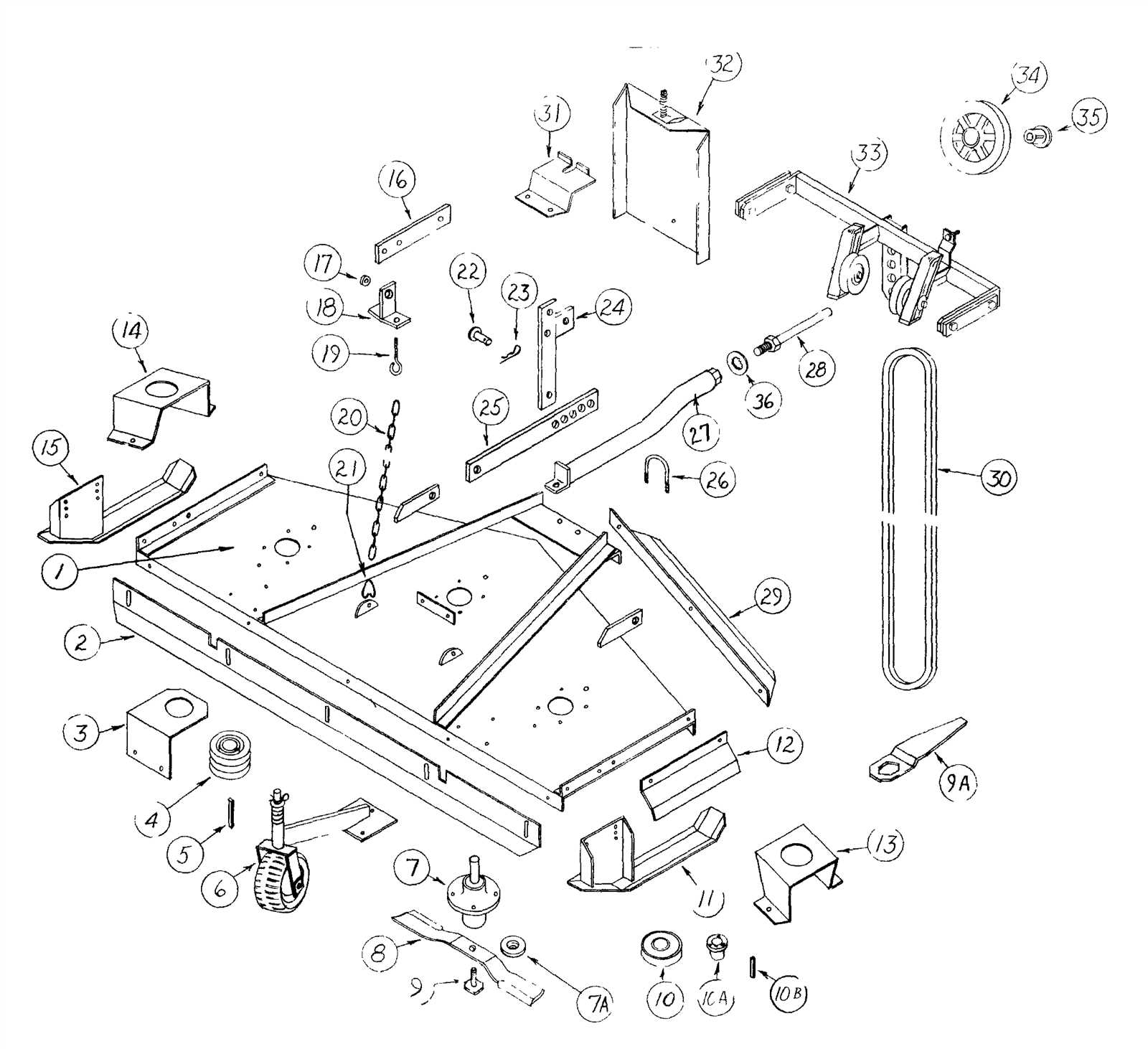

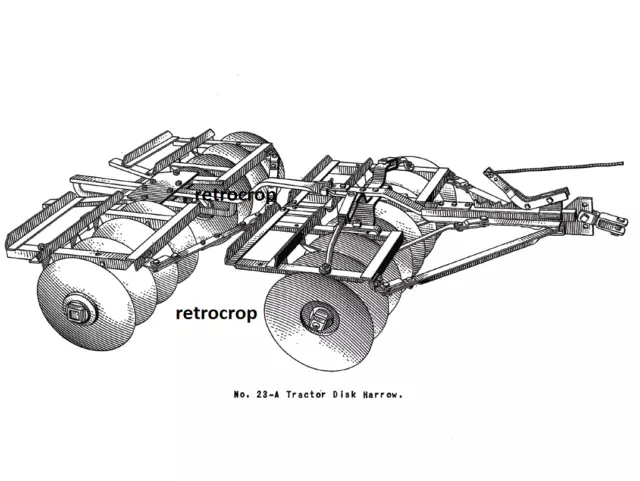

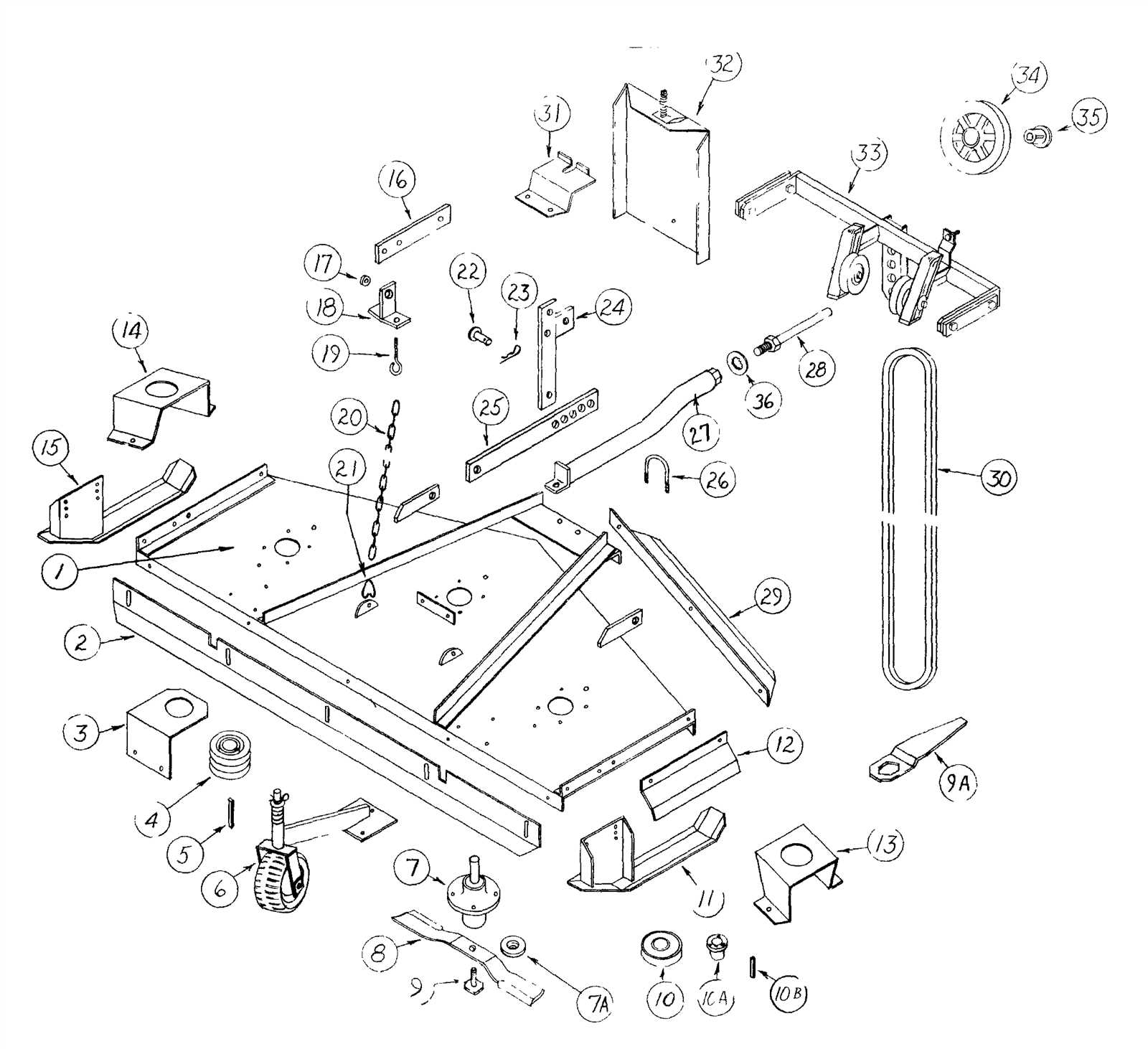

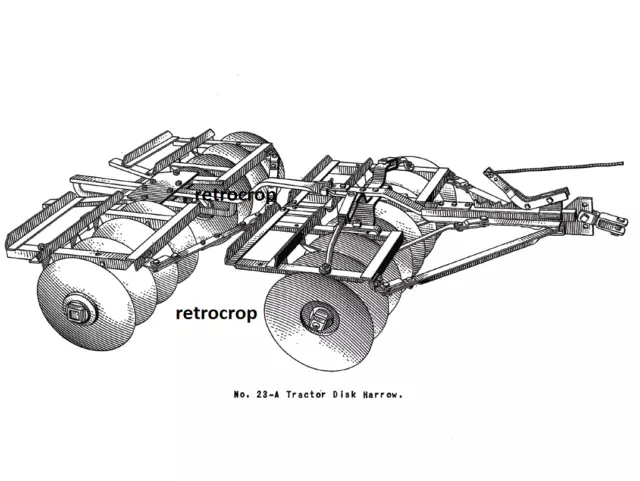

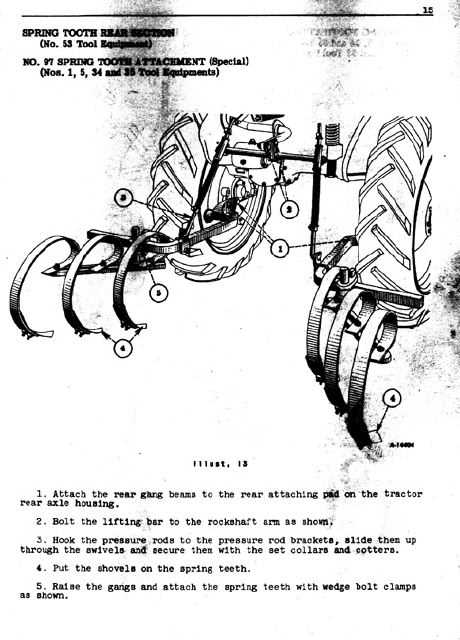

When maintaining or repairing agricultural machinery, it’s essential to have a clear understanding of how different elements are organized. Proper knowledge of the equipment’s structure not only aids in efficient troubleshooting but also ensures the longevity of the machine by facilitating timely replacements and adjustments.

Every mechanical system, no matter its complexity, consists of various interconnected elements that must work together seamlessly. Recognizing how these components are positioned relative to one another can make the repair process more straightforward and save valuable time in the field.

Detailed breakdowns of these mechanical assemblies provide vital insights. Whether you’re an experienced technician or just starting out, having access to such comprehensive layouts ensures that any maintenance task can be approached with confidence.

