In the realm of heavy machinery, comprehending the intricate relationships between various components is crucial for optimal performance and maintenance. A thorough exploration of these relationships not only enhances operational efficiency but also extends the lifespan of the equipment. This section delves into the essential structure of a specific model, providing insights that are invaluable for both novice users and seasoned professionals.

By dissecting the layout of individual elements, one can gain a clearer perspective on their functions and interactions. Understanding these connections enables operators to troubleshoot issues more effectively, ensuring that machinery runs smoothly. Moreover, this knowledge is indispensable for planning maintenance tasks and procuring the necessary replacements when the time comes.

Whether you’re engaged in routine upkeep or addressing specific concerns, familiarizing yourself with the configuration of components will empower you to make informed decisions. This guide serves as a resource to navigate through the various aspects of the equipment, facilitating a deeper understanding of its inner workings and fostering greater efficiency in your operations.

Understanding the Kubota KX71-3

This section delves into the intricacies of a popular mini excavator model, highlighting its design, functionality, and applications. Recognizing how the components work together is essential for operators and maintenance personnel, as it enhances both efficiency and longevity of the equipment. This machine is known for its versatility, making it suitable for a variety of tasks, from landscaping to construction projects.

Key Features

The featured model boasts a compact design that enables easy maneuverability in tight spaces. Its powerful engine provides robust performance, while the hydraulic system ensures precision and control during operation. Understanding these features helps in optimizing usage and ensuring that the machine meets the demands of various jobs effectively.

Maintenance Insights

Regular upkeep is crucial for any heavy machinery, and this model is no exception. Familiarity with the layout of internal components allows operators to conduct timely inspections and repairs, minimizing downtime. Additionally, knowing the location of essential systems aids in troubleshooting potential issues, leading to smoother operation and prolonged equipment lifespan.

Key Features of the KX71-3 Model

This section explores the standout attributes of a compact excavator that enhance its functionality and efficiency in various applications. From impressive power to versatile design, these features make it a preferred choice for many operators.

Performance and Power

- Robust engine delivering high horsepower for demanding tasks.

- Efficient hydraulic system for improved lifting and digging capabilities.

- Compact size allows for maneuverability in tight spaces.

Operator Comfort and Convenience

- Spacious cab designed for maximum operator comfort.

- Intuitive controls for easy operation and quick learning curve.

- Enhanced visibility for better job site awareness.

