In any plumbing system, the effective operation of essential connections relies on precise construction and the proper assembly of individual elements. Each component, no matter how small, plays a crucial role in ensuring that the entire system functions smoothly and efficiently. Knowing how these elements interact is vital for anyone involved in maintenance or installation tasks.

When examining the various elements of a plumbing system, it becomes clear that there are distinct groups of interconnected pieces. Some are designed for secure attachment, while others help control the flow or seal connections tightly. Understanding the function of each part can help troubleshoot issues or guide replacement when necessary.

Whether you’re a professional plumber or a DIY enthusiast, familiarizing yourself with these interconnected components will lead to a better grasp of how systems are assembled and maintained. This knowledge not only increases efficiency but also ensures safety and durability in your plumbing projects.

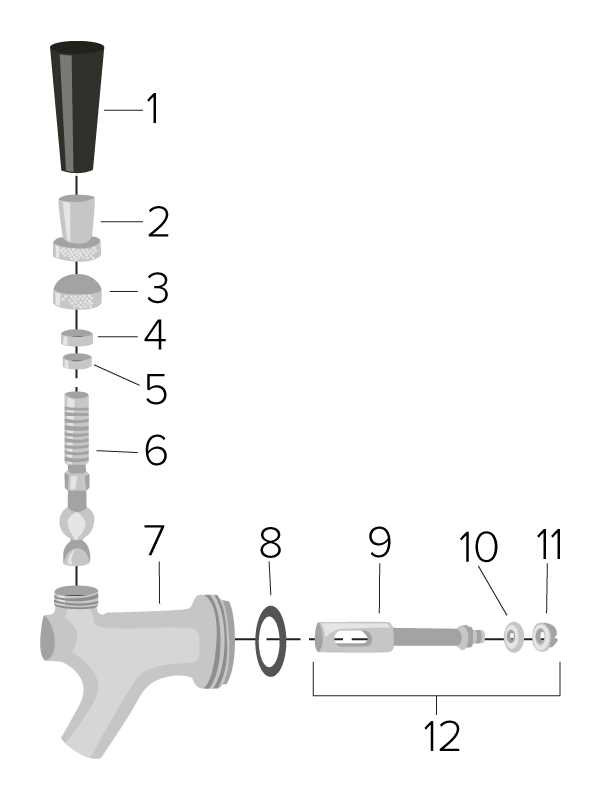

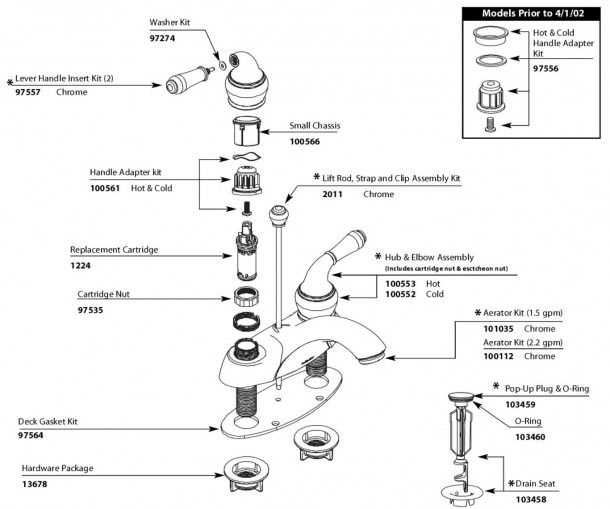

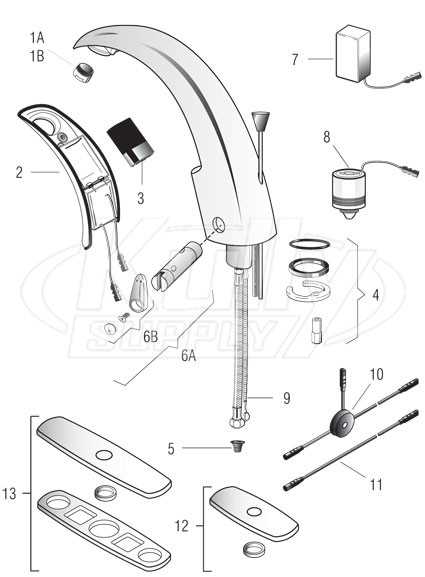

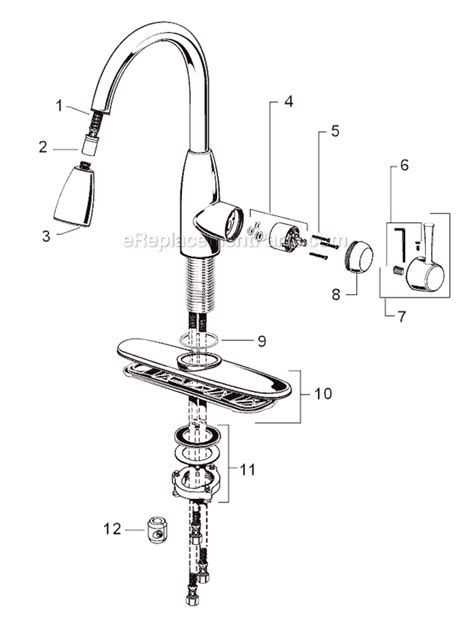

Understanding the Basics of Spigot Parts

This section provides an overview of essential components found in various mechanisms, focusing on their functionality and interaction. Grasping these fundamentals is crucial for anyone looking to enhance their knowledge or skills in related fields.

- Functionality: Each component serves a specific purpose, contributing to the overall efficiency of the system.

- Interaction: Understanding how these elements work together is key to troubleshooting and maintenance.

- Material: Different materials impact durability and performance, making selection critical.

