In various industries and households, a well-organized coiling mechanism is essential for effective storage and usage of long flexible items. These systems are designed to facilitate smooth operation, quick deployment, and secure storage. To ensure reliable performance, it’s important to have a clear understanding of the essential elements that make up such a structure.

The fundamental components work together to provide optimal functionality. Each piece serves a specific role, whether it’s for maintaining tension, facilitating smooth unwinding, or ensuring durability under constant use. Without a proper grasp of these elements, users may experience inefficiencies or damage to the entire system over time.

By exploring the individual functions and interactions of these components, one can enhance both the longevity and efficiency of the entire setup. Knowing how these different elements come together allows for better maintenance practices and informed decision-making when purchasing or repairing such equipment.

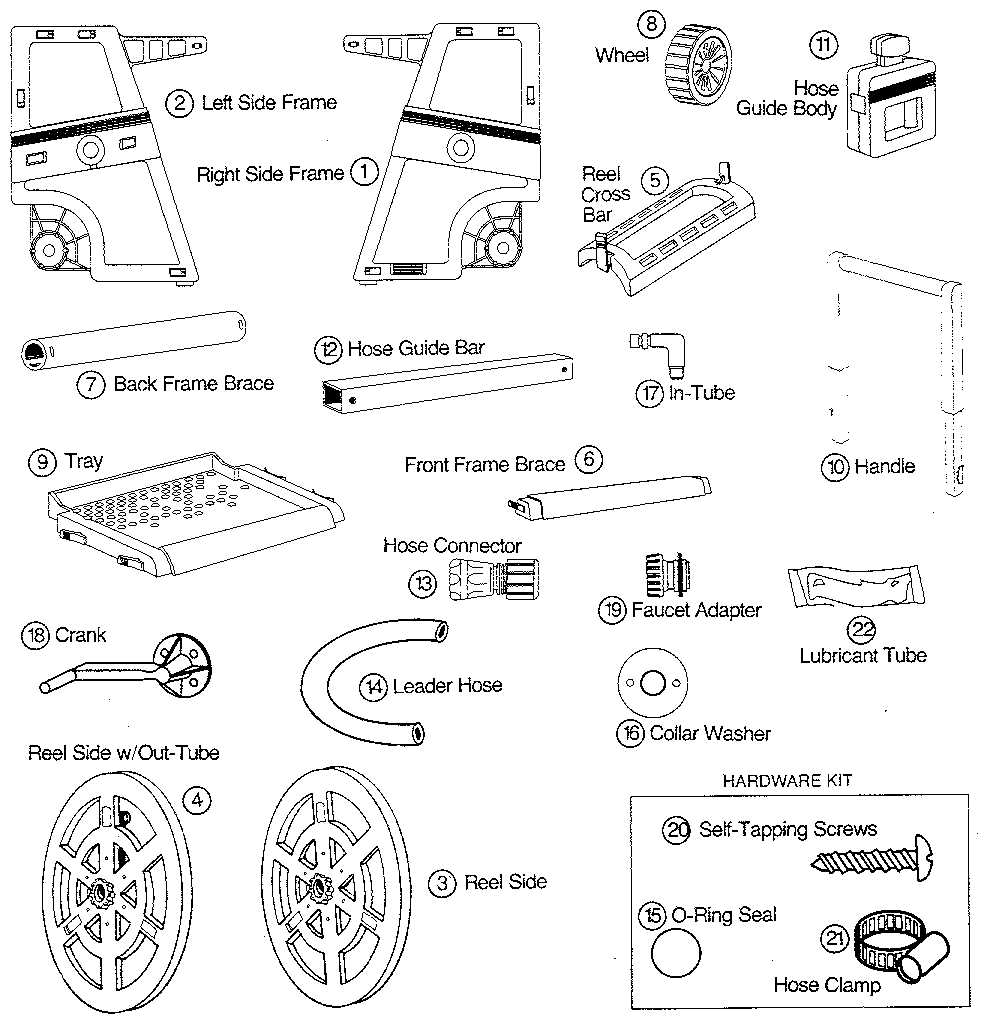

