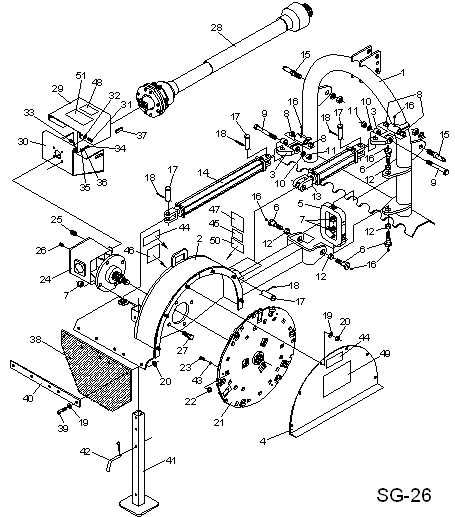

In the world of landscaping and forestry, the effectiveness of a cutting device heavily relies on its internal structure and the various elements that work in harmony. A comprehensive grasp of these components not only enhances maintenance practices but also optimizes operational efficiency. By familiarizing oneself with the intricate layout of these devices, users can ensure longevity and performance during challenging tasks.

Component identification plays a pivotal role in troubleshooting and repair. When operators have a clear understanding of how each piece fits into the whole, they can address issues more swiftly and accurately. This knowledge empowers users to manage their machinery effectively, preventing potential downtime and costly repairs.

Additionally, being well-versed in the individual roles of each segment can significantly contribute to safety measures. Recognizing which parts are critical to safe operation allows for better preparation and vigilance, ultimately fostering a more secure working environment. Through detailed exploration of these elements, operators can elevate their expertise and enhance their overall experience with heavy-duty machinery.

Understanding Rayco Stump Grinders

Exploring the mechanisms behind specialized machinery designed for earthworks unveils a range of components crucial for efficient operation. These tools are engineered to tackle challenging tasks, enhancing productivity in land management and landscaping projects.

Key Features

- Robust construction for durability

- Advanced cutting technologies

- Compact design for maneuverability

- Hydraulic systems for optimal power transfer

Benefits of Efficient Machinery

- Increased efficiency in land clearing

- Reduction in manual labor requirements

- Improved safety during operation

- Ability to access hard-to-reach areas

Importance of Maintenance for Equipment

Regular upkeep of machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to breakdowns, increased operational costs, and safety hazards. By prioritizing care, operators can enhance efficiency and minimize the risk of unforeseen issues.

Benefits of Regular Maintenance

- Increased Lifespan: Routine checks and repairs extend the operational life of equipment.

- Improved Performance: Well-maintained machinery operates at peak efficiency, delivering better results.

- Cost Savings: Preventative measures reduce the likelihood of costly repairs and downtime.

- Safety Assurance: Regular inspections help identify potential hazards, ensuring a safer working environment.

Key Maintenance Practices

- Regular Inspections: Schedule routine assessments to catch issues early.

- Cleaning: Keep machinery clean to prevent dirt and debris buildup that can cause wear.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

- Replacement of Worn Parts: Identify and replace components that show signs of wear and tear.

Common Components of Stump Grinders

Understanding the essential elements of tree removal machinery is crucial for effective operation and maintenance. These machines consist of various parts, each playing a significant role in ensuring efficiency and safety during the grinding process. Familiarity with these components can enhance performance and extend the lifespan of the equipment.

| Component | Description |

|---|---|

| Cutter Wheel | The primary component responsible for the cutting action, featuring sharp teeth designed to chip away at the wood. |

| Hydraulic System | A critical system that powers various movements and functions, allowing for smooth operation and control. |

| Engine | The powerhouse of the machinery, providing the necessary energy to operate the cutter and other components. |

| Control Panel | The interface where the operator manages the machine’s functions, ensuring ease of use and safety. |

| Tracks or Wheels | The mobility elements that allow the machine to move over different terrains while maintaining stability. |

| Frame | The structural backbone that supports all other components and provides durability during operation. |

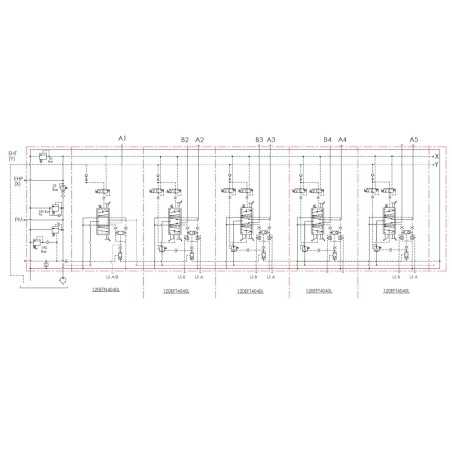

How to Read Parts Diagrams

Understanding schematic representations is crucial for effective maintenance and repair of machinery. These visual guides provide a detailed view of components and their relationships, enabling users to identify specific elements and their functions. Mastering this skill can significantly enhance the efficiency of your work.

Familiarize Yourself with Symbols: Different diagrams use unique symbols to represent various components. Spend time learning these symbols, as they are the key to deciphering the information presented. Each symbol conveys specific meanings that contribute to a holistic understanding of the assembly.

Follow the Flow: Many illustrations depict the connection between parts in a logical sequence. Observing the flow can help you grasp how different elements interact within the system. Look for arrows or lines that indicate relationships, and trace them to see how one part influences another.