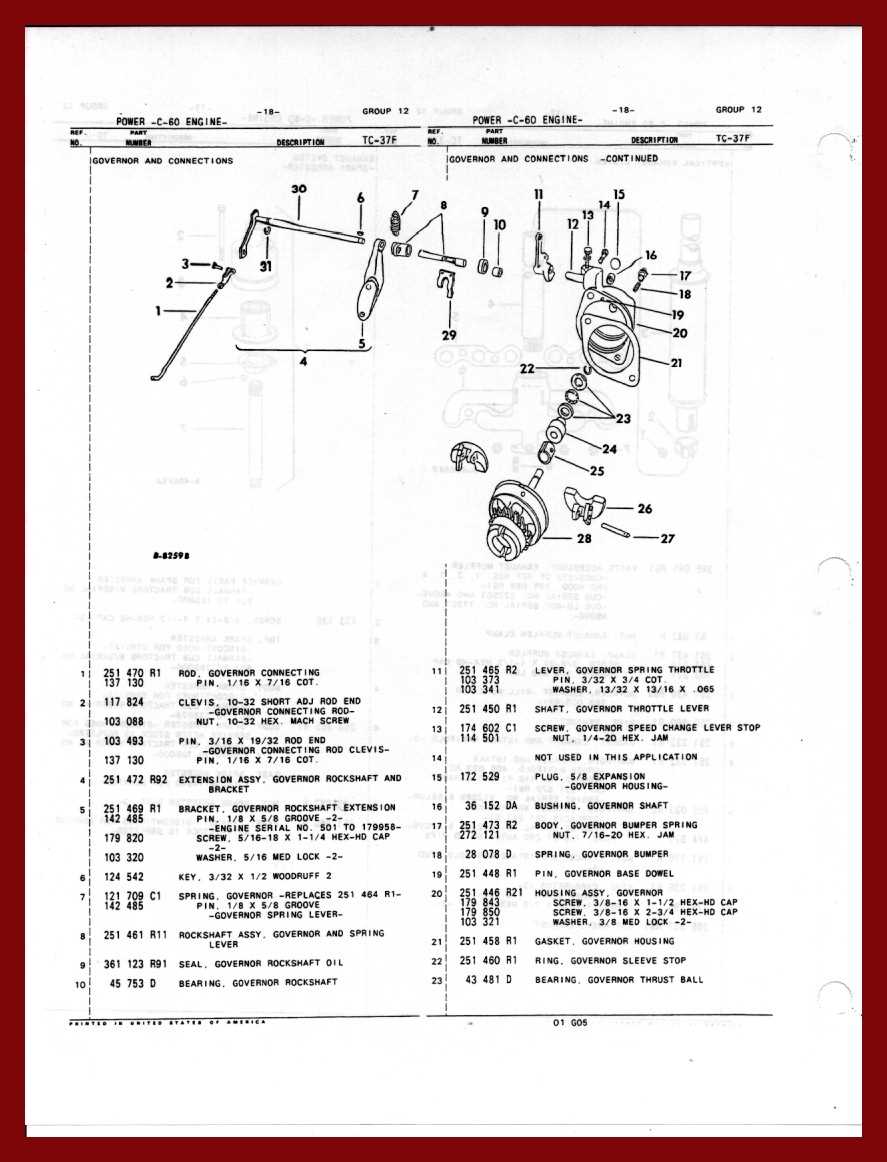

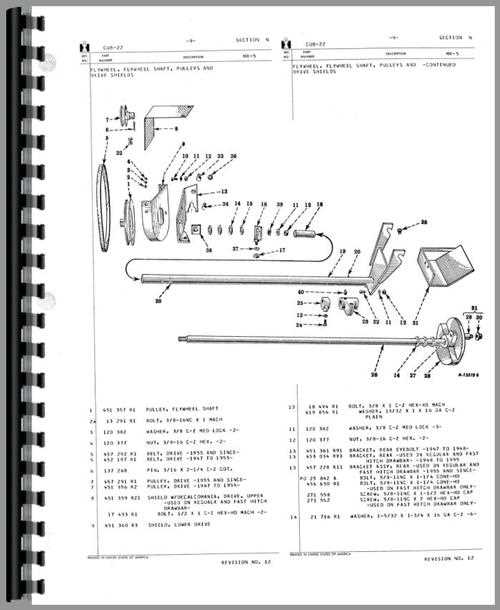

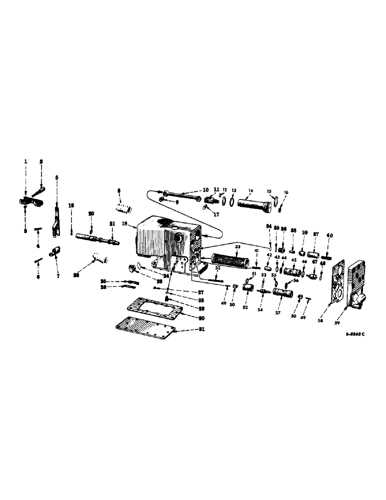

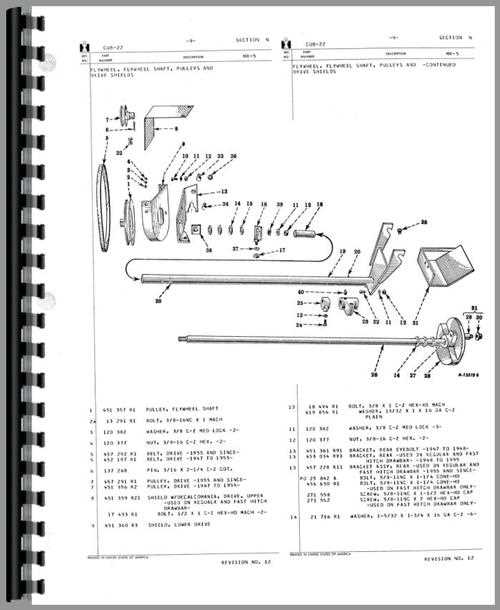

Understanding the Farmall Cub Engine Components

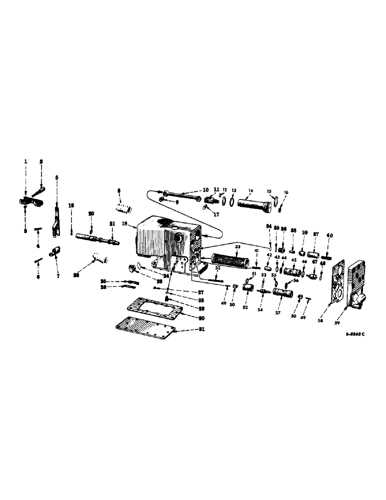

The internal combustion mechanism within these vintage tractors is a prime example of robust engineering, designed to provide steady and reliable power over time. To ensure smooth functionality, the various elements of the engine work together in perfect harmony, driving the machinery forward. Each individual part contributes to the overall efficiency, making maintenance and understanding of the system crucial for optimal performance.

Key Sections of the Engine

When examining the engine, it is essential to recognize how the core components operate. The piston and cylinder work together to generate movement through controlled explosions, converting fuel into mechanical energy. Additionally, the crankshaft translates the up-and-down motion into rotational force, driving other parts of the tractor.

