The efficient operation of any agricultural equipment relies on the precise coordination of its various elements. For professionals working with large-scale machinery used for cutting and conditioning grass, it is essential to be familiar with the specific components that make up the machine. Each part has a critical function, contributing to the overall performance and durability of the equipment. A thorough understanding of these individual elements ensures smoother operation and can help with maintenance and troubleshooting.

Identifying each component and knowing how it interacts with other parts is crucial for maximizing efficiency. This includes knowing the structure and placement of key elements such as cutting mechanisms, drive systems, and safety features. Proper maintenance or replacement of worn-out components not only prevents breakdowns but also ensures the longevity of the machine.

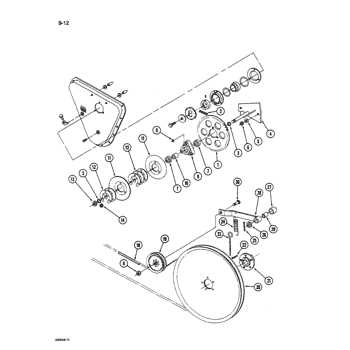

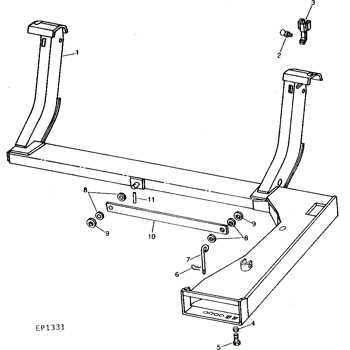

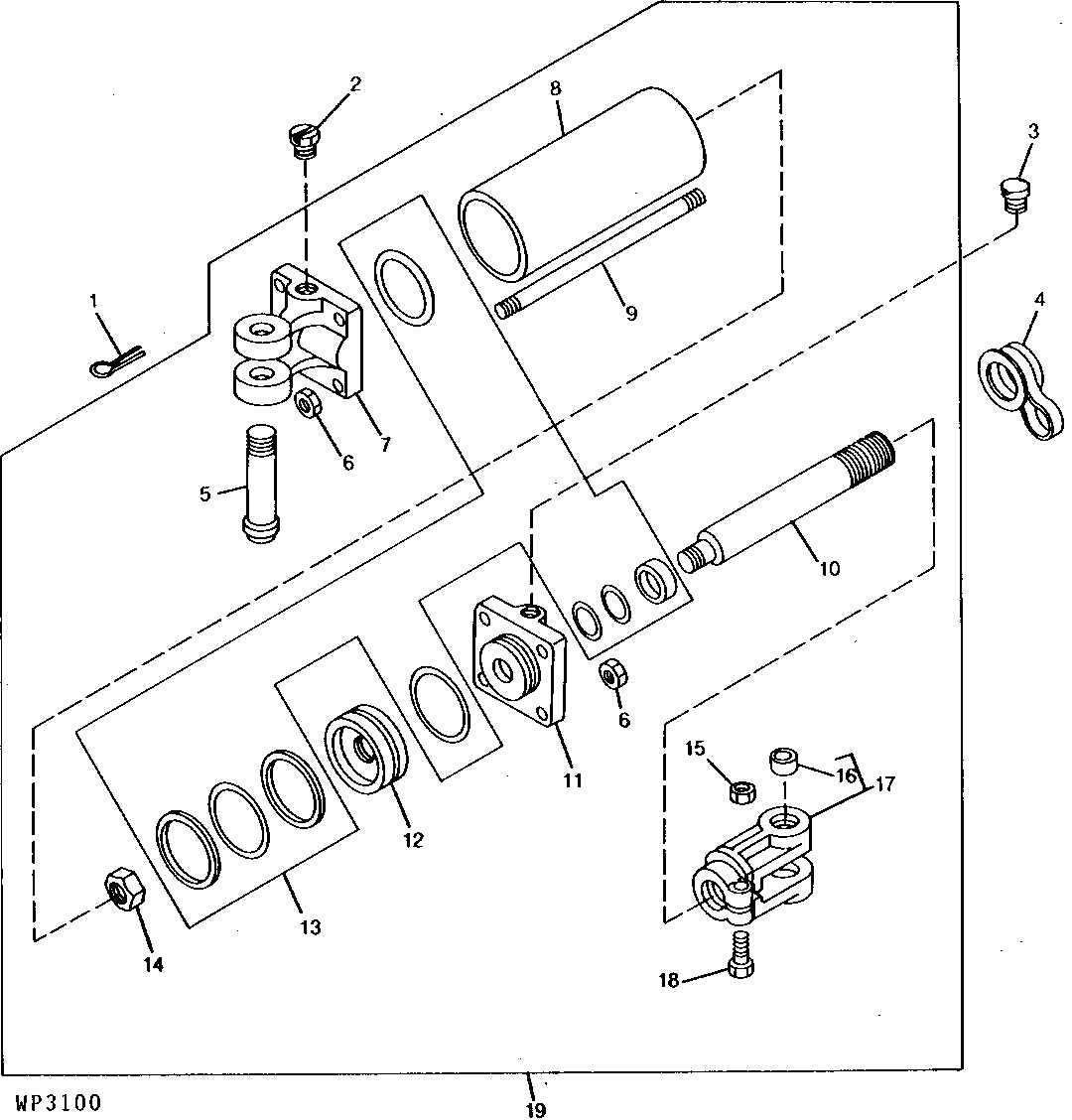

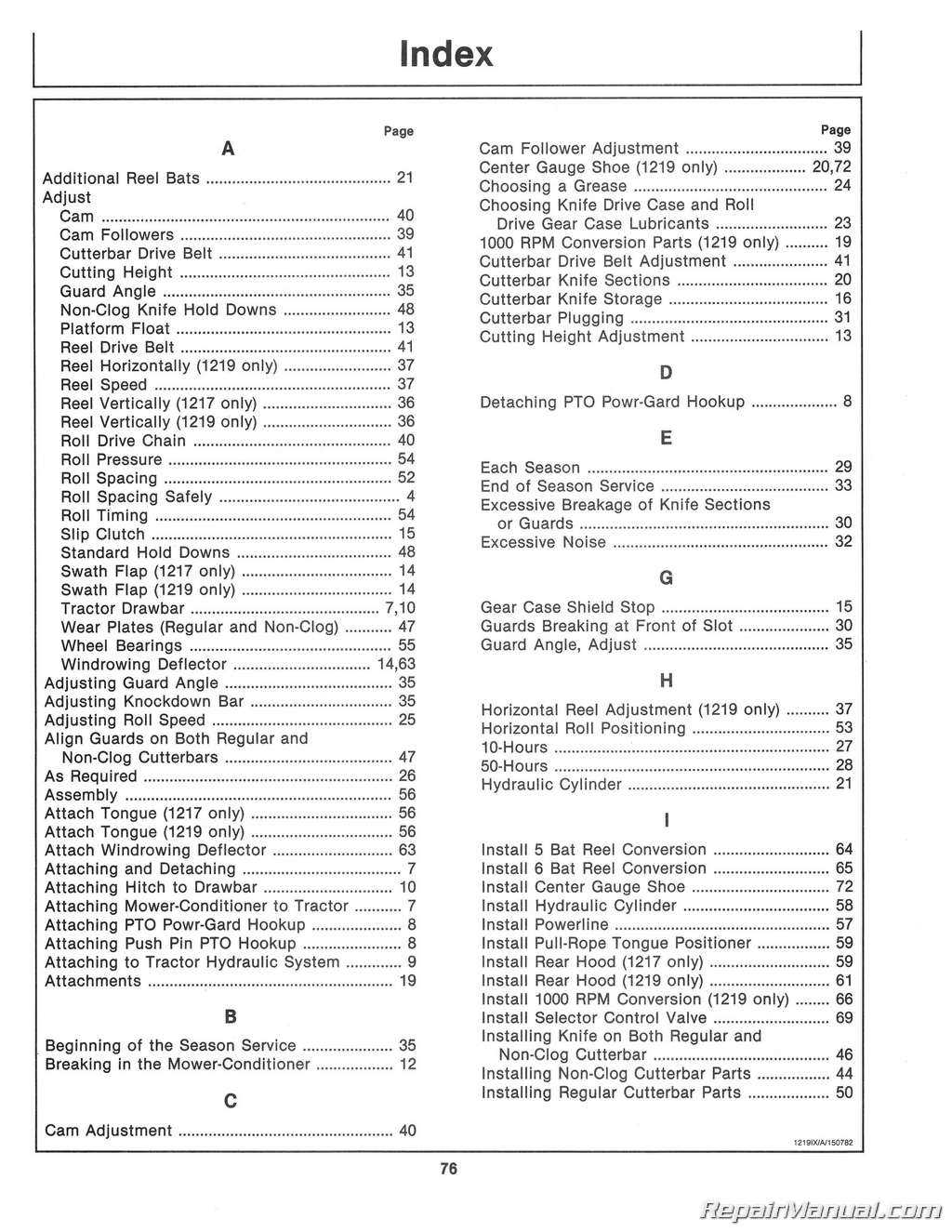

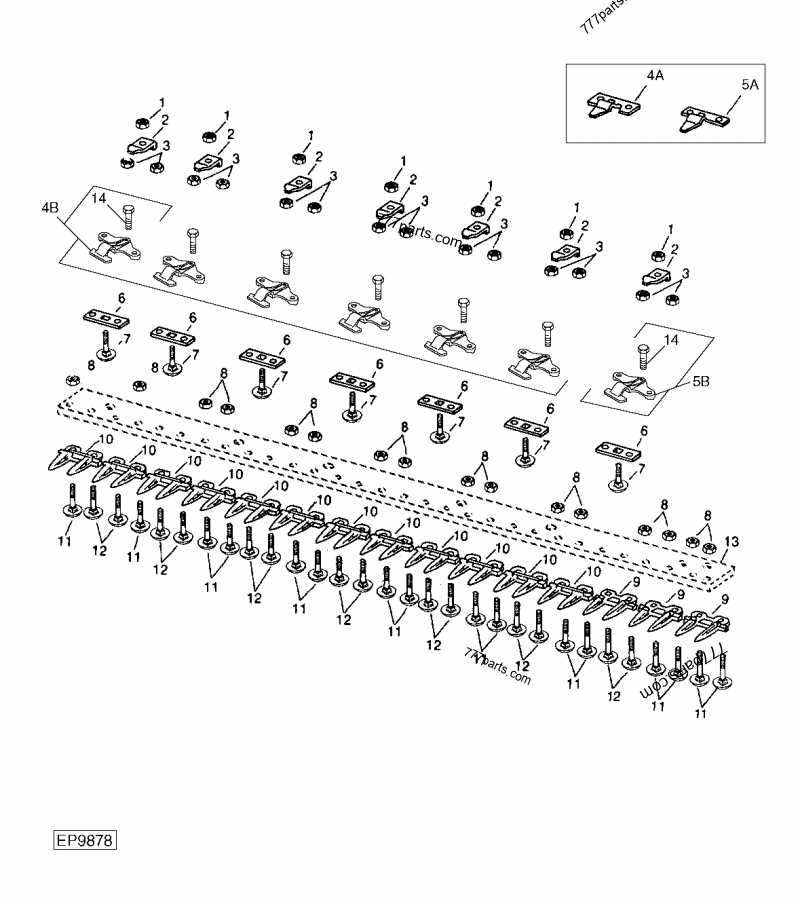

Visualizing the layout of all these parts through diagrams or charts can be a useful tool for operators and technicians alike. It allows them to quickly pinpoint potential issues and maintain a smooth workflow. Understanding the layout also aids in the process of setting up, assembling, and disassembling equipment for repairs or transport.

Understanding the John Deere 1219 Haybine Design

The design of agricultural machinery plays a critical role in ensuring efficient and reliable performance in the field. When it comes to crop harvesting, equipment that balances ease of use with durability is essential. A well-thought-out structure allows for maximum productivity, while minimizing the wear and tear on both the machine and the operator. In this section, we will explore how the innovative design principles behind this specific mower-conditioner model contribute to its effectiveness in various farming environments.

At its core, the engineering of this equipment focuses on optimizing the flow of crop material through the system. Each component is strategically positioned to enhance the cutting, conditioning, and transportation processes. The unique features, including the reel and cutter bar arrangement, ensure that even dense or wet crops are handled with precision. The build quality and material selection also contribute to the longevity and robustness required for rigorous tasks in the field.

Additionally, the adaptability of the machine’s design allows it to perform efficiently across a range of conditions. Whether dealing with tall grass or thick hay, the structure is engineered to maintain consistent cutting height and thorough conditioning. This is particularly important for improving drying times and overall crop quality.