Pay Attention to Labels: Often, diagrams include labels or numbers next to components. These annotations provide additional context, such as part names or reference numbers, which can be invaluable when ordering replacements or consulting manuals.

Utilize a Legend: A legend is often provided alongside the illustration, detailing the meaning of various symbols and markings. Referencing this can clarify any confusion and enhance your understanding of the schematic.

Practice Makes Perfect: The more you work with these representations, the more comfortable you will become. Try to analyze different schematics to reinforce your skills and gain confidence in interpreting them accurately.

Identifying Wear and Tear Signs

Recognizing the indications of deterioration is essential for maintaining equipment efficiency and longevity. Regular inspections can prevent minor issues from escalating into significant problems, ensuring optimal performance and safety.

Key signs of wear and tear to look for include:

- Unusual noises during operation

- Decreased performance or power output

- Visible damage such as cracks or dents

- Excessive vibration or movement

- Inconsistent operation or frequent stalling

Monitoring these factors can help in early detection and timely maintenance, thus prolonging the life of your machinery. Regular upkeep not only enhances performance but also ensures safety for the operator and surroundings.

In addition to visual and auditory signs, consider the following preventative measures:

- Establish a routine inspection schedule.

- Keep a maintenance log to track repairs and replacements.

- Use quality lubricants and replace filters regularly.

- Stay informed about the specific needs and specifications of your equipment.

By being proactive and attentive to these signs, you can effectively manage your machinery’s condition and avoid costly repairs.

Replacement Parts: When and Why

Understanding the need for new components is crucial for maintaining machinery efficiency and longevity. Over time, certain elements can wear down or become damaged, leading to decreased performance or safety hazards. Recognizing when to replace these items can ultimately save time and costs in the long run.

Signs of Wear

Common indicators that a component requires attention include unusual noises, reduced functionality, or visible deterioration. Regular inspections can help identify these issues early, allowing for timely replacements before they escalate into more significant problems.

The Benefits of Timely Replacement

Replacing worn or faulty elements not only enhances performance but also prolongs the lifespan of the equipment. It ensures safety for operators and can improve overall productivity, making it essential to prioritize these updates in maintenance routines.

Finding Authentic Rayco Parts

When it comes to maintaining outdoor machinery, ensuring the use of genuine components is crucial for optimal performance and longevity. Authentic parts guarantee that your equipment runs smoothly and meets safety standards, preventing potential issues that may arise from inferior alternatives.

Identifying Genuine Components

To recognize authentic elements, start by researching reliable suppliers. Reputable dealers often provide detailed information regarding their products, including origin and compatibility. Look for certifications and warranty offerings that support the authenticity of the items.

Benefits of Using Genuine Components

Utilizing original components offers several advantages:

| Advantage | Description |

|---|---|

| Performance | Ensures optimal functionality and efficiency of your machinery. |

| Durability | Original parts are designed to withstand wear and tear over time. |

| Safety | Reduces the risk of accidents and malfunctions associated with substandard components. |

| Warranty | Genuine items often come with warranties that cover defects and performance issues. |

DIY Repair vs. Professional Services

When it comes to maintaining and fixing machinery, individuals often face a choice between tackling repairs themselves or enlisting the help of experts. Each option carries its own set of advantages and challenges, which can influence the decision based on various factors like skill level, time, and cost.

Choosing to handle repairs independently can be rewarding. Here are some benefits:

- Cost Savings: Performing repairs yourself often eliminates labor costs.

- Skill Development: DIY repairs enhance your knowledge and technical skills.

- Convenience: You can work at your own pace and on your own schedule.

However, there are potential downsides to consider:

- Time-Consuming: Repairs may take longer than anticipated, especially for complex issues.

- Risk of Error: Mistakes can lead to further damage, which might be costly to fix.

- Lack of Experience: Without proper knowledge, some repairs might be beyond your capabilities.

On the other hand, hiring professionals offers its own set of benefits:

- Expertise: Professionals bring specialized knowledge and experience to the table.

- Efficiency: Repairs are typically completed more quickly due to their expertise.

- Warranty and Guarantees: Many professional services offer guarantees on their work, providing peace of mind.

Nevertheless, there are considerations when opting for professional help:

- Higher Costs: Professional services can be expensive, particularly for complex repairs.

- Dependence: You may need to rely on their schedule and availability.

- Less Personal Involvement: You might miss out on the satisfaction of solving the problem yourself.

Ultimately, the choice between DIY repairs and professional services depends on your individual circumstances, including your comfort level with machinery, available time, and budget. Carefully weighing the pros and cons can lead to the best decision for your repair needs.

Tips for Efficient Stump Grinding

Achieving optimal results in the process of removing tree remnants requires careful planning and execution. Understanding the right techniques and tools can greatly enhance efficiency and effectiveness. Here are some essential strategies to consider.

| Tip | Description |

|---|---|

| Preparation | Clear the area of debris and obstacles to ensure a smooth operation. Mark any underground utilities to avoid damage. |

| Tool Selection | Choose the appropriate equipment for the size and type of the remains. Ensure it is well-maintained and suited for the job. |

| Technique | Utilize a systematic approach, working from the outer edges inward. This method helps to gradually reduce the size of the remnants effectively. |

| Safety First | Always wear protective gear, including goggles and gloves, to safeguard against flying debris and potential injuries. |

| Post-Operation Cleanup | Once the job is complete, remove any leftover debris and fill the hole with soil or mulch to restore the area. |