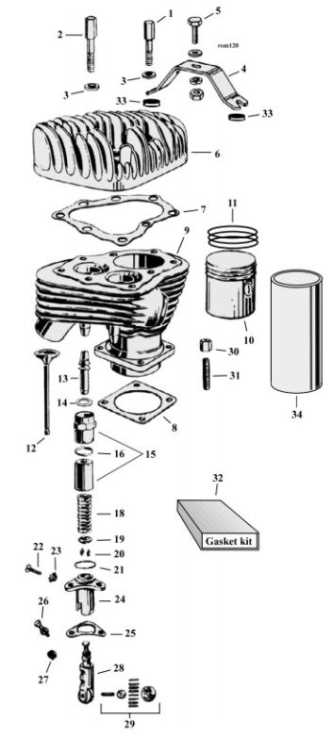

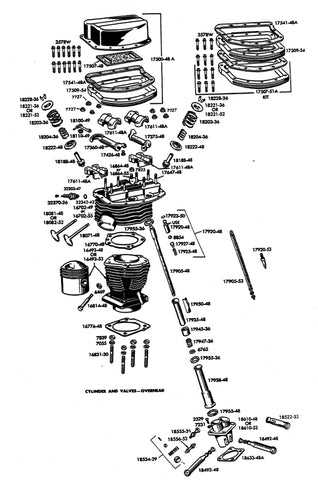

| Pistons |

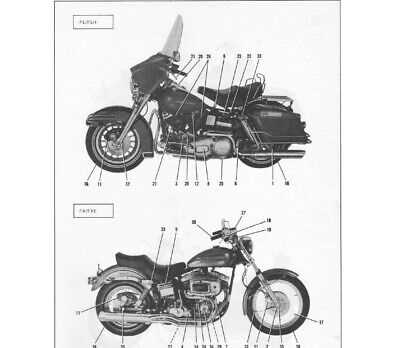

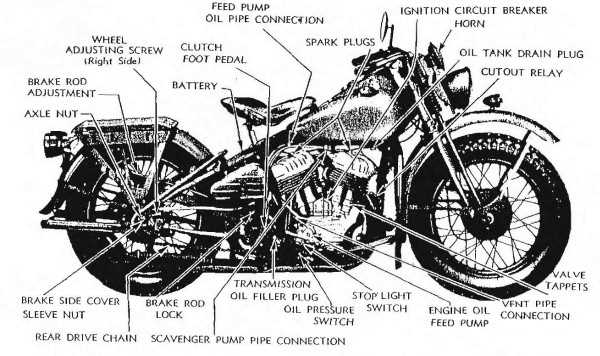

Parts Crucial for Engine Performance

The optimal performance of a vehicle’s power system relies on the seamless interaction between various key components. Each element plays a vital role in ensuring the machine runs smoothly and efficiently. Understanding the importance of these elements is essential for maintaining long-term reliability and performance.

