foliage |

| Deck | Encloses the cutting blades and protects other components |

| Transmission | Transfers power from the engine to the wheels |

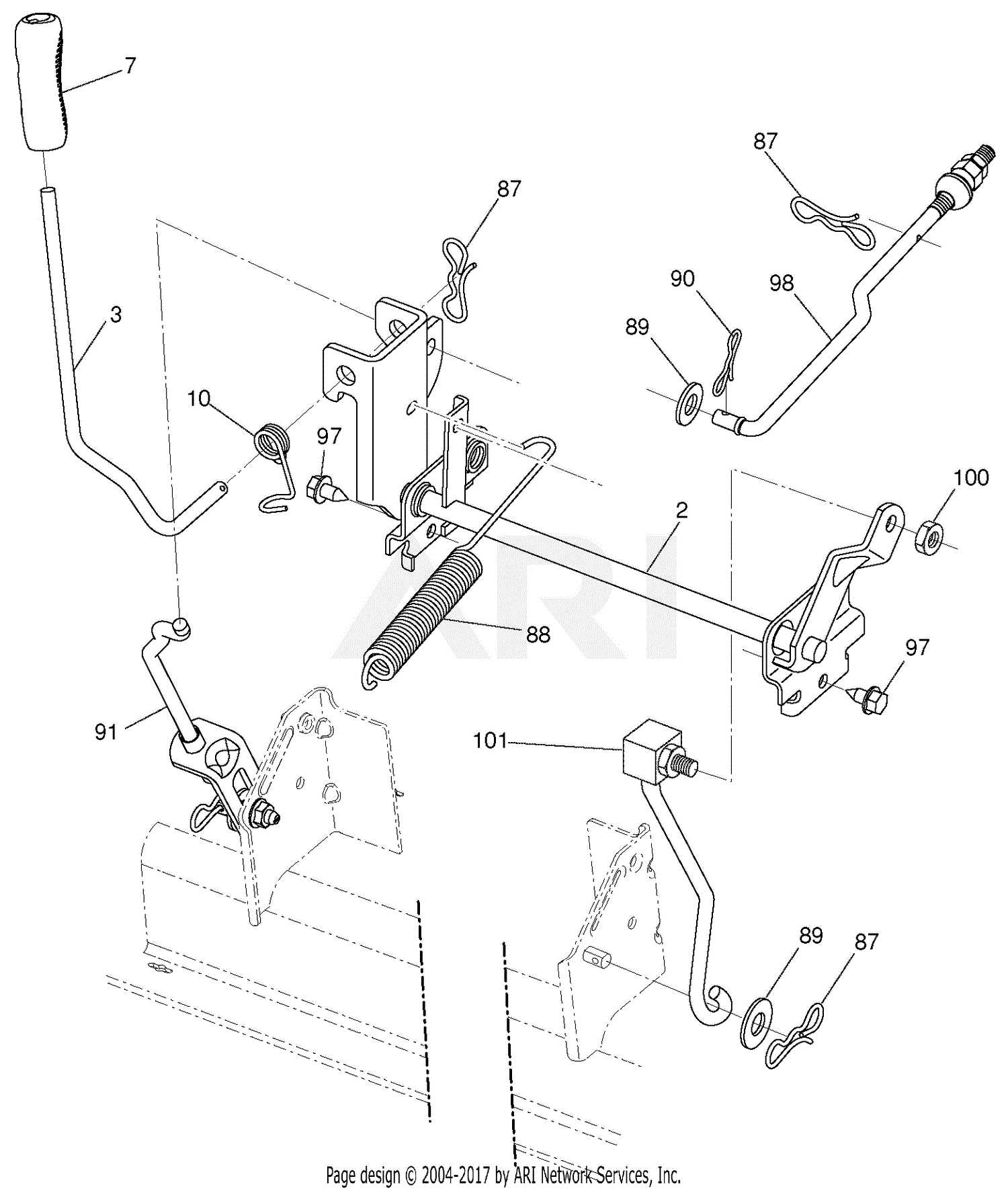

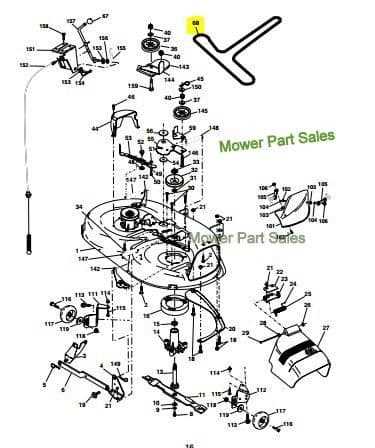

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repair. This visual representation serves as a guide to identify each element and its function, enabling users to navigate the intricate assembly with ease.

