Understanding the structure and organization of various mechanical elements in a vehicle is essential for maintenance and repair. By knowing how different components interact, you can ensure that all systems function smoothly and efficiently. This knowledge is especially valuable for identifying specific mechanical connections and ensuring optimal operation.

Each system within a vehicle is designed to work in harmony with others. From key mechanical elements to essential connectors, recognizing their placement and functionality allows for better insight into the overall mechanical performance. Such information can be a helpful guide in diagnosing issues and performing replacements.

In this section, we will take a closer look at how specific elements are aligned and integrated. You will gain a better understanding of how these elements contribute to the smooth operation of a vehicle and how their arrangement impacts overall system efficiency.

Understanding the Components of Front End Parts

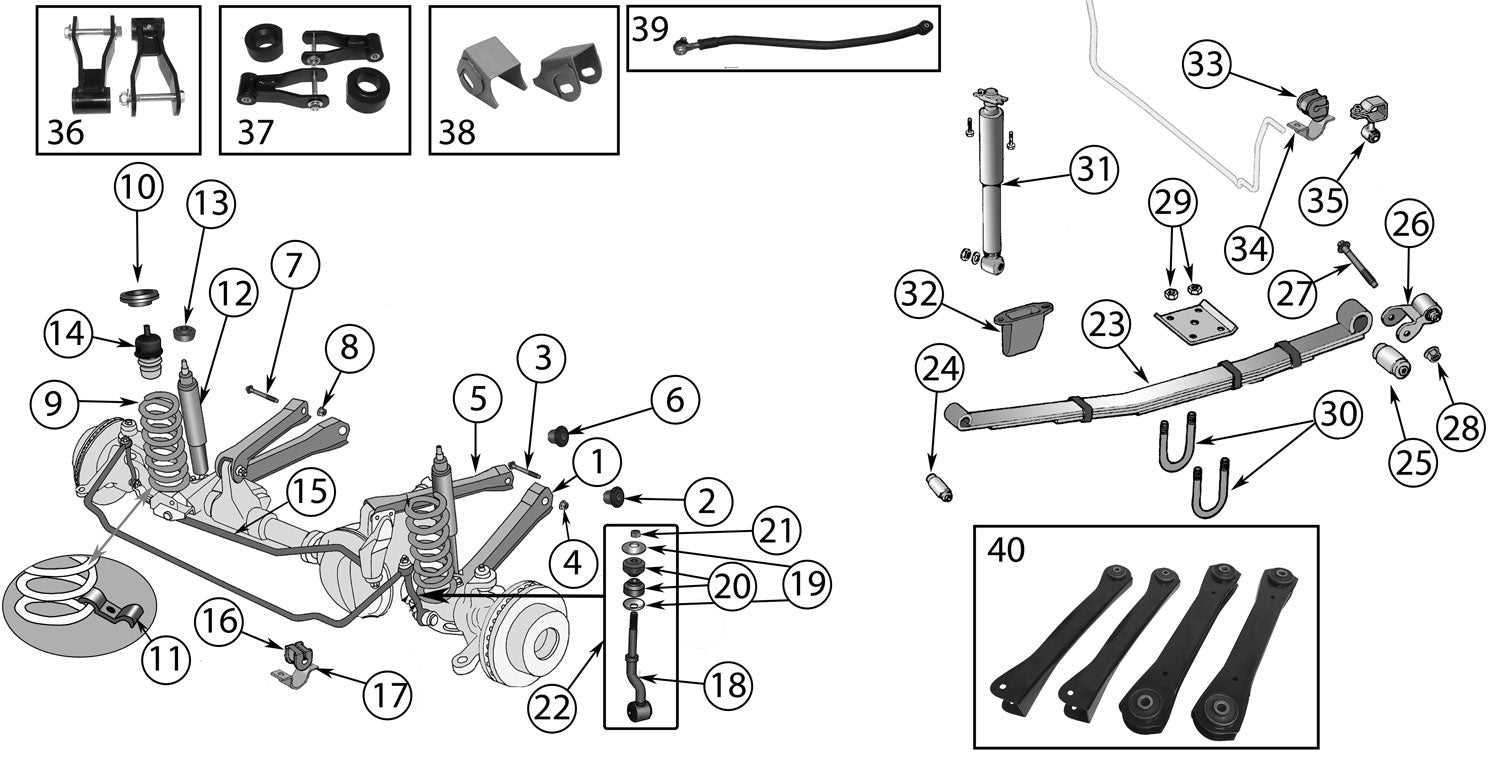

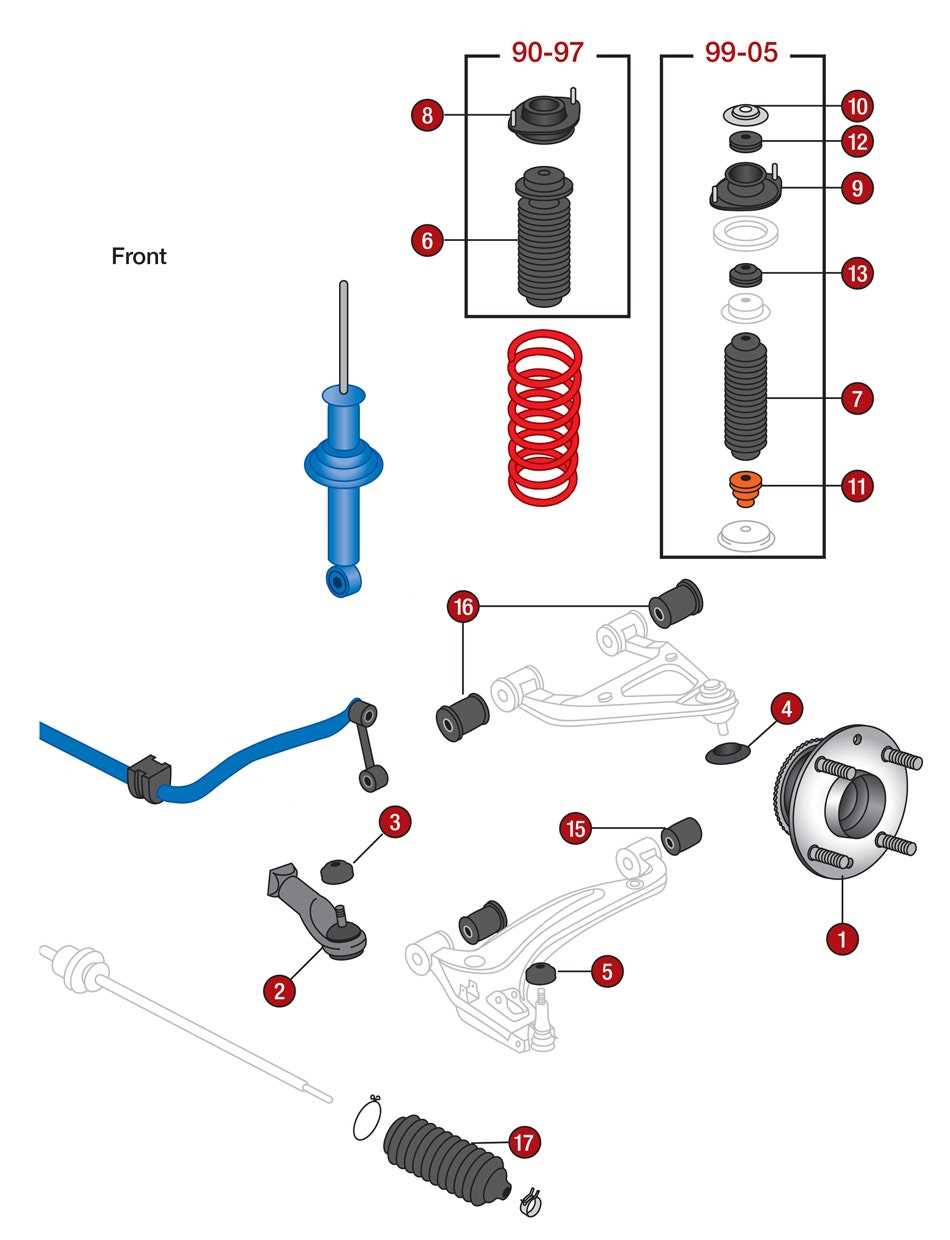

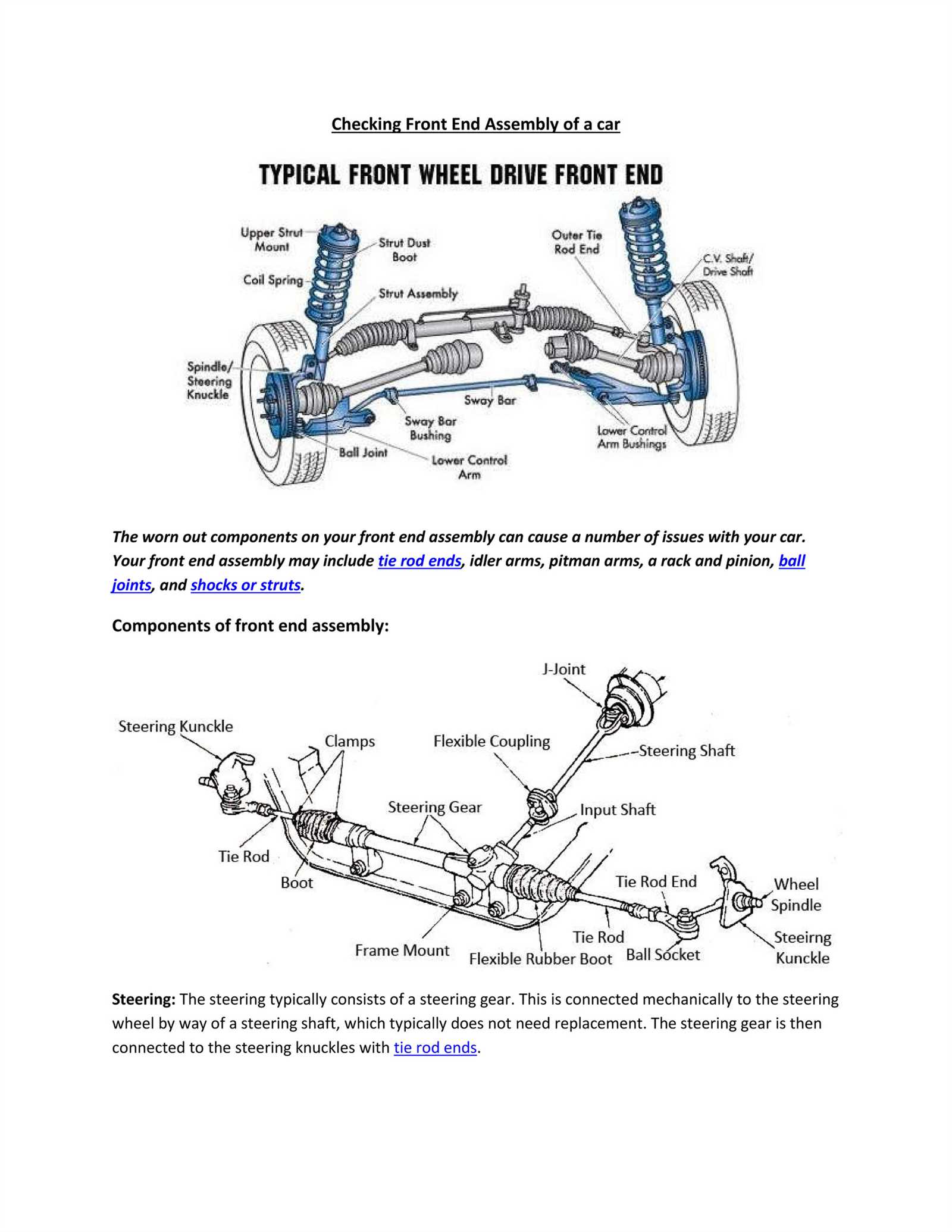

To understand how various vehicle mechanisms work together, it’s essential to dive into the components that control the steering, handling, and balance. These elements function as a collective system to ensure smooth and safe driving, offering stability and control under different conditions.

