When it comes to maintaining and enhancing the efficiency of agricultural machinery, having a clear overview of its individual components is essential. This section aims to provide insights into the intricate workings of a specific model, shedding light on how each element contributes to overall performance.

Exploring the intricacies of machinery not only aids in troubleshooting but also empowers operators to make informed decisions regarding upgrades and repairs. A comprehensive understanding of these elements can significantly enhance the longevity and reliability of your equipment.

In the following sections, we will delve into the various segments of this particular machine, providing visual aids and detailed explanations to ensure clarity and facilitate effective maintenance practices. Whether you are a seasoned operator or a novice, this guide aims to be your ultimate resource.

Understanding John Deere 2320 Components

Grasping the intricacies of machinery is essential for effective maintenance and operation. Every machine consists of various elements that work harmoniously to ensure optimal performance. Familiarity with these components can enhance both the longevity and efficiency of the equipment.

Key Elements of the Machinery

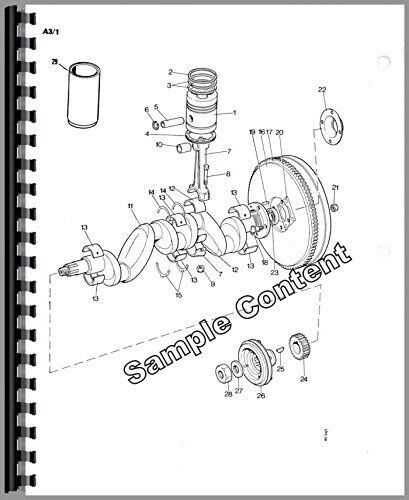

- Engine: The heart of the equipment, responsible for generating power.

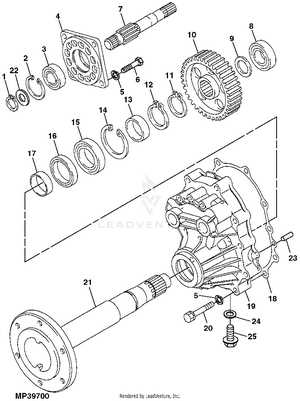

- Transmission: Facilitates the transfer of power from the engine to the wheels.

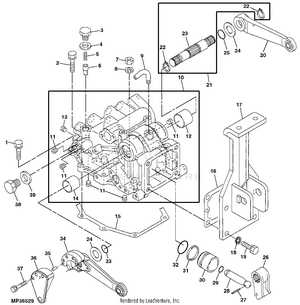

- Hydraulic System: Vital for enabling various functions, such as lifting and steering.

- Chassis: The frame that supports all other components.

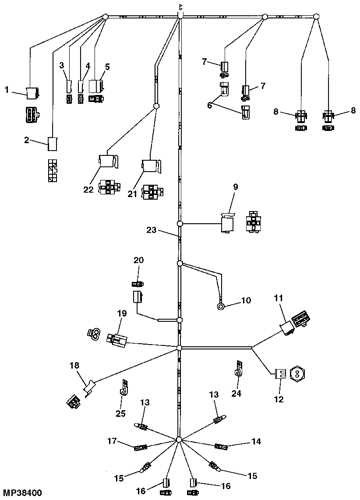

- Electrical System: Powers lights, instruments, and electronic controls.

Maintenance Considerations

- Regular Inspection: Frequent checks can identify potential issues early.

- Fluid Levels: Maintaining appropriate fluid levels is crucial for smooth operation.

- Filter Changes: Timely replacements of filters can prevent damage to the engine.

- Wear Parts: Keep an eye on components that are prone to wear and tear.

Understanding these vital parts and their functions empowers operators to ensure their machinery remains in peak condition, ultimately leading to enhanced performance and reliability.