Key Benefits

- Enhances troubleshooting skills.

- Simplifies ordering replacements.

- Improves overall efficiency in repairs.

Components Overview

- Engine: The powerhouse of the machine.

- Transmission: Controls movement and speed.

- Deck: Houses cutting tools.

- Wheels: Provides mobility and stability.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor equipment requires regular upkeep and attention. By implementing a few key practices, you can extend the lifespan of your machinery and enhance its efficiency. Here are some essential maintenance tips that every owner should follow.

Regular Cleaning

Maintaining cleanliness is crucial for preventing dirt and debris from accumulating and causing wear. After each use, wipe down surfaces and remove any clippings or residue. A clean machine operates more efficiently and reduces the risk of corrosion.

Scheduled Inspections

Frequent checks of critical components help identify potential issues before they escalate. Examine belts, blades, and wheels for signs of wear or damage. Early detection allows for timely repairs, ultimately saving you time and money.

| Maintenance Task | Frequency |

|---|---|

| Clean exterior and components | After each use |

| Check and replace oil | Every 50 hours |

| Inspect blades for sharpness | Monthly |

| Tighten bolts and screws | Every 25 hours |

| Check tire pressure | Monthly |

By adhering to these guidelines, you can ensure that your equipment remains reliable and efficient for many years. Consistent maintenance not only enhances performance but also contributes to a safer working environment.

Common Issues with Riding Mowers

Owning a grass-cutting machine can come with its share of challenges. Understanding these common problems is essential for maintaining optimal performance and ensuring longevity. Issues can arise from various components, affecting the efficiency and effectiveness of the machine.

Engine Troubles

One prevalent issue is engine difficulties, which can manifest as poor starting or unusual noises. These problems may stem from a variety of sources, including fuel quality, air filters, and spark plugs. Regular maintenance and timely replacements can significantly reduce the risk of these issues, ensuring smooth operation.

Deck and Blade Problems

Another frequent concern involves the cutting deck and blades. Dull or damaged blades can lead to uneven cutting and increased wear on the engine. Additionally, debris buildup under the deck can hinder performance and create hazards. Regular inspections and proper cleaning can help prevent these complications, promoting a healthier lawn and a more efficient cutting experience.

Identifying Parts by Model Number

Understanding how to recognize components through their model identifiers is essential for effective maintenance and repairs. Each identifier offers a unique reference that simplifies the search for the correct replacements, ensuring optimal functionality of your equipment.

Importance of Model Numbers

Model numbers serve as a key that unlocks detailed information about specific components. They allow users to access manuals and reference materials, making the identification process straightforward and efficient.

How to Locate Model Numbers

Typically, model identifiers can be found on the equipment’s frame or engine. Familiarizing yourself with these locations helps streamline your search and enhances your ability to procure the right components swiftly.

Where to Buy Replacement Parts

Finding high-quality components for your outdoor equipment can be a straightforward process if you know where to look. Various sources offer a range of options, from authorized dealers to online marketplaces, ensuring that you can locate the necessary items to keep your machinery in optimal condition.

Authorized Dealers

Visiting an authorized dealer can provide peace of mind. These retailers typically offer original components that match your equipment’s specifications. Additionally, knowledgeable staff can assist with any inquiries regarding compatibility and installation.

Online Marketplaces

The internet has revolutionized the way we shop for components. Numerous online platforms specialize in outdoor machinery, offering a wide variety of products. Be sure to verify the seller’s reputation and read customer reviews to ensure quality.

| Source | Pros | Cons |

|---|---|---|

| Authorized Dealers | Genuine items, expert advice | Higher prices |

| Online Marketplaces | Competitive pricing, wide selection | Variable quality, shipping delays |

| Local Hardware Stores | Immediate availability, community support | Limited selection |

DIY Repairs for Mower Owners

Taking care of your outdoor equipment can save both time and money. Engaging in simple maintenance tasks not only prolongs the lifespan of your machinery but also empowers you with the knowledge to tackle common issues as they arise. With a little guidance, anyone can handle basic repairs confidently.

Understanding Common Issues

Familiarizing yourself with typical problems helps streamline the repair process. Whether it’s a stubborn engine, dull blades, or electrical concerns, identifying the issue early can prevent further damage. A solid grasp of your machine’s functionality is the ultimate key to effective troubleshooting.

Essential Tools for Repairs

Having the right tools on hand makes DIY repairs significantly easier. Basic items like wrenches, screwdrivers, and safety gear should be part of your toolkit. Investing in quality tools ensures durability and effectiveness during maintenance tasks, making the entire experience more enjoyable.