The efficient operation of agricultural machinery relies on understanding the intricate setup of its essential components. These machines, designed to handle large-scale farming tasks, consist of various interconnected elements that work together to ensure optimal performance. By gaining insight into the detailed configuration of these systems, operators can maintain and repair equipment with greater ease.

In this section, we will explore a specific type of agricultural tool, focusing on its structural elements and functionality. Knowing how each part contributes to the whole mechanism will not only improve its longevity but also enhance its efficiency in field operations. We’ll delve into the assembly of this tool, explaining how the various sections interact and how to identify and replace key elements when necessary.

Understanding the layout of such equipment is crucial for both new and experienced users. This guide aims to provide a clear and concise reference, aiding in troubleshooting and ensuring that the machine remains in top working condition. With proper knowledge, maintaining agricultural machinery becomes less of a challenge, allowing for smoother operation in the long run.

Understanding the Vermeer R23 Rake Structure

The mechanical layout of this agricultural tool is a complex system of interconnected components, each designed to perform specific tasks during operation. Its framework ensures efficiency, durability, and ease of use, making it a valuable asset in various field conditions. By exploring its internal configuration, we can better understand how each part contributes to the overall functionality and longevity of the machine.

Key Elements of the System

- Main frame: The backbone of the device, providing structural support and ensuring stability during work in the field.

- Wheel assemblies: Responsible for mobility and smooth maneuverability across uneven terrain, these are essential for consistent performance.

- Tine arms: These extend outward to engage the material, ensuring that everything is gathered effectively for collection.

Operational Mechanisms

Each functional aspect of the system is driven by a combination of mechanical and hydraulic operations, allowing it to handle various materials efficiently. From material collection to discharge,

Key Components of the Vermeer R23 Rake

The machine is comprised of several crucial elements, each contributing to its overall functionality. Understanding the role of these components is essential for maintaining optimal performance. Below is an overview of the most important elements and their significance in the operation.

Frame Assembly: The sturdy foundation supports the entire structure and ensures stability during use. It connects all other parts, providing the necessary framework for smooth operation in various conditions.

Wheel Mechanism: The wheels allow for seamless movement, guiding the machine efficiently over different types of terrain. Their design ensures minimal ground disturbance while maintaining a steady flow.

Rotary Arms: These rotating arms are responsible for gathering and moving material. Their synchronized movement ensures even collection, contributing to the machine’s precision.

Tine Bars: Attached to the rotating arms, these bars are equipped with flexible tines that sweep material into a uniform row. The tines are designed for

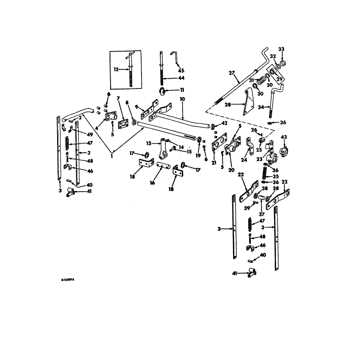

How to Identify R23 Rake Parts

Understanding the different components of agricultural machinery can be essential for proper maintenance and efficient performance. Recognizing specific elements of the equipment can help in timely repairs and replacement, ensuring the longevity and functionality of the machine.

The first step is to familiarize yourself with the overall structure. Look for the key segments that make up the system. Each component plays a critical role in the operation, from the core framework to the more intricate mechanisms. Knowing how to spot these features is crucial to ensure that you are working with the correct elements.

Inspect the main frame to locate any distinctive characteristics that differentiate it from other machinery types. Pay close attention to the arrangement and shape of smaller elements, as these may indicate where specific actions or movements occur. If you find wear or damage, this can often signal the need for replacement of key elements.

Additionally, take note of the rotating and moving components. These parts are esse

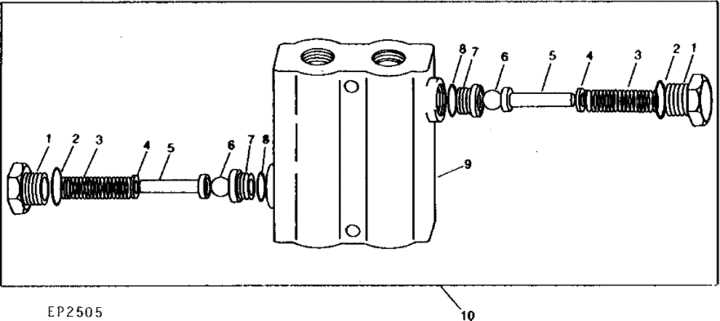

Diagram Breakdown of the Rake’s Main Sections

The mechanical structure can be divided into several critical components, each contributing to its overall functionality. Understanding how these sections interconnect and operate ensures effective maintenance and use. This breakdown explores the primary segments, offering a closer look at their roles within the entire framework.

