Maintaining and repairing outdoor machinery can be a daunting task for many enthusiasts and professionals alike. Familiarity with the internal components and their configurations is crucial for ensuring optimal performance and longevity of your tools. A comprehensive overview of various elements involved provides insight into effective maintenance practices.

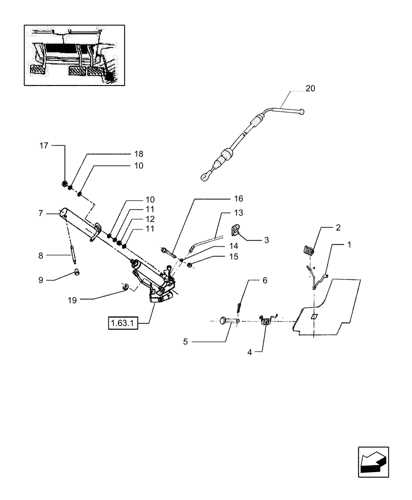

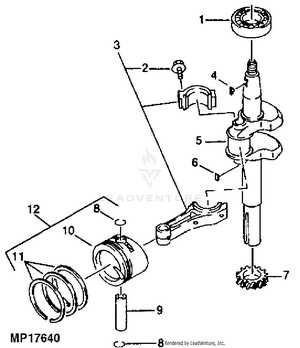

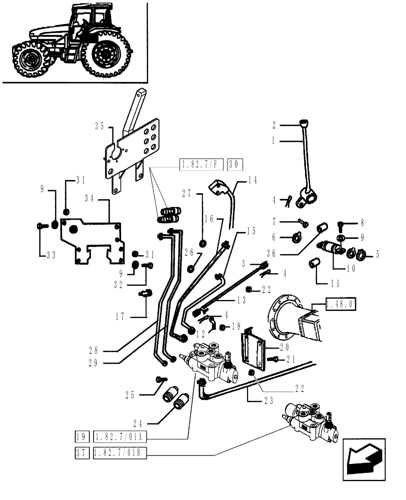

Detailed illustrations serve as invaluable resources, guiding users through the intricacies of machinery assembly and disassembly. By examining these visual aids, one can easily identify necessary components and their specific functions. This knowledge not only simplifies repairs but also enhances the overall understanding of the equipment.

Whether you’re tackling a minor issue or conducting a major overhaul, having access to precise representations of your machinery will empower you to make informed decisions. In this section, we will delve into the various parts, facilitating a smoother journey towards achieving your ultimate gardening goals.

