When it comes to maintaining outdoor spaces, having a thorough understanding of your cleaning device can make all the difference. This guide offers a closer look at the various components that ensure optimal performance, making it easier to troubleshoot issues and perform necessary maintenance. Knowing each element’s function will enhance your ability to use your equipment effectively.

Every device is composed of several integral components that work in harmony to deliver powerful cleaning results. By familiarizing yourself with these elements, you can quickly identify what might be affecting the efficiency of your machine. This knowledge not only aids in repairs but also empowers you to maximize the lifespan of your equipment.

In this exploration, we will delve into the various sections and features, providing clarity on how they interact and contribute to the overall functionality. Understanding these relationships is essential for anyone looking to maintain their cleaning device in peak condition.

Understanding Your Stanley Pressure Washer

Gaining insight into your cleaning equipment is essential for effective use and maintenance. Familiarizing yourself with the various components can enhance performance and longevity. This section will guide you through the fundamental elements of your cleaning machine, ensuring you can operate it with confidence and efficiency.

Key Components to Know

Every cleaning device is made up of several critical elements that work together to achieve optimal results. Here are the main parts to be aware of:

- Motor: Powers the machine, providing the necessary energy for operation.

- Pump: Creates the pressure needed for the water to effectively remove dirt and grime.

- Nozzle: Directs the flow of water, allowing for different spray patterns to suit various tasks.

- Hose: Transports water from the source to the nozzle, available in various lengths and materials.

- Trigger: Controls the release of water, giving you control over the flow and pressure.

Maintenance Tips

To ensure your equipment remains in top shape, regular maintenance is crucial. Here are some best practices:

- Check the motor and pump for any signs of wear or damage.

- Clean the nozzle regularly to prevent clogs and ensure a consistent spray pattern.

- Inspect the hose for leaks or cracks that could reduce efficiency.

- Store the machine in a dry place to avoid moisture damage.

- Follow the manufacturer’s guidelines for regular servicing and replacement of worn components.