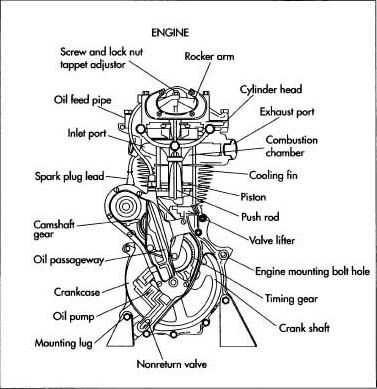

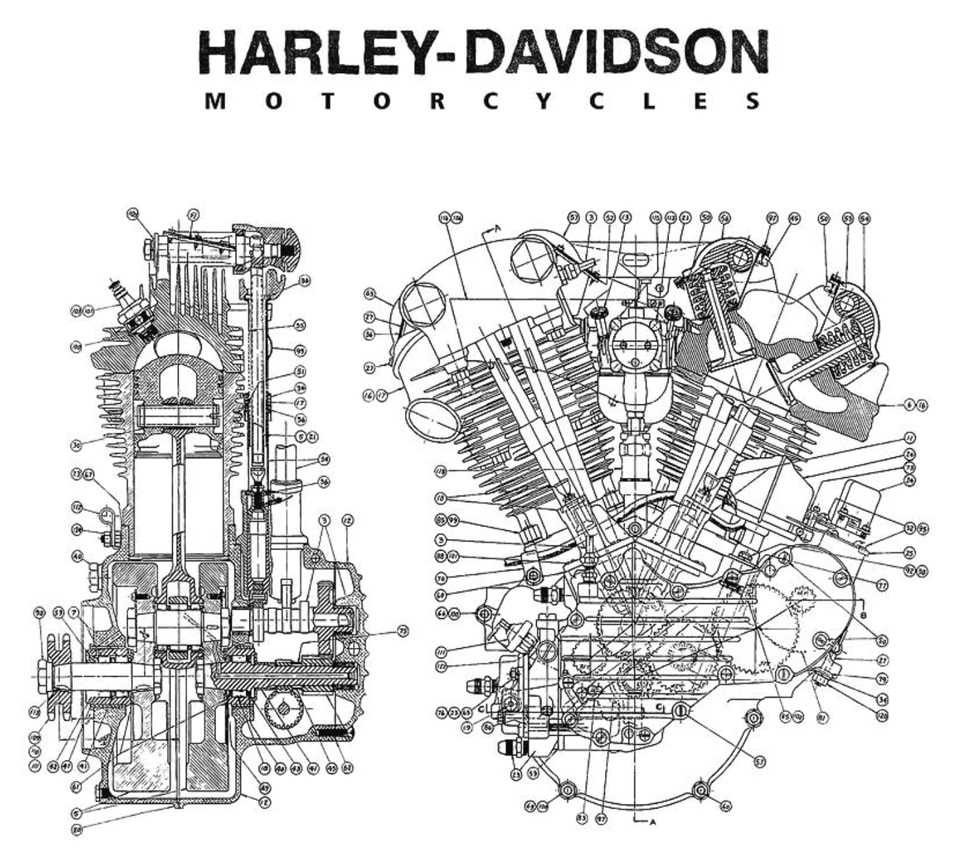

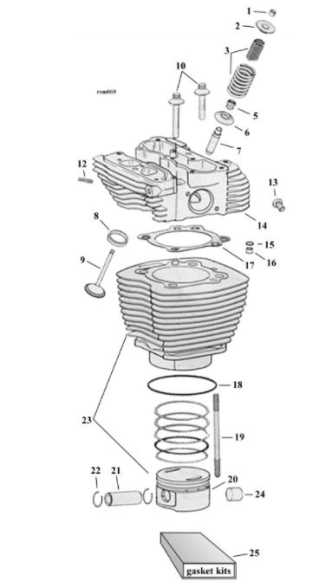

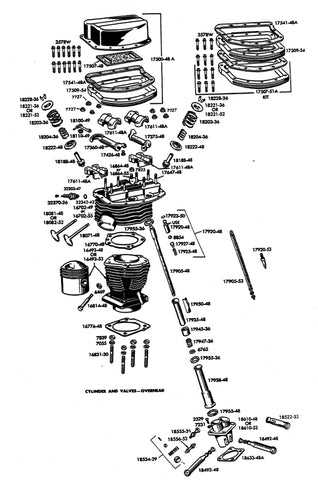

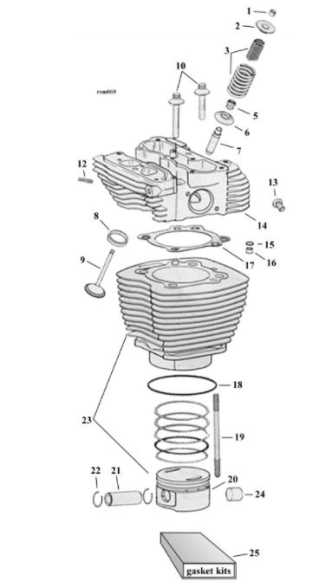

Pistons are responsible for converting the pressure generated by combustion into mechanical energy. Their condition directly affects the power output and overall operation of the machine.

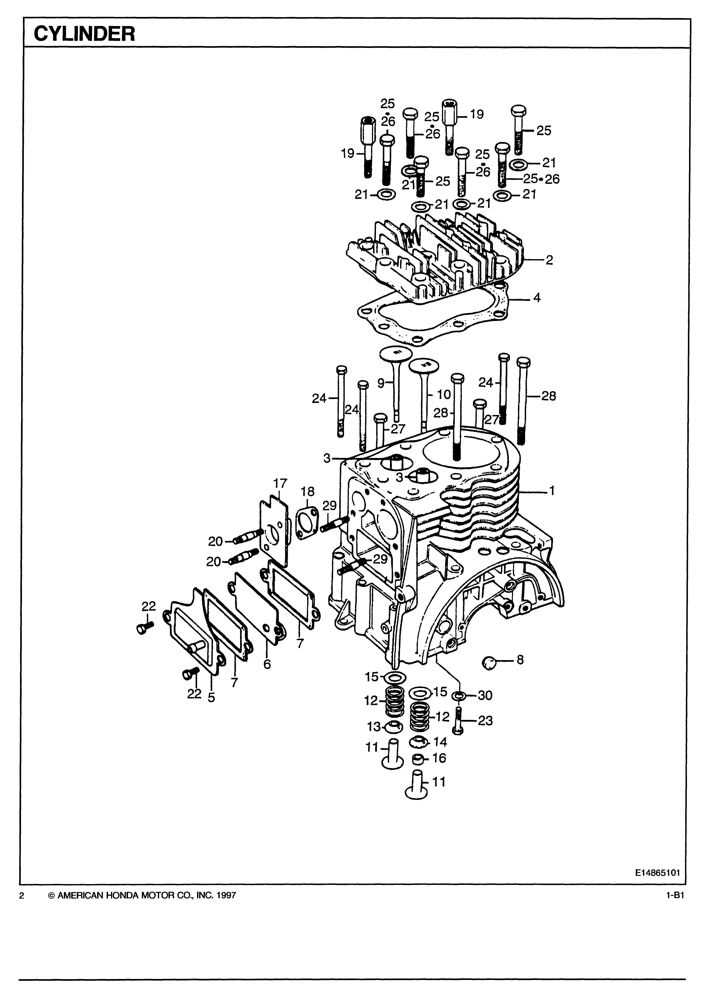

Cylinder heads manage the airflow into and out of the power chamber, impacting the efficiency of the combustion process. Proper maintenance ensures steady power generation.