Supporting Systems

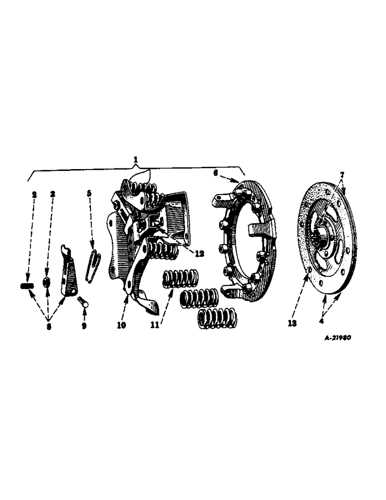

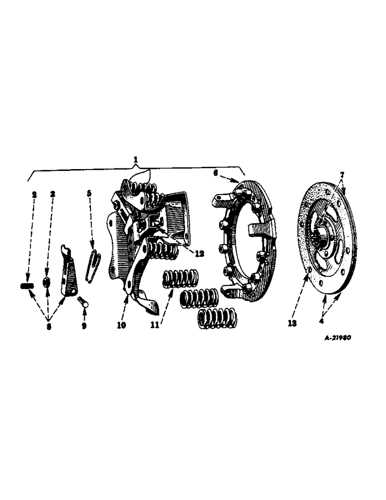

Key Parts of the Tractor Transmission

The transmission of a tractor is a crucial component that allows the machine to operate efficiently, converting the engine’s power into usable force. Understanding the main components of the transmission system helps maintain optimal performance and longevity. This section will outline the primary elements of the transmission mechanism, providing insight into their functions and importance.

Main Transmission Components

The core elements of the transmission system include gears, shafts, and bearings. Each of these elements plays a vital role in ensuring smooth operation. Gears transfer the engine’s power, while the shafts support and guide these gears. Bearings, in turn, reduce friction, allowing the moving parts to rotate freely.