Key Elements in Steering and Control

- Suspension System: This unit absorbs shocks from the road, maintaining tire contact and ensuring a smooth ride.

- Steering Rack: Responsible for translating the driver’s movements into the wheel’s motion, allowing for precise direction changes.

- Control Arms: These act as connectors between the frame and the wheels, providing necessary movement while keeping everything in alignment.

Stability and Balance

Main Structural Elements in Front End Assembly

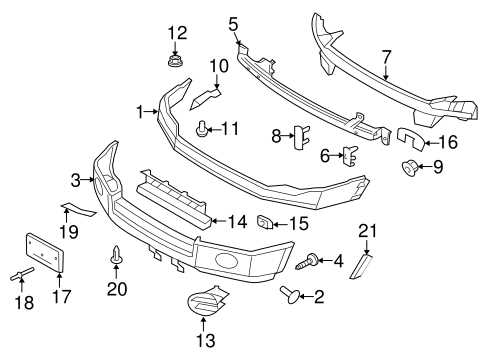

The core components of the forward vehicle structure play a crucial role in both stability and safety. These key elements are designed to absorb impact, support essential systems, and provide the framework for other mechanical and electrical assemblies. Understanding how these components interact is vital for both maintenance and repair, ensuring optimal performance and longevity.

Primary Framework Components

The foundation of the assembly includes several metal structures that form the backbone of the vehicle’s frontal area. These include beams, braces, and panels, each with a distinct function. Their primary purpose is to distribute force in case of collisions and provide anchoring points for various systems such as the cooling system and headlights.

