When it comes to machinery, comprehending the individual elements is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality of the equipment, ensuring it operates smoothly and efficiently.

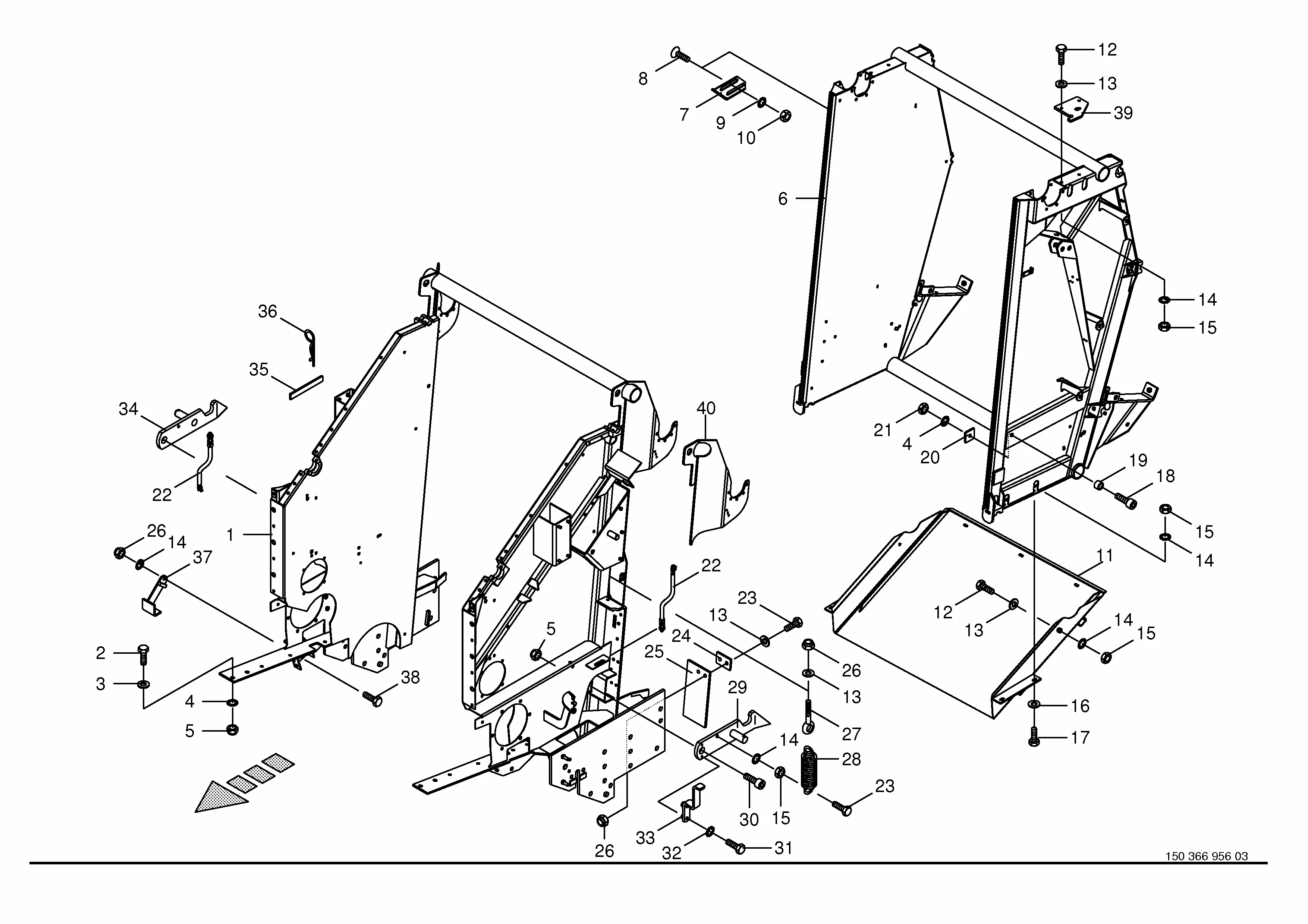

Visual representation of these elements can significantly enhance one’s ability to identify and troubleshoot issues. By exploring detailed schematics, operators can gain insights into how each part interacts within the system, facilitating easier repairs and replacements.

Ultimately, a thorough grasp of these intricacies not only boosts productivity but also prolongs the lifespan of the machinery. Therefore, delving into the specifics of these crucial components is essential for anyone involved in equipment management.

Ditch Witch 1030 Overview

This section provides an insightful look into a specific model known for its efficiency and versatility in underground tasks. Designed for various applications, this equipment excels in trenching, boring, and other essential functions. Understanding its components and operational features can greatly enhance performance and maintenance practices.

Key Features

- Robust construction ensuring durability and longevity.

- Powerful engine providing reliable performance in diverse conditions.

- Compact design facilitating maneuverability in tight spaces.