| Component |

Function |

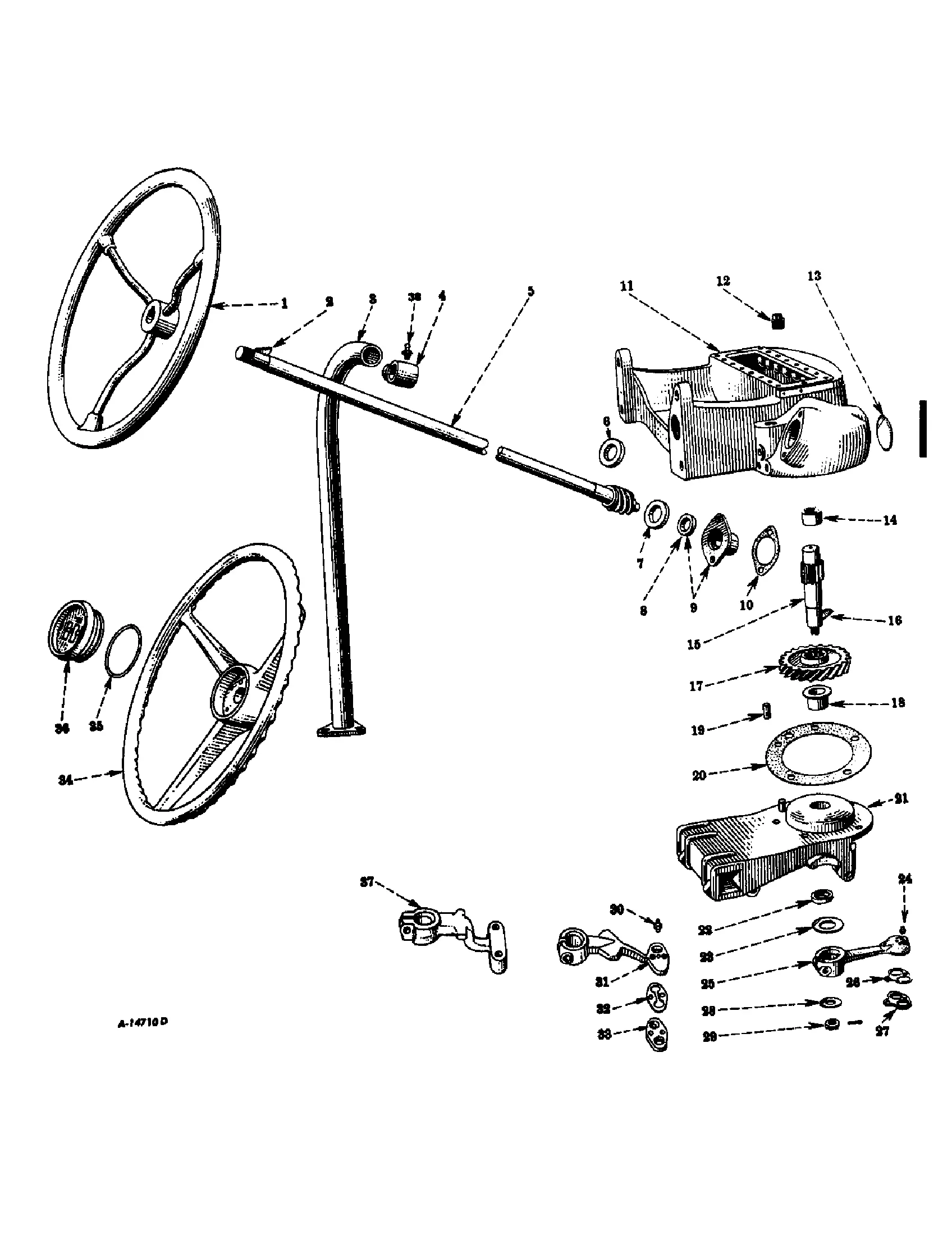

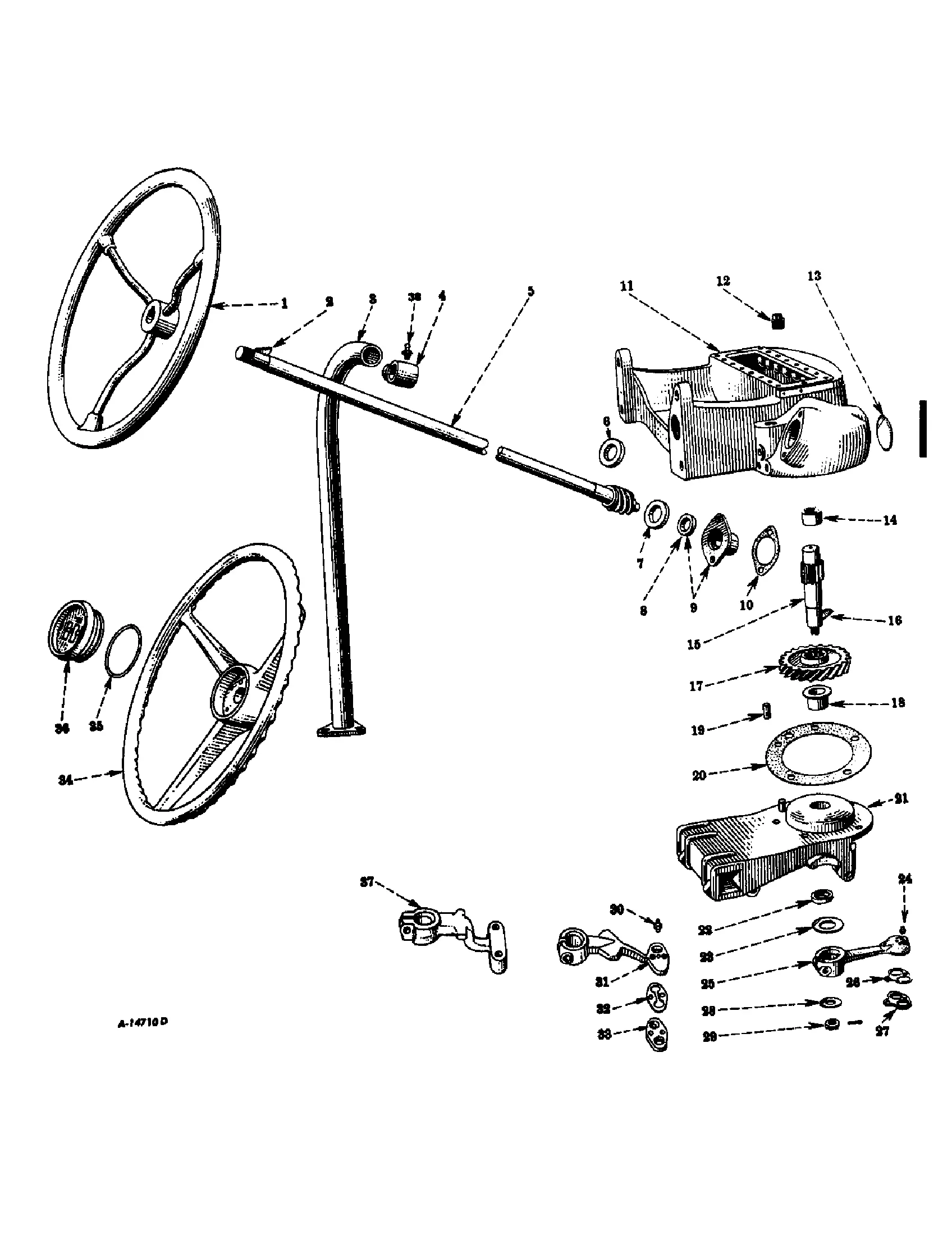

Exploring the Steering Mechanism in Detail

The steering mechanism is a critical component that ensures the smooth operation and control of any vehicle. Understanding its design and functionality is essential for anyone looking to maintain or repair it effectively. In this section, we will examine the key elements that allow precise maneuvering and control, highlighting how these components work together to provide a reliable driving experience.

Key Components of the Steering Mechanism

The main elements of the system include a set of gears, rods, and joints, all working in unison to translate driver input into wheel movement. The steering wheel serves as the starting point, where rotational force is applied and transmitted down through a shaft. This movement is then directed through the linkage system, which ensures that the vehicle responds accurately to the driver’s intentions.