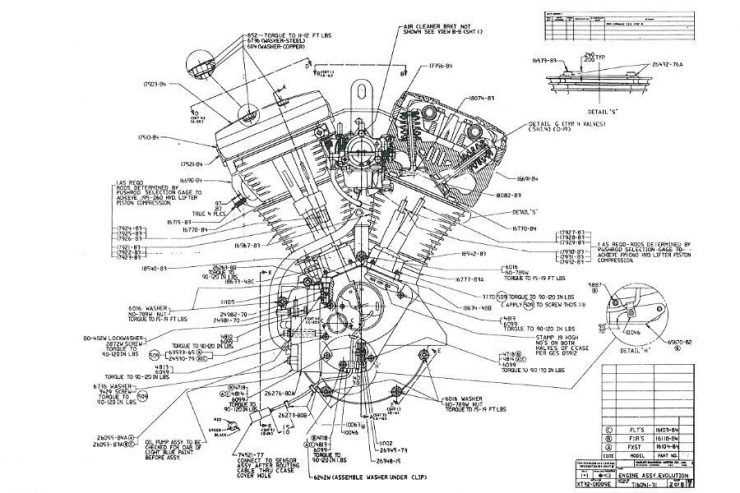

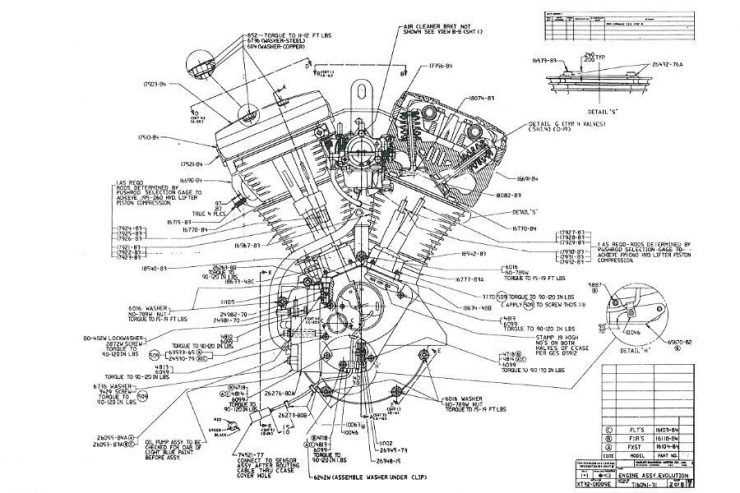

The crankshaft transforms the linear motion of the pistons into rotational force. A well-maintained crankshaft is crucial for sustaining the smooth operation of the power system.

Camshafts control the opening and closing of valves, ensuring proper timing for air and fuel intake. Any wear in this component can significantly influence performance.

The timing chain synchronizes the motion of the camshaft and crankshaft, ensuring that everything runs in harmony. A well-functioning timing chain is necessary for optimal efficiency and smooth operation.

Cooling System Elements in Harley Engines

The cooling system plays a crucial role in maintaining optimal performance, preventing excessive heat buildup, and ensuring long-term reliability. These components work together to regulate temperature, providing efficient heat dissipation and prolonging the lifespan of mechanical systems.

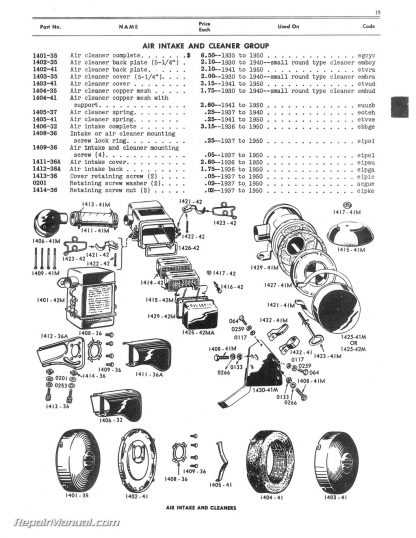

- Air Circulation Mechanism: Many models rely on a natural airflow system to dissipate heat. This design eliminates the need for liquid cooling, making it simpler and effective in keeping the machinery cool during operation.

- Cooling Fins: Strategically placed metal ridges help increase the surface area, allowing heat to escape more efficiently, particularly in high-temperature environments or during extended use.

- Oil Cooling System: In certain models, oil serves a dual purpose, both lubricating and absorbing heat from critical components. This system directs the oil through dedicated pathways, ensuring consistent thermal management.

- Thermal Sensors: Modern iterations are equipped with sensors that monitor temperature levels in real-time, automatically adjusting other elements to maintain an optimal range.

All of these features work collectively to ensure stable performance, even under challenging conditions, ensuring the machinery remains efficient and durable.