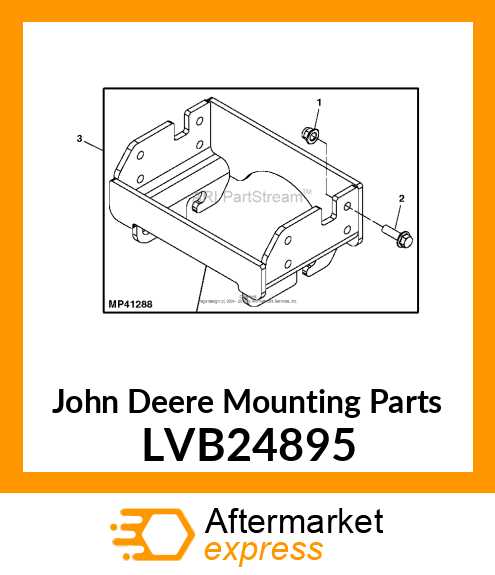

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of these components play a crucial role in ensuring that technicians can quickly identify and address issues. These illustrations not only enhance comprehension but also streamline the repair process.

Benefits of Visual Representations

- Enhanced Clarity: Detailed visuals help in distinguishing between various components, making it easier to locate specific items during maintenance.

- Time Efficiency: By providing a quick reference, these illustrations reduce the time spent searching for parts, allowing for quicker repairs.

- Accurate Reassembly: Clear visuals guide users through the correct assembly of machinery, minimizing errors that could lead to further complications.

Facilitating Knowledge Transfer

- Training Tool: These illustrations serve as valuable resources for training new technicians, enabling them to understand complex systems more easily.

- Improved Communication: Visual aids foster better communication among team members, allowing them to discuss repairs with a common reference point.

- Documentation: Having a visual guide provides a permanent record of machinery components, aiding in future maintenance and upgrades.