Maintaining Optimal Performance

Over time, wear and tear on the steering components can impact the

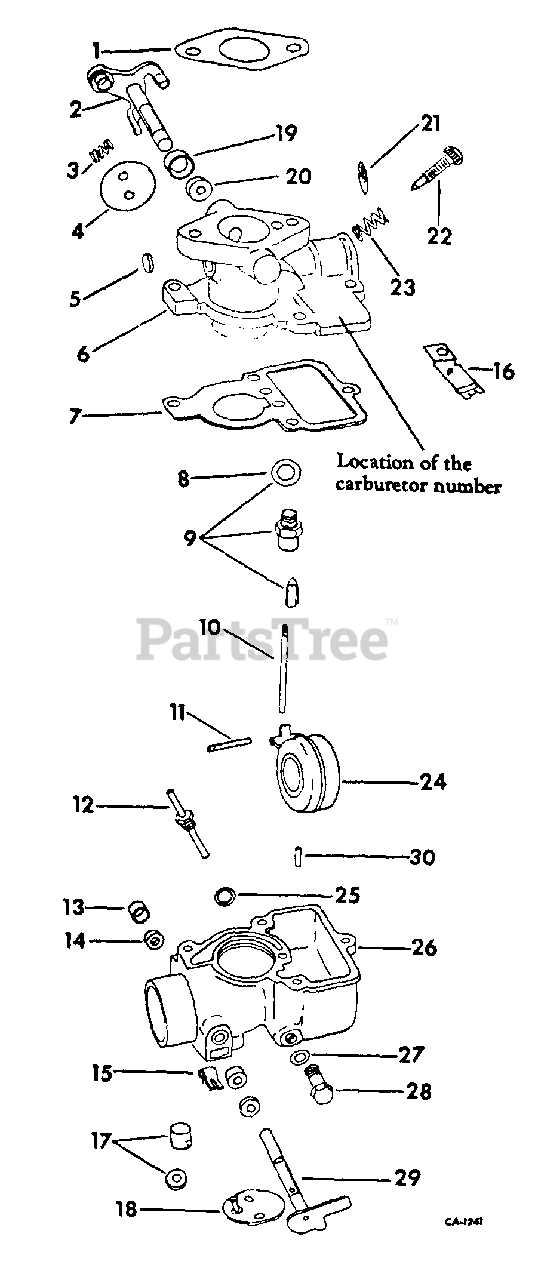

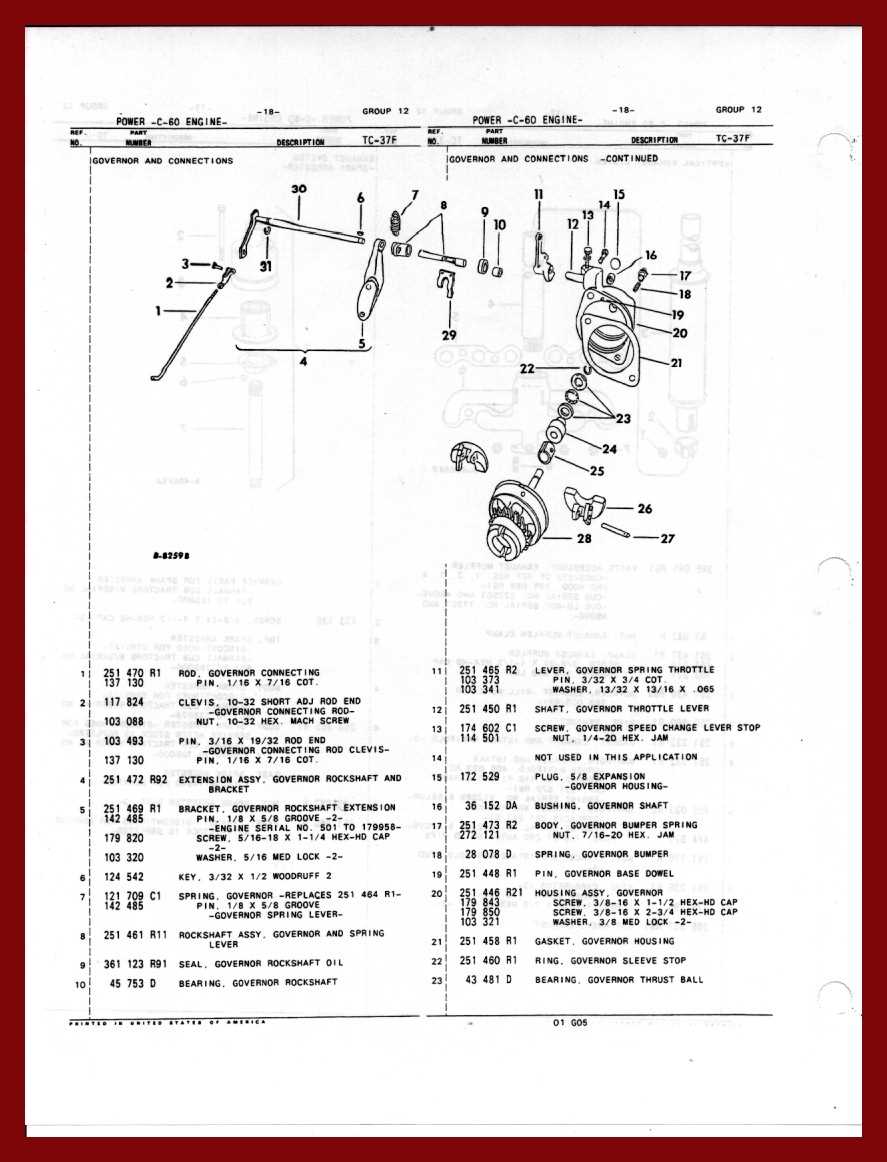

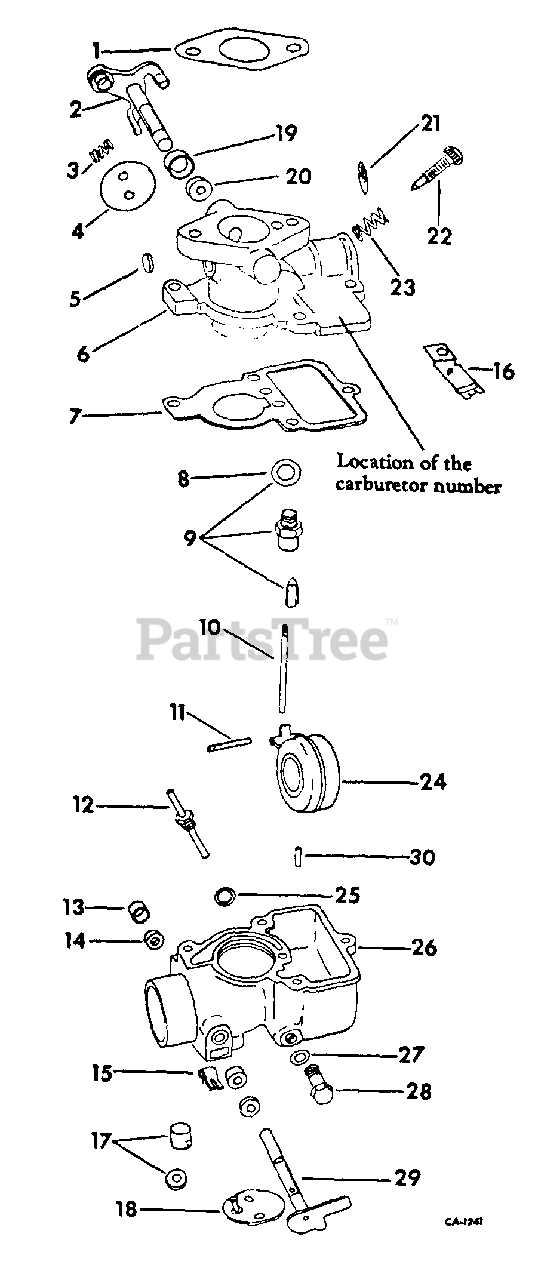

Fuel System Diagram for Efficient Performance

The fuel system plays a crucial role in ensuring the smooth and efficient operation of any vehicle. A well-maintained system allows for proper fuel flow, optimizing engine performance and reducing unnecessary strain. Understanding the structure of this system is key to ensuring peak efficiency and longevity of the engine.

Key components of the system include fuel tanks, lines, and filters, each working together to deliver the necessary energy to the engine. Regular inspection and maintenance of these elements will help avoid disruptions in the fuel supply, ensuring that the engine runs at its best. Proper fuel filtration is especially important to prevent impurities from entering the system, which can lead to malfunctions.

By familiarizing yourself with how the fuel system is designed and how each part contributes to its overall function, you can make informed decisions on maintenance. This ensures that the system continues to provide optimal power and efficiency over time.

Electrical System Overview and Key Elements

The electrical framework is essential for the functioning of various components, ensuring the reliable operation of all connected elements. This section provides a concise explanation of the key components and their interactions within the system, highlighting their critical roles in maintaining optimal performance.

Main Power Supply and Distribution

The system’s primary source of energy typically originates from a battery, which distributes power to various circuits. A charging mechanism, such as an alternator or generator, keeps the battery charged while the machine is running, ensuring a continuous supply of energy.

