The intricate design of high-pressure cleaning systems involves a variety of essential elements that work in harmony to ensure optimal functionality. These components, though often overlooked, play a critical role in the overall performance and efficiency of the equipment.

In this section, we will explore the various elements involved in these systems, highlighting their unique functions and interconnections. Gaining insight into these components not only enhances your understanding but also empowers you to maintain and troubleshoot the equipment effectively.

By delving into the mechanics behind these high-performance systems, you’ll uncover the ultimate synergy between each element, leading to more informed decisions regarding repairs and upgrades. This knowledge is invaluable for anyone seeking to maximize the potential of their cleaning technology.

Understanding Pressure Washer Pump Functionality

The effectiveness of a cleaning device relies heavily on its internal mechanisms, which play a crucial role in generating the necessary force for thorough cleansing. This section delves into how these essential components operate to create a powerful flow, enabling users to tackle various cleaning tasks with ease.

Key Components and Their Roles

At the heart of the system, the motor drives a series of mechanisms that work in tandem. The initial stage involves the intake of water, which is then transformed through various stages to increase its velocity. Each element contributes uniquely to this process, ensuring that the output meets the demands of different surfaces and types of grime.

How Functionality Affects Performance

The efficiency of these internal elements directly influences the overall performance. A well-designed assembly allows for optimal fluid dynamics, resulting in a steady stream that maximizes cleaning power. Regular maintenance is vital, as wear and tear can diminish effectiveness, making it essential for users to understand the interplay between each component for optimal results.

Essential Components of Pressure Washer Pumps

Understanding the fundamental elements that contribute to the efficient functioning of cleaning equipment is crucial for both maintenance and performance. Each component plays a specific role, ensuring that the device operates smoothly and effectively. Familiarity with these elements can aid users in troubleshooting and enhancing their cleaning experience.

Main Elements

- Motor: Provides the necessary power to operate the system, converting electrical energy into mechanical energy.

- Compressor: Increases the pressure of the fluid, enabling it to be expelled at high velocities.

- Valves: Control the flow of the liquid, ensuring it moves through the system efficiently.

- Seals: Prevent leaks and ensure that the internal components function optimally.

Supportive Features

- Intake Filter: Filters out debris to protect internal components from damage.

- Hoses: Carry the fluid from the source to the nozzle, designed to withstand high pressure.

- Nozzle: Regulates the spray pattern and pressure, allowing for versatility in cleaning tasks.