- Advanced technology enhancing operational efficiency.

Applications

- Utility installation for water, gas, and electricity.

- Telecommunication infrastructure development.

- Landscaping and irrigation system implementation.

- Environmental restoration projects.

Understanding these attributes helps users maximize their investment and improve productivity in various projects.

Importance of Parts Diagrams

Understanding the layout of components is crucial for effective maintenance and repairs. Such visual representations serve as a roadmap, guiding users through intricate systems and enabling them to identify essential elements quickly.

These visuals enhance the efficiency of troubleshooting by clearly delineating each segment’s role. When users can easily reference a detailed illustration, they reduce the risk of errors during assembly or disassembly.

Moreover, familiarity with these layouts promotes better communication among technicians and fosters a deeper understanding of machinery functionality. This ultimately leads to improved performance and longevity of the equipment.

Common Issues with Ditch Witch 1030

In the realm of compact excavation machinery, various challenges can arise that affect performance and reliability. Identifying and addressing these issues promptly is essential for maintaining operational efficiency and prolonging the lifespan of the equipment. This section highlights some prevalent problems encountered during usage.

Hydraulic System Failures

Hydraulic systems are critical for the effective operation of digging machinery. Common symptoms of hydraulic issues include erratic movements and reduced power. Regular inspection and maintenance can help mitigate these problems.

| Issue | Symptoms | Solutions |

|---|---|---|

| Leaking Fluid | Puddles under the machine | Check seals and hoses for damage |

| Slow Response | Delayed movements during operation | Inspect fluid levels and filters |

| No Pressure | Inability to lift or move attachments | Examine pump functionality |

Engine Performance Issues

Engine-related problems can significantly hinder the operation of digging equipment. Regular maintenance can help prevent these issues from developing into more serious complications.

| Issue | Symptoms | Solutions |

|---|---|---|

| Overheating | Warning lights and reduced performance | Check coolant levels and radiator |

| Hard Starting | Difficulty initiating operation | Inspect battery and starter components |

| Unusual Noises | Grinding or knocking sounds | Evaluate engine mounts and internal components |

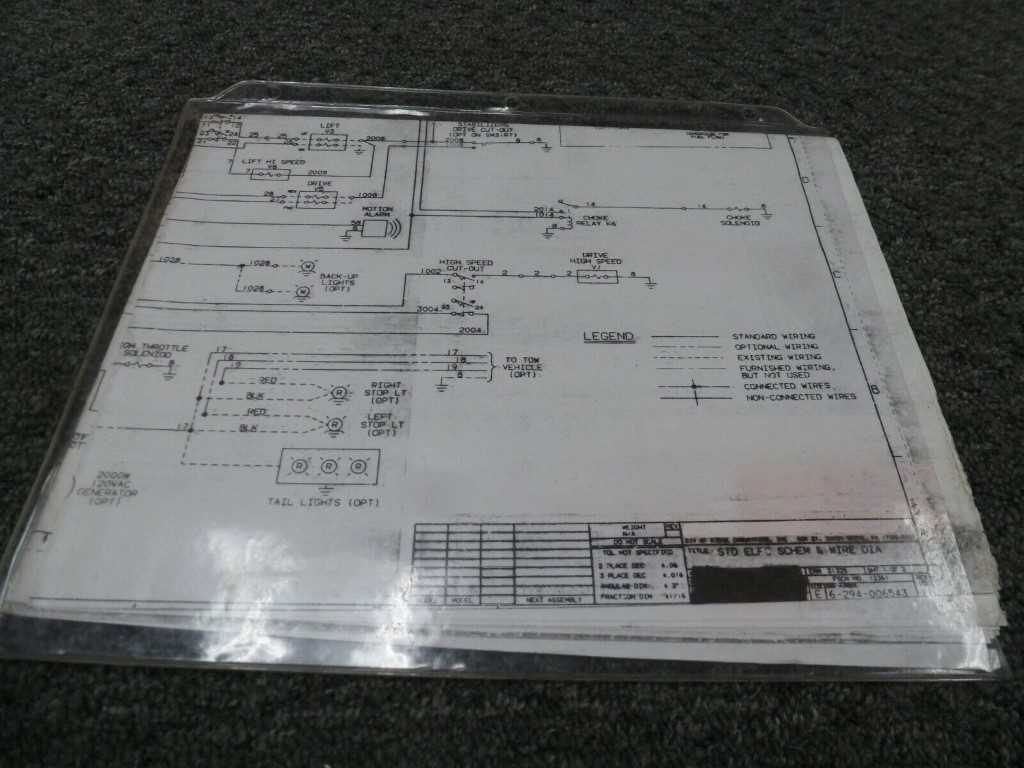

How to Interpret Parts Diagrams

Understanding schematic illustrations is essential for effective maintenance and repair tasks. These visual representations help identify individual components and their relationships within a larger system, facilitating troubleshooting and part replacement. Mastering the art of reading these visuals can significantly enhance your efficiency and accuracy when working on machinery.