Support and Reinforcement Elements

In addition to the core framework, there are smaller reinforcements that strengthen key areas. These components ensure that the load is evenly distributed

Key Functional Parts and Their Roles

In any system or mechanism, understanding the primary components and how they operate is crucial. Each element contributes to the overall functionality, ensuring the seamless operation of the system. These essential elements work together, performing specific tasks that are vital for optimal performance.

Main Elements and Their Tasks

The core components of the system each have a distinct role. One may be responsible for processing data, while another ensures smooth control over operations.

Common Materials Used in Front End Systems

The structural components of a vehicle’s suspension and steering mechanisms are crafted from a range of materials designed to optimize performance, durability, and safety. These materials are chosen for their ability to withstand the demands of road conditions and vehicle load, ensuring long-lasting service and reliable operation under various circumstances.

Steel Alloys

One of the most common materials used in critical support structures is steel alloys. Known for their exceptional strength and rigidity, these alloys provide the necessary reinforcement for load-bearing components. In addition to being resistant to deformation, steel alloys are treated to prevent corrosion, making them ideal for parts exposed to environmental factors like moisture and road salt.

Differences Between Mechanical and Electronic Front Parts

Understanding the differences between traditional mechanical components and modern electronic systems is crucial for anyone involved in maintenance or repair work. While both types serve essential roles in various structures, they operate in fundamentally different ways and require different approaches in terms of maintenance and performance optimization.

Mechanical Components

Mechanical systems rely on physical structures and movements to function. These components often include gears, levers, and other mechanisms that work together through manual or powered actions. Durability is a key advantage of these systems, but they can also be prone to wear and

How Front End Parts Affect Vehicle Safety

The components located at the forefront of a vehicle play a crucial role in ensuring the safety of its occupants. These elements are designed not only for aesthetic appeal but also for functionality and protection. Their design and material choice significantly influence how well a vehicle can withstand impacts and provide safety during collisions.

