Maintaining and repairing outdoor machinery requires a clear understanding of the different elements that make up the equipment. Every machine is designed with specific parts that work in harmony to ensure smooth operation. Knowing how these components are organized and connected can simplify troubleshooting and maintenance tasks.

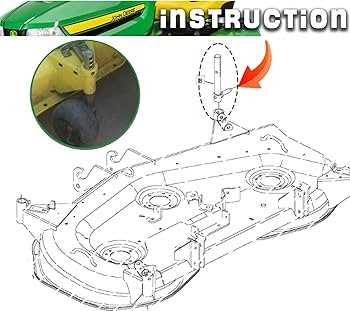

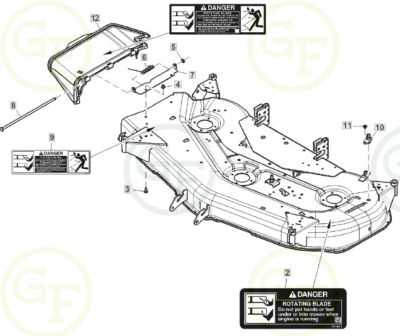

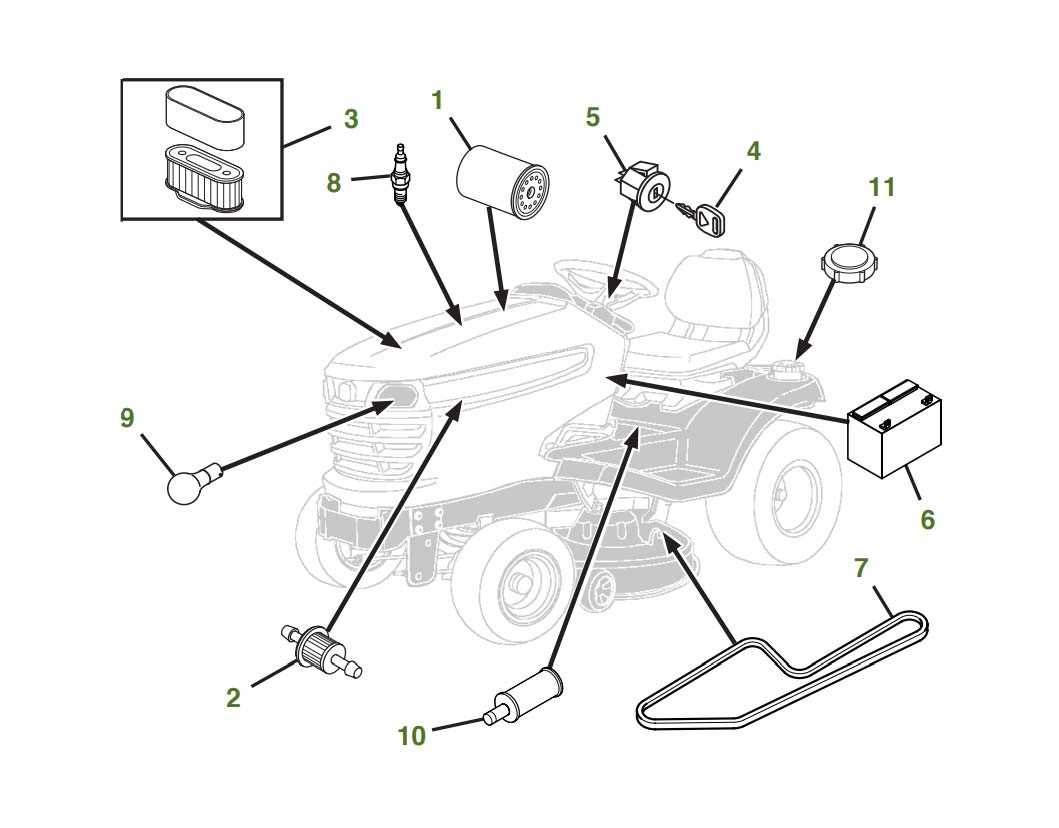

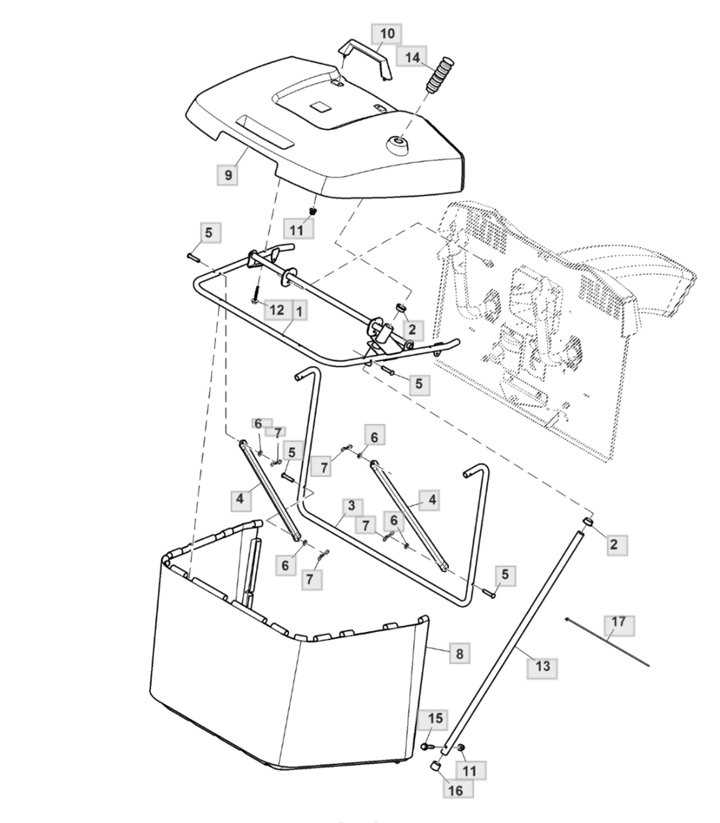

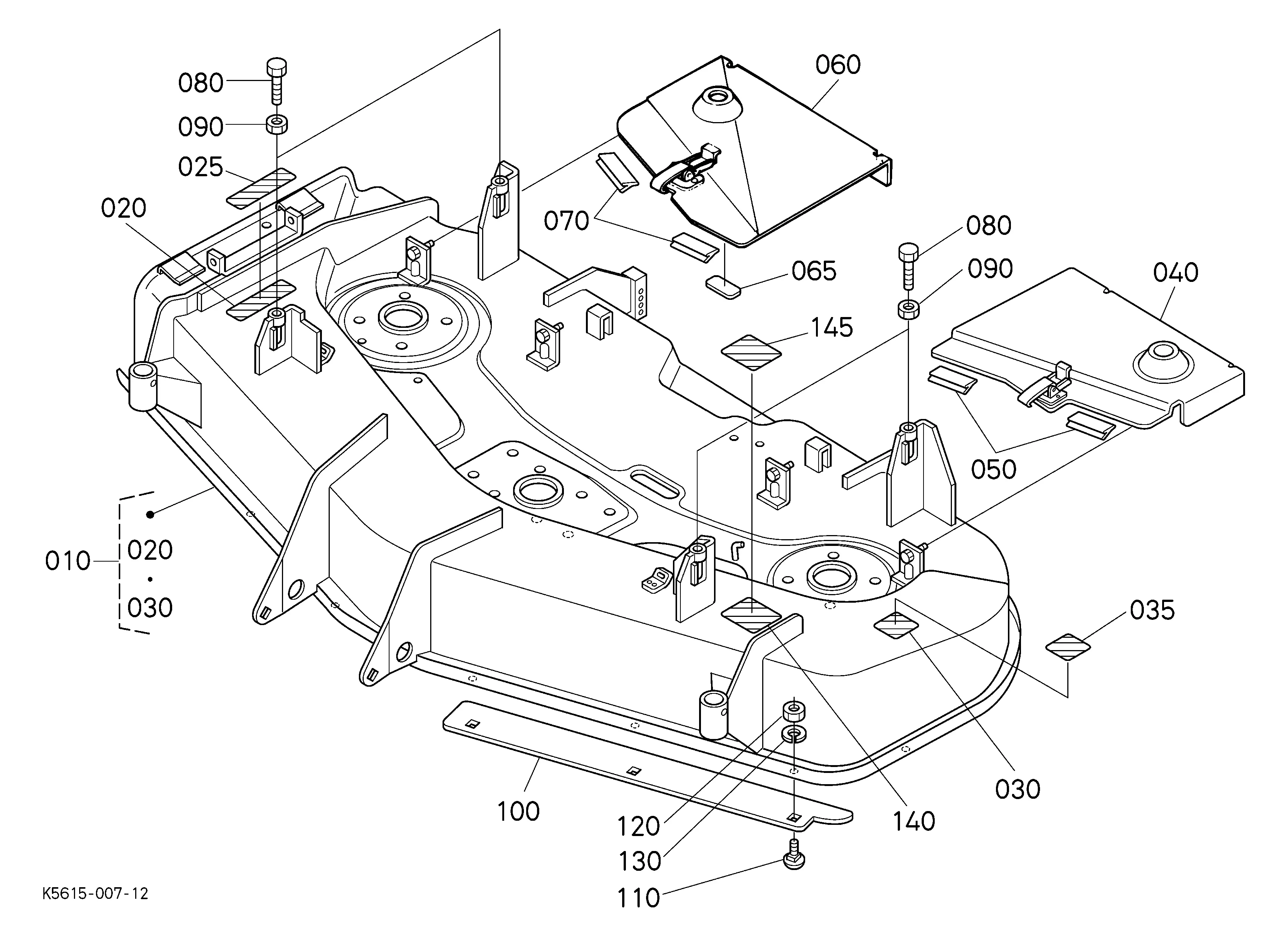

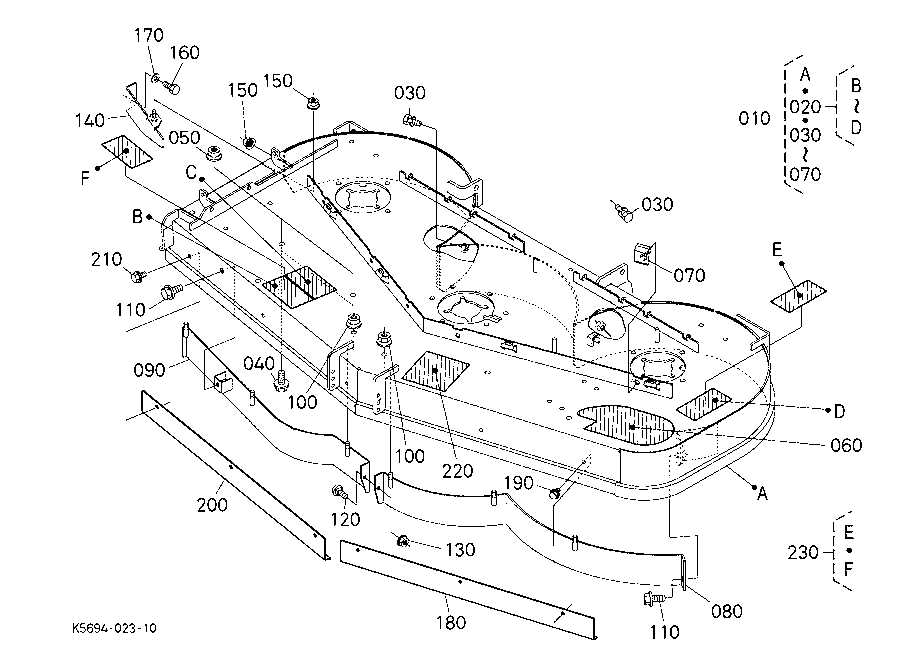

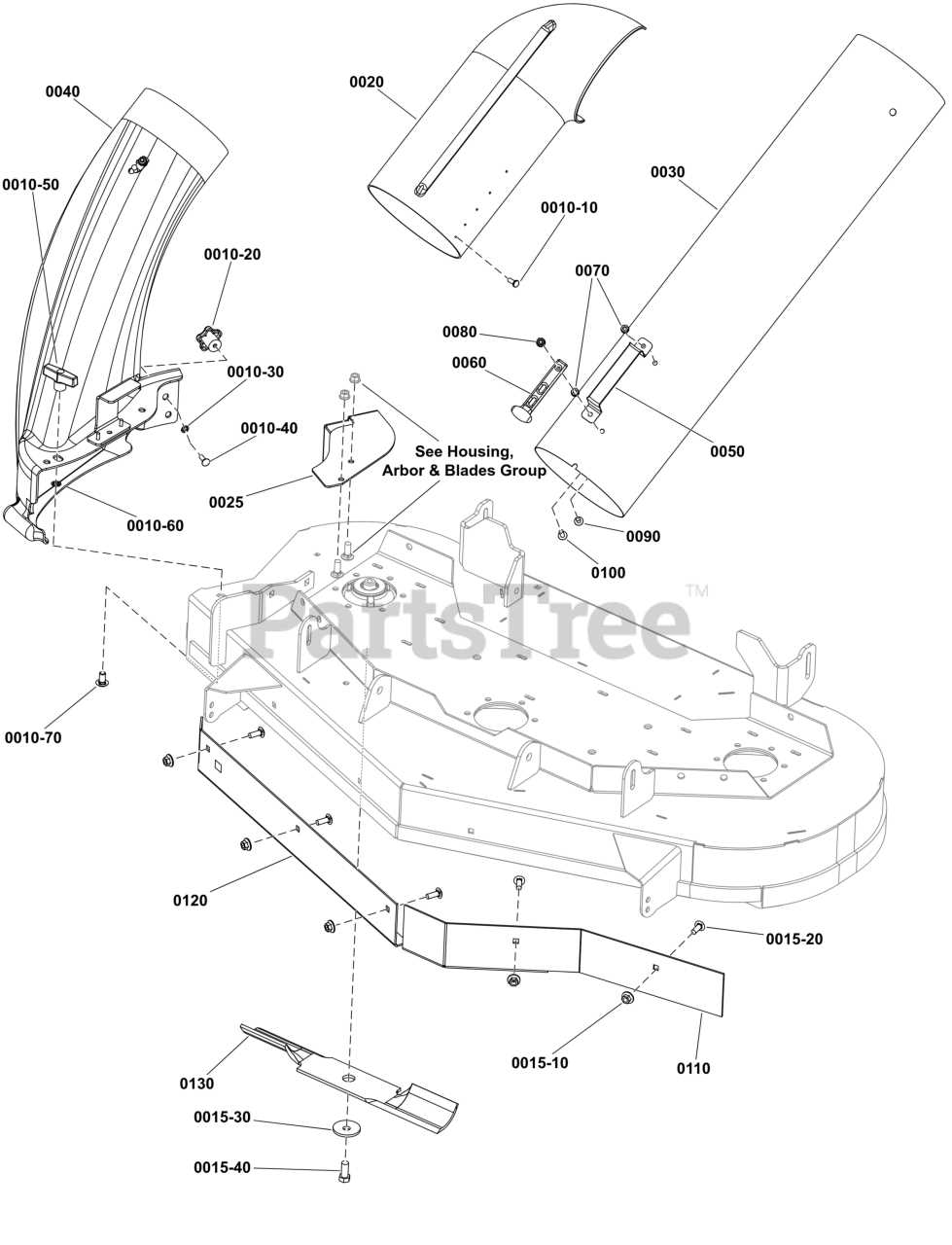

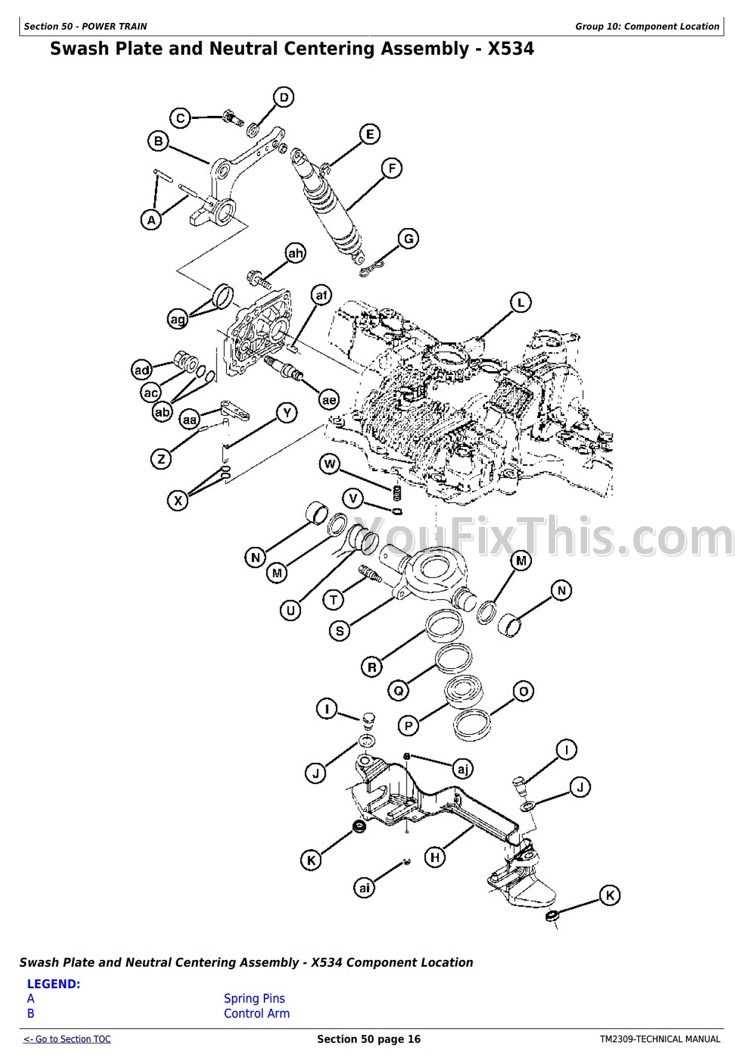

Detailed illustrations and labels play a crucial role in identifying the necessary components for repairs or replacements. These visual aids help owners and technicians quickly locate parts, improving both efficiency and accuracy during service work. By referencing such diagrams, users can gain a comprehensive view of their equipment’s interior, aiding in decision-making processes related to parts management and upgrades.