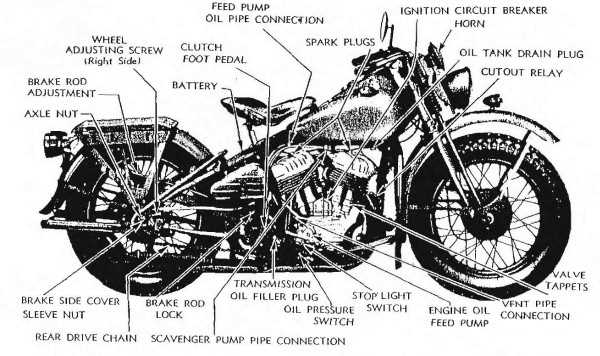

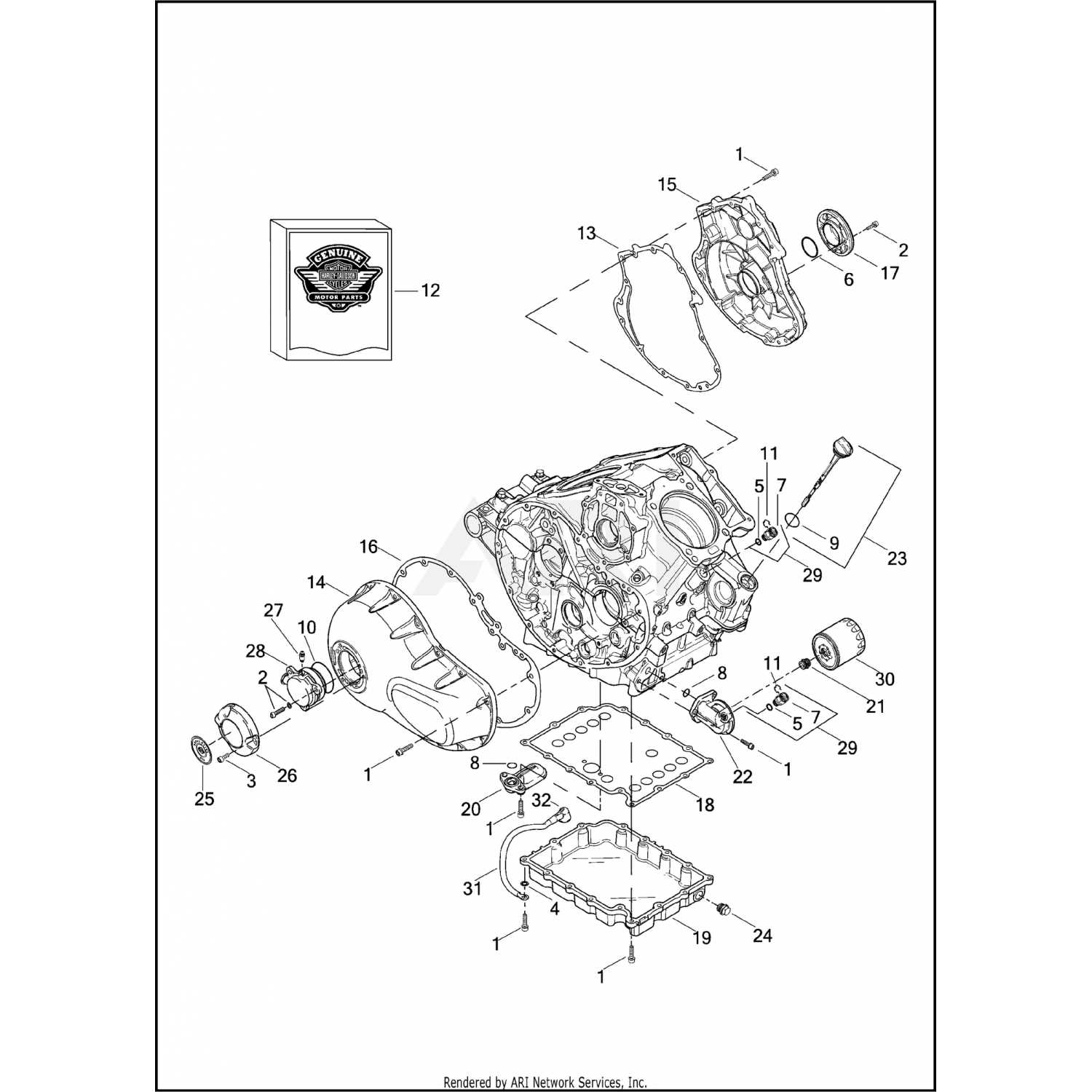

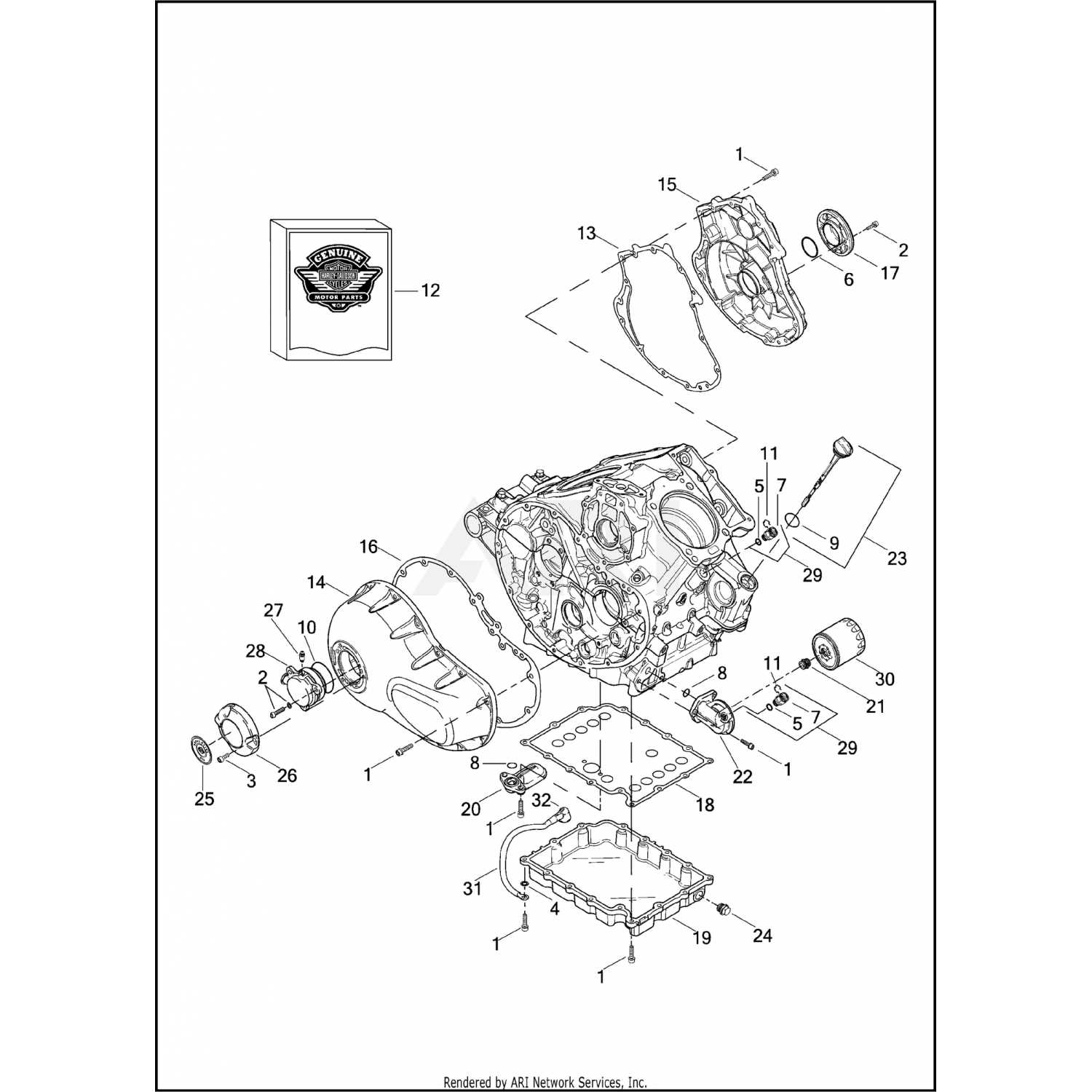

Lubrication Parts and Their Role

The lubrication system plays a crucial role in ensuring the smooth operation and longevity of mechanical components. By reducing friction between moving elements, this system prevents wear and overheating, ultimately enhancing performance. Proper maintenance of these components is essential to keep the machinery functioning efficiently over time.

Oil Filters are responsible for removing impurities from the lubricant, ensuring that only clean oil circulates through the system. This prevents debris from causing damage to critical components.

Pumps move the oil through the system, ensuring that all areas are adequately lubricated. Without them, parts would be deprived of necessary lubrication, leading to increased friction and potential failure.

Lubricant Lines deliver oil to specific areas, ensuring precise distribution. Their role is to ensure that every part receives the right amount of lubrication at the right time.

In conclusion, a well-maintained lubrication system is essential for reducing wear, improving efficiency, and extending the life of mechanical components.