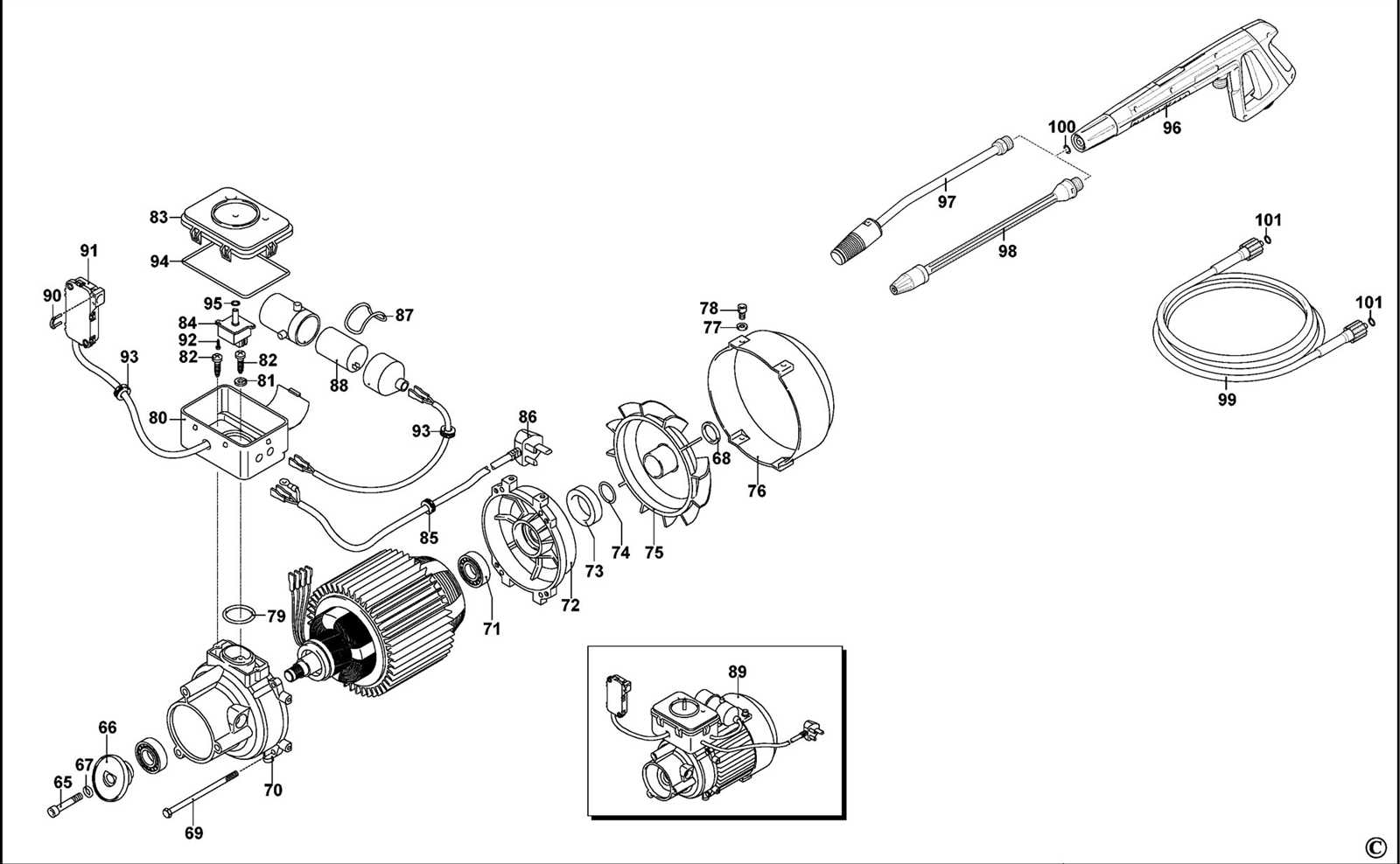

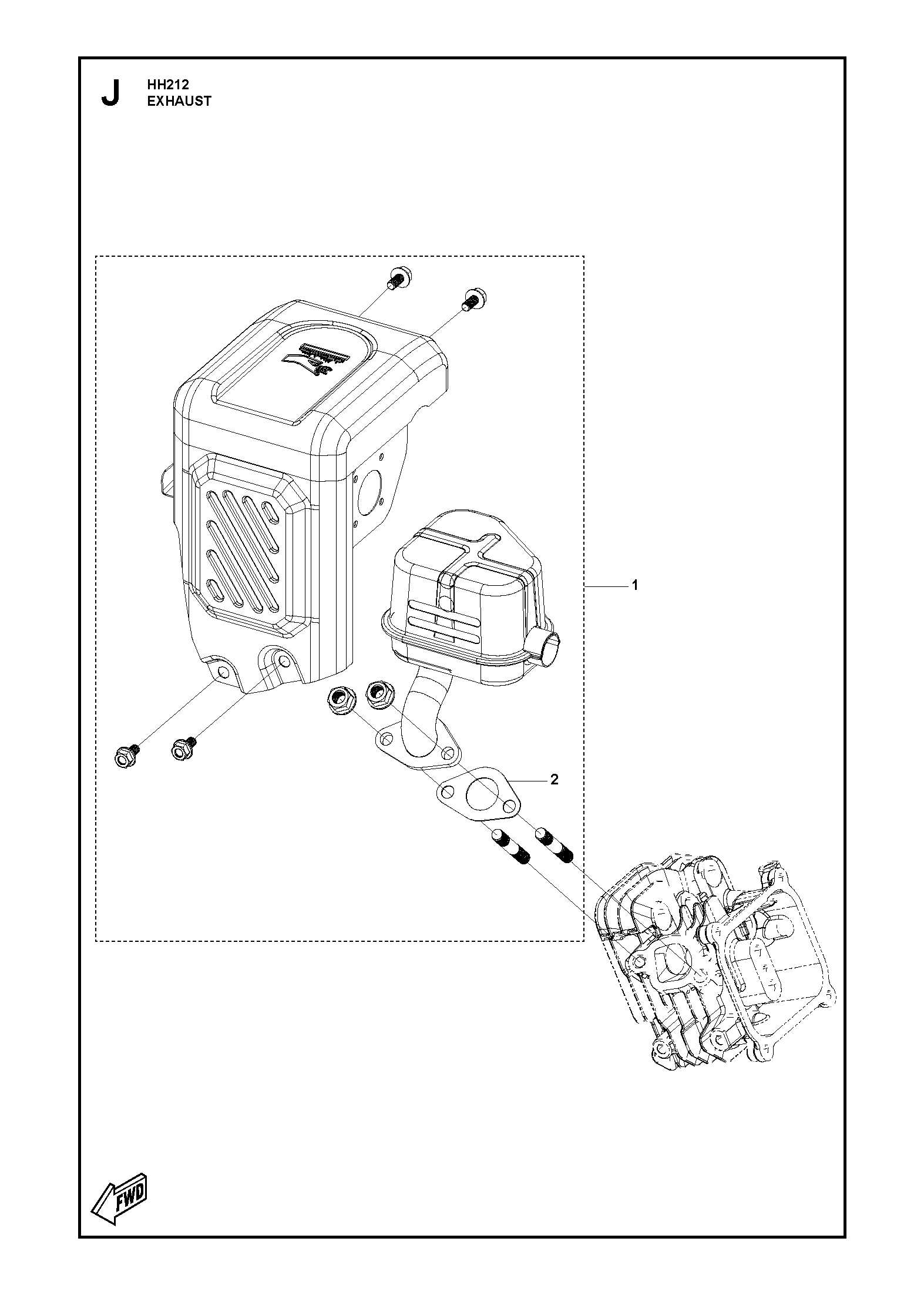

Importance of Parts Diagrams

Understanding the components of any device is crucial for effective maintenance and repair. Visual representations of these elements not only provide clarity but also enhance the efficiency of troubleshooting processes. By offering a comprehensive overview, such illustrations serve as essential tools for both professionals and enthusiasts alike.

Benefits of Visual Guides

Utilizing visual aids in repair tasks offers several advantages:

| Advantage | Description |

|---|---|

| Clarity | Illustrations simplify complex assemblies, making it easier to identify and understand individual components. |

| Efficiency | Quick reference to visuals speeds up the identification of issues and necessary parts during maintenance. |

| Reduced Errors | Having a clear visual guide minimizes the risk of misidentification, which can lead to improper repairs. |

| Accessibility | Diagrams make it easier for individuals with varying levels of expertise to engage with the maintenance process. |

Conclusion

Incorporating visual representations into maintenance practices is invaluable. They not only enhance understanding but also contribute to more effective and efficient repairs. Embracing these resources can lead to improved performance and longevity of equipment.

Common Components of Pressure Washers

Understanding the essential elements of cleaning devices can greatly enhance their effectiveness and longevity. These crucial components work together to create a powerful cleaning experience.

- Motor: The heart of the system, providing the necessary energy to operate.