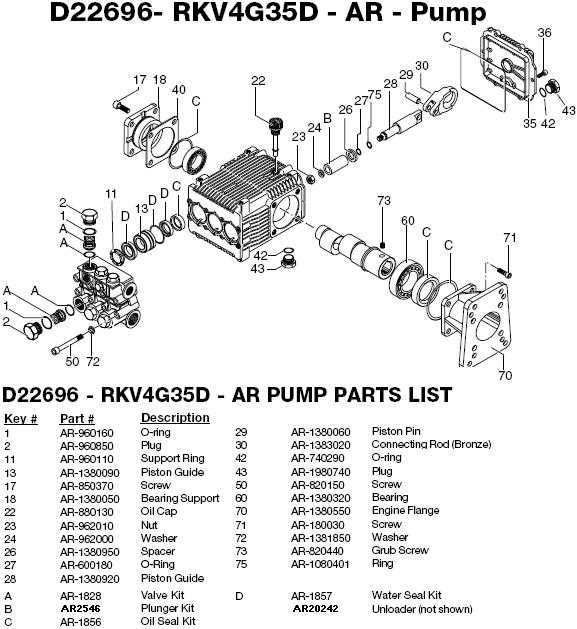

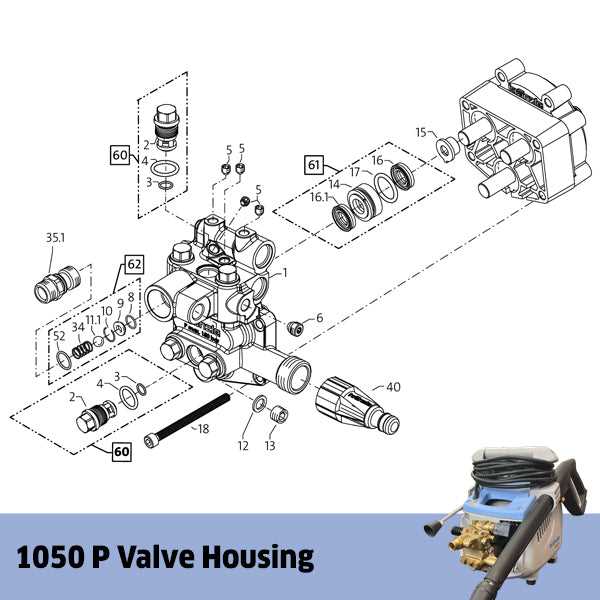

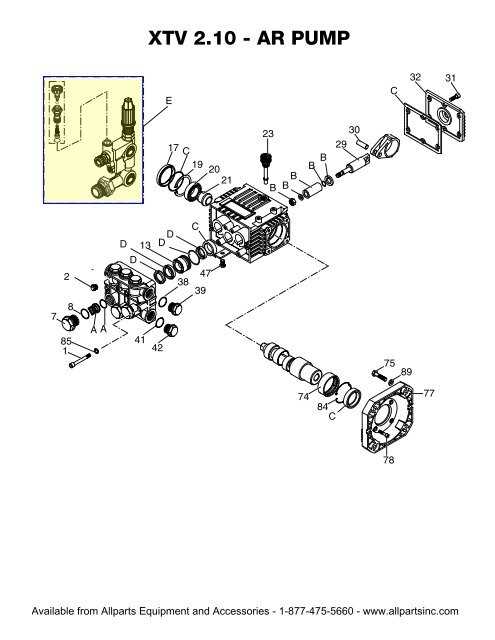

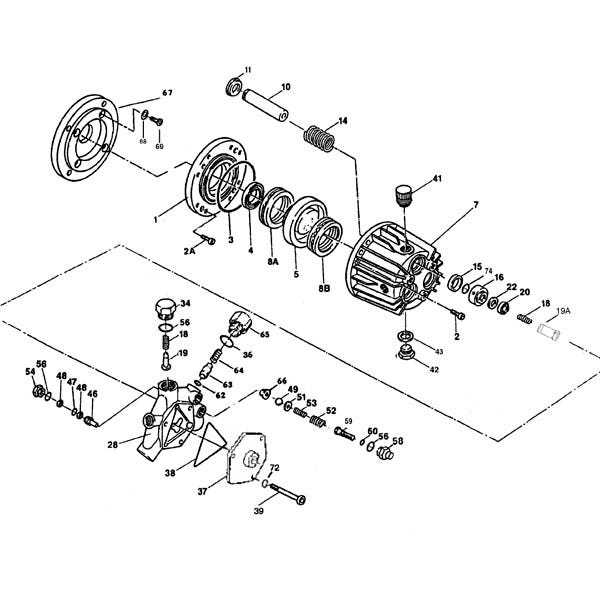

How to Read Pump Diagrams

Understanding schematic representations of mechanical systems is essential for effective maintenance and troubleshooting. These illustrations provide vital information about the components and their relationships, enabling users to grasp the functionality of the entire system. Knowing how to interpret these visuals can save time and enhance the efficiency of repairs.

First, familiarize yourself with the symbols used in these representations. Each symbol corresponds to a specific element, such as valves, seals, and connectors. Key features often include arrows indicating the direction of flow and lines representing various connections. Pay attention to the legend, which typically explains the meaning of each symbol, making it easier to decode the schematic.

Next, analyze the layout of the illustration. Look for clusters of components that work together and observe how they connect with one another. This will help you understand the flow of the system and identify potential points of failure. Visualizing the relationships between different elements is crucial for diagnosing issues effectively.

Finally, consult the accompanying documentation if available. Manuals often provide additional insights and specifications that enhance your understanding of the system. Cross-referencing the schematic with real-life components can further aid in grasping how everything fits together, ensuring you are well-equipped to manage any tasks related to the mechanical assembly.

Common Types of Pressure Washer Pumps

When it comes to high-pressure cleaning devices, the heart of the system lies in its various types of mechanisms. Each type is designed to deliver unique benefits, optimizing performance for different tasks and user needs.

Triplex Pumps

Triplex mechanisms are known for their efficiency and durability. These systems feature three pistons, allowing for a smoother operation and enhanced pressure output. They are often found in commercial-grade devices, providing the ultimate cleaning power for tough jobs.

