In the realm of aquatic maintenance, the intricate interplay of various elements plays a crucial role in ensuring optimal performance. Each piece is designed to work in harmony, contributing to the overall efficiency and longevity of the system. Recognizing the significance of each component can greatly enhance your understanding and management of pool care.

Diving into the specifics, one can discover a wealth of information regarding the individual parts and their functionalities. This knowledge empowers pool owners to identify potential issues and facilitate timely repairs, ultimately leading to a more enjoyable swimming experience. Grasping the layout of these essential elements is key for effective troubleshooting.

Whether you are a seasoned professional or a novice, familiarizing yourself with these mechanisms is the first step towards mastering your aquatic environment. By examining the intricate details, you can ensure that every aspect operates at its peak, paving the way for a pristine and inviting pool.

Understanding Hayward de 3600 Components

The intricate assembly of filtration systems plays a crucial role in maintaining optimal water quality. Each element within this system is designed to function in harmony with the others, ensuring efficiency and longevity. Grasping the purpose and functionality of these individual components is essential for effective maintenance and troubleshooting.

Filtration Media serves as the heart of the system, capturing impurities and particles. This material can vary in composition, affecting the overall performance and clarity of the water. Regular inspection and replacement of the media are vital to uphold filtration efficacy.

Flow Control Valves regulate the movement of water through the system. These mechanisms help manage pressure and flow rates, ensuring that the filtration process operates smoothly. Understanding their operation can aid in diagnosing flow issues and optimizing performance.

Manifold Assemblies play a significant role in distributing water evenly across the filtration media. They facilitate the effective removal of contaminants by maximizing contact with the filtration material. A well-functioning manifold is crucial for maintaining consistent water quality.

Pressure Gauges provide essential feedback regarding the system’s operational status. By monitoring pressure levels, users can determine when maintenance is required, preventing potential damage and ensuring efficient performance.

Cleaning Systems enhance the longevity of the filtration components. They are designed to remove accumulated debris and maintain optimal flow. Regular use of these systems contributes significantly to the overall health of the water treatment setup.

In conclusion, a comprehensive understanding of these essential components fosters better maintenance practices and extends the lifespan of the entire filtration assembly. By familiarizing oneself with the roles and functionalities of each part, users can ensure their systems remain efficient and effective.

Overview of Hayward de 3600 System

This section explores a sophisticated filtration system designed to enhance water clarity and quality. Its innovative design and functionality make it a popular choice for pool maintenance.

- Efficient Filtration: The unit utilizes advanced filtering elements to remove impurities effectively.

- Durable Construction: Crafted from high-quality materials, ensuring longevity and reliability.

- Easy Maintenance: The system is designed for user-friendly upkeep, facilitating straightforward cleaning and servicing.

Understanding this system’s components and their roles can help users maximize performance and efficiency.

Key Features of Hayward de 3600

This section explores the essential attributes of a leading filtration system, designed to enhance pool maintenance and ensure optimal water clarity. Its advanced engineering provides users with an efficient and reliable solution for maintaining pristine aquatic environments.

Efficiency and Performance

- High flow rate for quick filtration

- Durable construction ensuring longevity

- Effective removal of debris and contaminants

User-Friendly Design

- Easy access for maintenance and cleaning

- Clear instructions for straightforward installation

- Compact size for versatile placement

Common Issues with Hayward de 3600

In any filtration system, several common problems can arise, affecting performance and efficiency. Recognizing these issues early can prevent further complications and ensure smooth operation.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Clogged Filter | Reduced water flow, increased pressure | Clean or replace the filter media |

| Leaking Connections | Water pooling, damp areas | Tighten or replace seals and fittings |

| Poor Water Clarity | Cloudy or discolored water | Check chemical balance and clarify |

| Noisy Operation | Unusual sounds during operation | Inspect for debris and lubricate components |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. Adopting a proactive approach can significantly enhance functionality and prevent unexpected issues. Here are some essential strategies to maintain optimal performance and extend the lifespan of your system.

Regular Cleaning

Consistent cleaning of components is crucial for preventing debris buildup that can impede operation. Remove any dirt or particles that accumulate on the surface and within internal mechanisms. Utilize appropriate cleaning agents and tools to avoid damage while ensuring all parts are free from contaminants.

Routine Inspections

Conducting periodic inspections helps identify wear and tear before they escalate into major problems. Check for any signs of deterioration, loose connections, or irregular functioning. Timely detection allows for prompt repairs or replacements, minimizing downtime and enhancing overall efficiency.