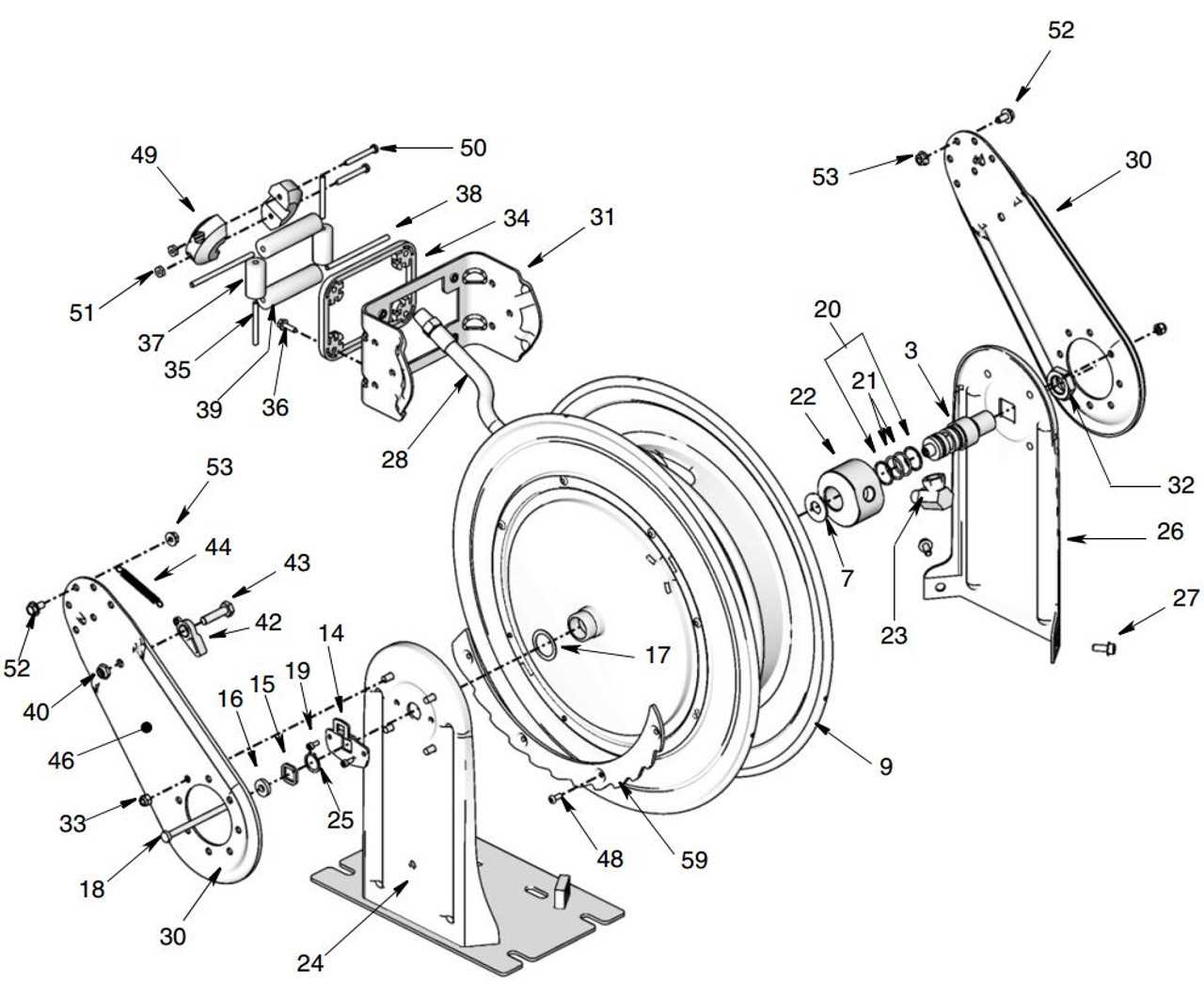

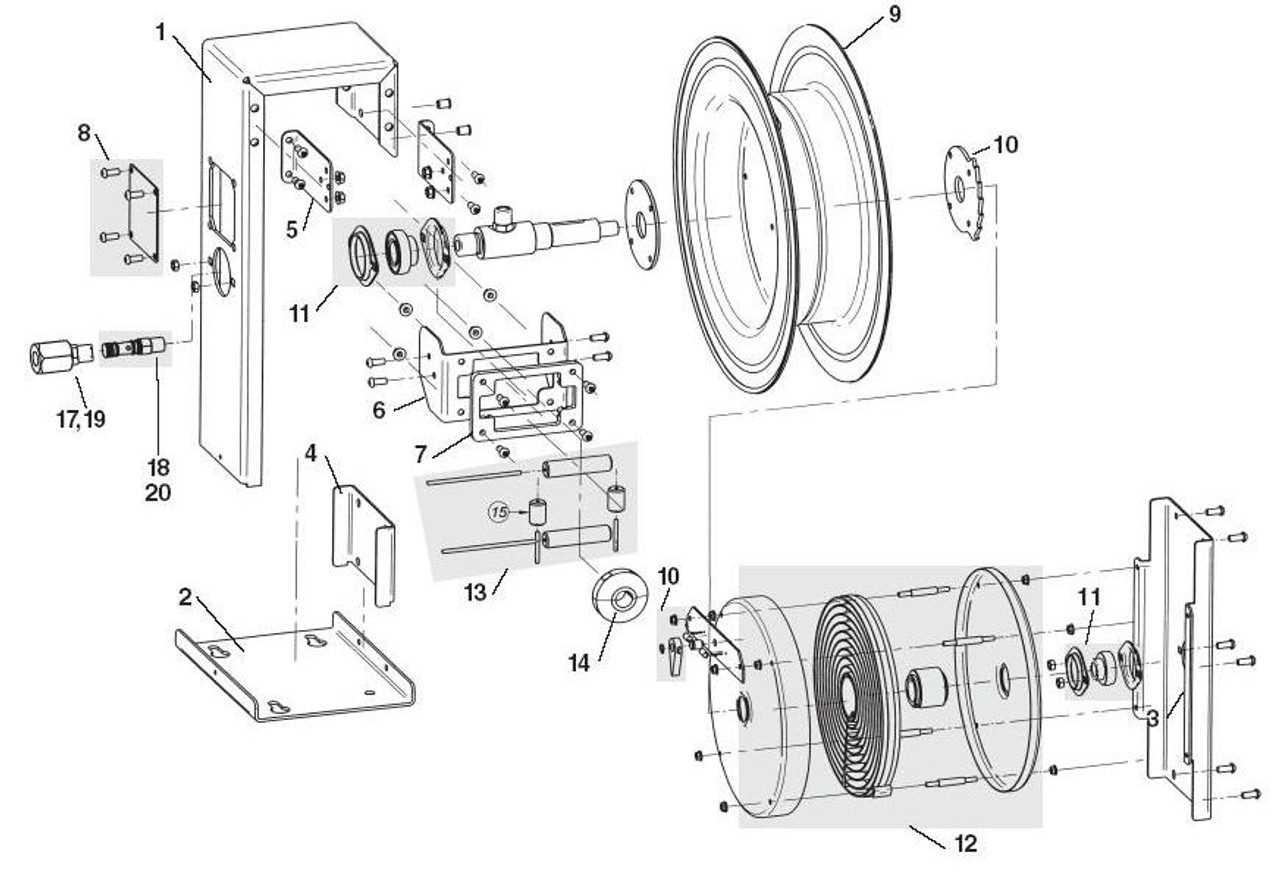

Understanding Hose Reel Components

To properly manage and store flexible tubing used in various applications, it’s essential to understand the individual elements that contribute to the overall system’s functionality. These components work together to ensure smooth operation, ease of handling, and durability. A closer look at these items provides insight into their purpose and how they affect performance and longevity.