- Pump: Responsible for generating high-pressure water flow, essential for effective cleaning.

- Hose: Transfers water from the pump to the nozzle, often varying in length and material.

- Nozzle: Directs the flow of water, available in various shapes for different cleaning tasks.

- Frame: Supports and protects the internal components while providing mobility.

Familiarity with these elements allows users to delve deeper into troubleshooting and maintenance, ultimately leading to a more satisfying cleaning experience.

How to Read a Parts Diagram

Understanding a component illustration is essential for effective maintenance and repairs. Such visuals provide a clear representation of individual elements and their relationships within a system. By familiarizing yourself with the layout, you can streamline the troubleshooting and assembly processes.

To effectively interpret a component illustration, consider the following steps:

- Identify the Key: Most illustrations come with a legend or key that explains symbols and numbering. Familiarize yourself with these to understand the components.

- Break Down the Sections: Look for distinct sections within the illustration. Group similar elements together to grasp the overall structure more easily.

- Trace Connections: Follow lines or arrows that indicate how components interact. This will help you understand the flow and function of the entire system.

- Check for Notes: Pay attention to any annotations or notes included in the illustration. They often provide valuable insights or warnings that can aid in repairs.

By following these steps, you’ll gain confidence in navigating any technical illustration, making repairs and maintenance tasks more efficient and effective.

