The effective functioning of any agricultural machinery relies on the intricate design and interrelation of its various elements. Each component plays a significant role in ensuring optimal performance and productivity. Understanding these components not only aids in maintenance but also enhances the operational efficiency of the machine.

In this section, we will explore the essential elements that constitute this important piece of equipment. By examining how each part contributes to the overall functionality, users can gain valuable insights into troubleshooting and repairs. Familiarity with these components enables operators to optimize their usage and extend the lifespan of the machine.

Through a detailed overview, readers will be equipped with the knowledge needed to identify individual parts and their specific functions. This understanding is crucial for anyone looking to improve their skills in operating and maintaining this vital equipment in the agricultural sector.

Understanding the essential elements of a hay-making machine is crucial for efficient operation and maintenance. Each part plays a significant role in the overall functionality, contributing to the effectiveness of the process. Familiarity with these components helps users optimize performance and troubleshoot issues effectively.

The following table outlines the primary components and their respective functions:

| Component | Function |

|---|---|

| Feeding Mechanism | Guides and directs the crop into the compression chamber. |

| Compression Chamber | Compresses the material into compact shapes. |

| Binding System | Secures the compressed material with twine or netting. |

| Tires | Provide mobility and support for the machine during operation. |

| Control Panel | Allows the operator to manage the machine’s functions and settings. |

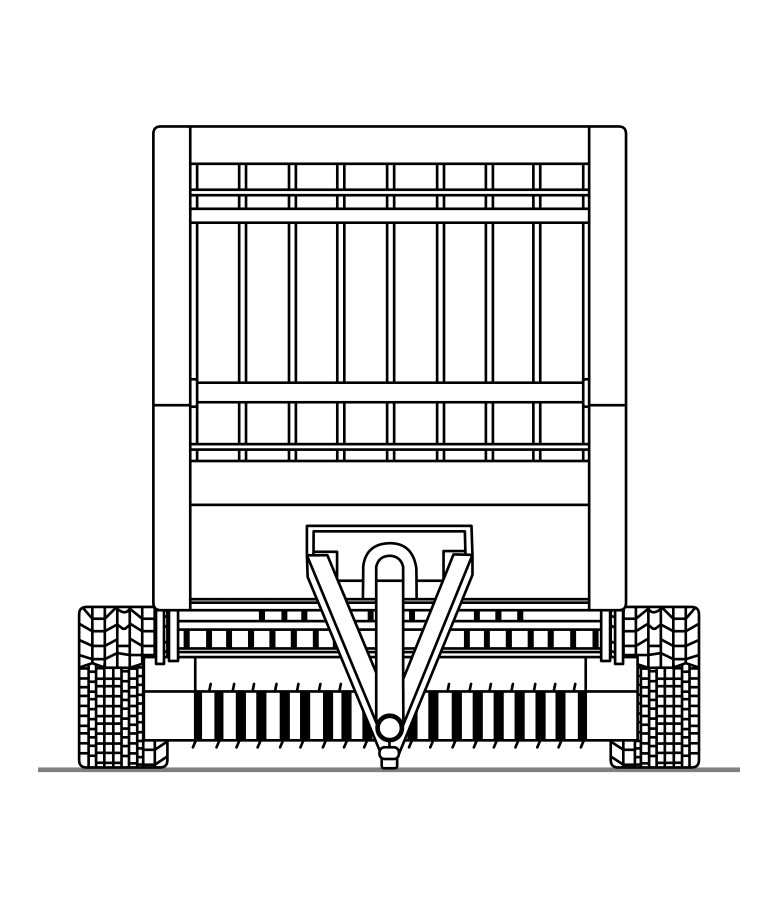

Understanding the Parts Diagram

The components layout is essential for anyone looking to grasp the intricacies of machinery. This visual representation aids users in identifying and comprehending the various elements that constitute the equipment. Familiarity with the configuration of these components is crucial for efficient operation and maintenance.

Each section of the illustration serves to highlight specific features, enhancing the user’s ability to troubleshoot issues and perform repairs. By examining this layout, operators can quickly locate necessary items, ensuring that any adjustments or replacements can be made promptly.

Moreover, the clarity of such visuals plays a significant role in training new personnel. Understanding how each element interacts within the system fosters a deeper knowledge of the overall functionality, contributing to more effective and confident usage.

Maintenance Tips for Baler Parts

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Regular attention to components helps prevent unexpected breakdowns and maintains efficiency during operation. Below are some effective strategies for maintaining critical elements of your equipment.

1. Regular Inspections: Conduct frequent checks to identify any wear or damage. Look for signs of rust, cracks, or loose connections. Early detection can save time and reduce repair costs.

2. Lubrication: Keeping moving elements well-lubricated is vital for smooth operation. Use the recommended lubricants and ensure all grease points are adequately serviced to minimize friction and wear.