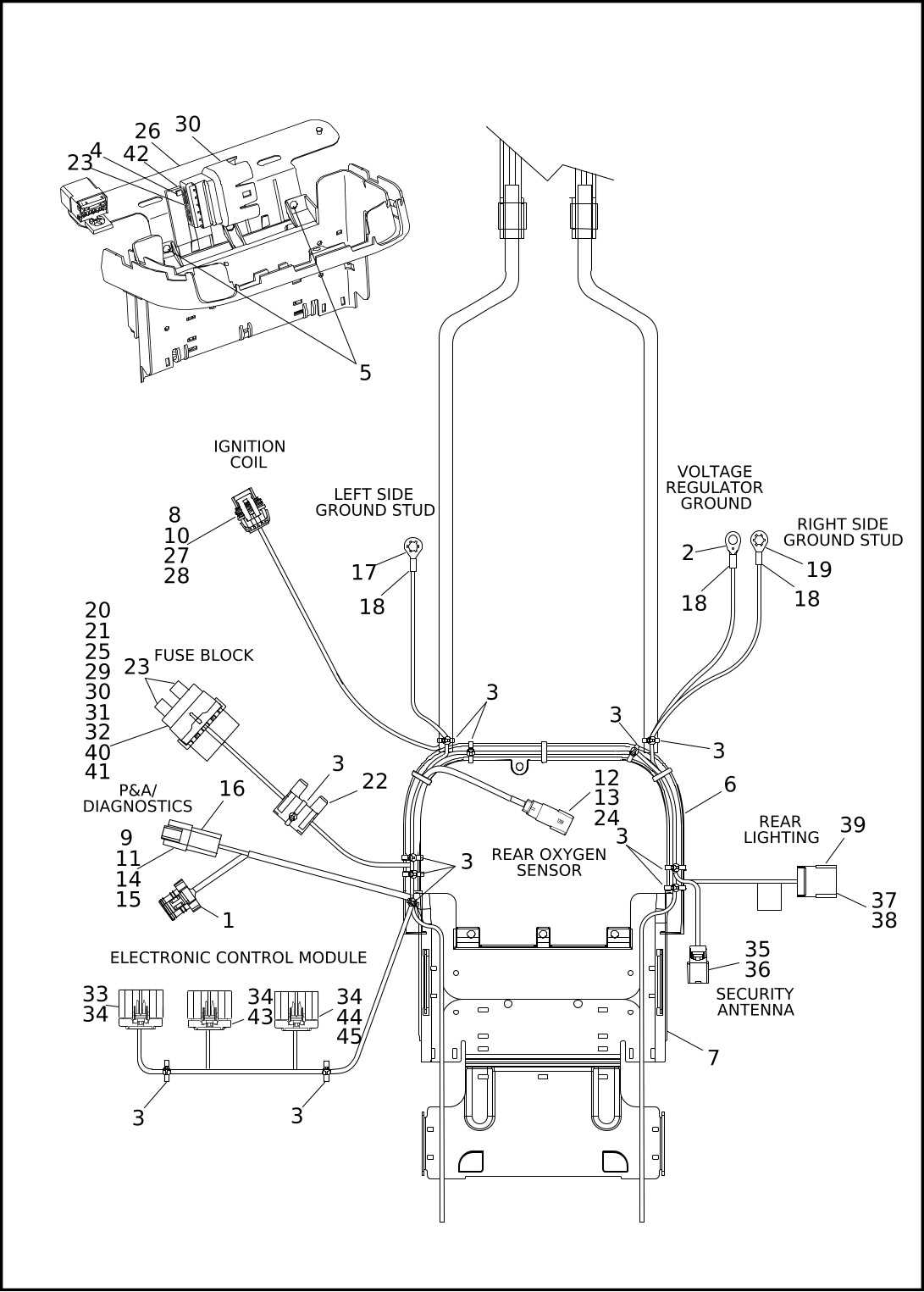

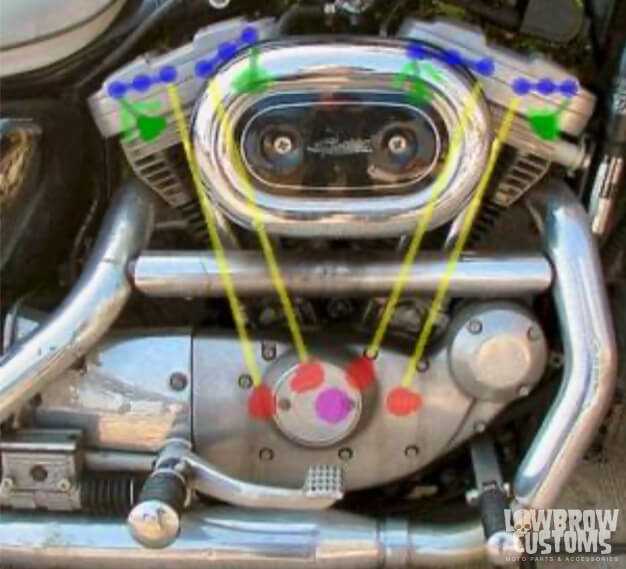

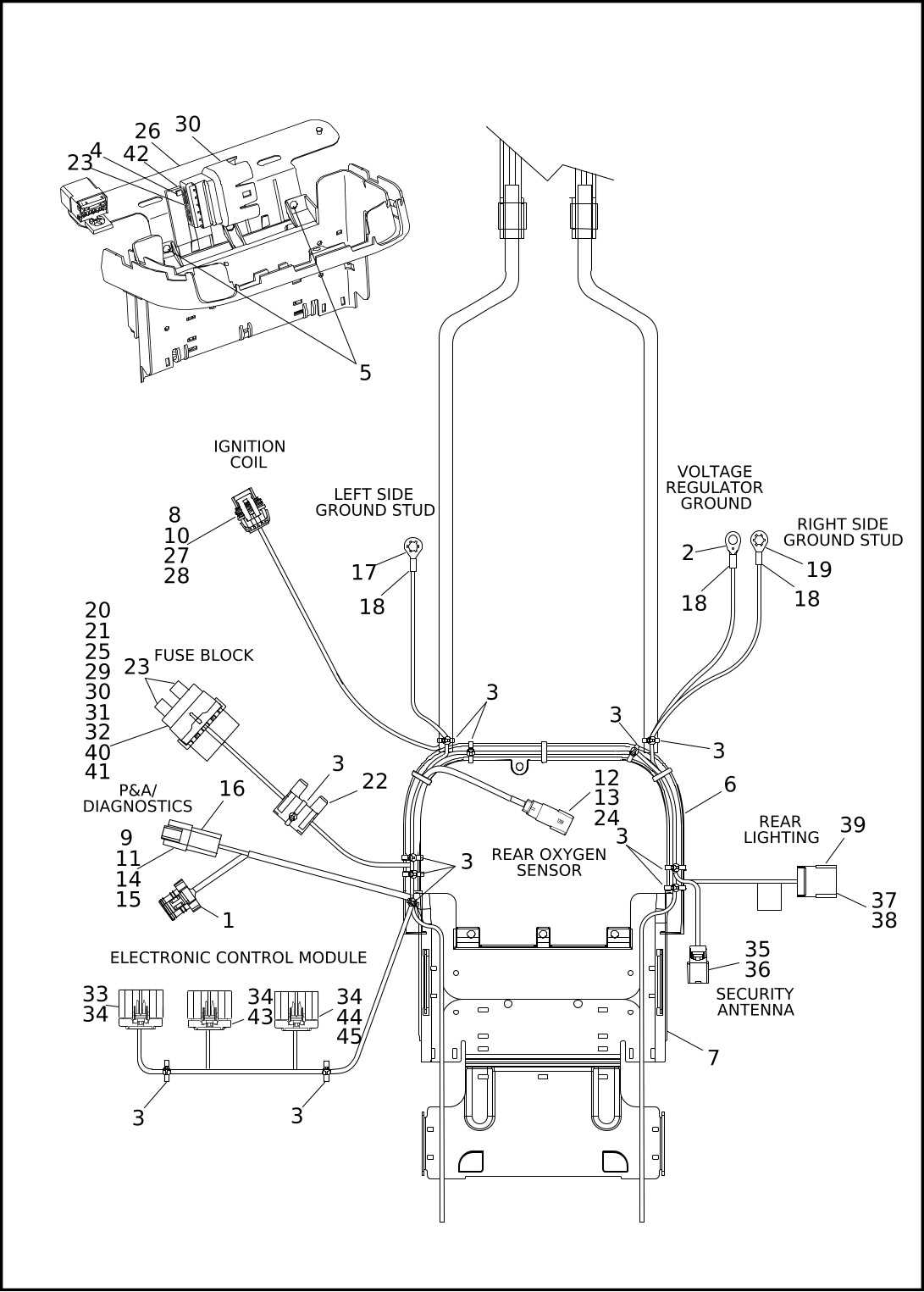

Ignition System Components and Functions

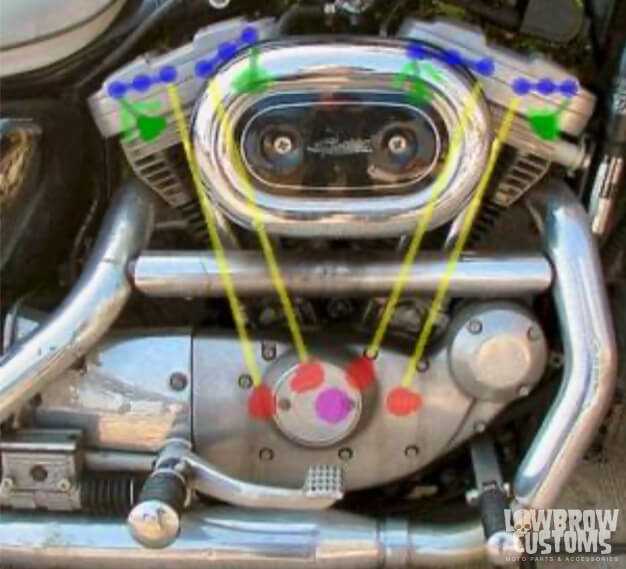

The ignition system is a crucial element in the functioning of a motorcycle, responsible for initiating the combustion process within the combustion chamber. This system comprises several components that work together to create a reliable spark, ensuring optimal engine performance and efficiency.

Key Components

The primary elements of the ignition system include the spark plug, ignition coil, and distributor. The spark plug generates the spark necessary for combustion, while the ignition coil transforms low voltage from the battery into high voltage, enabling the spark plug to ignite the fuel-air mixture. The distributor directs the high-voltage current to the appropriate spark plug at the right moment during the engine’s cycle.

Functionality Overview

Each component plays a vital role in ensuring the ignition process operates smoothly. The ignition coil receives a signal from the electronic control unit, causing it to generate a high-voltage pulse. This