Common Wear Points in the Vermeer R23 Over time, frequent use of any agricultural equipment can lead to the gradual deterioration of certain components. It’s important to understand which areas are most prone to wear and tear, especially when working in tough conditions. Identifying these critical zones helps ensure timely maintenance and extends the overall lifespan of the machinery.Bearings and Joints

Over time, frequent use of any agricultural equipment can lead to the gradual deterioration of certain components. It’s important to understand which areas are most prone to wear and tear, especially when working in tough conditions. Identifying these critical zones helps ensure timely maintenance and extends the overall lifespan of the machinery.Bearings and Joints The bearings and pivot joints are subjected to constant movement, making them susceptible to friction-based damage. Regular lubrication can mitigate some of the stress, but these parts often require close monitoring for wear. Neglecting these components can lead to reduced efficiency and eventual breakdowns.Tines and Drive Mechanisms

The bearings and pivot joints are subjected to constant movement, making them susceptible to friction-based damage. Regular lubrication can mitigate some of the stress, but these parts often require close monitoring for wear. Neglecting these components can lead to reduced efficiency and eventual breakdowns.Tines and Drive Mechanisms The metal tines and associated drive mechanisms are essential for performance, yet they face considerable strain during operation. Frequent exposure to rugged materials can cause bending, breakage, or wear of these parts, neceReplacing Critical Vermeer R23 Rake Components

The metal tines and associated drive mechanisms are essential for performance, yet they face considerable strain during operation. Frequent exposure to rugged materials can cause bending, breakage, or wear of these parts, neceReplacing Critical Vermeer R23 Rake Components Maintaining and restoring essential machinery components is crucial for optimal performance and longevity. When dealing with equipment that endures heavy usage, knowing how to effectively replace key elements ensures continued operation and minimizes downtime.To successfully replace these components, follow these steps:

Maintaining and restoring essential machinery components is crucial for optimal performance and longevity. When dealing with equipment that endures heavy usage, knowing how to effectively replace key elements ensures continued operation and minimizes downtime.To successfully replace these components, follow these steps:

- Identify the component that requires replacement.

- Gather the necessary tools and new parts.

- Follow the specific instructions for disassembly to avoid damaging surrounding areas.

- Install the new component, ensuring proper alignment and secure fitting.

- Test the equipment to verify successful installation and functionality.

Key components that often require attention include:

- Drive belts: Essential for power transmission, wear and tear can lead to decreased efficiency.

- Bearings: Critical for smooth operation, damaged bearings can cause excessive friction and heat.

- Hydraulic hoses: These play a vital role in fluid movement, and any leaks can result in performance issues.

- Blades: Sharp and well-maintained blades are necessary for effective operation; dull or damaged ones should be replaced promptly.

By prioritizing the maintenance of these vital components, operators can ensure that their machinery remains in peak condition, ultimately enhancing productivity and safety.Maintenance Tips for Your R23 RakeProper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps prevent costly repairs. Implementing a systematic approach to caring for your machinery will yield significant benefits in the long run.Regular Inspections Conducting frequent checks is crucial for identifying potential issues before they escalate. Inspect all components for signs of wear or damage, paying close attention to critical areas. Look for loose connections, cracks, or corrosion. Addressing these concerns promptly will help maintain the overall health of your apparatus.Lubrication and Cleaning

Conducting frequent checks is crucial for identifying potential issues before they escalate. Inspect all components for signs of wear or damage, paying close attention to critical areas. Look for loose connections, cracks, or corrosion. Addressing these concerns promptly will help maintain the overall health of your apparatus.Lubrication and Cleaning Keeping moving parts adequately lubricated is vital to prevent friction and wear. Use the recommended lubricants and follow the manufacturer’s guidelines for application. Additionally, regularly clean the equipment to remove dirt, debris, and any buildup that can hinder performance. A clean machine operates more efficiently and is less prone to breakdowns.Remember: Consistent maintenance routines lead to enhanced functionality and durability, allowing your equipment to perform at its best for years to come.Where to Source Vermeer Rake Parts

