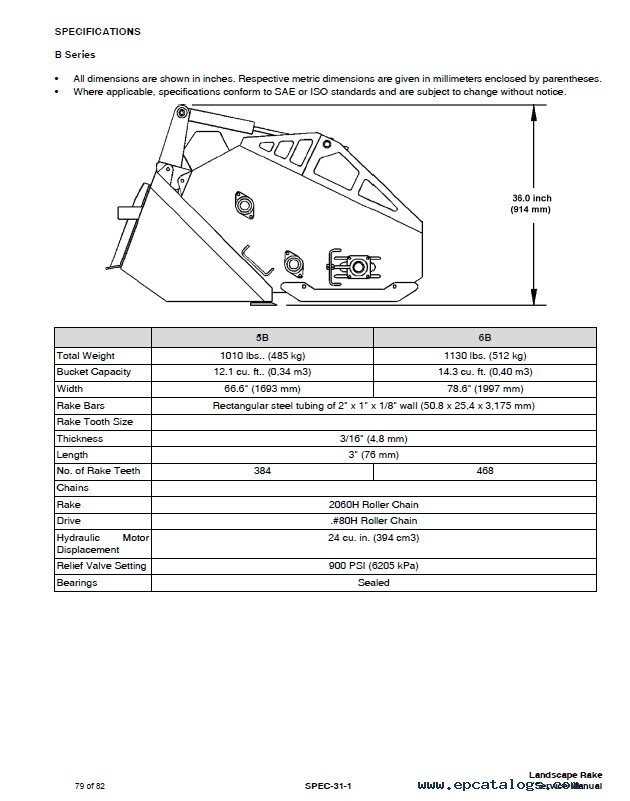

In the world of outdoor landscaping and construction, having the right equipment is essential for achieving optimal results. A specific implement designed for leveling and grading soil can significantly enhance efficiency and effectiveness on the job site. Grasping the intricate details of its design not only aids in proper maintenance but also empowers users to maximize its potential.

Each element of this implement serves a unique purpose, contributing to its overall functionality. Recognizing how these elements interact with one another provides valuable insights for both new and experienced users. This knowledge ensures that operators can navigate any challenges that may arise during usage, leading to improved performance and longevity of the tool.

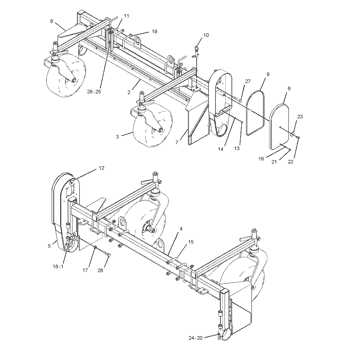

For those keen on delving deeper into the workings of this specialized equipment, a visual representation can prove invaluable. By examining a detailed outline of its components, one can gain clarity on assembly, disassembly, and potential upgrades. This exploration opens doors to greater understanding and capability, transforming the way users approach their landscaping projects.

Understanding Harley Rake Components

Grasping the various elements of ground preparation machinery is essential for effective operation and maintenance. Each component plays a crucial role in enhancing performance and ensuring durability. By familiarizing oneself with these elements, users can optimize functionality and extend the lifespan of their equipment.

Key Elements of Ground Preparation Machinery

At the heart of any efficient implement lies a collection of vital pieces. These elements work in harmony to achieve a specific task, whether it’s leveling, grading, or cultivating soil. Understanding the relationship between these components can significantly impact the effectiveness of the equipment.

Maintenance and Care

Regular inspection and upkeep of these essential parts are paramount. Ensuring that each piece functions correctly not only boosts efficiency but also prevents premature wear and tear. Regular maintenance can help identify potential issues early, allowing for timely interventions. Investing time in understanding these components ultimately leads to smoother operations and better results.