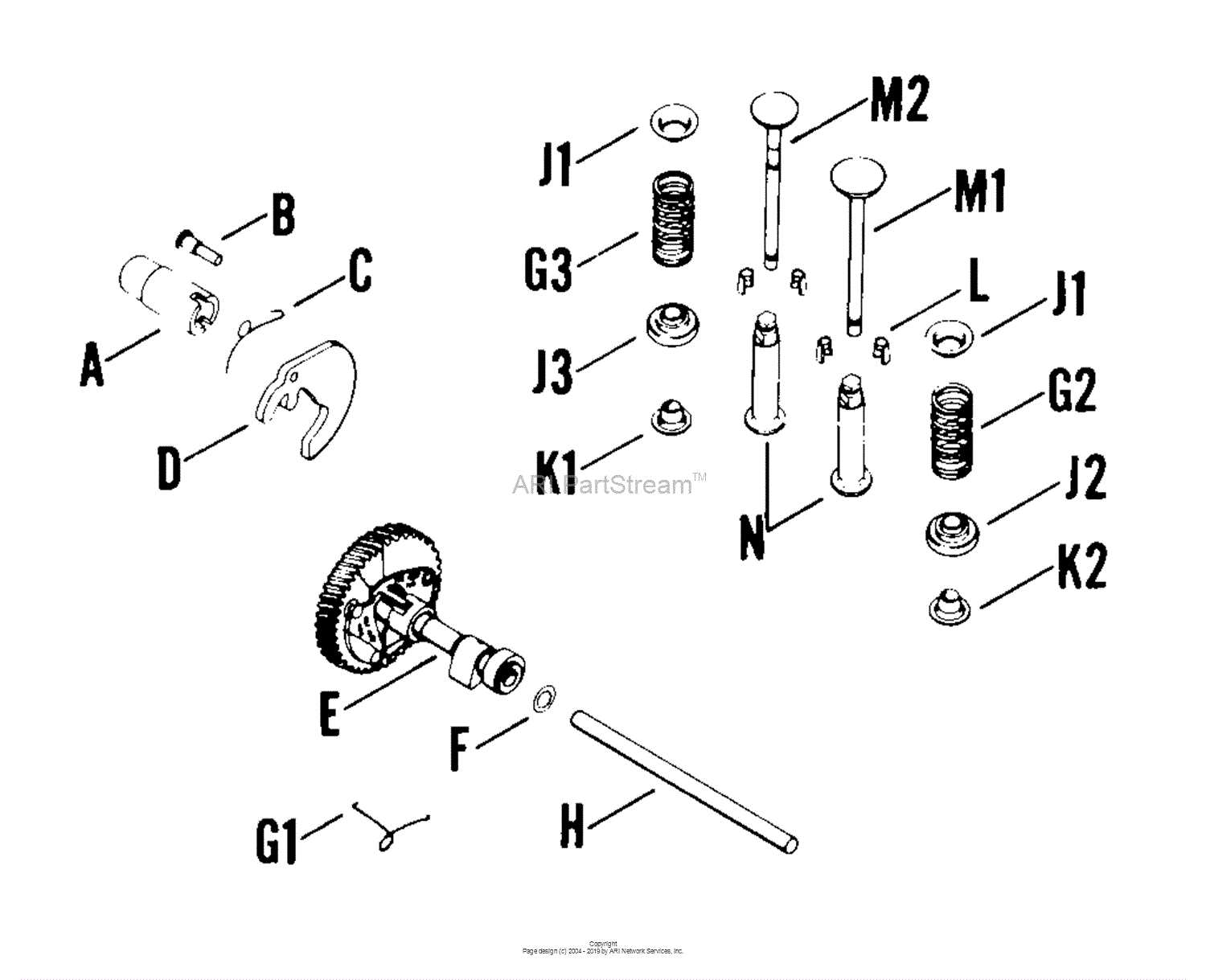

Identifying Key Machinery Elements

Understanding the critical components of agricultural equipment is essential for effective maintenance and operation. Each part plays a vital role in ensuring optimal performance, and recognizing these elements can significantly enhance the efficiency of the machinery.

