In the realm of outdoor machinery, comprehending the various elements that contribute to optimal performance is essential for effective maintenance and repair. This knowledge not only ensures longevity but also enhances functionality, enabling users to tackle landscaping tasks with confidence. A thorough grasp of the individual components can lead to improved efficiency and reduced downtime.

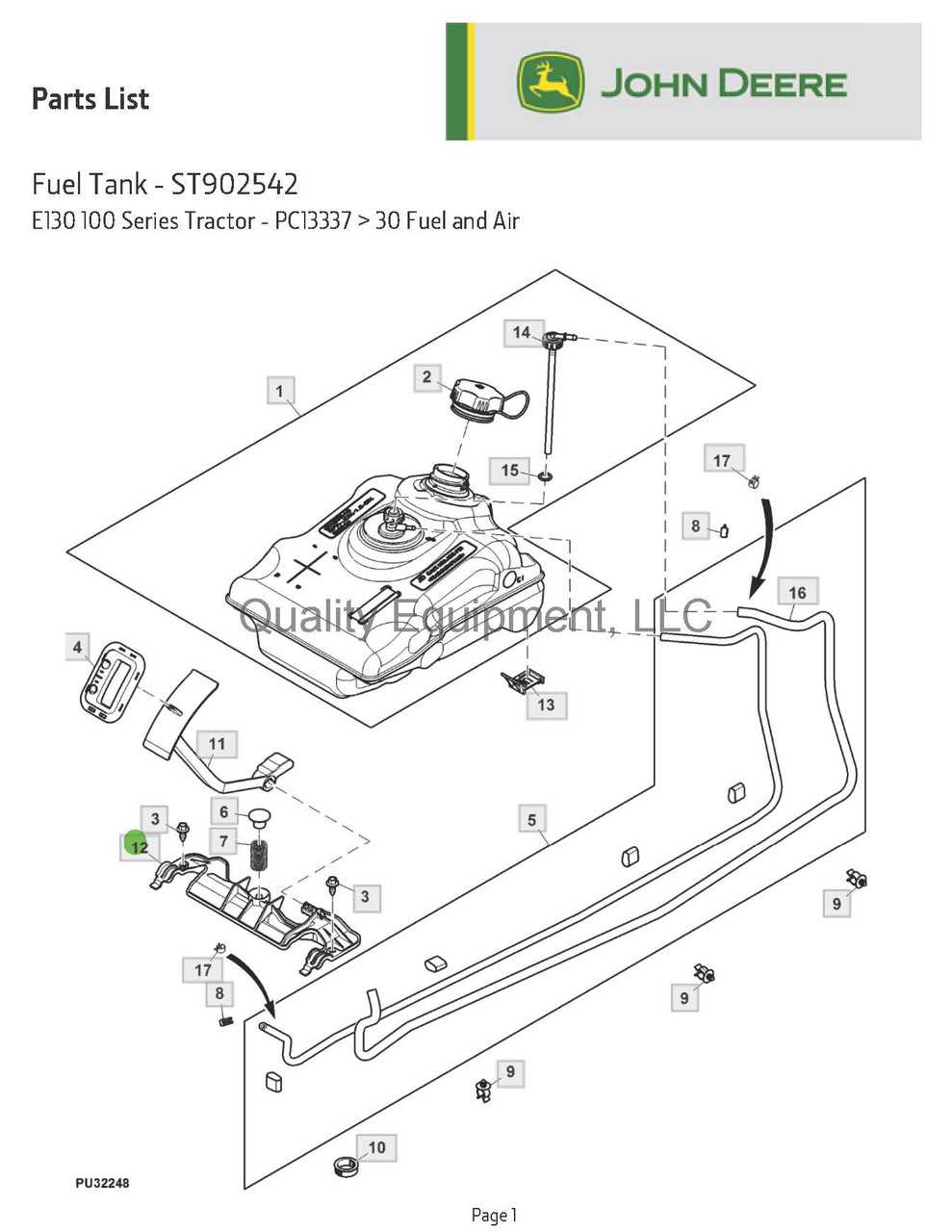

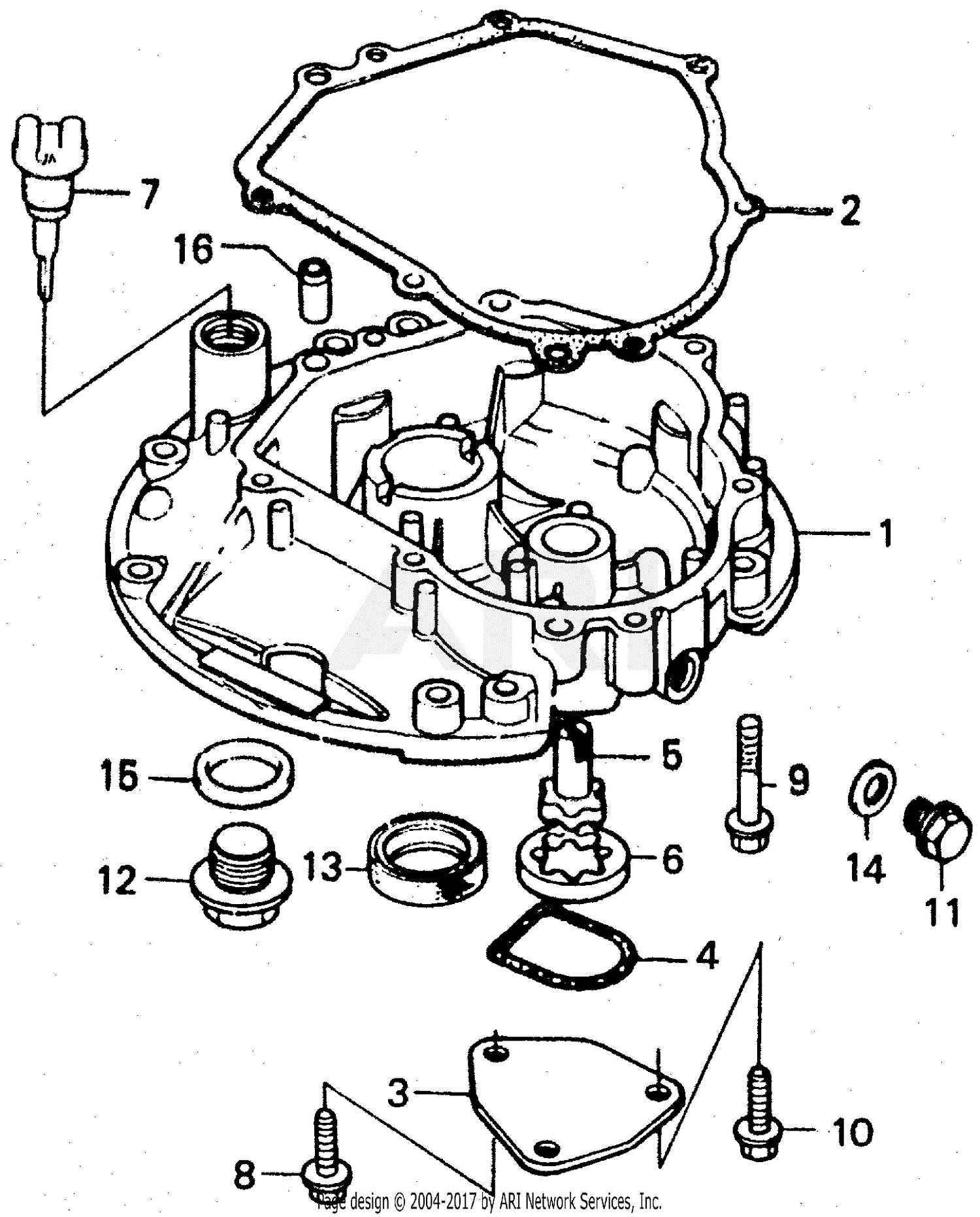

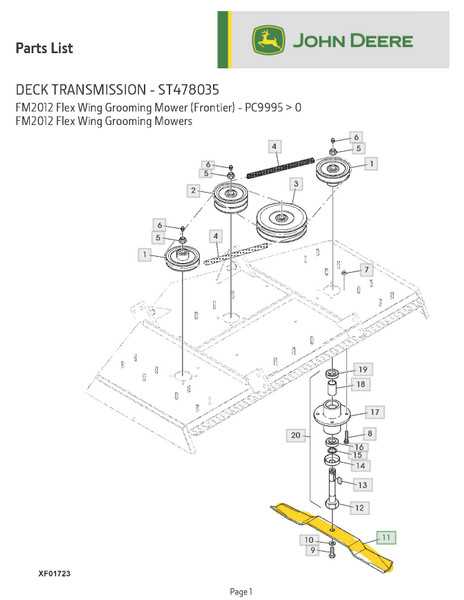

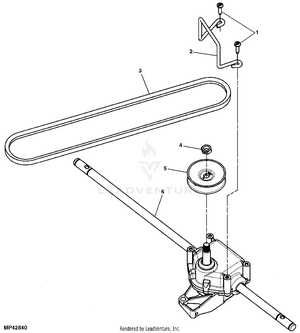

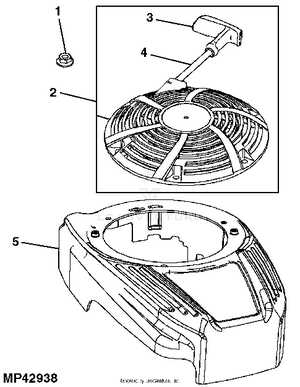

Visual aids play a crucial role in this understanding, as they provide a clear representation of how different pieces interconnect and operate together. Utilizing detailed schematics can simplify the process of identifying specific parts, making it easier to troubleshoot issues and source replacements when necessary. Familiarity with these illustrations can empower users to take a more hands-on approach to equipment care.

As you delve into the intricacies of your machinery, remember that each component has a unique role to play. Whether you are a seasoned professional or a casual user, recognizing the significance of every element will enhance your experience and enable you to maintain your tools with greater expertise. This exploration serves as a valuable resource for anyone looking to optimize their outdoor equipment’s performance.

Understanding the John Deere JS46 Model