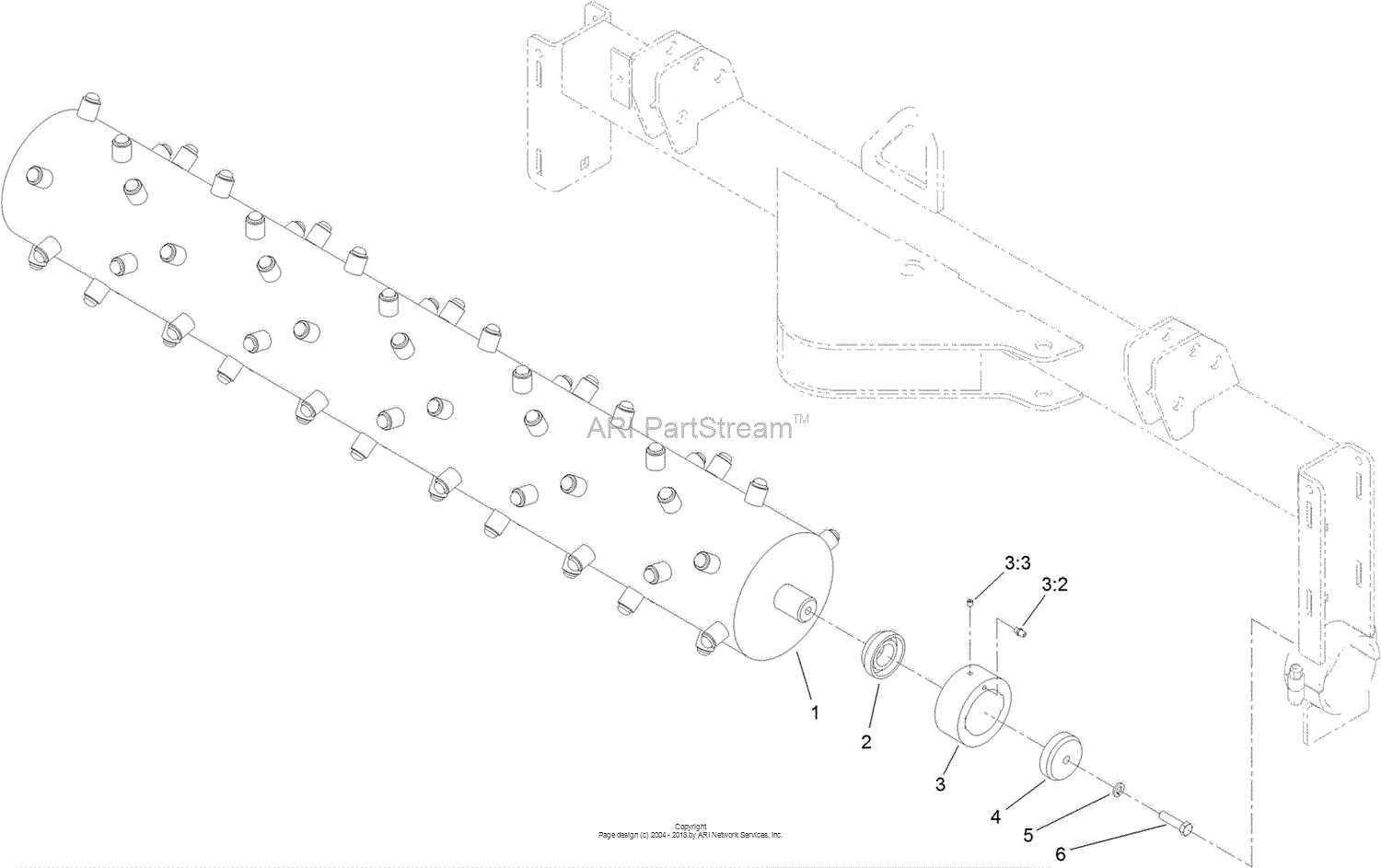

Essential Parts of a Harley Rake

This section will explore the fundamental components that contribute to the efficiency and functionality of this equipment. Each element plays a crucial role in ensuring optimal performance and versatility, enabling users to tackle various landscaping tasks effectively.

Frame: The sturdy structure provides stability and support, essential for handling the rigors of outdoor work.

Teeth: These sharp extensions are pivotal for breaking up soil and clearing debris, ensuring a thorough job.

Hitch: This connection mechanism allows seamless attachment to tractors or other machinery, enhancing maneuverability.

Adjustable Angle: The ability to modify the tilt of the tool is crucial for adapting to different terrain and achieving desired results.

Wheels: Durable rollers ensure smooth movement across surfaces, reducing effort and increasing efficiency during operation.