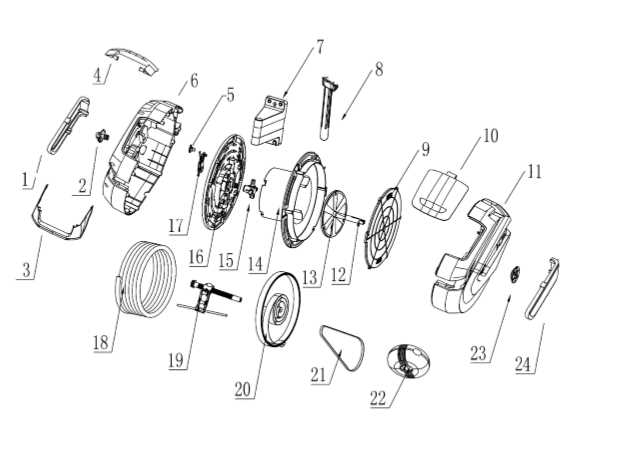

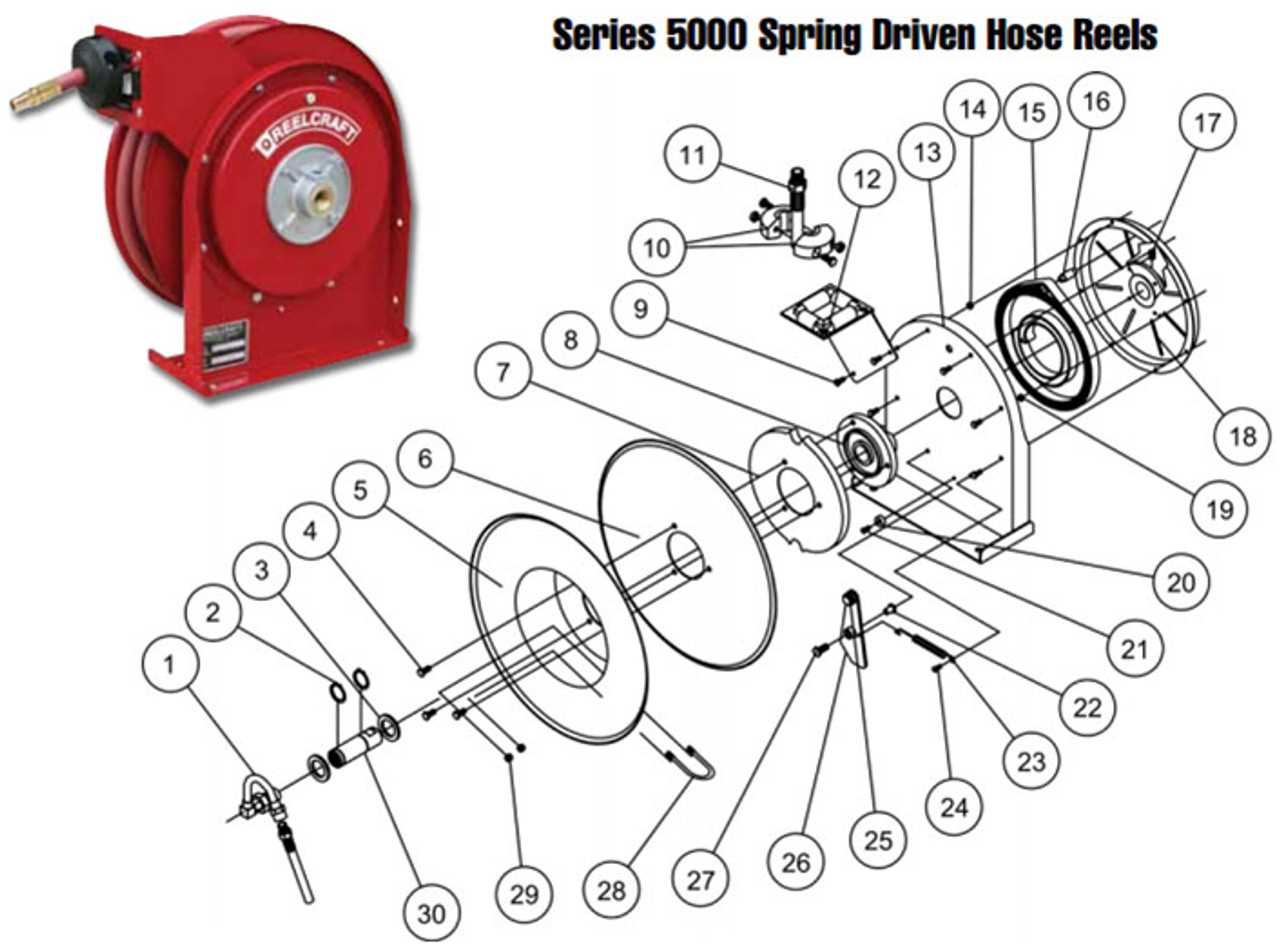

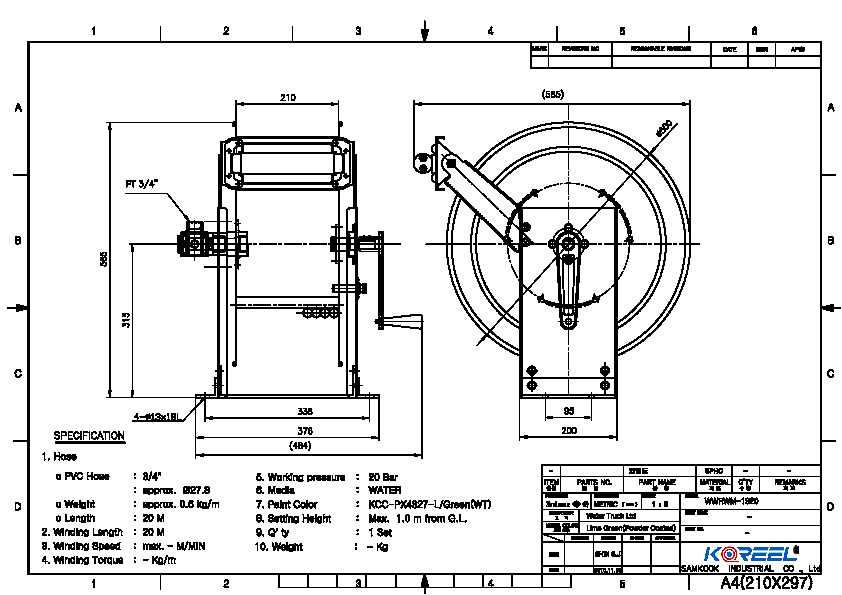

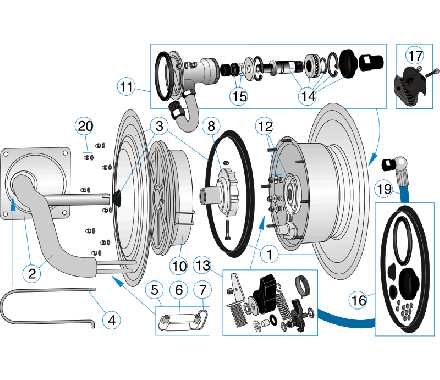

Key Components and Their Functions

- Base Structure – The foundation of the system, typically made from durable materials, supports all other components and provides stability.

- Rotating Mechanism – This allows for easy winding and unwinding of the tubing, ensuring efficient retraction and storage.

- Guide System – Helps direct the tubing as it is being rolled or unrolled, preventing tangling or damage during operation.

- Locking Mechanism – Prevents unintended unwinding by securing the tubing in place once it has been extended or retracted.

- Handle or Crank – Provides manual control for operating the system, allowing users to reel in or release the tubing as needed.

- Mounting Bracket – Facilitates attachment to walls, vehicles, or other surfaces, ensuring that the system is secure and easily accessible.

Material Considerations

- Metal – Often used in structural components for its strength and long-lasting properties.

- Plastic – Typically employed in lighter components due to its resistance to corrosion and impact.

- Rubber – Used in sealing and cushioning elements, offering flexibility and wear resistance.

Essential Parts of Hose Reels

Understanding the fundamental components of these systems is crucial for effective use and maintenance. Each element plays a significant role in ensuring smooth operation and longevity.

- Frame: Provides structural support and stability.

- Drum: The central element where the material is wound and stored.

- Guide: Ensures proper alignment during unwinding and rewinding.

- Swivel: Allows flexible movement while preventing tangling.

- Handle: Facilitates manual control and adjustment.

- Brake: Controls the unwinding process to prevent free spooling.

By delving into these key components, users can enhance functionality and ensure optimal performance.

How Hose Reels Function

The operation of these essential tools relies on a simple yet effective mechanism designed for convenience and efficiency. When activated, the system enables smooth extension and retraction, allowing for easy handling of various tasks. The inner workings involve a combination of rotational movement and tension control, ensuring that the material can be unwound and rewound with minimal effort.

Types of Hose Reels Available

There are various types of winding devices designed to store and manage flexible tubing for different applications. These systems are built to suit specific environments, needs, and usage scenarios. Whether for residential, commercial, or industrial settings, the right model can greatly improve convenience and efficiency in handling hoses and cables.

One category includes manual versions, where users manually wind the tubing back into the container. These are typically more affordable and easy to use for smaller, less demanding tasks. Another popular option is the automatic system, which features a spring or motor-driven mechanism to retract the material effortlessly, making it ideal for large-scale operations or frequent use. For heavy-duty applications, there are reinforced models designed to withstand harsh environments and heavy pressure. These versions often feature durable materials and enhanced structural integrity to ensure long-lasting performance.