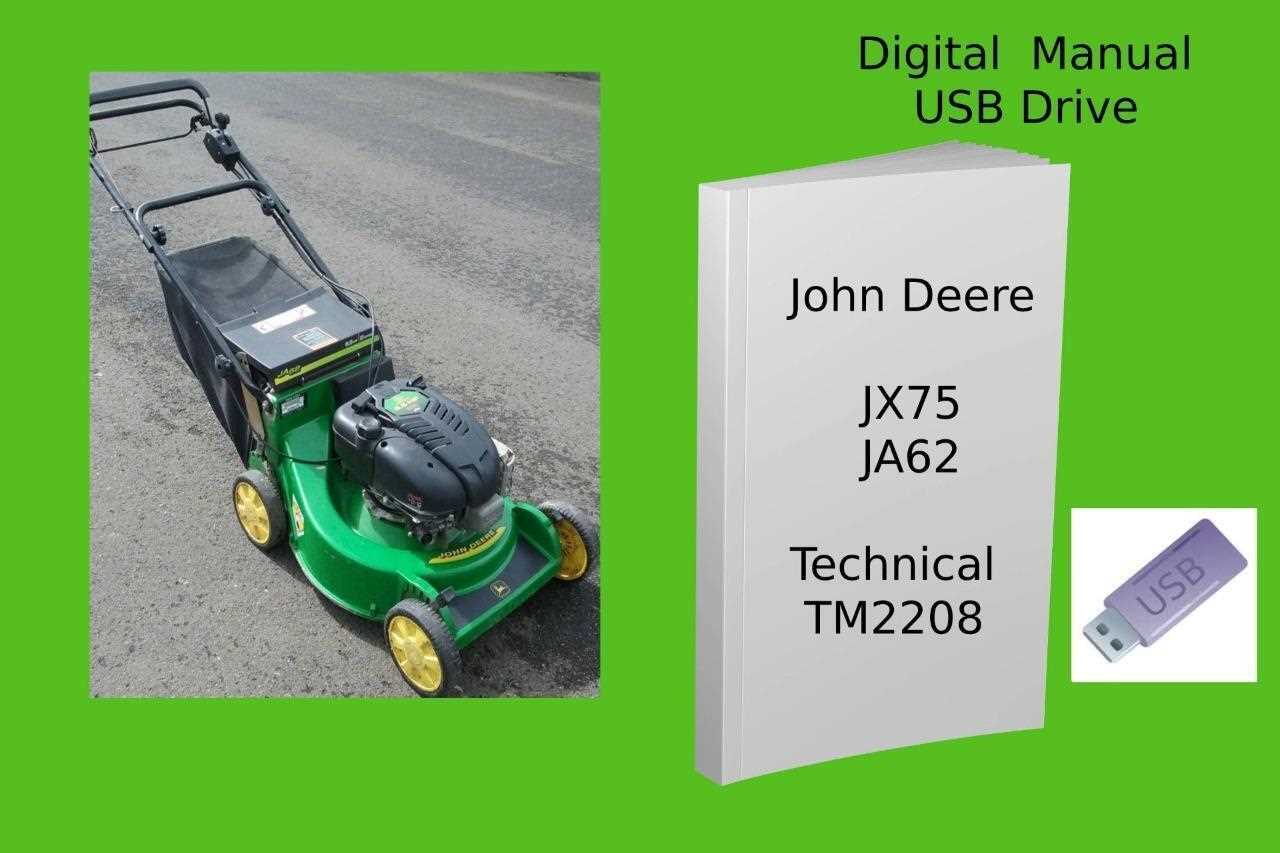

Understanding the John Deere JX75

This section explores a well-regarded model in the lawn care equipment world, focusing on its design, functionality, and components. Knowing the intricate details of this machine can enhance maintenance and repair efficiency, ensuring optimal performance for all gardening tasks.

Design and Features

The design of this mower emphasizes durability and ease of use, featuring a robust structure that withstands various weather conditions. Its innovative characteristics provide a seamless mowing experience, making it a favorite among enthusiasts and professionals alike.

Maintenance Essentials

Regular upkeep is crucial for prolonging the life of this equipment. Understanding the essential elements that require attention, such as the engine, blades, and wheels, allows users to keep their machine in peak condition. Routine checks and timely replacements ensure that every mowing session is efficient and effective.

Key Features of JX75 Mowers

This section explores the essential attributes of these powerful lawn care machines, highlighting what makes them stand out in the market. Designed for efficiency and performance, these mowers provide users with a reliable solution for maintaining a pristine lawn.

| Feature | Description |

|---|---|

| Engine Performance | Robust engines deliver consistent power for optimal cutting efficiency. |

| Cutting Width | Wide cutting decks allow for quicker mowing of larger areas. |

| Height Adjustment | Multiple height settings enable users to achieve the desired grass length. |

| Durability | Constructed with high-quality materials for long-lasting use. |

| User Comfort | Ergonomic designs ensure ease of operation and reduced fatigue. |

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as essential tools for both professionals and enthusiasts, allowing for quick identification and comprehension of complex systems.

Enhancing Efficiency

Utilizing visual aids can significantly streamline repair processes. By clearly illustrating where each component fits, these guides minimize the time spent searching for parts and reduce the likelihood of errors during assembly or disassembly.

Facilitating Troubleshooting

When issues arise, having a detailed representation of the machine aids in diagnosing problems. Users can delve into specific areas, making it easier to pinpoint failures and implement effective solutions without unnecessary guesswork.