This segment explores the intricacies of a popular lawn maintenance machine, designed to enhance gardening efficiency and precision. Its design showcases a blend of functionality and user-centric features, catering to both novice and seasoned landscapers.

Key attributes include:

- Robust engine performance for reliable operation.

- Adjustable cutting height for tailored grass management.

- Ergonomic controls ensuring user comfort.

Users often appreciate:

- Ease of maneuverability in various terrains.

- Durability of components contributing to long-term usage.

- Accessibility of replacement parts for maintenance.

Ultimately, understanding this machine’s features can significantly enhance gardening outcomes and prolong its operational life.

Key Features of the JS46 Mower

This mower is designed to deliver exceptional performance and efficiency, making it a popular choice for homeowners and professionals alike. Its innovative features ensure ease of use and reliability, allowing users to achieve optimal results in their landscaping tasks.

Power and Performance

The machine is equipped with a robust engine that provides ample power, ensuring smooth operation across various terrains. Its cutting system is engineered for precision, allowing for an even and clean cut every time.

User-Friendly Design

Ergonomically designed controls and adjustable features enhance the overall user experience. The lightweight frame and easy maneuverability make it accessible for users of all skill levels.

| Feature | Description |

|---|---|

| Engine Power | Strong engine for reliable performance |

| Cutting Width | Optimal width for efficiency |

| Height Adjustment | Multiple settings for varied grass lengths |

| Lightweight Frame | Easy to maneuver in tight spaces |

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of these elements serve as valuable tools for both professionals and enthusiasts. They enhance clarity, ensuring that individuals can identify each component and comprehend its function within the larger system.

Benefits of Visual Representations

- Facilitates quick identification of components.

- Streamlines the repair process by providing clear guidance.

- Reduces the likelihood of errors during assembly or disassembly.

- Enhances communication between technicians and users.

Applications in Maintenance and Repair

- Servicing machinery by locating parts needing attention.

- Ordering the correct replacements without confusion.

- Training new personnel in understanding equipment layouts.

Incorporating these visual guides into maintenance practices ultimately leads to increased efficiency and longevity of equipment.

Common Parts for JS46 Maintenance

Regular upkeep of your equipment ensures optimal performance and longevity. Understanding essential components and their roles can help you effectively maintain your machine. Here are key elements to consider for routine servicing.