The systematic layout of parts within a machine is not only essential for repair purposes but also for ensuring that each piece functions optimally. Recognizing where each part fits into the larger structure helps avoid mistakes during reassembly and maintenance procedures. A deeper look at the machine’s assembly reveals the interconnectivity of parts that drive its overall performance.

Overview of John Deere X534 Parts

This section provides a detailed exploration of the key components and their functions within the machine. It focuses on the various sections that contribute to its efficient operation, ensuring optimal performance across different tasks. Understanding the layout and role of each element is crucial for effective maintenance and troubleshooting.

Key elements of the equipment include the engine assembly, drive system, and control mechanisms, each designed to work harmoniously. The reliability and longevity of the unit depend on the quality and condition of these components.

- Engine System: Central to the functionality, it powers the entire machine, ensuring smooth operation and efficient energy transfer.

- Transmission: This system controls the movement and speed, offering precision in handling various tasks.

- Electrical Components: Responsible for powering the controls, lights, and other accessories essential for day-to-day use.

- Steering and Suspension: Provides the necessary support and maneuverability for smooth navigation on different terrains.

- Chassis: The foundational structure that houses and protects all other critical parts.

Understanding the arrangement and interactions between these components helps in diagnosing issues and ensuring the equipment runs smoothly for longer periods.

Key Components of the X534 Model

The core elements of this machine are engineered to provide both durability and efficiency. Understanding the integral components can help users maximize its performance and ensure long-term reliability. These essential parts work harmoniously to deliver exceptional results for various tasks and applications.