Understanding these core elements will empower users to maximize their machine’s potential, leading to the best possible outcomes in their projects.

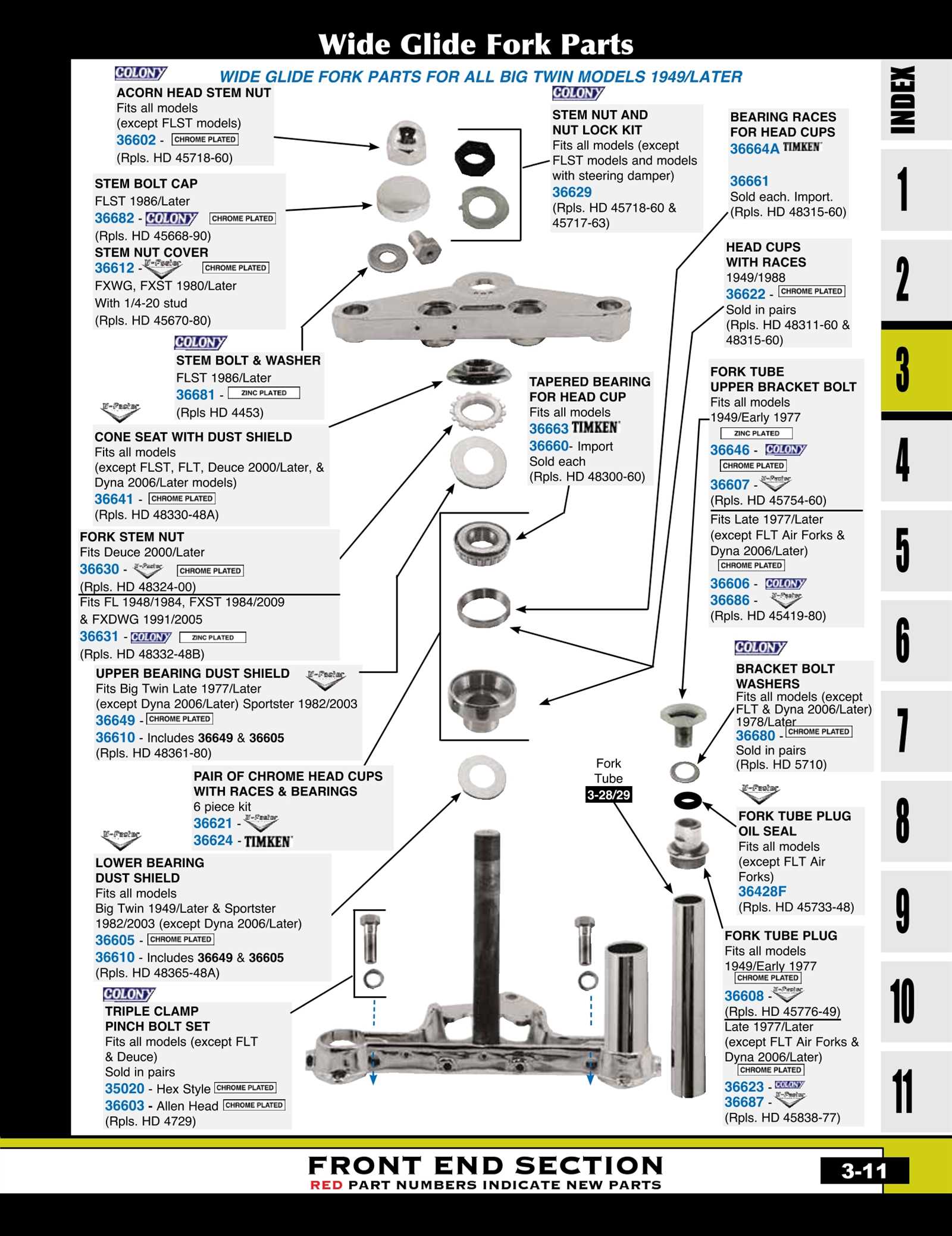

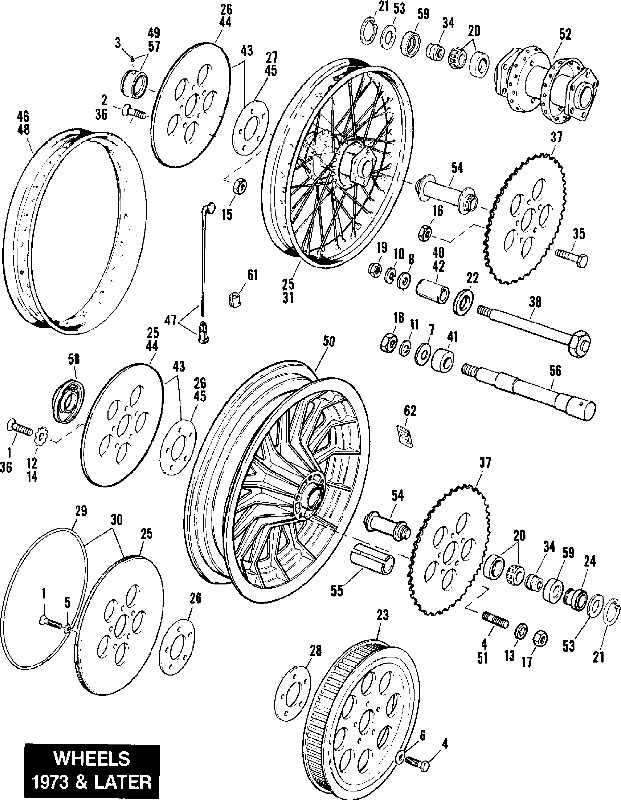

How to Read a Parts Diagram

Understanding a visual representation of components is essential for efficient assembly or repair. Such illustrations provide a clear layout, showcasing the relationship between different elements and their respective functions. By familiarizing yourself with these images, you can simplify the maintenance process and enhance your knowledge of the equipment.

First, identify the key sections of the illustration. Typically, these visuals are divided into several segments, each representing a specific assembly or function. Look for labels or numbers that correspond to individual items. This will help you navigate through the various components with ease.

Next, pay attention to the connections and orientations indicated in the image. Lines or arrows often depict how parts fit together, ensuring that you understand their positioning. Accurate placement is crucial for the overall performance of the system, so be meticulous in your observation.

Additionally, familiarize yourself with any accompanying legends or notes. These can provide vital information regarding specifications, such as sizes and materials, which may not be immediately obvious from the visual alone. Understanding these details can significantly influence your repair or assembly strategy.

Lastly, practice makes perfect. The more you study and refer to such illustrations, the more intuitive it will become to interpret them effectively. Over time, you’ll gain confidence in recognizing components and their roles, streamlining your tasks.

Common Issues with Rake Parts

In the world of outdoor machinery, several challenges can arise that affect the performance and longevity of equipment components. Understanding these common problems is essential for ensuring efficient operation and minimizing downtime.

Wear and Tear