- Blades: Sharp and well-maintained blades are crucial for a clean cut. Regular sharpening or replacement is necessary for efficiency.

- Filters: Air and oil filters should be changed periodically to prevent dirt and debris from affecting engine performance.

- Belts: Drive belts are essential for transferring power. Inspect for wear and replace as needed to avoid slippage or breakage.

- Wheels: Ensure that wheels are in good condition and properly inflated for smooth operation. Check for any damage that might affect movement.

- Spark Plug: A functioning spark plug is vital for starting and running the engine efficiently. Replace it as part of regular maintenance.

By keeping these components in check, you can enhance the reliability and efficiency of your machinery, ensuring it remains in peak condition for all tasks.

How to Read Parts Diagrams

Understanding visual representations of component layouts is crucial for effective maintenance and repairs. These illustrations serve as guides, helping users identify each element’s placement and function within a machine. By familiarizing yourself with these visuals, you can streamline the process of troubleshooting and part replacement.

Key Elements to Look For

When examining these representations, focus on symbols and labels that denote different components. Each item is often numbered or coded, corresponding to a list that provides further details. Pay attention to the lines and connections, as they indicate how various elements interact with each other.

Utilizing the Information

Once you’ve identified the components, refer to the accompanying descriptions to understand their specific roles and compatibility. This knowledge allows for more informed decisions when sourcing replacements or performing upgrades, ensuring your machinery operates smoothly.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a daunting task. Fortunately, several reliable sources exist that offer a wide array of options to ensure optimal performance and longevity of your machinery. Understanding where to seek these items is essential for any owner or operator.

Online Retailers

The internet is a treasure trove for sourcing necessary components. Various websites specialize in providing a vast selection of alternatives, often with user-friendly search features that simplify the shopping experience.

Local Suppliers

Visiting local dealerships or hardware stores can also yield beneficial results. Many of these establishments carry essential replacements or can order them for you, providing personalized assistance in the process.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, and often lower prices. |

| Local Suppliers | Immediate availability and expert advice. |

Troubleshooting Common Issues

Addressing frequent problems can significantly enhance the performance and longevity of your equipment. Understanding the signs of malfunction is essential for effective maintenance. By identifying these issues early, you can avoid more extensive repairs and ensure optimal functionality.

Unresponsive Engine: If the engine fails to start, check the battery connections and fuel levels. A lack of power or fuel can often lead to this issue.

Uneven Cutting: This may indicate dull blades or uneven tire pressure. Regularly inspect the cutting components for wear and adjust the tires accordingly.

Excessive Vibration: If you notice unusual shaking during operation, examine the mounting bolts and check for any loose parts. Tightening these can help stabilize the machine.

Overheating: Ensure that the cooling system is clean and free from debris. Regularly check the coolant levels to prevent overheating during use.

By regularly inspecting these areas, you can delve deeper into any underlying issues and maintain the ultimate efficiency of your equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These original items are crafted specifically for the equipment, providing a perfect fit and superior reliability compared to alternatives.

| Benefit | Description |

|---|---|

| Quality Assurance | Original components meet strict manufacturing standards, ensuring durability. |

| Compatibility | Designed to work seamlessly with specific machinery, reducing the risk of malfunctions. |

| Warranty Protection | Using genuine components often maintains warranty coverage for the equipment. |

| Performance | Authentic items enhance the overall functionality and efficiency of the machinery. |

| Safety | Original parts minimize safety risks associated with inferior substitutes. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any machinery. Regular attention to key components not only enhances performance but also minimizes the likelihood of costly repairs. By adhering to a consistent maintenance schedule and being mindful of wear and tear, users can ensure their equipment remains in optimal condition for years to come.

Regular Inspections

Conducting routine inspections is crucial. Look for signs of wear, loose fittings, and any unusual noises during operation. Identifying potential issues early can prevent minor problems from escalating into major failures. Make it a habit to check fluid levels and filters regularly, ensuring everything operates smoothly.

Proper Cleaning

Keeping equipment clean is often overlooked yet vital for longevity. Debris and dirt buildup can hinder performance and lead to premature wear. After each use, take the time to clean key areas, removing any accumulated dirt and grime. This simple step can make a significant difference in maintaining efficiency and reliability.