Keeping moving parts adequately lubricated is vital to prevent friction and wear. Use the recommended lubricants and follow the manufacturer’s guidelines for application. Additionally, regularly clean the equipment to remove dirt, debris, and any buildup that can hinder performance. A clean machine operates more efficiently and is less prone to breakdowns.Remember: Consistent maintenance routines lead to enhanced functionality and durability, allowing your equipment to perform at its best for years to come.Where to Source Vermeer Rake Parts Finding the right components for your agricultural machinery can greatly enhance performance and prolong the life of your equipment. Whether you are in need of replacements or upgrades, knowing where to acquire quality items is crucial. This section explores various avenues for obtaining essential elements for your specific model, ensuring you can keep your machinery running smoothly.Authorized Dealers

Finding the right components for your agricultural machinery can greatly enhance performance and prolong the life of your equipment. Whether you are in need of replacements or upgrades, knowing where to acquire quality items is crucial. This section explores various avenues for obtaining essential elements for your specific model, ensuring you can keep your machinery running smoothly.Authorized Dealers One of the most reliable sources for quality components is through authorized dealers. These distributors typically offer original items that meet manufacturer specifications. In addition to new supplies, many authorized sellers provide access to service manuals and technical support, helping you make informed decisions about replacements.Online MarketplacesThe internet has revolutionized the way we shop for machinery components. Numerous online platforms specialize in offering a wide range of items, often at competitive prices. When using these platforms, ensure you check the seller’s ratings and reviews to confirm the quality of the offerings. Furthermore, many sites feature user-friendly search tools to help you locate the exact components you need.Ensuring Longevity of Your R23 Rake

One of the most reliable sources for quality components is through authorized dealers. These distributors typically offer original items that meet manufacturer specifications. In addition to new supplies, many authorized sellers provide access to service manuals and technical support, helping you make informed decisions about replacements.Online MarketplacesThe internet has revolutionized the way we shop for machinery components. Numerous online platforms specialize in offering a wide range of items, often at competitive prices. When using these platforms, ensure you check the seller’s ratings and reviews to confirm the quality of the offerings. Furthermore, many sites feature user-friendly search tools to help you locate the exact components you need.Ensuring Longevity of Your R23 Rake Maintaining the durability of your agricultural implement is essential for optimal performance and productivity. By implementing effective strategies for care and upkeep, you can significantly extend its lifespan and enhance its functionality. This section provides valuable insights into the practices that contribute to the long-term reliability of your equipment.Regular Maintenance PracticesRoutine inspections are crucial for identifying wear and tear before they escalate into significant issues. Regularly examine components for signs of damage or deterioration. Keeping the machinery clean and free of debris will not only improve its appearance but also prevent unnecessary strain on its mechanisms. Utilize appropriate lubricants to ensure smooth operation and reduce friction on moving parts.Proper Storage Techniques

Maintaining the durability of your agricultural implement is essential for optimal performance and productivity. By implementing effective strategies for care and upkeep, you can significantly extend its lifespan and enhance its functionality. This section provides valuable insights into the practices that contribute to the long-term reliability of your equipment.Regular Maintenance PracticesRoutine inspections are crucial for identifying wear and tear before they escalate into significant issues. Regularly examine components for signs of damage or deterioration. Keeping the machinery clean and free of debris will not only improve its appearance but also prevent unnecessary strain on its mechanisms. Utilize appropriate lubricants to ensure smooth operation and reduce friction on moving parts.Proper Storage Techniques Storing your implement correctly is vital in protecting it from harsh environmental conditions. Choose a dry, sheltered location to shield it from moisture, which can lead to rust and corrosion. Covering your equipment when not in use will provide an additional layer of protection against dust and debris. By taking these precautions, you can maintain the integrity of your machine and ensure its efficient operation for years to come.

Storing your implement correctly is vital in protecting it from harsh environmental conditions. Choose a dry, sheltered location to shield it from moisture, which can lead to rust and corrosion. Covering your equipment when not in use will provide an additional layer of protection against dust and debris. By taking these precautions, you can maintain the integrity of your machine and ensure its efficient operation for years to come.

| Main Section | Function |

|---|---|

| Frame Assembly | Provides the foundational support, holding the various elements together and ensuring stability during operation. |

| Wheel Mechanism | Facilitates smooth movement across different terrains, allowing efficient operation and handling. |

| Tine Bars | Responsible for the gathering and manipulation of material, ensuring precise control during the task. |