Identifying Worn Parts Quickly

Recognizing the signs of deterioration in your equipment can significantly enhance its performance and longevity. By being proactive in assessing the condition of various components, you can prevent more severe issues and ensure optimal functionality. This section outlines effective methods to identify wear and tear efficiently.

Visual Inspection Techniques

Begin with a thorough visual examination of all accessible components. Look for cracks, chafing, or any discoloration that might indicate fatigue. Pay special attention to areas that experience friction or pressure, as these are typically the first to show signs of wear. Using a magnifying glass can aid in detecting minor damages that might go unnoticed at first glance.

Performance Monitoring

Regularly monitor the performance of your equipment during use. Any unusual sounds, vibrations, or drops in efficiency can signal potential issues. If you notice a decrease in operational power or consistency, it may be time to investigate further. Keeping a log of performance trends can also help identify patterns of deterioration over time.

Replacement Parts for Stanley Models

Maintaining the efficiency and performance of your equipment often requires specific components to be replaced over time. Understanding the different elements that may need attention can help prolong the lifespan and functionality of your machine. This section explores the essential replacements that may be necessary for various models.

Common Components to Consider: Regular usage can lead to wear and tear on critical parts. Key items such as hoses, nozzles, and connectors may require replacement to ensure optimal operation. Additionally, filters and seals play a crucial role in maintaining performance and preventing leaks.

Finding the Right Fit: It is vital to select components that are compatible with your specific model. Referencing a detailed guide can assist in identifying the correct pieces, ensuring seamless integration and function. Investing in quality replacements will not only enhance performance but also ensure safety during operation.

In summary, being proactive about identifying and replacing worn elements can greatly improve your equipment’s reliability and effectiveness, helping you achieve the best results in your cleaning tasks.

Maintenance Tips for Longevity

To ensure the extended life of your cleaning equipment, regular upkeep is essential. Proper care not only enhances performance but also prevents costly repairs over time. Here are some effective strategies to keep your device in top shape.

| Tip | Description |

|---|---|

| Regular Cleaning | After each use, remove any debris and dirt. This prevents buildup that can affect performance. |

| Inspect Hoses | Check hoses for wear and tear. Replace any damaged sections to avoid leaks and ensure proper flow. |

| Lubricate Moving Parts | Apply lubricant to any moving components to reduce friction and prolong their life. |

| Store Properly | Keep the equipment in a dry, sheltered area to protect it from environmental damage. |

| Follow Manufacturer’s Guidelines | Adhere to the instructions provided for maintenance schedules and procedures to maintain warranty coverage. |

Implementing these simple yet effective practices can significantly enhance the durability and functionality of your cleaning device, ensuring it serves you well for years to come.

Where to Buy Genuine Parts

When it comes to maintaining the efficiency of your cleaning equipment, sourcing authentic components is crucial. Genuine items ensure compatibility and longevity, helping you avoid issues that can arise from using substandard alternatives. Knowing where to find these original supplies can make all the difference in your upkeep efforts.

Authorized retailers and service centers are reliable sources for authentic items, providing assurance that you are purchasing quality. These outlets often have a comprehensive inventory and knowledgeable staff ready to assist with your needs. Additionally, exploring the manufacturer’s official website can lead you to certified distributors, ensuring you access the right components for your machinery.

Online marketplaces may also offer a variety of options, but caution is advised. Verify the seller’s reputation and look for reviews to ensure you receive genuine products. Investing time in locating trusted sources pays off, as it enhances the performance and durability of your equipment.

DIY Repairs: Safety First

Engaging in home repairs can be rewarding, but prioritizing safety is essential. Proper precautions not only protect you but also enhance the effectiveness of your work. Understanding potential hazards and preparing adequately can prevent accidents and ensure a smooth repair experience.

Before starting any repair task, consider the following:

Wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This minimizes the risk of injury from tools and materials. Ensure your workspace is clear of clutter to avoid trips and falls. Additionally, familiarize yourself with the equipment and its operational manual to handle it properly.

Being mindful of these safety measures can significantly impact the success of your DIY endeavors, allowing you to delve into repairs with confidence and achieve ultimate satisfaction.