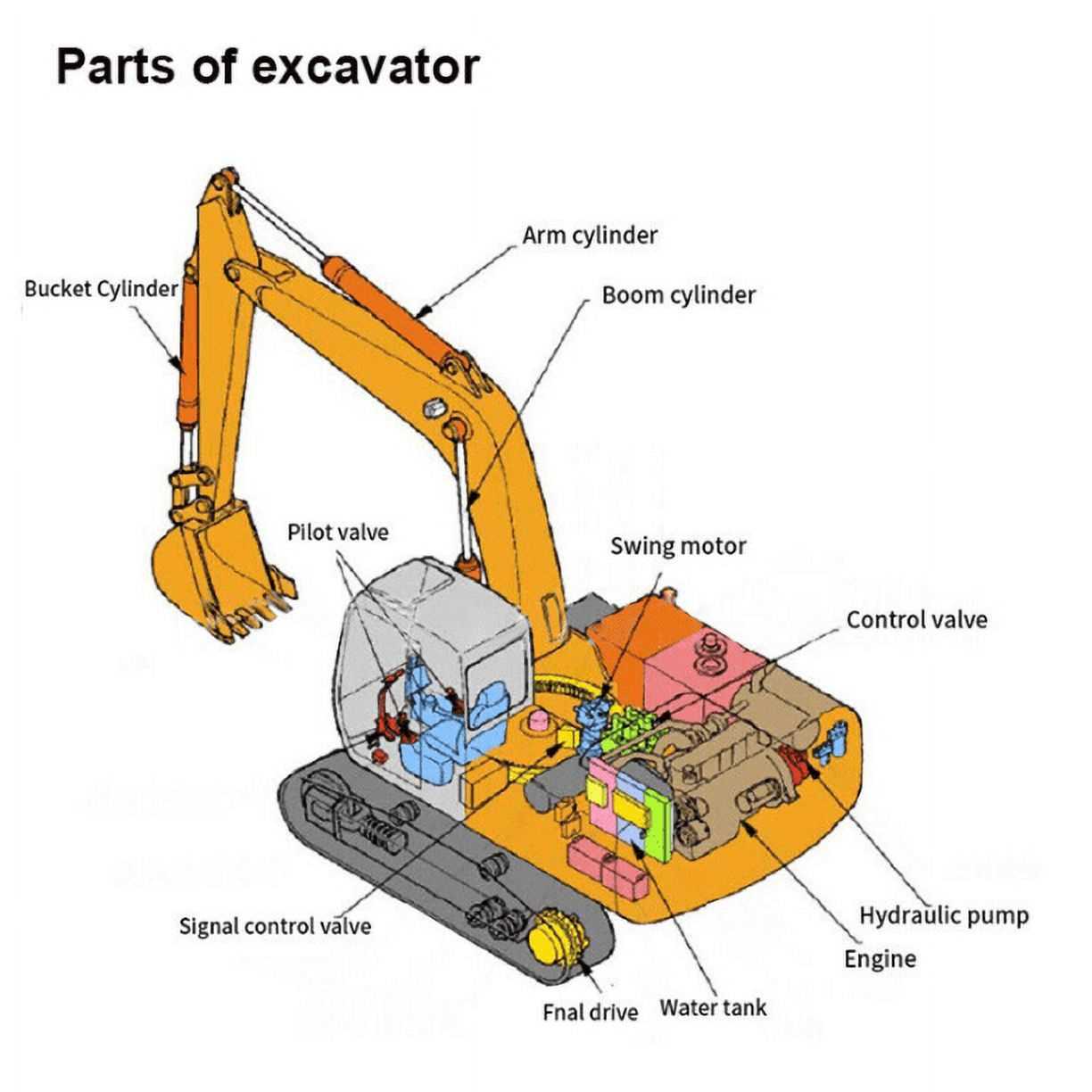

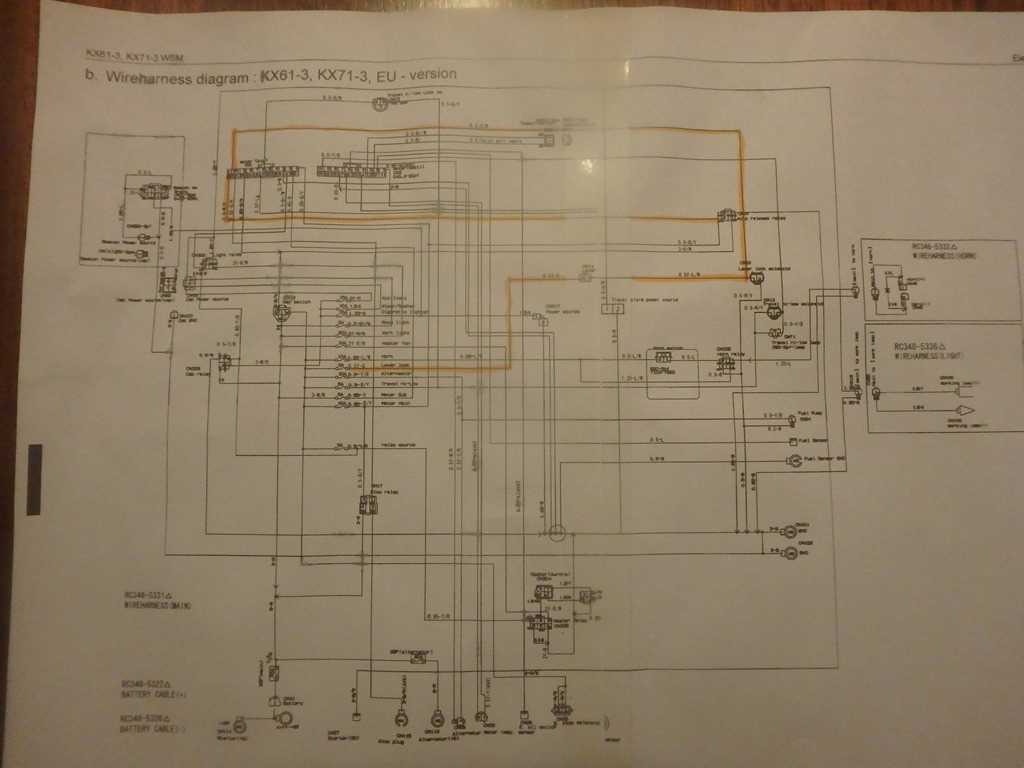

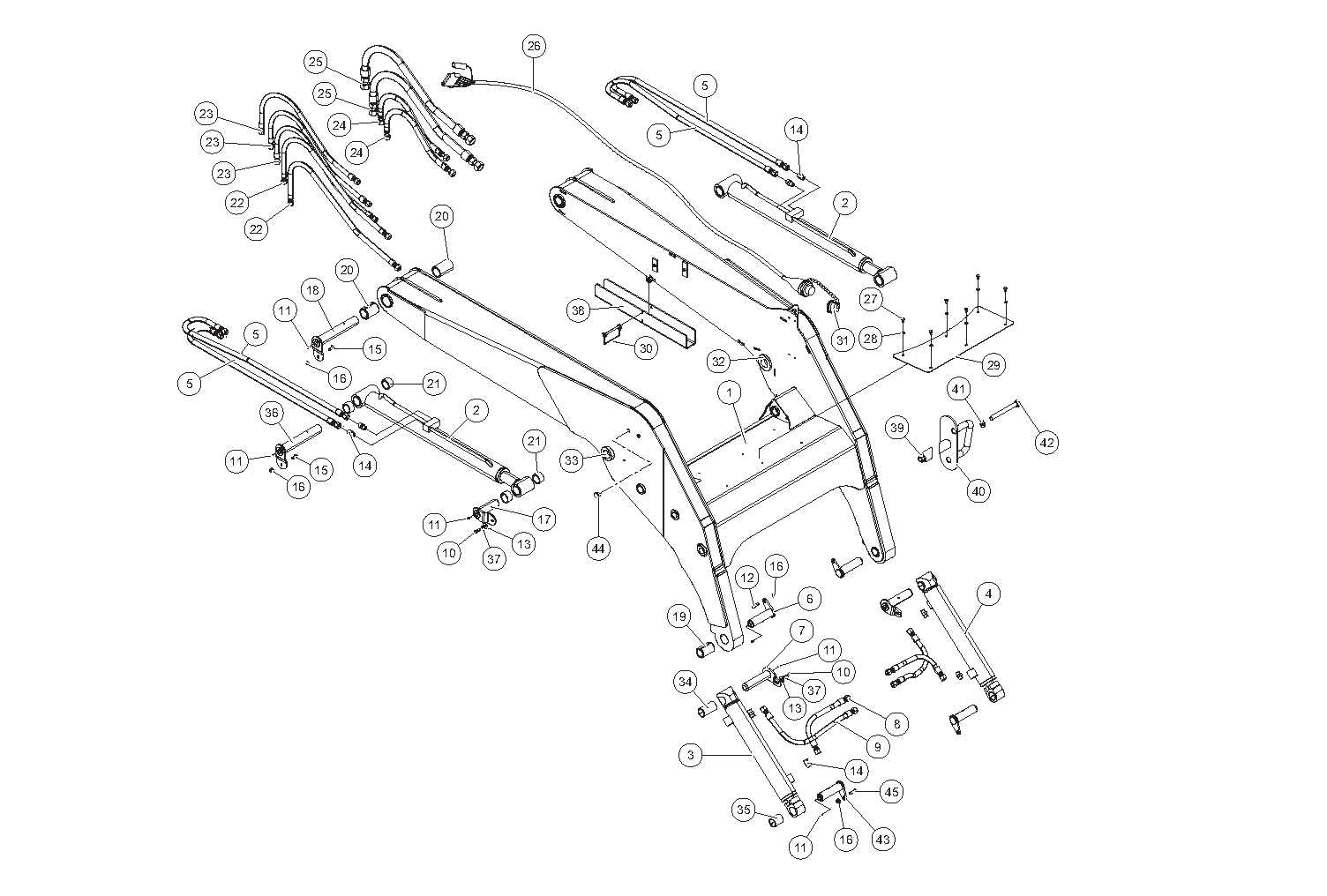

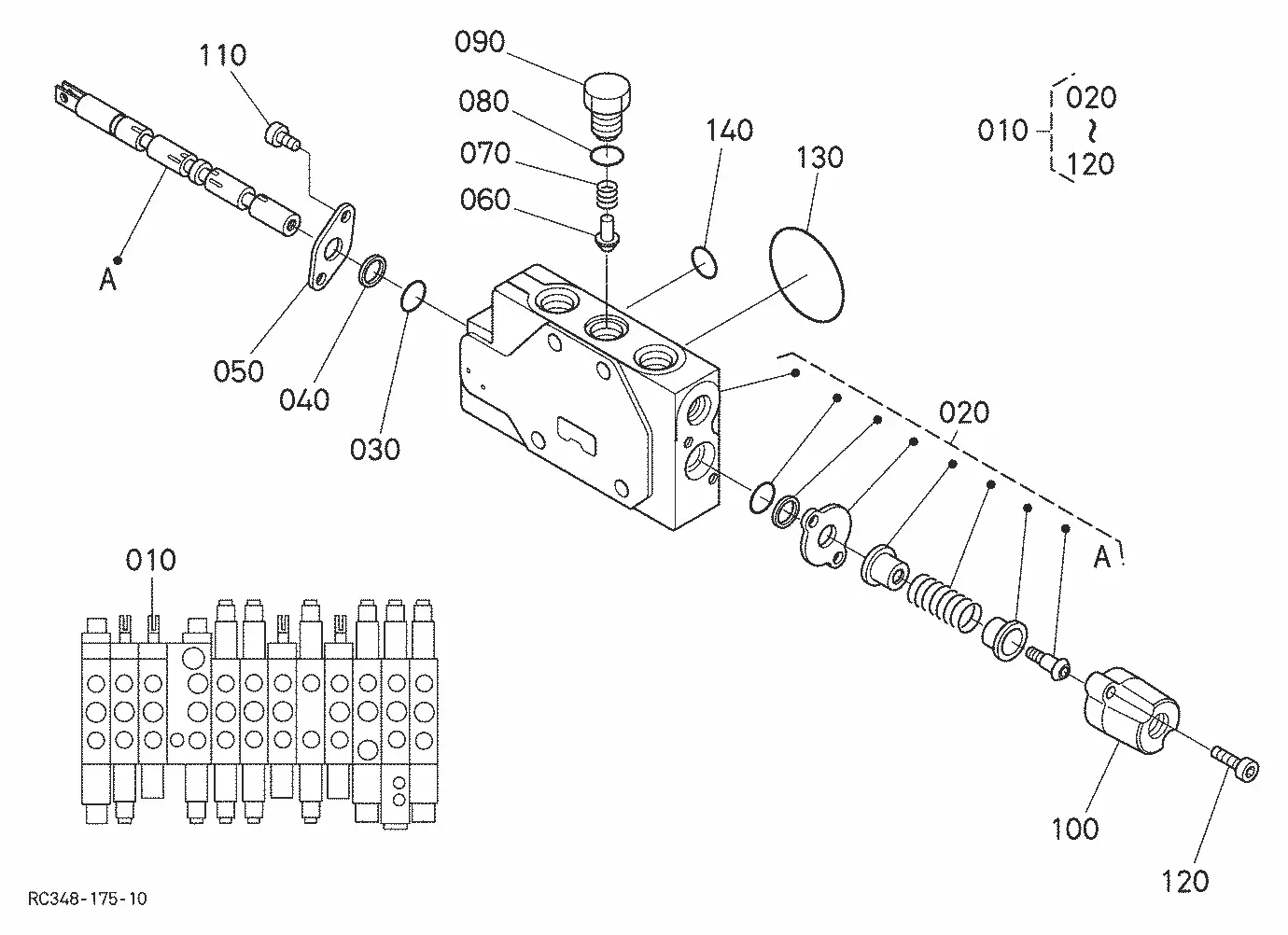

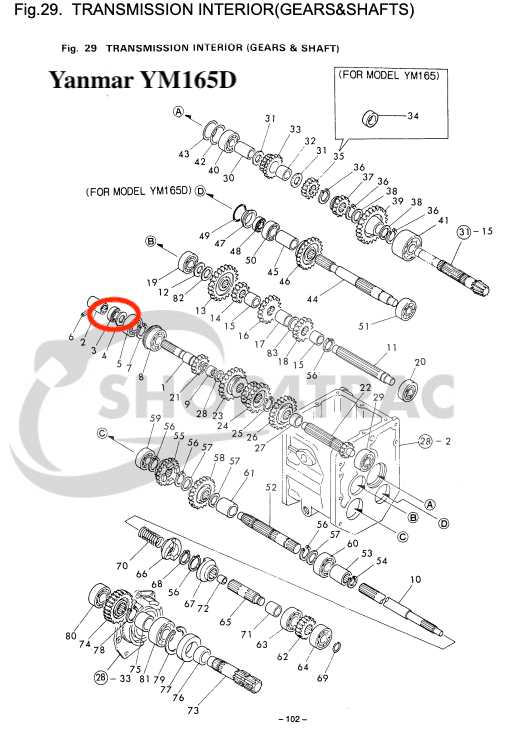

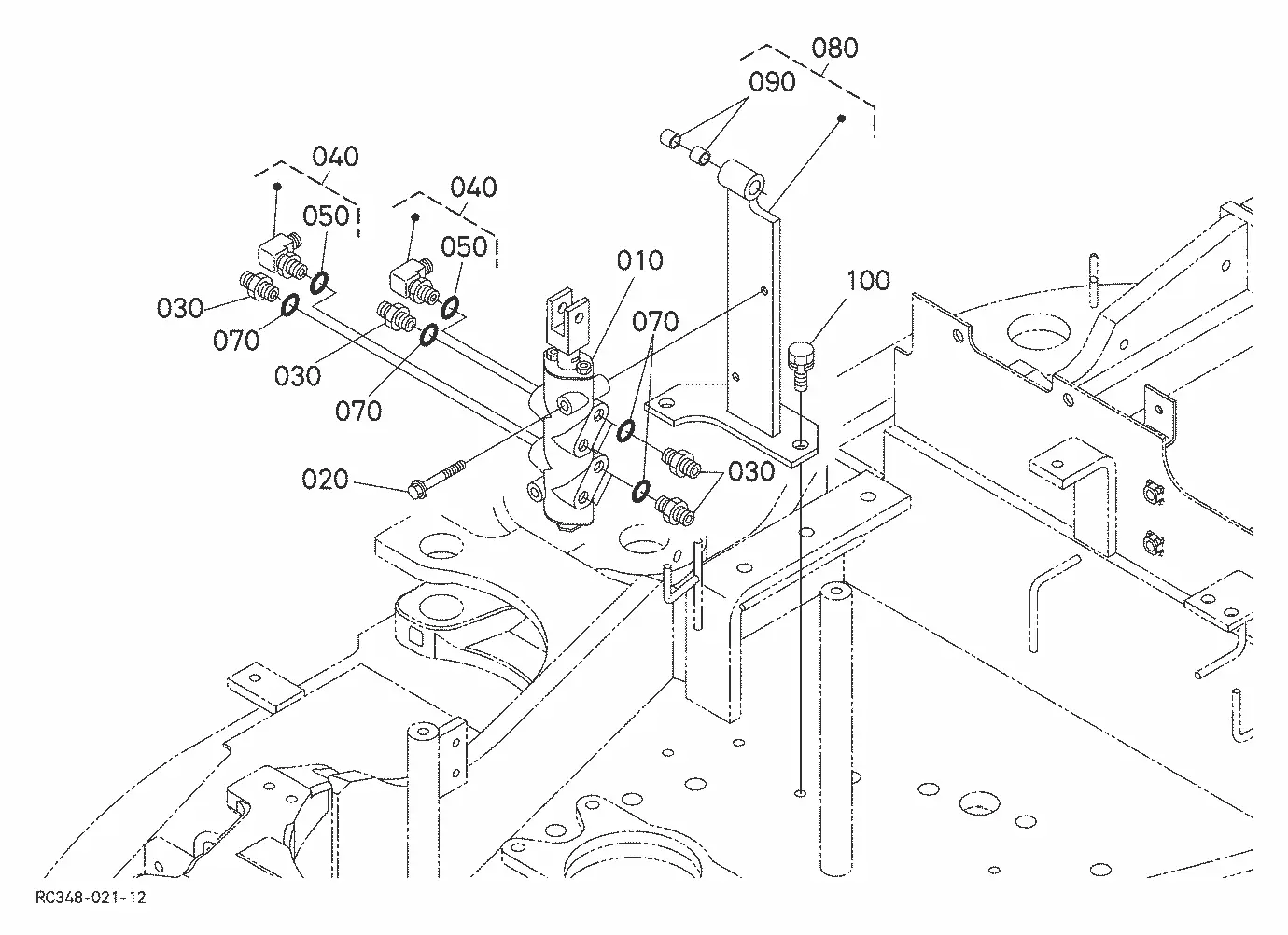

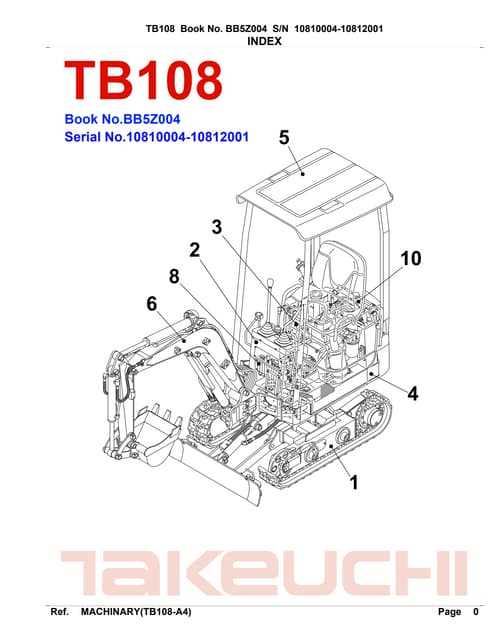

Importance of Parts Diagrams

Visual representations of component arrangements play a crucial role in maintenance and repair processes. They provide a clear overview, enabling users to identify and locate each item effectively, which can save time and enhance accuracy.

Benefits of Visual Guides

- Enhances understanding of the assembly.

- Facilitates troubleshooting and repairs.

- Simplifies ordering replacements.

- Reduces the likelihood of errors during reassembly.

Best Practices for Using Visual Representations

- Refer to the guide regularly during maintenance.

- Keep it accessible in the workspace.

- Update the representation as modifications occur.

- Use alongside manuals for comprehensive guidance.

Common Replacement Parts Explained

In the world of heavy machinery, understanding essential components that frequently need substitution can enhance performance and longevity. Knowing what to look for when maintenance is required can save time and money.

Essential Components

- Hydraulic Filters: Vital for maintaining fluid cleanliness and preventing system damage.

- Tracks: Offer traction and stability; wear and tear is common.

- Bucket Teeth: Essential for digging; they can become blunt or break over time.

Indicators of Wear

- Unusual Noises: Can signify component failure.

- Reduced Efficiency: A drop in performance may indicate that replacements are needed.

- Fluid Leaks: Often a sign of deteriorating seals or connections.

