When it comes to maintaining an efficient aquatic environment, grasping the intricacies of vital machinery is essential. The components of these systems work in harmony to ensure optimal performance and longevity. Familiarity with each element can significantly enhance operational efficiency and facilitate troubleshooting.

In this exploration, we will delve into the various elements that constitute these essential systems. Recognizing the ultimate purpose of each part will empower users to make informed decisions regarding maintenance and repairs. A comprehensive overview will not only demystify the inner workings but also promote a deeper appreciation for the technology involved.

Moreover, understanding these components can help in identifying potential issues before they escalate into costly problems. With a clear grasp of how each section functions, users can ensure their aquatic environment remains inviting and enjoyable year-round. This guide aims to illuminate the path toward a more effective and reliable system.

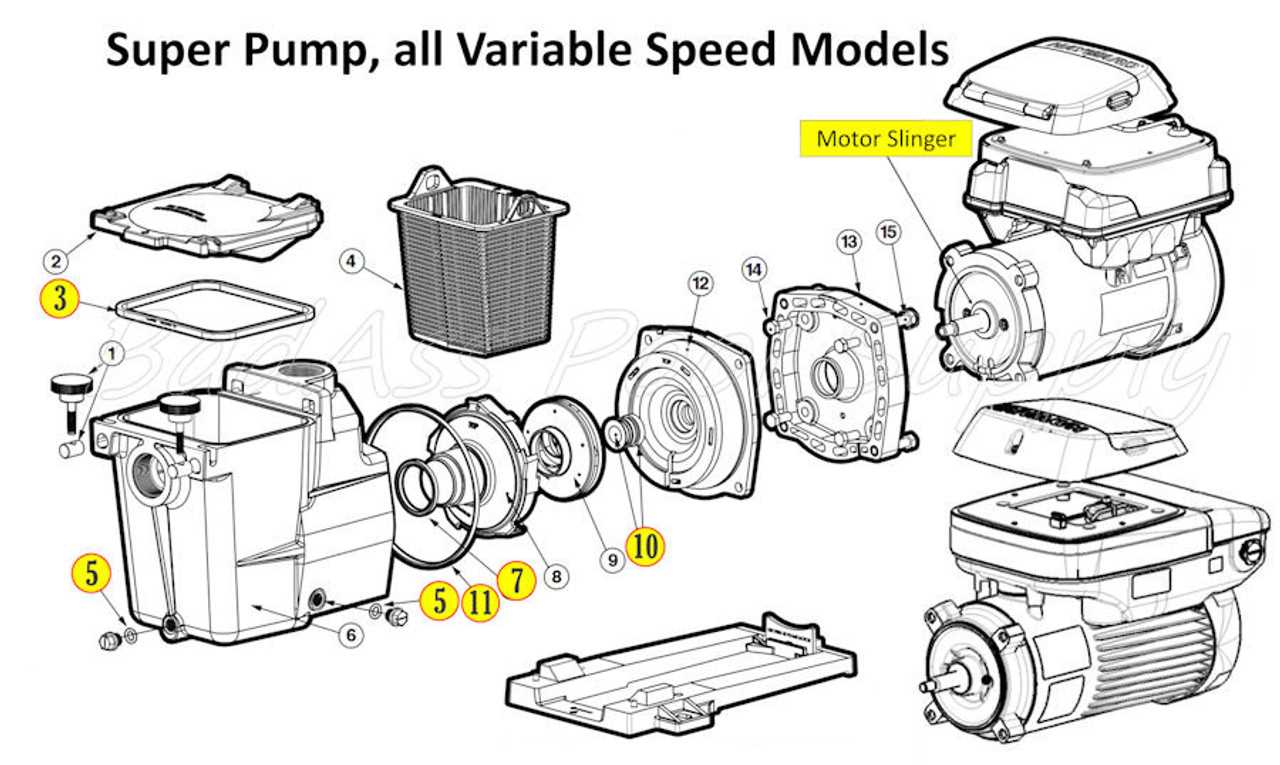

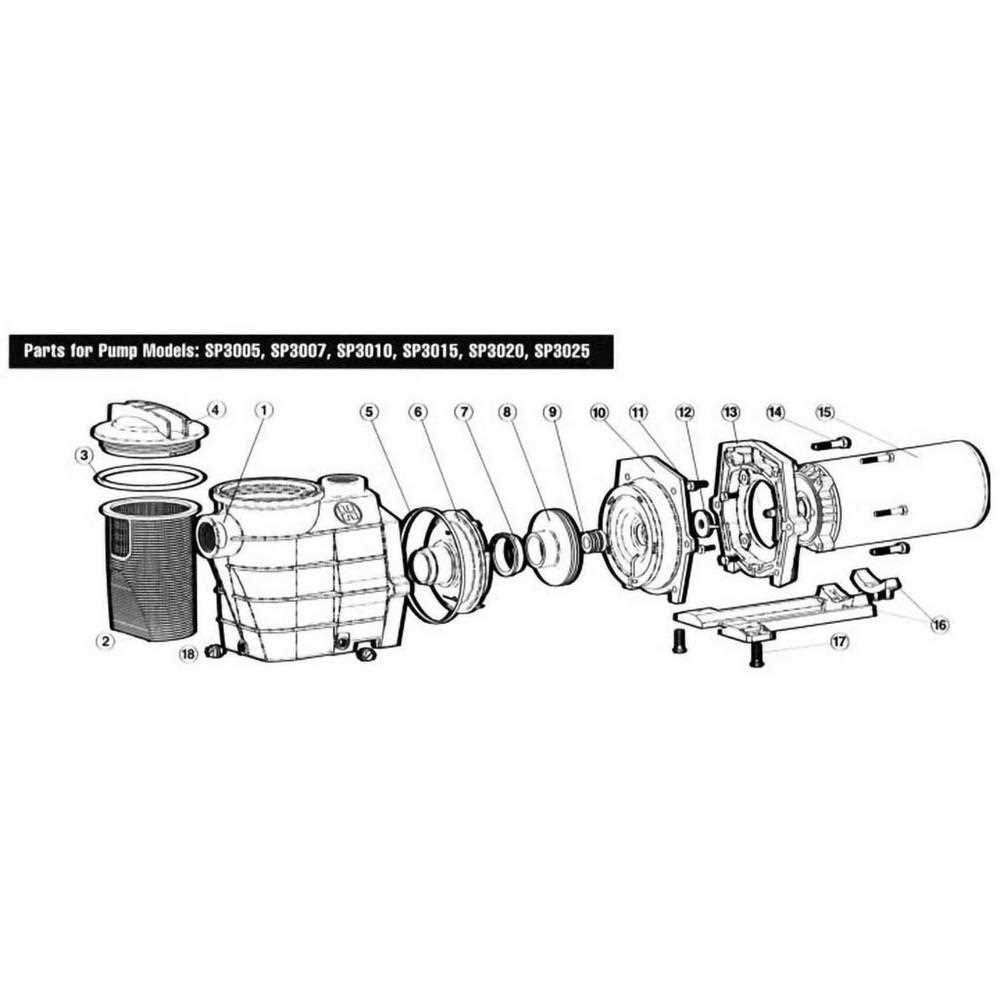

Understanding Hayward Super Pump Components

Comprehending the various elements that make up a water circulation system is essential for effective maintenance and optimal performance. Each component plays a significant role in ensuring smooth operation, enhancing efficiency, and prolonging the lifespan of the entire unit. By familiarizing yourself with these integral parts, you can better address any issues that may arise and ensure your system runs effectively.

Main Elements of the System

The core components of the system typically include the motor, volute, strainer basket, and impeller. Each of these plays a crucial role in water movement and filtration, which are essential for maintaining clean and clear water in your pool or spa.