One of the primary concerns is the natural degradation of elements due to frequent use. Over time, components may experience friction and stress, leading to cracks or breakage. Regular inspections can help identify signs of wear early, allowing for timely replacements and maintaining optimal function.

Improper Alignment

Another issue is misalignment, which can cause uneven distribution of force. This not only affects the machinery’s performance but also increases the risk of further damage. Ensuring that all components are correctly positioned can prevent excessive wear and enhance operational efficiency. Regular maintenance and adjustments are key to avoiding these pitfalls.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the lifespan of your equipment. By implementing a consistent maintenance routine, you can ensure optimal performance and minimize the risk of costly repairs. This section outlines key practices that will help you maintain your machinery in top condition.

First and foremost, routinely inspect all components for wear and tear. Identifying issues early can prevent further damage and enhance the overall efficiency of the machine. Pay special attention to moving parts, as they are more susceptible to degradation over time.

Additionally, keep the equipment clean. Accumulated dirt and debris can lead to operational issues and hinder performance. Regular cleaning not only improves functionality but also allows for a thorough inspection of all parts.

Lubrication is another critical aspect of maintenance. Ensuring that all necessary areas are properly lubricated reduces friction and wear, thereby prolonging the life of the machine. Use high-quality lubricants as recommended by the manufacturer.

Lastly, follow the manufacturer’s guidelines for maintenance schedules and service intervals. Adhering to these recommendations helps maintain optimal performance and avoids potential problems down the line. By prioritizing these practices, you can enjoy a longer and more reliable operational lifespan for your equipment.