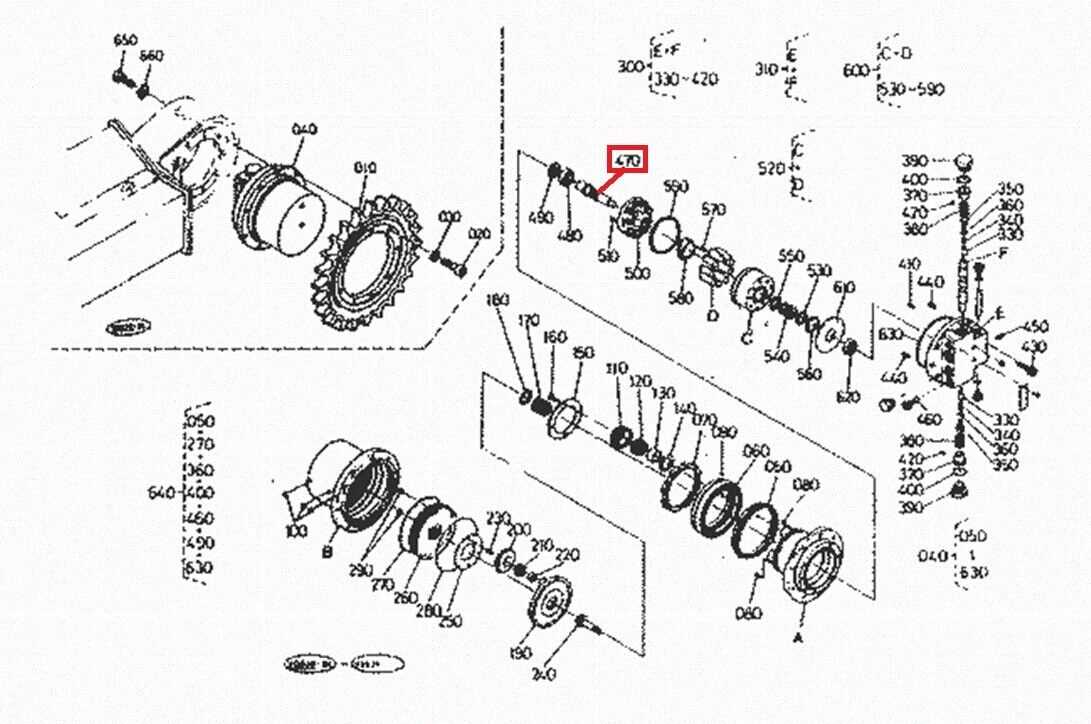

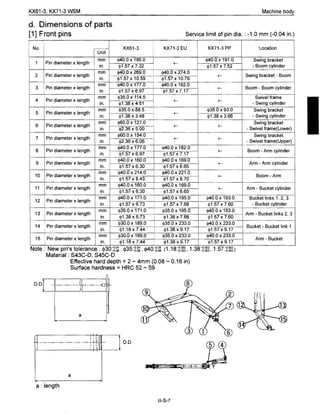

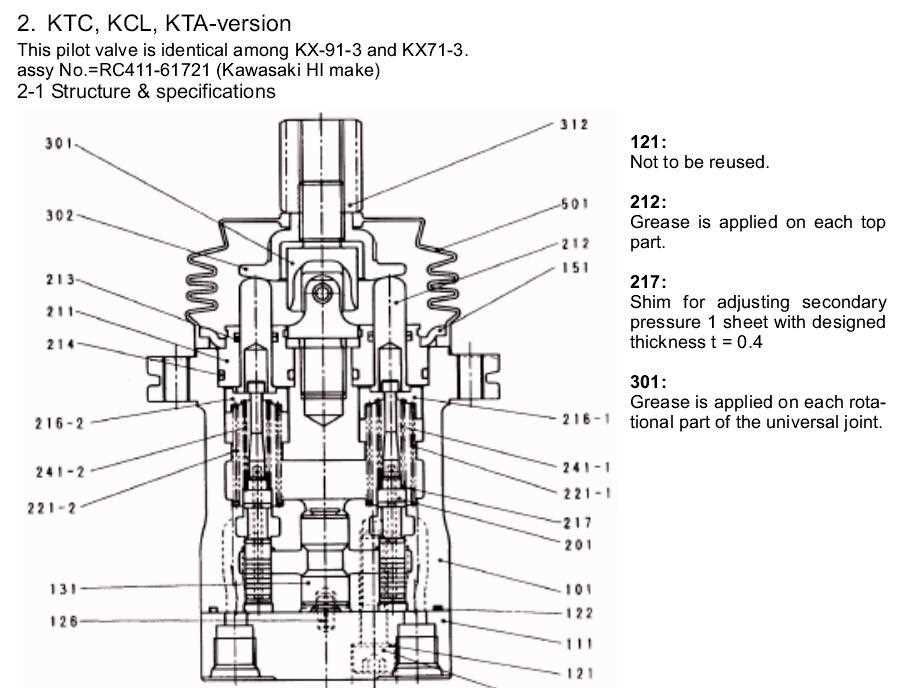

How to Read the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. This illustration provides a systematic way to identify each element, ensuring that users can locate and understand the function of various sections within the machinery.

To begin, familiarize yourself with the overall layout. Most illustrations are organized logically, often grouping related parts together. Look for numbers or labels that correspond to a list, as these references typically provide detailed descriptions of each element.

Next, pay attention to the connections between different sections. Arrows or lines often indicate how components interact or fit together, which is essential for troubleshooting issues. Understanding these relationships can lead to a more efficient repair process.

Lastly, take note of any accompanying legends or notes. These can offer additional insights or specifications that are vital for selecting the correct replacements or adjustments. By delving into these details, you will enhance your ability to maintain and operate the equipment effectively.