Structural Integrity and Impact Absorption

Structural integrity is vital for a vehicle’s ability to protect passengers. The framework and materials used in these components are engineered to absorb energy during a collision, thereby reducing the force transmitted to the cabin. Advanced materials and innovative designs can enhance this absorption capacity, ultimately improving occupant safety.

Alignment and Handling

Proper alignment of the components also impacts the handling and stability of the vehicle. Misalignment can lead to decreased maneuverability and an increased risk of accidents. When these elements are well-maintained and functioning correctly, they contribute to a smoother driving experience, enhancing overall safety on the road.

Front End Parts and Their Maintenance Needs

The elements that constitute the forward assembly of a vehicle play a crucial role in ensuring both safety and performance. These components require regular attention to maintain optimal functionality and longevity. Understanding their maintenance requirements can prevent unforeseen issues and enhance the overall driving experience.

Common Components and Their Care

Several crucial elements make up the forward assembly, including suspension systems, steering mechanisms, and braking units. Regular inspections and timely replacements of wear-prone components can significantly impact vehicle performance. For instance, ensuring that the suspension system is free from leaks and adequately lubricated will improve ride comfort and handling.

Importance of Timely Maintenance

Neglecting the upkeep of these crucial elements can lead to decreased efficiency and potential safety hazards. Regular checks for alignment and tire wear, along with brake pad inspections, are essential practices. Routine maintenance not only ensures smoother operation but also extends the lifespan of the vehicle’s assembly, ultimately saving time and costs in the long run.

Upgrading Front End Parts for Performance

Enhancing the components responsible for steering and suspension can significantly elevate your vehicle’s handling, stability, and overall driving experience. By investing in high-quality upgrades, you can achieve better responsiveness and improved control, transforming your ride into a more dynamic and enjoyable experience.

One effective way to boost performance is through the installation of high-performance shock absorbers and struts. These components play a crucial role in managing the vehicle’s response to road conditions, providing a smoother ride and minimizing body roll during turns. Upgrading to adjustable units allows for fine-tuning, enabling drivers to tailor their setup to suit specific driving styles or conditions.

Moreover, replacing stock bushings with polyurethane or spherical alternatives can enhance feedback and reduce flex. This improvement leads to a more connected feel between the driver and the road, allowing for precise maneuvering and enhanced cornering abilities.

Additionally, upgrading control arms and sway bars can further stabilize the vehicle. Stiffer sway bars reduce body roll, improving cornering performance, while adjustable control arms allow for fine-tuning of alignment settings, promoting optimal tire contact with the road surface. Overall, these enhancements contribute to a more engaging and controlled driving experience.

Diagnostic Tips for Identifying Front End Issues

Understanding and diagnosing challenges in vehicle handling can significantly enhance safety and performance. This section provides practical guidance on how to effectively identify potential complications within the vehicle’s suspension and steering systems. By following these diagnostic tips, you can pinpoint issues that may affect the overall driving experience.

Common Symptoms to Observe

Recognizing specific indicators is crucial for effective troubleshooting. Pay attention to the following signs that may suggest underlying issues:

| Symptom | Possible Cause |

|---|---|

| Unusual noises when turning | Worn-out components or loose fittings |

| Vibration in the steering wheel | Imbalanced wheels or misaligned systems |

| Difficulty in steering | Low fluid levels or a failing pump |

| Uneven tire wear | Misalignment or faulty suspension elements |

Inspection Procedures

Conducting a thorough examination of the vehicle is essential for accurate diagnosis. Here are some recommended steps:

- Check fluid levels and look for leaks in the hydraulic systems.

- Inspect the condition of tires and ensure proper inflation.

- Evaluate the state of suspension components for signs of wear or damage.

- Test the steering system for responsiveness and any unusual behaviors.