Component Functions

| Component | Function |

|---|---|

| Motor | Drives the entire system, providing the necessary power for operation. |

| Volute | Channels the water flow efficiently from the impeller. |

| Strainer Basket | Traps debris and prevents it from entering the system. |

| Impeller | Creates the water flow necessary for circulation. |

Understanding these elements not only aids in troubleshooting but also enhances your ability to perform routine checks and maintenance, ultimately contributing to a well-functioning system.

Importance of Pump Diagrams for Maintenance

Understanding the layout and components of a fluid-moving device is crucial for effective upkeep and repair. Detailed visual representations serve as invaluable tools, enabling technicians to quickly identify elements, troubleshoot issues, and execute necessary maintenance procedures. By providing a clear overview, these illustrations enhance efficiency and accuracy in handling mechanical systems.

Facilitating Troubleshooting: Having a comprehensive visual guide allows for swift recognition of potential problems. When an issue arises, technicians can easily refer to the schematic to locate the affected sections, thereby minimizing downtime and streamlining the repair process.

Ensuring Proper Reassembly: After maintenance is performed, reassembling a system can be a complex task. Visual references help technicians ensure that every component is correctly positioned, reducing the risk of misalignment or improper installation that could lead to further complications.

Enhancing Training: For those new to the field, these illustrations provide an educational tool that promotes understanding of the intricate workings of fluid systems. They can assist in building foundational knowledge, which is essential for effective maintenance and operation.

In conclusion, visual representations of mechanical systems play a vital role in maintenance, ensuring efficiency, accuracy, and a deeper understanding of the equipment involved.

Common Issues with Super Pump Parts

Maintaining efficient operation in pool systems often involves addressing various challenges related to their components. Identifying and resolving these issues is crucial for optimal functionality and longevity of the equipment.

- Leakage: A frequent problem arises from seals and gaskets wearing out, leading to water loss. Regular inspections can help catch these issues early.

- Noisy Operation: Unusual sounds during operation might indicate worn bearings or debris in the motor. Cleaning and lubrication can often alleviate this.

- Reduced Flow Rate: A decline in water flow can stem from clogged filters or obstructions in the intake. Regular maintenance of these areas is essential.

- Electrical Issues: Malfunctions in the motor may result from electrical connections or faulty capacitors. Checking wiring and replacing faulty components can resolve these issues.

- Overheating: Excessive heat can damage internal components, often caused by insufficient water flow or a malfunctioning motor. Monitoring operational temperature is important.

By recognizing these common challenges, users can take proactive measures to ensure their equipment remains in top condition.

How to Identify Pump Components

Understanding the various elements of a circulating system is crucial for effective maintenance and troubleshooting. Familiarity with each component allows users to recognize issues and ensure optimal functionality. Below, we outline how to identify these essential elements in any circulation mechanism.

Main Elements of a Circulating System

- Motor: The driving force behind the operation, converting electrical energy into mechanical motion.

- Impeller: A rotating component that moves fluid through the system, increasing flow rate and pressure.

- Volute: The chamber that directs fluid from the impeller to the discharge pipe, optimizing flow efficiency.

- Seal: Prevents leaks and protects internal parts from corrosion and wear.

- Strainer: Captures debris and prevents blockages in the flow path.

- Base: The foundation that supports all components, ensuring stability during operation.

Identification Tips

- Visual Inspection: Examine each part for wear, cracks, or corrosion.

- Consult Documentation: Refer to manuals or online resources for diagrams and specifications.

- Ask for Assistance: Engage with professionals or online communities for insights and advice.

- Utilize Tools: Use gauges and meters to test performance and diagnose issues effectively.

By familiarizing yourself with these components and tips, you will enhance your ability to maintain and troubleshoot your circulation system efficiently.

Tips for Replacing Pump Parts

Replacing components of your circulation system can enhance efficiency and prolong its lifespan. Understanding a few essential guidelines can streamline the process and ensure optimal performance after installation.

Preparation Steps

- Turn off the power supply to the unit to avoid accidents.

- Gather all necessary tools and replacement components before starting.

- Consult the user manual for specific instructions related to your model.

