In the world of outdoor machinery, having a comprehensive understanding of individual components is crucial for optimal performance and maintenance. Familiarizing oneself with the various elements that make up these machines can lead to enhanced efficiency and longevity. Each component plays a pivotal role in ensuring seamless operation, making it essential to grasp their functions and interrelationships.

To navigate the intricacies of these tools, visual representations can serve as invaluable resources. They offer clarity and insight into how parts interact, allowing users to pinpoint specific areas needing attention or replacement. By delving into these visual guides, one can ultimately foster a deeper connection with their equipment and ensure it runs smoothly.

Whether you are a seasoned professional or a novice, understanding the layout and functionality of these crucial elements can save time and reduce frustration. Engaging with detailed schematics can empower users to tackle repairs confidently, leading to a more rewarding experience with their machinery.

Understanding the Echo SRM 266

This section explores the intricacies of a popular outdoor power tool, designed for efficiency and ease of use. Understanding its components and functionality is crucial for both maintenance and effective operation. By delving into the specifics, users can enhance their experience and ensure longevity of the equipment.

Key Features and Benefits

The tool boasts a range of features that make it suitable for various tasks. Its lightweight design allows for prolonged use without excessive fatigue, while the powerful engine ensures that even challenging jobs are handled with ease. Additionally, the ergonomic grip enhances comfort, making it a favorite among both professionals and hobbyists.

Maintenance Tips for Longevity

To keep the equipment in top condition, regular maintenance is essential. This includes checking and replacing the air filter, ensuring the spark plug is functioning correctly, and sharpening the cutting blade. Proper maintenance not only improves performance but also extends the life of the tool, allowing users to get the most out of their investment.

Key Features of the Echo SRM 266

This section explores the standout characteristics of a highly regarded trimmer, focusing on its performance, durability, and user-friendly design. These elements make it an exceptional choice for both professionals and homeowners alike.

Performance

- Powerful engine delivers high efficiency for various tasks.

- Lightweight design reduces fatigue during extended use.

- Adjustable cutting speed for versatility across different conditions.

Durability

- Robust construction ensures longevity even in demanding environments.

- Corrosion-resistant materials enhance resilience against the elements.

- Easy access to maintenance points for straightforward upkeep.