- Battery: Provides the necessary voltage for starting the engine and running electrical components.

- Alternator/Generator: Maintains the battery’s charge and powers electrical systems while in operation.

Brake System Breakdown and Maintenance Tips

Proper upkeep of the brake mechanism is essential for ensuring smooth operation and safety. Understanding the key components involved in the braking process allows for easier identification of potential issues and helps prevent failures. Regular inspection and care of this system are crucial to maintaining optimal performance.

When performing maintenance, it is important to check for signs of wear and tear, such as fading responsiveness or unusual noises during use. Addressing these early can save significant repair costs and downtime. Lubricating moving parts, inspecting the hydraulic lines for leaks, and adjusting tension are some of the key tasks to keep the system functioning reliably.

Additionally, replacing any worn-out elements at the first sign of damage is vital to preventing more extensive malfunctions. Always refer to a reliable manual when unsure of specific maintenance steps to ensure accurate repairs.

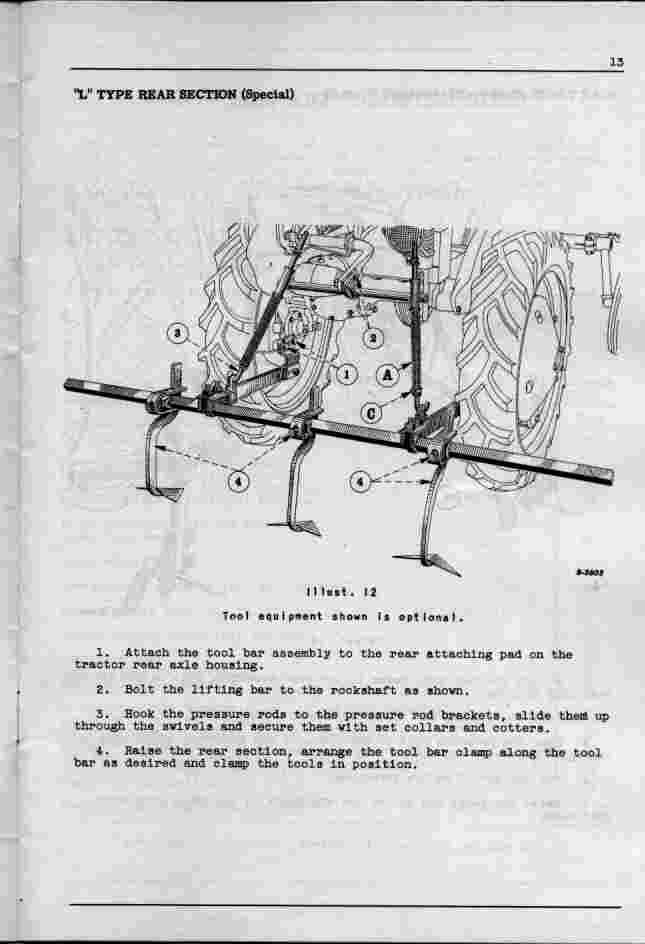

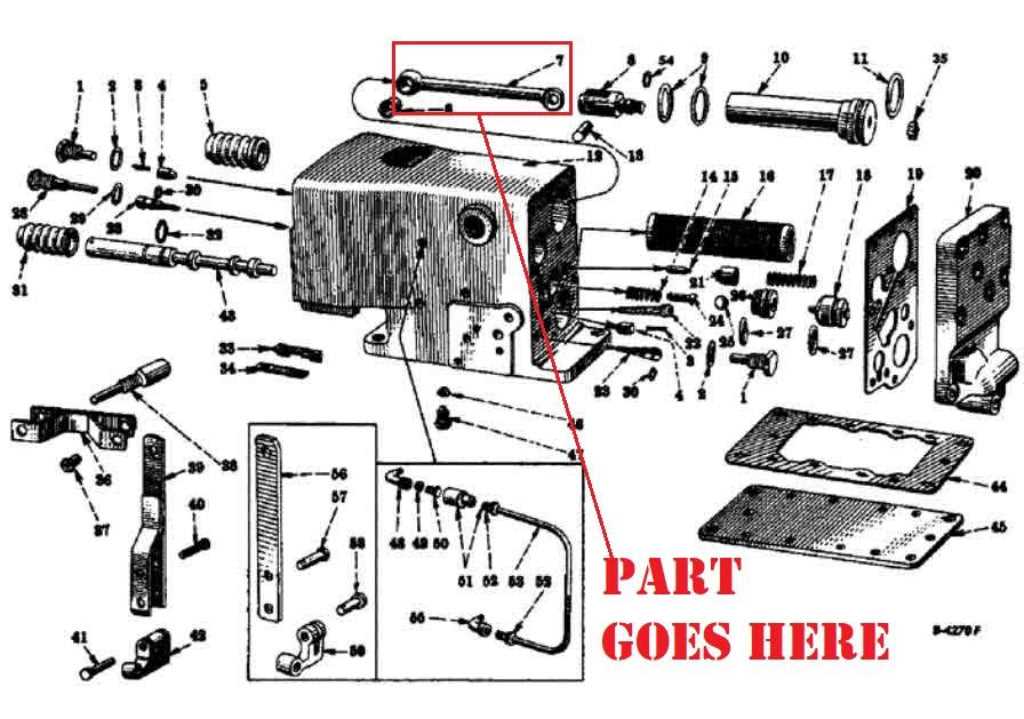

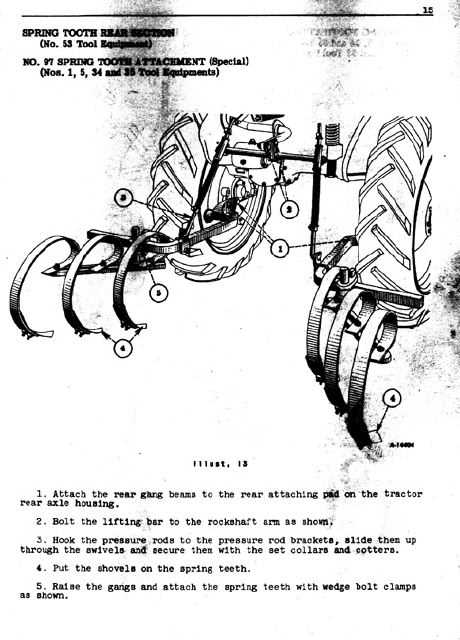

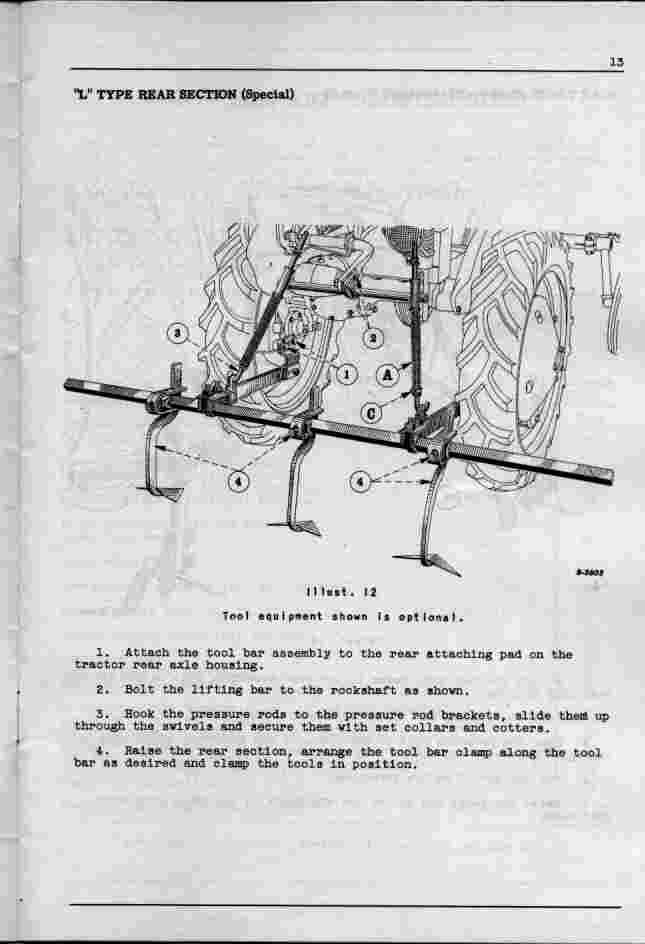

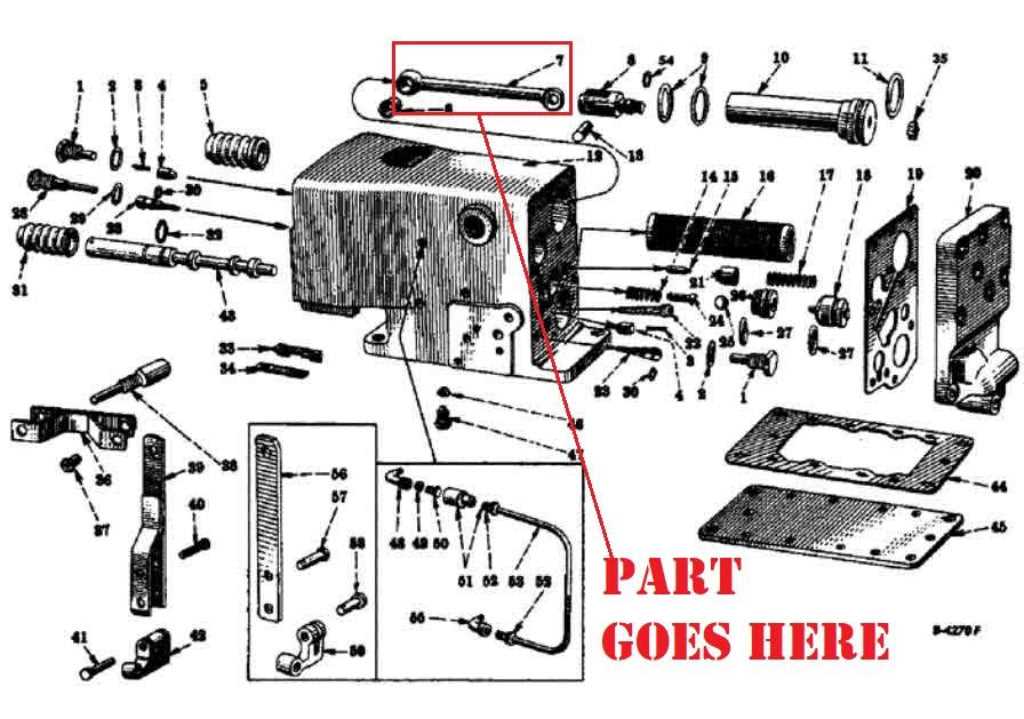

Hydraulic System Components for Farmall Cub

The hydraulic system in agricultural machinery plays a crucial role in enhancing operational efficiency. It allows for the seamless transfer of force through fluid pressure, facilitating the movement and control of various implements. Understanding the key elements of this system is essential for effective maintenance and operation.