Aftermarket Parts: Pros and Cons

Exploring alternative components for vehicles can provide both advantages and drawbacks for enthusiasts. While these substitutes often promise enhanced performance and customization, they may also present challenges in terms of quality and compatibility. Understanding the balance between benefits and potential issues is essential for making informed choices.

One significant advantage of using alternatives is the potential for cost savings. Many enthusiasts find that these components are often priced more competitively than original options, making upgrades more accessible. Additionally, there’s a wide variety of choices available, allowing for personalized modifications that cater to individual preferences.

However, it’s important to consider the potential downsides. The quality of these components can vary greatly, leading to concerns about durability and performance. Moreover, compatibility issues may arise, resulting in installation difficulties or reduced efficiency. Ensuring that the selected components meet necessary standards is crucial for maintaining overall vehicle performance.

Assembly Instructions for Harley Rake

This section provides a detailed guide for assembling your landscape grooming tool. Follow the steps outlined below to ensure a smooth and efficient setup, maximizing the effectiveness of your equipment for land preparation and soil refinement.

Tools Required

- Socket wrench set

- Torque wrench

- Adjustable pliers

- Screwdriver set

- Safety gloves

Assembly Steps

- Begin by laying out all components on a flat surface. Verify that all pieces are included by comparing them with the provided checklist.

- Attach the main frame to the mounting hitch using the designated bolts. Ensure that all bolts are tightened to the specified torque settings.

- Connect the hydraulic lines, making sure there are no kinks or twists. Secure them with the provided clamps.

- Install the working elements, ensuring they are aligned correctly and secured with the appropriate fasteners.

- Double-check all connections and fasteners for tightness before moving to the next step.

- Finally, test the assembly by operating the tool briefly to ensure everything functions smoothly.

By adhering to these instructions, you will achieve a reliable setup that enhances the performance of your landscape management tool.

Finding Genuine Replacement Parts

Ensuring the longevity and performance of your equipment often hinges on the quality of components used. Sourcing authentic items is essential for maintaining optimal functionality and reliability. This section delves into effective strategies for acquiring high-quality replacements that meet rigorous standards.

Here are some key approaches to consider:

- Authorized Dealers: Seek out certified vendors who specialize in your specific brand. These sources often guarantee the authenticity and compatibility of their offerings.

- Manufacturer’s Website: Visiting the official website can provide direct access to genuine items and detailed information on compatibility.

- Online Marketplaces: Utilize reputable e-commerce platforms with strong buyer protection policies. Always check seller ratings and reviews to avoid counterfeit options.

When evaluating potential sources, prioritize the following criteria:

- Quality Assurance: Ensure that the components meet industry standards and have been rigorously tested.

- Return Policy: A reliable source will offer a clear return policy, allowing for exchanges if the item does not meet expectations.

- Customer Support: Look for suppliers that provide comprehensive customer service to assist with any inquiries or concerns.

By taking the time to research and identify credible sources, you can confidently secure the components necessary for optimal performance, ensuring your equipment remains in peak condition for years to come.

Upgrades to Enhance Rake Performance

Improving the efficiency of your landscaping tool can significantly impact its functionality and ease of use. By focusing on various enhancements, you can achieve better results, increase durability, and optimize performance for various tasks. This section explores effective modifications that can elevate the effectiveness of your equipment.

Key Enhancements

Several key improvements can be made to optimize your device’s performance. From adjusting the attachment types to upgrading the structural components, each modification plays a role in achieving superior results. Below are some of the most beneficial upgrades:

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Quality Tines | Switching to durable materials like hardened steel | Increased longevity and reduced wear |

| Adjustable Height | Incorporating mechanisms for height adjustment | Enhanced versatility for different tasks |

| Enhanced Frame | Upgrading to a reinforced frame design | Improved stability and strength under heavy use |

| Attachment Compatibility | Adding options for compatible attachments | Expanded functionality for varied applications |

Maintenance Considerations

Regular maintenance and timely upgrades are essential for optimal performance. Keeping components well-maintained ensures that your tool operates efficiently and prolongs its lifespan. Consider scheduling routine inspections and replacing worn-out parts to maintain high functionality.