Engine: The heart of the machine, designed to provide consistent power and performance. This component is crucial for driving the machine’s various functions, ensuring smooth operation even under heavy loads.

Transmission: An essential part that controls the movement of the machine. It plays a key role in transferring power from the engine to the wheels, allowing for precise control and smooth maneuvering across various terrains.

Chassis: The framework that supports all other components. It is built to withstand harsh conditions while maintaining structural integrity, ensuring that all parts stay securely in place during operation.

Steering Mechanism: This system provides the user with control over the machine’s direction. Designed for ease of use, it enables precise adjustments, which are important for both navigation and safety.

Wheels and Tires: Designed to provide optimal traction and stability, these components are vital for maneuvering across different surfaces, ensuring both efficiency and safety during operation.

Understanding the Engine Layout

The structure of the power unit plays a critical role in ensuring smooth operation and durability. An efficient configuration allows all components to work harmoniously, optimizing performance while maintaining reliability. The engine setup consists of multiple sections, each designed to support the vehicle’s overall function and longevity.

Key components such as the power generation system, cooling apparatus, and drive mechanisms are interconnected to enable effective energy transfer. The configuration of these elements is strategically designed to maximize fuel efficiency, minimize wear, and enhance overall operation. Understanding how these sections integrate is essential for maintaining optimal performance and troubleshooting potential issues.

In this section, we will explore how each major section contributes to the engine’s efficiency, providing insights into their respective roles and interconnections.