Key Elements to Note

- Labels: Each element typically has a corresponding label or number, which is crucial for identification.

- Lines and Connectors: Lines indicate how components are interconnected, showing pathways for power or fluid flow.

- Legend: A legend often accompanies the visual, explaining symbols and color codes used throughout.

Steps to Follow

- Familiarize yourself with the overall layout before diving into specifics.

- Locate the labels for key components to understand their functions.

- Trace the connections to see how elements interact with each other.

- Refer to the legend for clarification on any unfamiliar symbols.

- Make notes of any items that may require replacement or inspection.

By following these guidelines, you can effectively interpret schematic illustrations, ensuring a smoother repair process and better outcomes for your equipment.

Finding Replacement Parts

Locating suitable components for machinery can often be a challenging task. Ensuring that the items match specifications and are of high quality is crucial for maintaining efficiency and safety. Understanding where to look and how to evaluate options can significantly streamline this process.

Sources for Components

There are several avenues to explore when searching for suitable items. Manufacturers, authorized dealers, and online marketplaces offer a variety of choices. Each source has its own advantages in terms of availability, pricing, and warranty.

Evaluation Criteria

When selecting replacements, consider the following factors to ensure optimal performance:

| Criteria | Description |

|---|---|

| Compatibility | Ensure the component fits the specific model. |

| Quality | Look for reputable brands or verified reviews. |

| Price | Compare costs across different platforms for the best deal. |

| Warranty | Check if there is a guarantee or return policy. |

Maintenance Tips for Ditch Witch 1030

Proper upkeep is essential for ensuring the longevity and efficient performance of your equipment. Regular maintenance helps to prevent unexpected breakdowns and costly repairs. Here are some key practices to consider for optimal care.

| Task | Frequency | Notes |

|---|---|---|

| Check fluid levels | Weekly | Inspect oil, coolant, and hydraulic fluids to ensure they are at recommended levels. |

| Inspect belts and hoses | Monthly | Look for signs of wear or damage; replace as necessary to prevent failures. |

| Clean air filters | Every 100 hours | Replace or clean filters to maintain optimal airflow and engine performance. |

| Check battery terminals | Every 3 months | Ensure connections are tight and free of corrosion for reliable starting. |

| Lubricate moving parts | Every 50 hours | Use recommended lubricants to minimize friction and wear. |

| Inspect tires | Monthly | Check for proper inflation and tread wear to ensure safe operation. |

Implementing these maintenance tasks will enhance the reliability of your machinery and help you avoid unnecessary downtime. Always refer to the manufacturer’s guidelines for specific recommendations tailored to your model.

Where to Buy Parts Online

In today’s digital age, finding components for machinery has become easier than ever. The internet offers a plethora of options, allowing users to locate the specific items they need with just a few clicks. From specialized retailers to larger marketplaces, the choices available can cater to various preferences and budgets.

Specialized Retailers

For those seeking expert knowledge and high-quality offerings, specialized online stores can be a great choice. These platforms typically focus on a narrow range of products, ensuring that customers receive not only the correct items but also valuable insights from experienced professionals. Researching reviews and comparing prices on these sites can lead to informed purchasing decisions.

General Marketplaces

Alternatively, general online marketplaces provide a wider array of options, often at competitive prices. Websites such as eBay or Amazon feature numerous sellers, which can facilitate comparison shopping. When using these platforms, it’s essential to check seller ratings and return policies to ensure a satisfactory buying experience.

Upgrades and Modifications Available

Enhancing machinery can significantly improve performance, efficiency, and longevity. Various upgrades and modifications can be implemented to tailor equipment to specific tasks and optimize its capabilities. These enhancements range from functional improvements to aesthetic adjustments, providing users with options to customize their tools according to individual needs.

Performance Enhancements: Upgrading components such as the engine, transmission, or hydraulic systems can lead to increased power and efficiency. Replacing older parts with high-performance alternatives often results in faster operation and better fuel economy.

Safety Features: Adding modern safety equipment, like advanced monitoring systems or improved lighting, ensures that operators can work in a safer environment. These modifications help prevent accidents and enhance overall safety on the job site.

Ergonomic Adjustments: Improving the operator’s comfort is essential for long hours of use. Modifications such as adjustable seating, better controls, and enhanced visibility can make a significant difference in reducing fatigue and increasing productivity.

Technology Integration: Incorporating the latest technology, like GPS tracking or remote operation capabilities, allows for greater precision and control. These advancements can streamline operations and provide valuable data for better decision-making.

Overall, investing in upgrades and modifications not only enhances functionality but also prolongs the lifespan of the machinery, ensuring it meets the demands of modern work environments.