Installation Guidelines

- Carefully remove the old component, noting the orientation and connections for reference.

- Clean the area where the new part will be installed to ensure a proper fit.

- Install the new component, securing it tightly but avoiding over-tightening.

- Reconnect any hoses or wiring, ensuring there are no leaks or loose connections.

- Restore power and test the system to confirm everything is functioning smoothly.

Choosing Quality Replacement Components

When it comes to maintaining your equipment, selecting high-grade replacement elements is crucial for ensuring longevity and optimal performance. Quality components not only enhance efficiency but also reduce the likelihood of future breakdowns. This section will guide you in making informed choices that lead to better operational outcomes.

Key Considerations for Selection

- Material Quality: Look for components made from durable materials that can withstand various environmental conditions.

- Compatibility: Ensure that the replacements are compatible with your existing setup to avoid installation issues.

- Manufacturer Reputation: Choose products from reputable brands known for their reliability and customer support.

Benefits of Investing in Quality

- Increased Lifespan: High-quality components tend to last longer, minimizing the need for frequent replacements.

- Enhanced Efficiency: Superior elements often operate more effectively, leading to improved performance.

- Cost Savings: Although initial investment may be higher, the reduction in maintenance and replacement costs over time makes it worthwhile.

By focusing on these aspects, you can ensure that your selection of replacement components contributes positively to the overall functionality and reliability of your system.

Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues related to your filtration system. Understanding the potential problems can help you maintain optimal performance and ensure longevity.

Common Issues and Solutions

- Inadequate Water Flow:

- Check for clogs in the skimmer or pump strainer.

- Inspect the impeller for obstructions.

- Ensure that the valves are set correctly.

- Strange Noises:

- Listen for rattling sounds, indicating loose components.

- Examine for worn bearings that may need replacement.

- Ensure the unit is installed on a level surface.

- Leaking Water:

- Check for loose fittings and tighten them as needed.

- Inspect the seals and gaskets for wear or damage.

- Look for cracks in the housing that may require replacement.

Preventative Measures

- Regularly clean the strainer basket to prevent debris buildup.

- Inspect hoses and connections for wear at least once a month.

- Schedule annual maintenance to identify issues before they escalate.

By following this guide, you can troubleshoot effectively and keep your filtration system running smoothly.

Benefits of Regular Pump Inspections

Regular evaluations of your water circulation system offer numerous advantages that enhance efficiency and longevity. By proactively identifying issues, you can ensure optimal performance and reduce the likelihood of unexpected breakdowns.

- Increased Efficiency: Routine checks help maintain peak operational performance, leading to lower energy consumption.

- Prolonged Lifespan: Regular maintenance can extend the life of your equipment by addressing minor issues before they escalate.

- Cost Savings: Early detection of problems often results in lower repair costs compared to emergency fixes.

- Enhanced Safety: Inspections ensure that the system operates safely, minimizing risks of leaks or malfunctions.

- Improved Water Quality: A well-maintained system contributes to cleaner and healthier water, benefiting both users and the environment.

Incorporating scheduled assessments into your routine can lead to a more reliable and efficient system, ultimately providing peace of mind and better performance.

Resources for Hayward Pump Owners

Maintaining and optimizing your water circulation system is essential for ensuring longevity and efficiency. Various resources are available to assist users in troubleshooting, enhancing performance, and obtaining necessary components for their equipment. This section outlines useful tools and references to support your maintenance journey.

Essential Online Resources

- User Forums – Engage with a community of enthusiasts to share experiences and solutions.

- Product Manuals – Access detailed guides and instructions for setup and upkeep.

- Video Tutorials – Watch step-by-step guides for repairs and maintenance tasks.

- Customer Support – Reach out to experts for personalized assistance and advice.

Replacement Component Suppliers

- Parts Store – A comprehensive selection of necessary components and accessories.

- Local Retailers – Find nearby stores that stock essential items for quick purchases.

- Discount Websites – Explore budget-friendly options for obtaining quality replacements.