Core Components

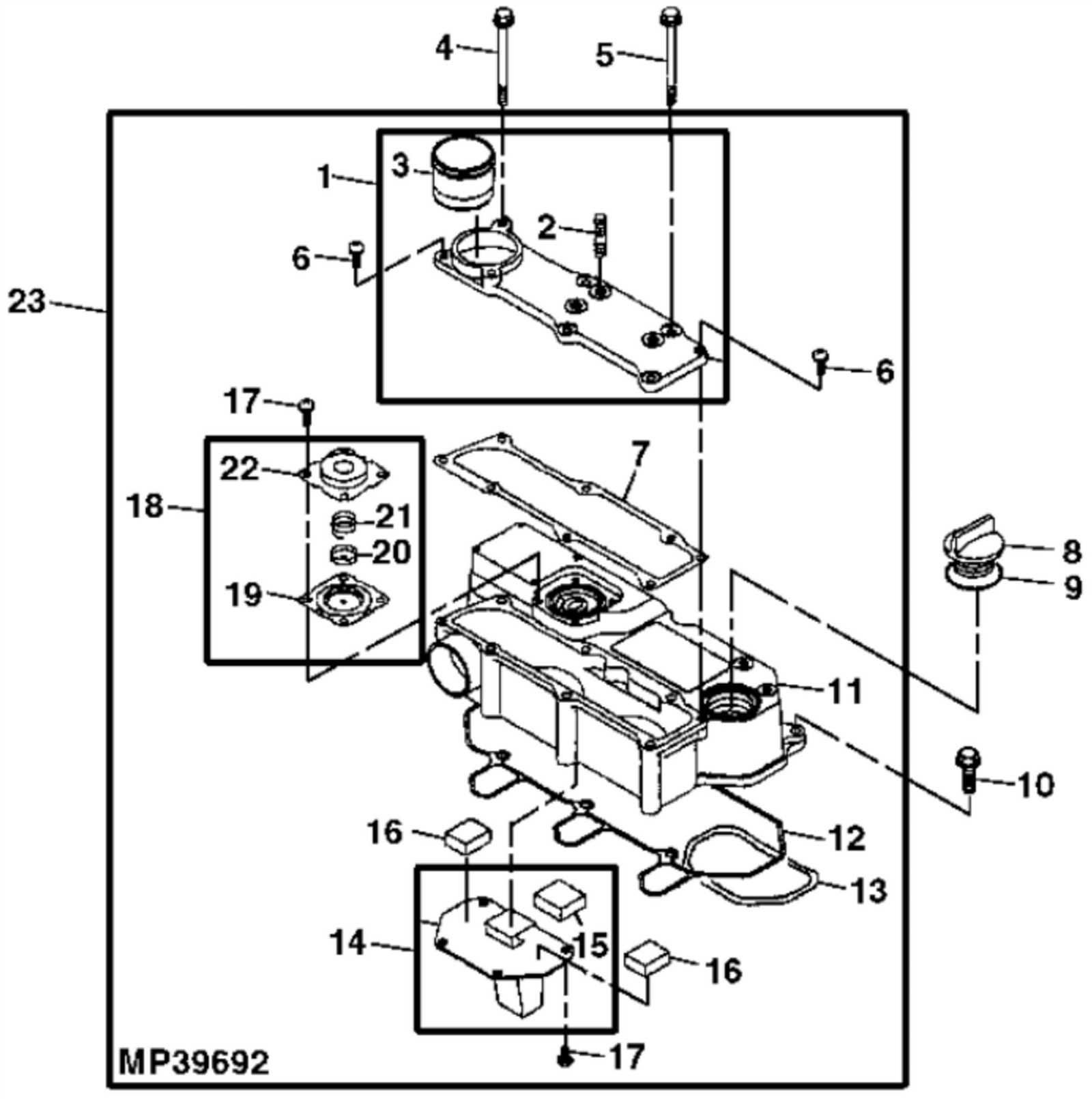

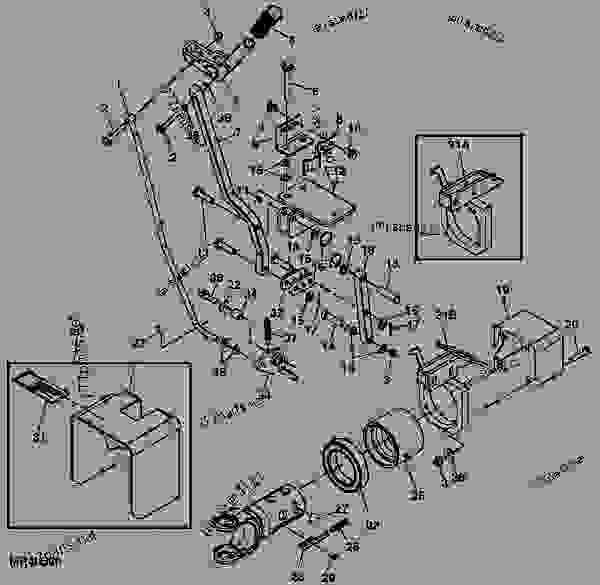

Machinery is typically composed of several core components, including the engine, transmission, and hydraulic systems. Each of these elements contributes to the overall functionality, with the engine providing power, the transmission facilitating movement, and the hydraulic systems enabling various operational tasks. Familiarizing oneself with these parts can help operators troubleshoot issues more effectively.

Maintenance Considerations

Regular upkeep of machinery is crucial to extend its lifespan and maintain peak performance. Key areas to monitor include wear and tear on moving parts, fluid levels, and the condition of belts and hoses. Proactive maintenance not only prevents costly repairs but also ensures that the equipment operates at its best during peak seasons. Understanding how to identify these elements and their specific functions can empower users to take better care of their machinery.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task, but understanding the best sources can streamline the process significantly. Whether you are seeking original manufacturer items or high-quality alternatives, various avenues are available to ensure you find what you need efficiently.

Authorized Dealers: One of the most reliable options is to visit authorized dealerships. These establishments typically offer genuine components that are specifically designed for your equipment, ensuring compatibility and performance. Furthermore, the staff at these locations can provide valuable insights and recommendations based on your specific requirements.