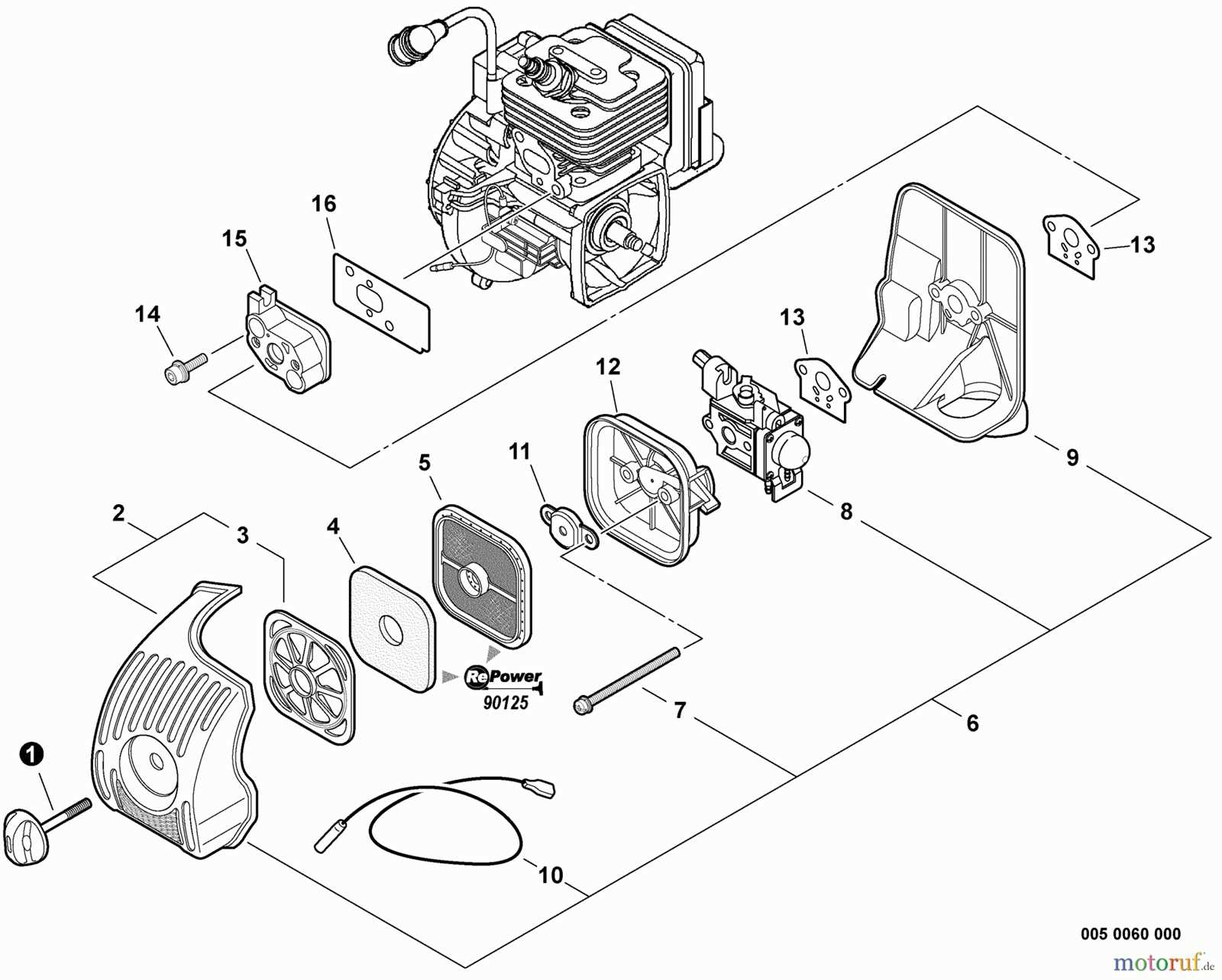

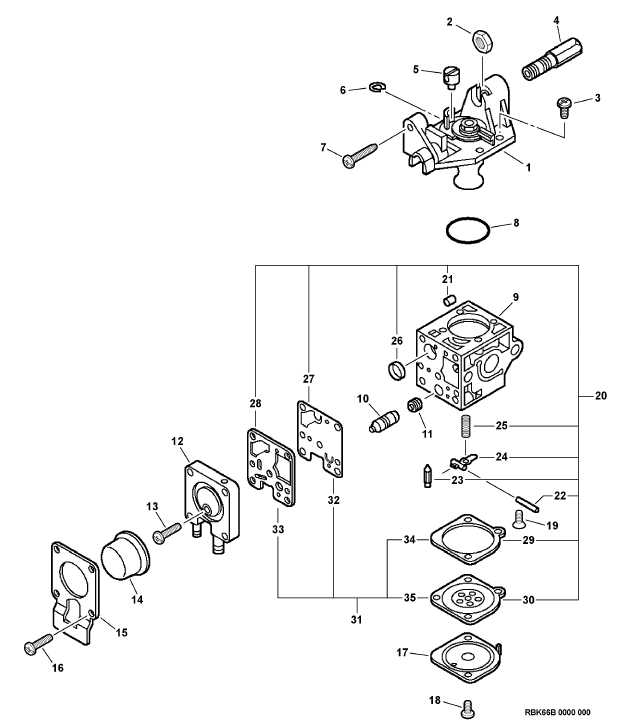

Importance of Parts Diagrams

Visual representations of components are crucial in understanding the intricate relationships and functions within machinery. These illustrations provide users with a clear roadmap to identify each element and its role, facilitating maintenance and repair tasks.

By offering a detailed view, these schematics help users quickly locate and assess parts that may need replacement or adjustment. This not only saves time but also enhances the efficiency of troubleshooting processes.

Moreover, such visuals serve as invaluable educational tools, allowing both novices and experts to delve deeper into the operational mechanics. Understanding these components leads to more informed decisions regarding upgrades and repairs.

Ultimately, these representations promote safety and longevity in equipment use, ensuring that users can effectively manage their tools while minimizing potential risks associated with improper handling.