In summary, the innovative design principles behind this equipment provide a powerful combination of efficiency, reliability, and adaptability, making it a trusted solution for modern agricultural needs.

Key Components of the 1219 Haybine

The efficient operation of any hay harvesting machine relies on several critical elements working together in harmony. Each component plays a unique role in ensuring smooth and effective cutting, conditioning, and transport of the crop. Understanding the key units within this machine helps in maintaining optimal performance and extending its lifespan. This section will highlight the primary sections that contribute to the overall functionality of the equipment.

Cutting Mechanism

The cutting mechanism is responsible for shearing the crop at the base to facilitate efficient harvest collection. This is typically achieved through a combination of sharp blades and moving sickle sections that ensure even and consistent cutting. A well-maintained cutting system is crucial to reduce crop damage and improve the speed of operation.

Conditioning and Transport System

The conditioning system plays an essential role in preparing the crop for drying. This component usually includes rollers or crimpers that compress the stems, enabling faster drying by exposing more surface area to the air. Once conditioned, the crop is conveyed through the machine and onto the collection platform, where it is ready for bundling or further processing.

| Component | Function |

|---|---|

| Cutting Blades | Shear the crop to ensure clean and precise cuts. |

| Conditioning Rollers | Compress and condition the crop for faster drying. |

| Transport Auger | Convey the cut and conditioned crop to the rear of the machine. |

Maintenance Tips for Haybine Parts

Regular upkeep of your mowing and conditioning equipment ensures it runs efficiently and extends its lifespan. By addressing potential wear and tear on key components, you can minimize downtime and optimize performance. Below are essential practices to keep the system in top condition, avoiding costly repairs and unnecessary interruptions in work.

Inspect and Clean Moving Components

Moving components, such as the blades and rollers, are subject to significant stress and wear. It’s important to routinely check these parts for signs of damage, corrosion, or debris buildup. Cleaning and lubricating them can help reduce friction and maintain optimal functionality. Make sure to replace any worn-out components to prevent further damage to adjacent parts.

Check for Proper Alignment

Incorrect alignment of the various mechanical sections can lead to uneven performance or damage to the equipment. Ensuring that each part is aligned correctly will reduce unnecessary strain on the system. Use a level and measuring tools to verify that everything is in place. Misaligned sections should be adjusted immediately to avoid further issues.

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Blades | Every 50 hours of use | Sharpen or replace as necessary |

| Rollers | Every 100 hours of use | Clean, lubricate, and replace if worn |

| Gearbox | Every 200 hours of use | Check oil levels and replace fluid |

How to Identify Worn Out Parts

Recognizing when components of agricultural machinery are nearing the end of their lifespan is crucial to maintaining optimal performance. Over time, the constant motion and strain placed on various elements can cause them to degrade, resulting in decreased efficiency and potential breakdowns. It’s essential to regularly inspect each element to ensure the equipment operates smoothly and effectively. In this section, we will explore how to spot the signs of wear and tear in mechanical systems.

Visual Inspection: The first step in identifying worn-out components is to conduct a thorough visual examination. Look for any signs of cracks, fraying, or deformation on moving parts. These are often clear indicators that the item is no longer in its optimal condition. Pay close attention to areas that experience frequent contact or friction, as they tend to wear down faster than other parts.

Unusual Sounds: Listen carefully during operation for any abnormal noises such as squeaking, grinding, or knocking. These sounds can signify that certain elements are not functioning as they should, often due to excessive wear. If the machinery starts making strange noises, it’s a good sign that some internal components need attention or replacement.

Reduced Efficiency: Another indicator of worn-out elements is a noticeable drop in overall performance. If the equipment struggles to perform tasks it once handled with ease, or if there is a decrease in output, it may be time to check the condition of the internal mechanisms. Inefficient operation could be a result of parts that are no longer functioning correctly.

Excessive Vibration: Increased vibration during operation can also point to damage or excessive wear on specific components. Parts that are loose or unbalanced can lead to improper functioning, which may cause further damage if left unaddressed. Regularly monitor the level of vibration during use to identify potential problems.