Online Retailers: The internet is a treasure trove of resources. Numerous online platforms specialize in equipment components, allowing you to compare prices and availability easily. Websites often provide detailed descriptions and customer reviews, making it simpler to make informed decisions.

Local Repair Shops: Community repair shops can be excellent sources for replacement items. These businesses often have access to a variety of components and may even stock used or refurbished options at a lower cost. Additionally, the technicians can offer personalized advice based on their experience with similar machinery.

Manufacturer Websites: Visiting the official website of the equipment manufacturer can provide direct access to a catalog of available components. Many manufacturers offer online ordering options, making it convenient to purchase what you need without leaving your home.

Auctions and Classifieds: Don’t overlook local auctions and classified ads, as they can yield valuable finds. Many sellers offer surplus or gently used items at competitive prices. Engaging with local farming or machinery communities can also lead to helpful recommendations for sources.

By exploring these diverse channels, you can ensure that your machinery remains in optimal working condition without undue hassle.

Common Issues with John Deere 2320

Tractors of this type often encounter several challenges that can affect their performance and reliability. Understanding these common problems can help operators maintain their machinery more effectively and avoid costly repairs.

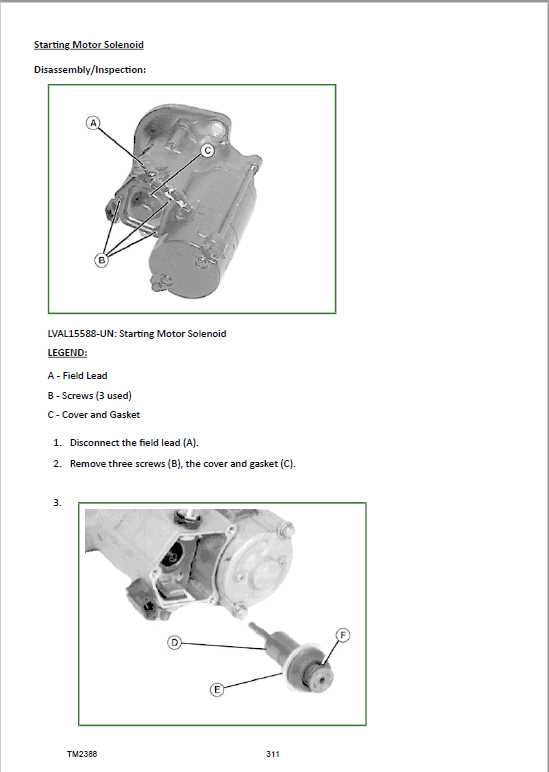

Engine Performance: One frequent issue is related to engine performance. Users may experience rough idling or stalling, which can often be traced back to fuel system problems, such as clogged filters or faulty injectors. Regular maintenance and timely inspections can mitigate these issues.

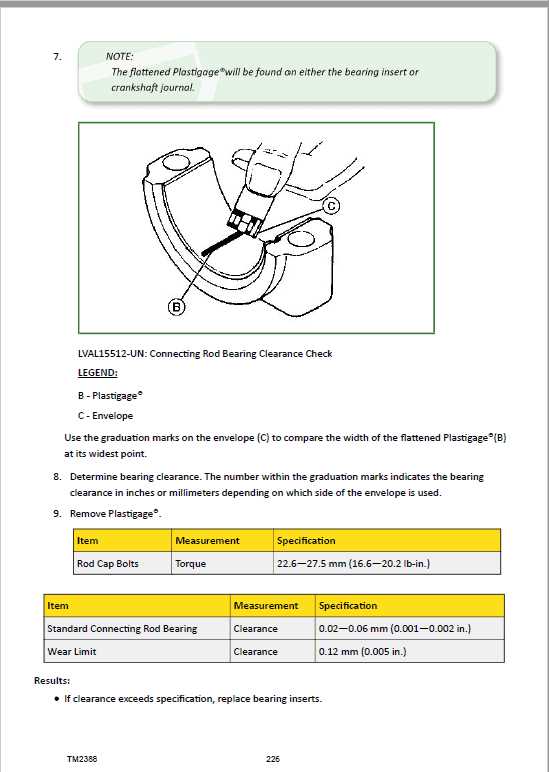

Hydraulic System Failures: Another area of concern is the hydraulic system. Leaks in hoses or seals can lead to a drop in pressure, affecting the tractor’s lifting capacity. Operators should routinely check for signs of wear and tear and address any leaks immediately to maintain optimal function.