Common Issues with Echo SRM 266

This section explores typical challenges encountered with a popular string trimmer model. Users often face a variety of mechanical and operational problems that can hinder performance and efficiency.

Frequent Problems

- Engine not starting

- Unstable idle speed

- Excessive vibration during operation

- String not feeding properly

- Fuel leaks

Troubleshooting Tips

- Check the fuel level and ensure it’s fresh.

- Inspect the air filter for clogs.

- Examine the spark plug for wear or damage.

- Make sure the cutting line is correctly installed.

- Regularly clean and maintain all components.

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone involved in maintenance or repair tasks. These illustrations serve as comprehensive guides, enabling users to identify components and their relationships within a device. Familiarity with these visuals can significantly streamline the troubleshooting and assembly processes.

To begin, it’s important to recognize the symbols and notations used in these illustrations. Each part is typically represented by a unique figure, which may be accompanied by a label or number for easy reference. By cross-referencing these identifiers with a corresponding list, you can gain insights into the specific components needed for repairs or replacements.

Additionally, pay attention to the arrangement of the parts in the illustration. The layout often reflects the order of assembly or disassembly, providing valuable context for how components interact. Understanding this spatial organization can help prevent mistakes during repairs and ensure that everything is reassembled correctly.

Lastly, don’t overlook any accompanying notes or instructions. These annotations can offer critical information regarding installation techniques, torque specifications, or maintenance tips, enhancing your overall understanding of the system. Mastering the art of reading these schematics can empower you to tackle repairs with confidence and efficiency.

Ordering Replacement Parts Online

In today’s digital age, acquiring components for machinery has become remarkably straightforward. Online platforms provide a convenient avenue for enthusiasts and professionals alike to source necessary items quickly and efficiently. With just a few clicks, you can find specific items that ensure your equipment remains in optimal condition, allowing you to tackle projects without delay.

Finding Reliable Retailers

When seeking to purchase components, it is essential to identify trustworthy suppliers. Look for websites that specialize in the equipment you own, ensuring they offer genuine and high-quality alternatives. Reading customer reviews and ratings can also provide insight into the reliability of the vendor, helping you make informed decisions.

Ensuring Compatibility and Quality

Before finalizing your order, verify that the chosen item is compatible with your equipment. Check the specifications and model numbers to avoid discrepancies. Additionally, opting for products from reputable manufacturers can greatly enhance the durability and performance of your machinery.

Maintenance Tips for Echo SRM 266

Proper upkeep of your gardening tool is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential breakdowns, allowing for a seamless experience during your outdoor tasks. Below are some key practices to follow for maintaining your device.

Regular Cleaning

Keeping your equipment clean is crucial. After each use, remove any debris, grass clippings, or dirt that may have accumulated. Pay special attention to the air filter and the cutting head, as these areas can easily become clogged and affect performance.

Inspecting and Replacing Parts

Regularly check for signs of wear and tear on the various components. This includes the cutting line, blades, and fuel system. If any parts appear damaged or worn out, replace them promptly to avoid further issues.

| Component | Inspection Frequency | Replacement Tips |

|---|---|---|

| Cutting Line | After every use | Ensure proper length for effective cutting |

| Air Filter | Every month | Clean or replace as needed |

| Blades | Every few uses | Sharpen or replace if damaged |

| Fuel System | Every season | Use fresh fuel to prevent clogging |

Where to Find OEM Parts

Locating original equipment components is essential for maintaining the efficiency and longevity of your machinery. These genuine elements ensure compatibility and optimal performance, making them a worthwhile investment for any user.

Authorized Dealers: One of the most reliable sources for authentic components is through official dealers. They typically have a comprehensive inventory and can provide expert assistance in identifying the correct items for your needs.

Online Retailers: Numerous online platforms specialize in genuine parts, offering convenient access to a wide selection. Make sure to verify the seller’s credibility to avoid counterfeit products.

Manufacturer Websites: Many manufacturers feature a dedicated section on their websites for ordering original components directly. This option often includes helpful resources like installation guides and support.

Local Repair Shops: Some local service centers stock genuine items or can order them for you. Building a relationship with these professionals may also yield valuable advice on maintenance.

In conclusion, investing time in sourcing authentic components will significantly enhance the performance and reliability of your equipment.