Common Issues with JX75 Models

This section explores frequent problems encountered with a popular line of lawn maintenance equipment, providing insights into potential complications that owners may face over time.

Engine Performance

- Difficulty starting the engine

- Inconsistent power output

- Excessive noise during operation

Cutting Issues

- Uneven grass cutting

- Clogs in the cutting deck

- Worn-out blades affecting performance

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. Numerous resources are available to ensure you locate high-quality substitutes that fit your specific model. From online retailers to local stores, understanding your options will streamline the replacement process.

Online marketplaces often offer a wide range of choices, allowing you to compare prices and read customer reviews. Manufacturer websites can provide original items directly from the source, ensuring compatibility and reliability. Additionally, local dealers may have the necessary components on hand, enabling you to receive personalized assistance and immediate availability.

Forums and online communities can also be valuable, as enthusiasts share their experiences and recommendations for sourcing specific items. Utilizing a combination of these avenues will help you effectively find what you need for optimal performance.

Step-by-Step Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a systematic approach to maintenance, you can prevent issues before they arise and enhance the overall efficiency of your machine. This guide provides practical steps that will help you maintain your device effectively.

1. Routine Inspection

Begin with a thorough examination of the machinery. Check for any visible wear and tear, loose connections, or leaks. Pay close attention to the blades and belts, as these components often require the most care. Performing a visual assessment regularly can help identify potential problems early on.

2. Cleaning and Lubrication

Keep the equipment clean to prevent dirt and debris from causing damage. Remove any buildup from critical areas, especially around moving parts. Additionally, apply lubricant to necessary joints and bearings to ensure smooth operation. This simple task can significantly reduce friction and wear, extending the lifespan of your device.

How to Use the Parts Diagram

Understanding a schematic representation of components can significantly streamline the maintenance and repair process. By effectively interpreting these visuals, users can easily identify individual elements and their connections, leading to more efficient troubleshooting and replacement procedures.

Familiarizing Yourself with the Layout

Begin by examining the overall structure of the schematic. Note the organization of various sections, which typically group related components together. This familiarity will help you locate specific items more swiftly when addressing issues.

Identifying Components and Their Functions

Once you grasp the layout, focus on recognizing each element and its role within the assembly. Use labels and legends provided to pinpoint parts accurately, ensuring you select the correct replacements for repairs.

Upgrades and Modifications Available

Enhancing the functionality and performance of your gardening equipment can lead to a more efficient and enjoyable experience. Various enhancements can be implemented to tailor the machine to specific needs, whether for improved power, versatility, or comfort. This section explores several options that can help elevate the capabilities of your unit.

Performance Enhancements

One of the primary areas for improvement lies in the engine and drive system. Upgrading to a higher horsepower engine can significantly boost cutting efficiency and speed. Additionally, implementing a more advanced transmission system can offer smoother operation and better torque distribution, making it easier to tackle diverse terrain.

Comfort and Usability Modifications

For increased comfort during extended use, consider adding ergonomic seats or enhanced steering systems. These modifications can reduce fatigue and improve overall control. Furthermore, attachments such as mulching kits or baggers can expand the utility of your machine, allowing it to handle a wider range of tasks effectively.

Expert Recommendations for Owners

Maintaining your equipment is crucial for optimal performance and longevity. Here are some valuable tips to enhance your ownership experience.

- Regularly inspect all components for wear and tear.

- Follow the manufacturer’s maintenance schedule to avoid unexpected issues.

- Use quality lubricants and fluids to ensure smooth operation.

- Store your machine in a dry, sheltered location to prevent rust and damage.

Additionally, consider these practices for better upkeep:

- Keep the exterior clean to avoid debris buildup.

- Check and adjust tire pressure regularly for improved efficiency.

- Invest in protective gear for safety during operation.

By following these expert recommendations, you can maximize the effectiveness of your machinery and ensure it serves you well for years to come.