Main Elements of the Hydraulic System

- Hydraulic Pump: Responsible for generating the necessary pressure to circulate fluid throughout the system.

- Hydraulic Cylinder: Converts hydraulic energy into mechanical energy, enabling lifting and moving actions.

- Control Valve: Regulates the flow of fluid to the cylinder, allowing for precise control of movement.

- Fluid Reservoir: Stores hydraulic fluid, ensuring the system has an adequate supply for operation.

Maintenance Tips

- Regularly check the fluid levels to ensure optimal performance.

- Inspect hoses and connections for any signs of wear or leaks.

- Clean or replace filters to prevent contamination of hydraulic fluid.

- Test the operation of the pump and valves to ensure they function properly.

How to Identify the Cooling System Parts

Understanding the components of the temperature regulation framework is essential for effective maintenance and troubleshooting. Recognizing each element’s function helps ensure optimal performance and longevity of the machinery.

Key Components to Recognize

- Radiator: This component dissipates heat from the engine coolant.

- Thermostat: Regulates the flow of coolant based on temperature.

- Water Pump: Circulates the coolant throughout the system.

- Cooling Hoses: Flexible tubes that transport coolant to and from the engine.

- Fan: Helps to increase airflow through the radiator.

Identifying Specific Elements

- Check for the radiator’s location at the front of the engine compartment.

- Locate the thermostat, usually situated near the engine block.

- Examine the water pump, typically found on the engine’s front side, driven by the crankshaft.

- Inspect the hoses for any signs of wear or leaks.

- Ensure the fan operates correctly to maintain airflow.