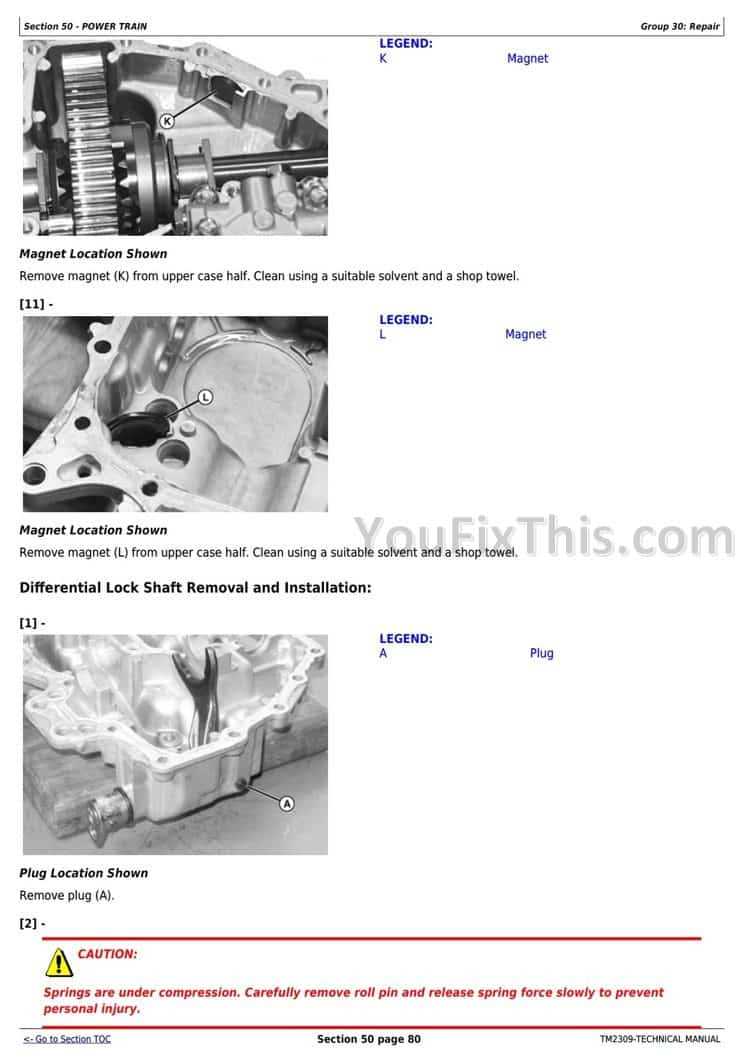

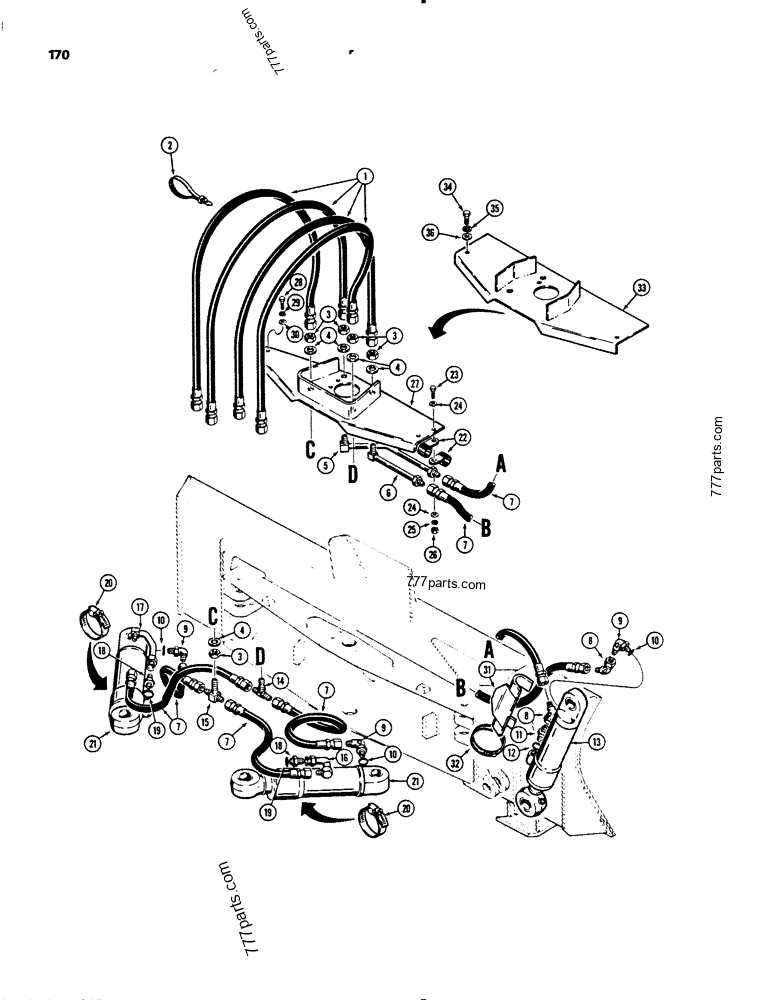

Transmission and Drive System Details

The transmission and drive mechanism plays a critical role in ensuring smooth movement and power delivery within the vehicle. This system is designed to efficiently transfer energy from the engine to the wheels, enabling proper handling across various terrains. Understanding the key components and their arrangement can help in maintaining optimal performance and extending the lifespan of the system.

Drive Belt and Pulley System: The primary elements of the drive system include a series of belts and pulleys that work together to transfer power. These components are designed to withstand significant stress while providing reliable torque to the wheels. Regular inspection is necessary to ensure that the belts are in good condition and properly tensioned for efficient power transfer.