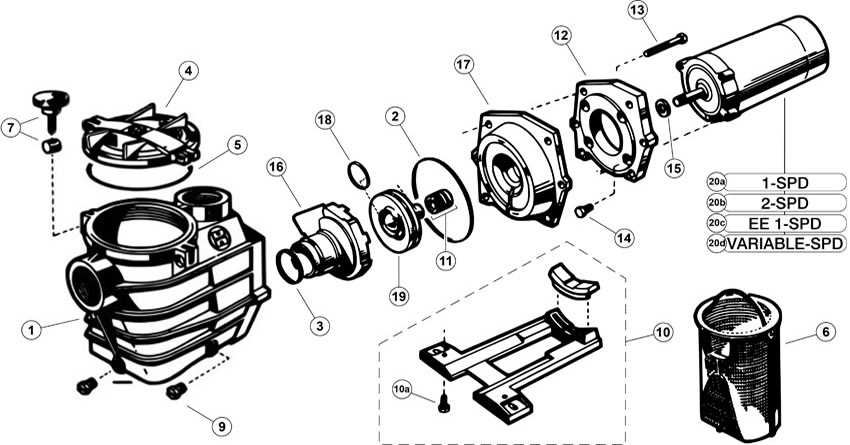

How to Interpret the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and troubleshooting. These illustrations serve as valuable guides, helping users to identify various elements and their interrelations. Familiarity with the layout can streamline repairs and enhance overall efficiency.

Begin by examining the legend or key, which often highlights the symbols used within the visual. Each symbol corresponds to a specific component, allowing for quick identification. Pay attention to the arrangement of these elements, as it often reflects their physical layout within the system.

Next, look for any numbering or labeling that provides further details about each part. This information can be essential when ordering replacements or seeking assistance. Ensure to cross-reference with any accompanying documentation, which may offer additional insights or specifications relevant to the components.

Finally, take note of any connections or pathways indicated in the illustration. Understanding how different parts interact can aid in diagnosing issues more effectively. A comprehensive grasp of this visual representation can empower users to maintain their systems with confidence and accuracy.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a straightforward task if you know where to look. Several reliable sources offer a wide variety of items, ensuring you can maintain optimal performance.

- Manufacturer’s Website: Start with the official site of the manufacturer. They often provide a comprehensive catalog of components, along with specifications and compatibility information.

- Authorized Dealers: Visit local or online dealers who are authorized to sell the brand’s products. These dealers typically have access to a complete inventory and can assist with specific inquiries.

- Online Marketplaces: Platforms like Amazon and eBay can be great resources. Look for trusted sellers with good ratings to ensure quality.

- Specialty Stores: Local hardware or pool supply stores may stock specific items or be able to order them for you.

- Second-hand Options: Consider checking classified ads or thrift shops for used components that might fit your needs.

By exploring these avenues, you can efficiently locate the necessary items to keep your system running smoothly.

DIY Repair Guide for Common Problems

When it comes to maintaining your equipment, understanding common issues and their solutions can save both time and money. Many users encounter similar challenges, and a little knowledge can empower you to tackle these repairs yourself. This guide will help you identify frequent problems and provide step-by-step instructions to resolve them effectively.

Identifying Common Issues

Before diving into repairs, it’s crucial to pinpoint the specific problem. Below are some frequent symptoms and their possible causes:

| Symptom | Possible Cause |

|---|---|

| Unusual Noises | Loose components or worn bearings |

| Poor Performance | Clogged filters or low fluid levels |

| Leaks | Deteriorated seals or loose fittings |

Step-by-Step Repair Instructions

Once you have identified the issue, follow these general steps to conduct repairs:

1. Gather Your Tools: Ensure you have the necessary tools such as screwdrivers, wrenches, and replacement parts.

2. Safety First: Disconnect power sources and ensure the area is safe to work in.

3. Disassemble Carefully: Take apart the affected components, noting their arrangement for reassembly.

4. Inspect and Replace: Examine parts for damage and replace as necessary. Be sure to clean any debris.

5. Reassemble: Put everything back together following the notes you made during disassembly.

6. Test Your Work: Reconnect power and test the equipment to ensure the issue has been resolved.

By understanding common issues and following these repair steps, you can maintain your equipment efficiently and effectively.

Expert Recommendations for Best Practices

Implementing optimal strategies in maintenance and operation can significantly enhance the longevity and efficiency of your equipment. Adhering to best practices not only ensures reliable performance but also minimizes potential issues that could arise from neglect. Below are some key recommendations to follow for effective management.

Regular Maintenance

- Establish a routine inspection schedule to identify any wear or damage early.

- Clean components regularly to prevent build-up that can lead to inefficiencies.

- Replace worn parts promptly to avoid more significant issues down the line.

Proper Usage

- Follow manufacturer guidelines for operation to ensure optimal performance.

- Avoid overloading equipment to prevent unnecessary strain and potential failure.

- Use only recommended accessories and add-ons to maintain system integrity.

By adhering to these expert recommendations, you can significantly enhance the performance and reliability of your systems, ensuring they operate at their best for years to come.