pulse travels through the distributor to the spark plug, igniting the mixture within the cylinder. Efficient operation of the ignition system contributes significantly to the overall performance, fuel efficiency, and emissions of the vehicle.

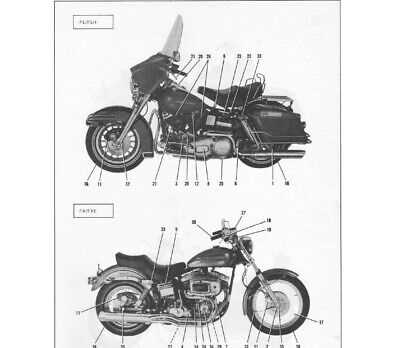

Exhaust System Parts in Harley Motors

The exhaust system is a crucial component of motorcycles, responsible for directing waste gases away from the engine while enhancing performance. Understanding the various elements that comprise this system is essential for maintenance and upgrades.

- Muffler: This component reduces noise produced by the engine’s exhaust gases.

- Header Pipes: These pipes connect the engine’s exhaust outlets to the rest of the exhaust system.

- Collector: A junction point where multiple exhaust pipes converge before exiting the system.

- Heat Shields: Protective coverings that prevent heat damage to surrounding components.

- Exhaust Tips: The visible end of the exhaust system, often customizable for aesthetics and performance.

Regular inspection and replacement of these components can lead to improved efficiency and a more satisfying riding experience.