Transmission Gearbox: At the core of the transmission is the gearbox, responsible for shifting between different gears to adjust the vehicle’s speed and power. Depending on the model, the system may feature a manual or automatic shifting mechanism, providing versatility in how the machine operates in different conditions.

In addition to the gearbox, various shafts and bearings work in harmony to ensure smooth engagement and disengagement of the gears. Maintenance of these components is crucial to avoid costly repairs and maintain seamless operation.

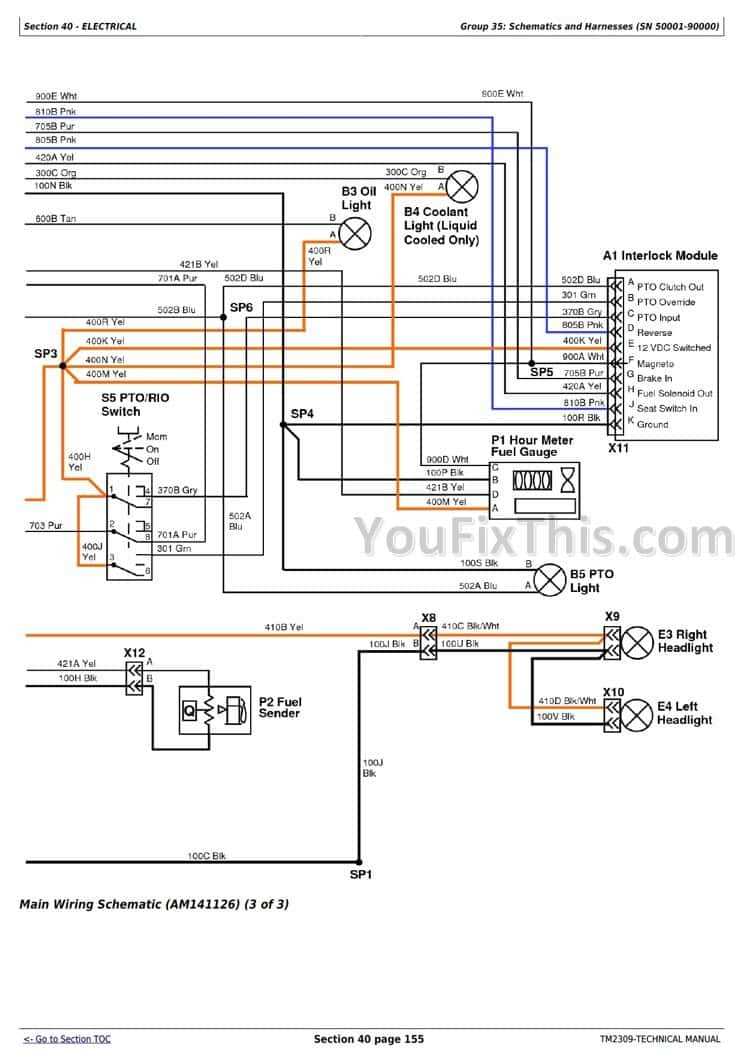

Electrical and Wiring Schematics

This section provides a detailed overview of the electrical connections and wiring layout essential for the smooth functioning of the machine. Proper understanding of these diagrams ensures efficient troubleshooting, maintenance, and upgrades. A clear grasp of the wiring paths and electrical components can prevent errors during assembly or repairs, leading to improved performance and longevity of the equipment.

