In the realm of mechanical systems, the efficiency of energy transfer is paramount. Various elements work in harmony to ensure smooth operation and optimal performance. A well-designed configuration can significantly enhance the functionality of machinery, making it essential for engineers and enthusiasts alike to grasp the intricacies involved.

Exploring the intricate relationships between various components reveals the underlying mechanics that drive performance. Each element plays a vital role in maintaining stability and precision, contributing to the overall effectiveness of the system. Analyzing these interconnections allows for a deeper appreciation of engineering principles and their practical applications.

This section aims to provide clarity on the essential components involved in this type of energy transmission. By breaking down the individual elements, we can better understand their purpose and how they contribute to the seamless operation of the entire system. Whether for maintenance, design, or improvement, a comprehensive overview of these features is invaluable for anyone engaged in mechanical design and engineering.

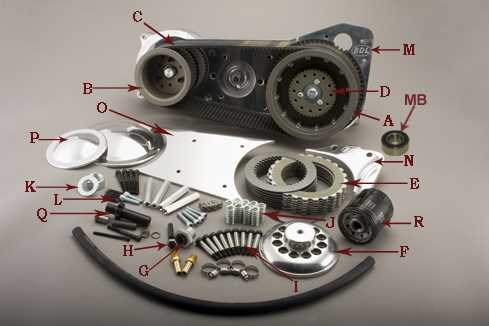

Bdl Belt Drive Overview

This section provides a comprehensive look at a crucial component in the realm of mechanical transmission systems. Understanding the functionality and structure of this assembly is essential for enthusiasts and professionals alike.

Key Features: The system is designed to enhance efficiency and performance in various applications, allowing for smoother operation and reduced wear. Its robust construction ensures longevity and reliability, making it a preferred choice in many setups.

Operational Insights: By delving into the mechanics, one can appreciate how this configuration minimizes friction and maximizes power transfer, ultimately contributing to a seamless experience. Regular maintenance and proper installation play pivotal roles in achieving optimal results.

Understanding Belt Drive Mechanics

The mechanism of power transmission using flexible loops plays a crucial role in various machinery and vehicles. This system efficiently transfers motion and energy from one component to another, ensuring smooth operation and reliable performance. By grasping the fundamentals of this technology, one can appreciate its significance in engineering and everyday applications.

Components and Functionality

At its core, this system comprises several essential elements that work in harmony. The primary components include a rotating element and the loop itself, which connects them. These parts interact to convert rotational energy, allowing for the transfer of torque and speed. Understanding how these elements function together is key to troubleshooting and optimizing performance.

Applications and Advantages

The versatility of this transmission method is evident in numerous industries, from automotive to manufacturing. Its flexibility allows for varying distances between components, making it adaptable for diverse configurations. Additionally, this approach often results in reduced noise levels and minimal maintenance requirements, offering significant benefits over other systems. Exploring its applications reveals the profound impact it has on modern technology.

Key Components of Bdl Systems

Understanding the essential elements of these mechanical systems is crucial for effective operation and maintenance. Each component plays a significant role in ensuring smooth functionality and longevity. Below, we outline the primary components that contribute to the overall performance.

Main Elements

- Motor: The engine provides the necessary power to initiate movement within the system.

- Couplings: These connectors link various parts, allowing for the transfer of torque and motion.

- Gears: Essential for modifying speed and torque, gears facilitate efficient energy transmission.

- Housings: Protective casings that house components, ensuring safety and preventing damage.

- Mounts: These support structures stabilize the assembly, minimizing vibrations and enhancing performance.

Additional Features

- Adjustment Mechanisms: Allow fine-tuning of tension and alignment for optimal operation.

- Lubrication Systems: Essential for reducing friction and wear between moving parts.

- Safety Devices: Include features like guards and sensors to prevent accidents and equipment failure.

- Connectors: Facilitate the integration of various components, ensuring seamless operation.

How to Read a Parts Diagram

Understanding an illustration that details components and their arrangements is essential for anyone involved in assembly or maintenance. This guide will help you navigate these visuals effectively, ensuring you grasp the relationships and functions of each element.

Here are some key steps to consider when interpreting these illustrations:

- Familiarize Yourself with the Symbols:

- Each symbol represents a different component or function.

- Look for a legend or key that explains the symbols used.

- Identify the Main Components:

- Locate the primary parts highlighted in the illustration.

- Note their connections and positions relative to each other.

- Understand the Flow or Sequence:

- Follow the lines or arrows that indicate movement or interaction.

- This will give insight into how the components work together.

- Refer to Additional Resources:

- Consult manuals or guides for further clarification.

- Look for video tutorials that can provide a visual walkthrough.

By following these steps, you’ll enhance your ability to decode any technical illustration, allowing for more efficient assembly and troubleshooting.

Common Issues with Belt Drives

Mechanical systems that utilize flexible connectors can encounter various challenges over time. Understanding these issues is essential for maintaining optimal performance and longevity. Regular inspection and proactive measures can prevent minor problems from escalating into major failures.

Wear and Tear

One of the most prevalent challenges involves the degradation of components due to constant friction and movement. This can lead to reduced efficiency and potential malfunction. Identifying signs of wear early can facilitate timely replacements, minimizing downtime and repair costs.

Misalignment

Another common issue is the misalignment of elements within the system. Even slight deviations can cause significant strain, resulting in uneven wear and increased noise levels. Proper alignment techniques and adjustments are crucial to ensure smooth operation and prolong the lifespan of the entire mechanism.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your system requires regular attention and care. Implementing effective maintenance practices can significantly enhance performance and reduce the risk of breakdowns. This section outlines essential tips to keep your equipment in top condition.

Regular Inspections

- Check for wear and tear on components regularly.

- Look for signs of misalignment or unusual vibrations.

- Inspect connectors and fasteners for tightness.

Cleaning and Lubrication

- Clean surfaces to prevent dust and debris buildup.

- Apply suitable lubricants to moving parts to minimize friction.

- Follow manufacturer recommendations for cleaning agents.

By adhering to these guidelines, you can ensure that your system operates smoothly and efficiently for years to come.

Upgrading Your Bdl Belt Drive

Enhancing your mechanical system can significantly improve performance and longevity. Upgrades not only boost efficiency but also contribute to smoother operation and reduced wear over time. Whether you’re looking to increase power output or enhance responsiveness, thoughtful modifications can make a substantial difference.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Transmission | High-performance gears | Improved torque and acceleration |

| Clutch | Lightweight materials | Enhanced responsiveness |

| System Alignment | Precision adjustments | Reduced friction and wear |

Investing in these enhancements can lead to the ultimate transformation of your setup, providing a better riding experience and improved reliability for years to come.

Choosing the Right Parts for Replacement

When it comes to ensuring optimal performance and longevity of your machine, selecting appropriate components for substitution is crucial. This section provides guidance on how to effectively navigate this process.

- Assess Compatibility: Ensure that the new components match the specifications of your existing setup.

- Quality Matters: Opt for high-quality materials that can withstand wear and tear.

- Consult Experts: Seek advice from professionals who have experience in the field.

- Consider Upgrades: Sometimes, newer options can enhance efficiency and performance.

By taking these factors into account, you can make informed decisions that contribute to the ultimate functionality of your equipment.