Additionally, there are wall-mounted, portable, and floor-standing variations. Wall-mounted devices are space-saving and ideal for smaller areas, while portable options provide flexibility for movement across large spaces. Floor-standing units are more robust and are commonly used in industrial settings, offering greater stability and storage capacity.

Common Issues with Hose Reel Parts

Understanding the frequent challenges that can arise with the components of a winding device is essential for proper maintenance and longevity. Issues can stem from wear and tear, improper usage, or environmental factors. Identifying these problems early can help ensure the device functions effectively.

Below are some typical complications encountered with these devices:

| Issue | Description | Possible Solution |

|---|---|---|

| Leaking Connections | Fluid may escape from joints due to loose fittings or damaged seals. | Tighten connections or replace worn seals. |

| Twisted Hose | Improper winding can lead to kinks and twists, affecting functionality. | Rewind carefully, ensuring even distribution. |

| Corrosion | Exposure to moisture can cause rusting of metallic elements. | Regularly clean and apply protective coatings. |

| Stiff Mechanism | Accumulated debris may hinder smooth operation. | Clean the moving parts and apply lubricant. |

Addressing these issues promptly will enhance the overall efficiency and lifespan of the device, ensuring reliable performance when needed. Regular inspections and maintenance routines can mitigate these common challenges.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to details can significantly extend its lifespan and maintain optimal performance. Here are some key practices to incorporate into your maintenance routine.

Firstly, regular inspections are crucial. Check for any signs of wear, damage, or corrosion. Promptly addressing minor issues can prevent them from escalating into major problems. Ensure all components are securely fastened and free from obstructions.

Cleaning is another vital aspect. Accumulated debris can hinder functionality, so make it a habit to remove any dirt or residue. Use appropriate cleaning agents to avoid damaging sensitive materials.

Lubrication plays a significant role as well. Applying the right type of lubricant to moving parts helps reduce friction and wear. Refer to manufacturer recommendations for the best products to use.

Lastly, store your equipment in a suitable environment. Protect it from extreme temperatures and moisture, which can lead to deterioration. Utilizing proper storage solutions can significantly enhance longevity.

Benefits of Using Hose Reels

Utilizing a specialized tool for managing and storing long flexible equipment offers numerous advantages. This system ensures efficient organization, preventing damage and simplifying both storage and retrieval. Whether for home or industrial purposes, it enhances overall productivity and durability of essential equipment, ultimately contributing to easier maintenance and longer service life.

Improved Organization

One of the primary benefits of this system is the significant improvement in organization. Keeping long, unwieldy items neatly stored prevents tangling and reduces the risk of wear and tear. It allows users to quickly access what they need without wasting time searching through a cluttered workspace.

Increased Durability

Proper storage of flexible equipment helps maintain its condition over time. By preventing unnecessary bending and kinks, the system reduces the likelihood of early damage, extending the life of the item. This is particularly important in environments where constant use is required, as it minimizes the need for frequent replacements.

| Benefit | Description |

|---|---|

| Space Saving | By keeping flexible items neatly stored, the system frees up valuable workspace and reduces clutter. |

| Enhanced Safety | A well-organized system minimizes tripping hazards and keeps equipment off the ground, improving overall safety in work areas. |

| Ease of Use | Retrieving and re-storing equipment becomes simple, reducing the time spent on setup and maintenance tasks. |

Choosing the Right Hose Reel Model

Selecting the correct model for your equipment is essential for ensuring efficiency and longevity. The right choice will depend on several factors, including the intended use, space available for storage, and durability requirements. Understanding these elements will help guide your decision-making process and ensure the optimal performance of your setup.

Key Factors to Consider

- Usage Frequency: If the tool will be used regularly, it’s crucial to choose a model that can withstand constant use without compromising its functionality.

- Material and Build Quality: Opt for sturdy materials like stainless steel or heavy-duty plastic, which offer long-lasting durability.

- Size and Storage: Consider how much space you have available for storage and whether a compact or wall-mounted design would better suit your needs.

Types of Models

- Manual Options: These are typically more affordable and simpler to use, perfect for occasional use in smaller areas.

- Automatic Versions: Ideal for frequent users, these provide convenience with features like motorized rewind and adjustable tension.

- Heavy-Duty Variants: Built for commercial or industrial settings, these options can handle larger loads and rougher conditions.