Component Overview

Each electrical component, from the battery to the ignition system, plays a crucial role in the overall functionality. Understanding the flow of electricity through these components allows for easier identification of potential issues. It is important to follow the correct wiring paths to maintain the integrity of the system and ensure that each part operates as intended.

Wiring Layout and Maintenance Tips

Maintaining the wiring system involves regular checks for signs of wear, corrosion, or damage. Proper insulation and secure connections are critical to prevent short circuits or power loss. Regular inspection of wires and connectors helps to avoid unexpected breakdowns and ensures that the machine operates at peak efficiency.

How to Identify Important Features

When dealing with any mechanical machine, recognizing key components is essential for proper maintenance and operation. It is crucial to understand the role of each part to ensure longevity and efficiency. By paying attention to the most prominent elements, one can quickly identify the parts that require attention or potential upgrades.

Step 1: Begin by locating the main operational elements such as the engine, drive system, and control panels. These are typically the core components that determine the overall functionality of the equipment.

Step 2: Focus on areas that may require regular maintenance, such as filters, belts, and battery connections. These components often need periodic checks to ensure smooth performance and avoid malfunctions.

Step 3: Pay close attention to structural components that provide stability and support, such as the chassis or frame. Identifying any signs of wear or damage in these areas is crucial for safety and operational effectiveness.

Step 4: Finally, familiarize yourself with any specialized features that may offer enhanced functionality, such as advanced steering mechanisms or upgraded attachments. Understanding these can help you maximize the machine’s potential.

Maintenance and Replacement Parts Guide

Proper upkeep and timely replacements are essential for ensuring the longevity and efficient operation of any machinery. This section offers a comprehensive approach to maintaining key components, focusing on the importance of periodic servicing and how to address common wear and tear. By understanding the critical elements that require attention, owners can optimize performance and reduce the risk of unexpected failures.

Key Components to Monitor

- Engine system and related parts

- Transmission components

- Electrical wiring and connectors

- Hydraulic and fuel systems

- Steering and control mechanisms

Steps for Effective Replacement

- Assess the condition of each part regularly to determine wear and damage.

- Consult the machine’s manual for manufacturer recommendations on replacement intervals.

- Choose high-quality, compatible replacements to ensure proper fit and function.

- Perform replacement in a clean, controlled environment to prevent contamination.

- Test the system after replacement to ensure everything operates smoothly.

Assembly and Disassembly Instructions

Proper assembly and disassembly of machinery are crucial for maintaining its performance and longevity. This section provides a detailed guide on how to correctly assemble and disassemble key components of the machine, ensuring efficiency and safety throughout the process. Following these instructions step-by-step will help prevent damage to the parts and make the task easier to complete.

| Step | Action | Important Notes |

|---|---|---|

| 1 | Begin with the removal of any protective covers or shields. | Ensure that all safety precautions are followed before starting. |

| 2 | Loosen the screws and bolts securing the main assembly. | Use the correct tools to avoid stripping threads. |

| 3 | Carefully disconnect electrical connections and hoses if present. | Label wires and hoses to facilitate reassembly. |

| 4 | Remove the component from its housing. | Lift carefully to avoid damaging any attached parts. |

| 5 | For assembly, reverse the disassembly steps. | Ensure all connections are secure and components are aligned properly. |

Common Troubleshooting Tips for X534

When dealing with mechanical equipment, it’s essential to understand a few fundamental steps that can help resolve common issues. By following some simple diagnostic procedures, most users can identify the source of problems and address them efficiently without professional assistance. Here are some general tips to assist you in troubleshooting your machinery.

Check the Battery and Electrical Connections

A frequent cause of operational issues is a weak or faulty battery. Ensure that the battery is fully charged and that all electrical connections are tight and free from corrosion. If necessary, clean the terminals and inspect the cables for any visible wear or damage that could cause power interruptions.

Inspect the Fuel System

Fuel-related issues can also prevent proper functioning. Check for any signs of fuel leaks, clogged filters, or contaminated fuel. Ensure that the fuel lines are clear, and the fuel tank is filled with clean, fresh fuel to prevent engine misfires or starting problems.