Axial Pumps

Axial designs are generally favored for residential use due to their compact size and affordability. With a simple construction, these devices are easy to maintain and operate effectively for lighter cleaning tasks, making them a popular choice among homeowners.

Identifying Pump Parts and Their Roles

Understanding the various components of a high-performance cleaning device is essential for effective maintenance and operation. Each element plays a crucial role in ensuring optimal functionality and longevity of the equipment.

Main Components

- Motor: Provides the necessary energy to drive the system.

- Intake Valve: Regulates the flow of fluid into the unit.

- Outlet Valve: Controls the release of fluid, ensuring pressure is maintained.

- Cylinder: Houses the mechanism for fluid compression.

- Piston: Creates the necessary force to propel the fluid.

- Efficiency: Each component contributes to the overall performance.

- Durability: Understanding roles aids in proper upkeep, extending the device’s lifespan.

- Problem Solving: Identifying components helps diagnose issues quickly.

Maintenance Tips for Pump Longevity

Ensuring the durability and efficiency of your cleaning device requires regular care and attention. By following a few essential practices, you can significantly extend its operational life and maintain optimal performance.

Firstly, routine inspections are crucial. Regularly check for any signs of wear or damage, particularly in critical components. Identifying issues early can prevent more significant problems down the line.

Next, keep the interior clean. Accumulation of debris or contaminants can hinder functionality. Regularly flush the system with clean water to remove any buildup, ensuring smooth operation.

Additionally, pay attention to lubrication. Properly lubricated components reduce friction and wear, enhancing the overall efficiency of your equipment. Refer to the manufacturer’s guidelines for the correct lubricants and intervals.

Temperature management is another vital aspect. Avoid operating your device in extreme conditions, as excessive heat can cause overheating and premature failure. Always follow the recommended temperature ranges.

Finally, consider seasonal maintenance. Before storing the unit for extended periods, take steps to prepare it, such as draining fluids and cleaning filters. This proactive approach can prevent deterioration and ensure it’s ready for use when needed.

Troubleshooting Common Pump Issues

Understanding the frequent complications that may arise in water delivery systems is essential for maintaining efficiency. This section highlights common challenges and provides solutions to ensure optimal operation.

No Flow: If water isn’t flowing, check for blockages in the inlet or outlet hoses. Ensure that all connections are secure and free from debris. Additionally, inspect the intake screen for any clogs that may impede water flow.

Low Pressure: Reduced output pressure can result from various factors, including worn seals or improper nozzle selection. Verify that the nozzle is appropriate for your task and inspect seals for wear and tear. Regular maintenance can prevent these issues from escalating.

Overheating: Excessive heat may indicate insufficient water supply or a malfunctioning motor. Ensure that the device is receiving a steady water source, and allow it to cool down during extended use. If overheating persists, consider consulting a professional.

Unusual Noises: Strange sounds can signal mechanical issues. Listen for grinding or rattling, which may suggest loose components or internal damage. Conduct a thorough inspection to identify and rectify any potential problems.

Addressing these common issues promptly can enhance the longevity and performance of your system. Regular inspections and maintenance are key to preventing minor complications from becoming major repairs.

Choosing the Right Replacement Parts

When maintaining outdoor equipment, selecting suitable components is crucial for optimal performance and longevity. The right choices can significantly enhance efficiency and reduce the likelihood of future repairs. Understanding the different options available and their specific functions will guide you in making informed decisions.

Factors to Consider

Before purchasing new components, consider factors such as compatibility, quality, and manufacturer reputation. It’s essential to ensure that the new elements fit seamlessly with your existing system. Higher quality products often provide better durability, so investing in reputable brands may save you money in the long run.

Types of Components

| Type | Description |

|---|---|

| Seals | Prevent leaks and maintain pressure, essential for efficient operation. |

| Valves | Regulate flow and control pressure levels, vital for safety and functionality. |

| Filters | Keep debris from entering the system, protecting internal components from damage. |

| Hoses | Transport fluid to various parts, must withstand high pressure and wear. |

Thoroughly researching and understanding these factors will enable you to choose components that not only fit but also enhance the overall performance of your equipment. By investing time in the selection process, you can ensure a more reliable and effective operation.