Transmission Problems: Transmission issues can also arise, resulting in difficulties when shifting gears. This can be caused by low fluid levels or internal wear. Ensuring proper fluid levels and regular service can help prevent more serious complications.

Electrical Failures: Lastly, electrical systems may present challenges, including battery drainage or malfunctioning lights. Corroded connections and worn-out components can contribute to these problems. Keeping the electrical system clean and regularly inspecting wiring can help ensure reliable operation.

Addressing these common issues proactively can lead to a smoother operating experience and extend the life of the machinery.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent attention and care. Regular upkeep not only enhances performance but also extends the lifespan of vital components. By adopting a few key practices, you can significantly reduce the risk of costly repairs and improve overall efficiency.

1. Regular Inspections: Conduct frequent checks on all mechanical systems to identify potential issues before they escalate. Pay close attention to wear and tear, as early detection can save time and resources.

2. Fluid Maintenance: Keep an eye on all fluid levels, including oil, coolant, and hydraulic fluids. Regularly change these fluids as recommended to ensure optimal operation and prevent damage from contaminants.

3. Cleanliness is Key: Maintain a clean working environment for your equipment. Remove dirt and debris from filters, screens, and engine components to enhance airflow and efficiency.

4. Proper Lubrication: Apply the appropriate lubricants to moving parts to reduce friction and wear. Refer to the manufacturer’s guidelines to choose the right products and intervals for lubrication.

5. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule provided by the manufacturer. This includes timely replacements of filters, belts, and other essential components.

6. Operator Training: Ensure that all operators are well-trained in the proper use and handling of the equipment. Knowledgeable operators are less likely to cause damage due to misuse or negligence.

Implementing these strategies will contribute to the longevity of your machinery, ensuring it remains reliable and efficient for years to come.

Compatibility with Other Models

When considering machinery, understanding how various models interconnect is crucial for optimal performance and maintenance. Many units share components that enhance versatility and streamline repairs. This section explores the compatibility of a specific model with others in the same lineup, facilitating informed decisions for users.

Interchangeable Components

Numerous elements across different models can be interchangeable, allowing for greater flexibility in repairs and upgrades. This compatibility often extends to attachments, engines, and drivetrain parts, ensuring that users can find suitable replacements without being restricted to a single model. Below is a summary of compatible components across selected models:

| Model | Compatible Parts |

|---|---|

| Model A | Engine components, transmission parts |

| Model B | Hydraulic systems, control units |

| Model C | Chassis, electrical systems |

Advantages of Compatibility

Utilizing components from various models can significantly reduce downtime and repair costs. Users benefit from enhanced availability of parts and can often find more cost-effective solutions through alternative sources. Understanding these relationships enables operators to maintain equipment efficiently and effectively.

Upgrading Your Equipment Efficiently

Enhancing your machinery can significantly improve performance and productivity. By focusing on systematic upgrades, you can ensure that each component works harmoniously, leading to optimal results and reduced downtime.

Assessing Your Current Setup

Before initiating any upgrades, it’s essential to evaluate your existing equipment. Identify areas that require improvement and prioritize components that will yield the greatest benefits.

Choosing the Right Components

Select high-quality replacements that fit seamlessly with your current setup. Consider factors such as durability, compatibility, and efficiency when making your choices.

| Component | Benefits | Considerations |

|---|---|---|

| Engine | Increased power and efficiency | Ensure compatibility with existing systems |

| Hydraulics | Improved lifting capacity | Check fluid requirements |

| Transmission | Smoother operation | Verify gear ratios |