Where to Find Official Diagrams

Accessing authentic illustrations is essential for anyone involved in maintenance and repair tasks. These visual guides provide crucial insights into components and their arrangement, ensuring efficient servicing. Various reliable sources are available to help you obtain these resources effectively.

Manufacturer Websites: The first place to check is the official site of the equipment manufacturer. Many companies provide downloadable resources or online viewing options for their models, often including comprehensive breakdowns of their machinery.

Authorized Dealers: Local authorized dealers can be a valuable resource. They typically have access to the latest technical documents and can offer support in acquiring the necessary illustrations tailored to specific models.

Service Manuals: Purchasing a service manual is another great option. These manuals often contain detailed schematics, assembly instructions, and maintenance tips that are invaluable for hands-on work.

Online Forums and Communities: Joining dedicated online forums or communities can also lead to useful discoveries. Members frequently share resources, tips, and even their own diagrams, creating a collaborative environment for troubleshooting and repairs.

Industry Publications: Trade magazines and industry publications may also feature detailed guides or references to where to find specific technical materials. Subscribing to these can keep you informed about the latest resources available.

Tips for Ordering Kubota Parts

When it comes to acquiring components for your machinery, a few key strategies can streamline the process and ensure you receive the correct items efficiently. Understanding your equipment’s specifications and the nuances of the ordering process can save time and reduce frustration.

1. Know Your Model: Before placing an order, it is crucial to have the specific model number at hand. This information helps suppliers identify the exact components you need, minimizing the risk of errors.

2. Utilize Official Resources: Consult authorized dealers or official websites for reference materials. These resources often provide comprehensive lists of available components, along with their corresponding identifiers.

3. Cross-reference Numbers: When searching for a specific item, cross-reference part numbers with different manufacturers if applicable. Sometimes, alternatives may be available that could be more cost-effective.

4. Keep a Record: Maintain a log of previously ordered components, including details like part numbers and order dates. This can simplify future purchases and help track maintenance history.

5. Verify Compatibility: Ensure that the items you are ordering are compatible with your machine. This may involve consulting manuals or seeking advice from professionals to avoid purchasing incompatible components.

6. Consider Delivery Times: Be mindful of shipping times, especially if you need the items urgently. Ordering well in advance can prevent unnecessary downtime in your operations.

7. Ask for Assistance: Don’t hesitate to reach out to suppliers for help if you’re uncertain about what you need. Experienced staff can provide valuable insights and recommendations based on your requirements.

By following these tips, you can enhance the efficiency of your ordering process and ensure that your machinery remains in optimal working condition.

Maintenance Guidelines for KX71-3

Regular upkeep is essential to ensure the longevity and efficiency of heavy machinery. Following a structured maintenance routine can prevent unexpected breakdowns and enhance performance. This section outlines key practices to keep your equipment in optimal condition.

Routine Inspections

- Check fluid levels regularly, including hydraulic fluid, engine oil, and coolant.

- Inspect filters and replace them as needed to maintain cleanliness and efficiency.

- Examine belts and hoses for signs of wear or damage.

Scheduled Servicing

- Perform comprehensive maintenance every 250 hours of operation.

- Change the engine oil and filter to promote engine health.

- Grease pivot points and joints to reduce friction and wear.

By adhering to these guidelines, operators can delve deeper into the upkeep of their machinery, ensuring its ultimate reliability and performance over time.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These high-quality replacements are specifically designed to meet the exact specifications required for seamless operation. Investing in genuine items reduces the likelihood of breakdowns and enhances overall efficiency.

One of the primary advantages of authentic replacements is their reliability. They undergo rigorous testing to guarantee they meet industry standards, providing peace of mind that your equipment will function as intended. This reliability translates to lower maintenance costs over time, as authentic components tend to require less frequent replacement.

Additionally, using original items often preserves the warranty of the machinery. Many manufacturers stipulate that utilizing non-genuine alternatives can void coverage, which could lead to significant expenses in repairs or replacements. By choosing authentic parts, owners protect their investment and ensure compliance with warranty conditions.

Furthermore, genuine components often offer better compatibility with existing systems, resulting in enhanced performance. Non-original parts may lead to inefficiencies or even damage, ultimately negating any initial savings. Prioritizing quality ensures that machinery operates at peak levels, contributing to productivity and reliability.