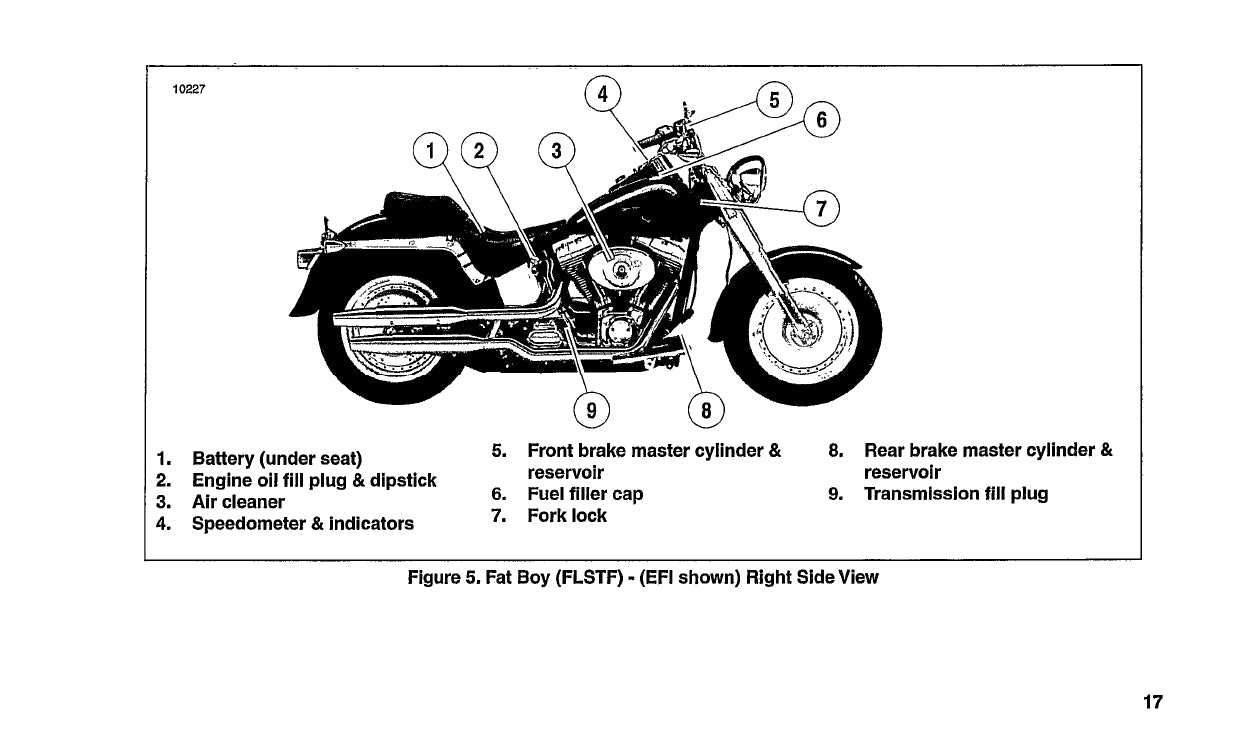

Maintenance Tips for Engine Longevity

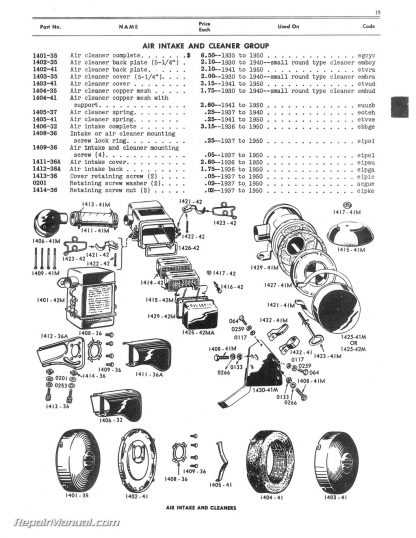

Ensuring the durability of your motor requires consistent care and attention. Regular maintenance not only enhances performance but also extends the life of various components. By following a few essential practices, you can keep your machinery in optimal condition.

- Regular Oil Changes: Frequent oil changes help maintain proper lubrication, reducing friction and wear on moving parts.

- Check Fluid Levels: Ensure that all fluids, including coolant and transmission fluid, are at appropriate levels to prevent overheating and ensure smooth operation.

- Inspect Filters: Clean or replace air and fuel filters periodically to ensure efficient airflow and fuel delivery.

- Monitor Tire Pressure: Maintaining the correct tire pressure can improve handling and reduce unnecessary strain on the entire system.

- Keep It Clean: Regularly clean the exterior and components to prevent dirt accumulation, which can lead to corrosion and mechanical issues.

By implementing these tips, you can significantly enhance the performance and reliability of your vehicle, ensuring a smooth ride for years to come.

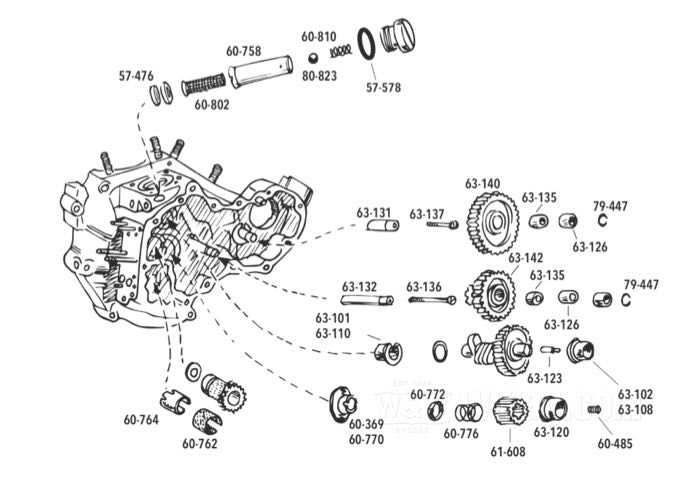

Upgrading and Replacing Engine Components

Enhancing performance and efficiency in motor vehicles often involves modernizing or substituting specific elements within the propulsion system. This process not only boosts functionality but can also lead to improved longevity and reliability of the overall mechanism.

When considering modifications, it is crucial to evaluate various aspects:

- Performance Enhancement: Upgrades can significantly increase horsepower and torque.

- Fuel Efficiency: New components may offer better fuel consumption rates.

- Reliability: Replacing worn-out elements ensures consistent operation.

- Customization: Tailoring components to suit individual preferences enhances the riding experience.

Before proceeding with any upgrades, follow these steps:

- Research: Investigate available options and determine compatibility.

- Consult Experts: Seek advice from knowledgeable professionals in the field.

- Quality Parts: Choose high-quality replacements to ensure durability.

- Installation: Follow guidelines meticulously for optimal results.

In conclusion, modernizing and replacing specific components is a vital aspect of maintaining and enhancing the overall performance of a motor vehicle, leading to a more enjoyable and efficient ride.