Tools Required for Part Replacement

Replacing components on agricultural machinery involves using specific tools to ensure efficient and safe handling. It is essential to have the right equipment on hand before starting any maintenance work. The process of swapping out worn or damaged elements requires not only technical knowledge but also the appropriate instruments for precision and durability. Ensuring that you are equipped with the proper tools will save time and prevent damage to the machine.

Wrenches and socket sets are crucial for loosening bolts and fasteners. They allow for the disassembly and reassembly of various sections without causing damage to the components. Additionally, screwdrivers are needed for any detailed adjustments or minor removals, while pliers come in handy when dealing with smaller parts that require gripping.

For tasks that involve the alignment or adjustment of key elements, a tape measure or ruler will ensure accurate measurements. Some repairs may also require a hammer or mallet to assist with loosening stubborn parts. For more complex procedures, specialized tools such as torque wrenches and hydraulic jacks might be necessary to ensure proper reinstallation and alignment of critical components.

Having a well-organized toolkit will enhance the overall efficiency of the replacement process and ensure that all work is completed to the highest standards of safety and performance.

Common Issues with Haybine Parts

Machines used in agricultural settings can encounter various challenges over time, particularly when components are exposed to constant wear and tear. Even the most robust systems require attention, as certain elements may begin to malfunction, affecting overall performance. Recognizing the common failures can help in timely repairs and maintenance.

Worn or Damaged Blades

One frequent issue is the degradation of cutting edges. Over time, blades may become dull, chipped, or bent, making it difficult to achieve a clean cut. This can lead to uneven material processing, which reduces efficiency. Regular inspection and replacement are necessary to maintain optimal functionality.

Drive System Failures

The drive mechanism, responsible for transferring power to various moving parts, is another area prone to breakdowns. Misalignment or worn-out bearings can cause excessive vibration, which in turn may lead to more serious damage if not addressed promptly. Ensuring that the drive belts and gears are in good condition is crucial for smooth operation.

Neglecting these issues can result in more costly repairs, reducing productivity and increasing downtime. Keeping an eye on common trouble spots and scheduling regular maintenance can significantly extend the life of the equipment.

Where to Find Genuine John Deere Parts

For anyone seeking high-quality replacement components for their agricultural equipment, the key is to focus on finding original, manufacturer-approved options. These components are specifically designed to ensure durability and optimal performance. When selecting replacement items, it’s essential to choose those that are crafted to match the specifications of the original machinery. This will not only extend the lifespan of the equipment but also minimize potential downtime and maintenance costs.

Official Dealerships and Service Centers

One of the most reliable sources for authentic components is through official dealerships and service centers. These locations often offer a wide selection of factory-approved components and have knowledgeable staff who can provide advice on the best items for your needs. Additionally, they often offer services like installation and maintenance, ensuring that the components are properly integrated into your equipment.

Online Retailers and Manufacturer’s Website

Another convenient option for sourcing original components is through the manufacturer’s official website or authorized online retailers. Many websites offer easy-to-use parts catalogs where you can search by model and category. It’s essential to verify the authenticity of the seller before making a purchase to avoid counterfeit products. Moreover, these online platforms often provide detailed information about each component, ensuring you’re choosing the correct item for your equipment.

In the end, whether you’re shopping locally or online, selecting genuine components ensures your machinery operates at peak efficiency and reliability.

Understanding Haybine Operating Mechanisms

To fully comprehend how a forage mower-conditioner functions, one must first explore the core components and mechanisms that drive its efficiency. These machines are designed to cut, condition, and windrow forage crops, optimizing the drying process for storage or further processing. By breaking down the operating principles, operators can better maintain, troubleshoot, and operate their equipment effectively.

Cutting System

The cutting system is the primary component responsible for slicing through crops. It typically consists of a series of sharp blades attached to a rotating bar. These blades move swiftly, ensuring that the forage is cut cleanly and uniformly.

- Counter-rotating knives ensure clean cuts and minimize damage to the plant.

- Adjustable cutting height allows for customization based on crop type and field conditions.

Conditioning Mechanism

After cutting, the forage enters the conditioning section, where it is processed to speed up drying. The conditioner breaks down the plant’s structure, creating more surface area for faster evaporation of moisture.

- Roller conditioning systems squeeze and crimp the plants, enhancing the drying process.

- Impeller-style systems use fast-moving fingers to aggressively crush the forage, ensuring optimal air flow for drying.