3. Clean Components: Regularly clean all parts to remove debris and residue. Dirt buildup can lead to overheating and inefficient performance. Use compressed air or a soft brush for hard-to-reach areas.

4. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided in the manual. This ensures that all necessary servicing is performed on time, which can enhance the lifespan of your machinery.

5. Replace Worn Components: Do not hesitate to replace parts that show significant wear. Using subpar or damaged components can lead to further issues down the line, affecting overall efficiency.

6. Store Properly: If the equipment is not in use, store it in a dry, covered area to protect it from the elements. Proper storage can prevent rust and prolong the life of various components.

Common Issues and Solutions

When operating agricultural machinery, various challenges may arise that can impact efficiency and productivity. Understanding these common problems and their respective solutions is crucial for maintaining optimal performance and ensuring the longevity of the equipment. Below are some typical concerns and effective strategies to address them.

Frequent Mechanical Failures

Mechanical failures can occur due to wear and tear or lack of maintenance. Regular inspections and timely replacements of worn components are essential. Implementing a routine maintenance schedule can significantly reduce the risk of unexpected breakdowns and improve the overall functionality of the machine.

Blockages and Jamming

Blockages often lead to inefficient operation and can be caused by debris or improperly set parameters. Clearing the feed area and adjusting the settings to match the type of material being processed are effective measures. Additionally, ensuring that all components are clean and free of obstructions can help prevent jamming.

How to Order Replacement Parts

Acquiring necessary components for your agricultural machinery is essential to ensure optimal performance and longevity. Understanding the process for obtaining these items can save time and reduce downtime during critical operations.

First, identify the specific components required for your equipment. Consult the user manual or the manufacturer’s documentation for a comprehensive list of needed items. This will assist in accurately pinpointing the required elements without confusion.

Next, reach out to authorized dealers or reputable suppliers who specialize in agricultural machinery. Ensure that they have access to the latest inventory and can provide authentic components. When placing your order, it is vital to have the correct identification numbers at hand to facilitate the selection process.

Consider exploring online platforms that offer detailed catalogs of available items. Many suppliers provide an easy-to-navigate interface where you can search for specific components by entering relevant information. This option can be particularly useful for comparing prices and availability.

Finally, after placing your order, verify the expected delivery timeline. Proper planning and timely acquisition of components will ensure that your equipment remains operational and efficient.

Comparing Components with Other Models

This section aims to explore the similarities and differences in the components utilized in various agricultural machinery. Understanding these distinctions can aid in making informed decisions when it comes to repairs, upgrades, or replacements.

When analyzing components, it is essential to consider several factors:

- Compatibility: Ensure that the components from different models can fit and function together effectively.

- Durability: Assess the longevity and robustness of components across models to determine which offers better performance.

- Functionality: Evaluate how the components operate within their respective machinery and their impact on overall efficiency.

- Cost: Compare the pricing of components between different models to identify cost-effective options without compromising quality.

Additionally, consulting user reviews and expert opinions can provide insights into the performance of components from various models. This information can be invaluable for those looking to optimize their machinery for better output and reliability.

Upgrades and Modifications Available

Enhancing machinery efficiency through various upgrades and modifications can significantly improve performance and longevity. By incorporating advanced features and components, operators can tailor equipment to meet specific operational demands, ensuring optimal functionality in diverse agricultural environments.

Performance Enhancements

Implementing performance upgrades may involve replacing standard components with high-efficiency alternatives. Upgrading to superior drive systems or enhancing the cutting mechanism can lead to increased throughput and reduced downtime during operation. These improvements not only boost productivity but also enhance the overall user experience.

Technology Integration

Integrating modern technology, such as GPS and automation systems, can provide valuable insights into operational efficiency. These innovations allow for precise monitoring and control, enabling users to optimize workflows and reduce waste. Moreover, incorporating software solutions can facilitate maintenance tracking and scheduling, ensuring equipment remains in peak condition.

Resources for Baler Owners

Owning and maintaining a harvesting machine requires access to a variety of resources to ensure optimal performance and longevity. Understanding the components, service options, and support available can greatly enhance the user experience and machine efficiency.

Essential Maintenance Guides

- Manufacturer manuals: Detailed documentation provided by the manufacturer offers insights into operation and upkeep.

- Online forums: Engaging with fellow machine owners can provide valuable tips and troubleshooting advice.

- Video tutorials: Visual aids can help illustrate maintenance techniques and repairs.

Parts Suppliers and Services

- Authorized dealers: Official vendors ensure the quality and compatibility of replacement components.

- Aftermarket suppliers: Explore various alternatives for potentially more affordable options.

- Local repair shops: Establish relationships with nearby services for quick fixes and routine inspections.