- Seals: Ensure a tight closure, preventing leaks.

- Connectors: Facilitate secure links between sections.

- Control mechanisms: Regulate flow and pressure within the system.

By exploring these elements, one can delve deeper into the complexities of design and operation, ultimately leading to more informed choices and better performance outcomes.

How Spigot Components Work Together

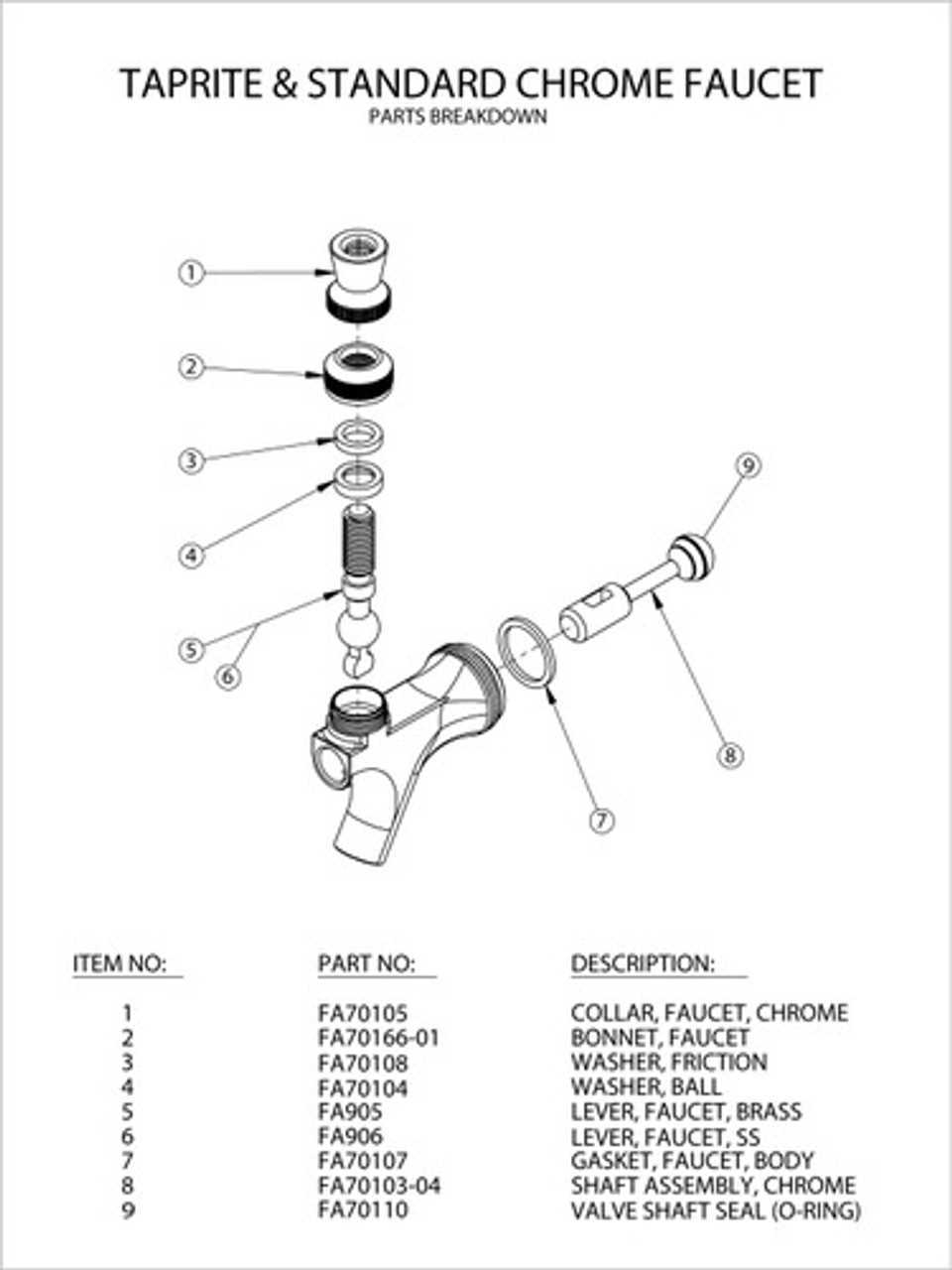

The interaction between various elements in a fluid delivery system is crucial for ensuring efficiency and reliability. Each component plays a specific role, contributing to the overall functionality while working harmoniously with others. Understanding how these elements integrate can enhance both performance and maintenance practices.

The Role of Each Element

Each individual piece serves a distinct purpose, from controlling flow to providing stability. For instance, the valve regulates the amount of liquid released, while the base offers support and ensures proper alignment. Together, these elements create a seamless experience, minimizing leaks and optimizing usage.

Synergy in Design

The design of this system emphasizes the importance of compatibility among its constituents. When elements are engineered to fit perfectly, the result is a unified mechanism that operates efficiently. Regular inspections and maintenance can further enhance this synergy, ensuring longevity and consistent performance.

Common Spigot Types and Their Features

Understanding the various types of connectors used in fluid systems is essential for optimal performance and efficiency. Each type serves specific applications, with distinct characteristics that influence their suitability for different tasks.

One prevalent variety is the threaded model, known for its ease of installation and secure fit. This type is often used in residential settings, ensuring a reliable connection in plumbing applications.

Another common variant is the quick-release option, designed for rapid assembly and disassembly. Its convenience makes it ideal for situations requiring frequent changes or maintenance.

Ball valves represent another important category, offering precise control over flow rates. Their robust design ensures durability, making them suitable for industrial environments.

Lastly, the push-fit version allows for simple connections without the need for tools. This feature appeals to DIY enthusiasts and professionals alike, enhancing versatility in various settings.

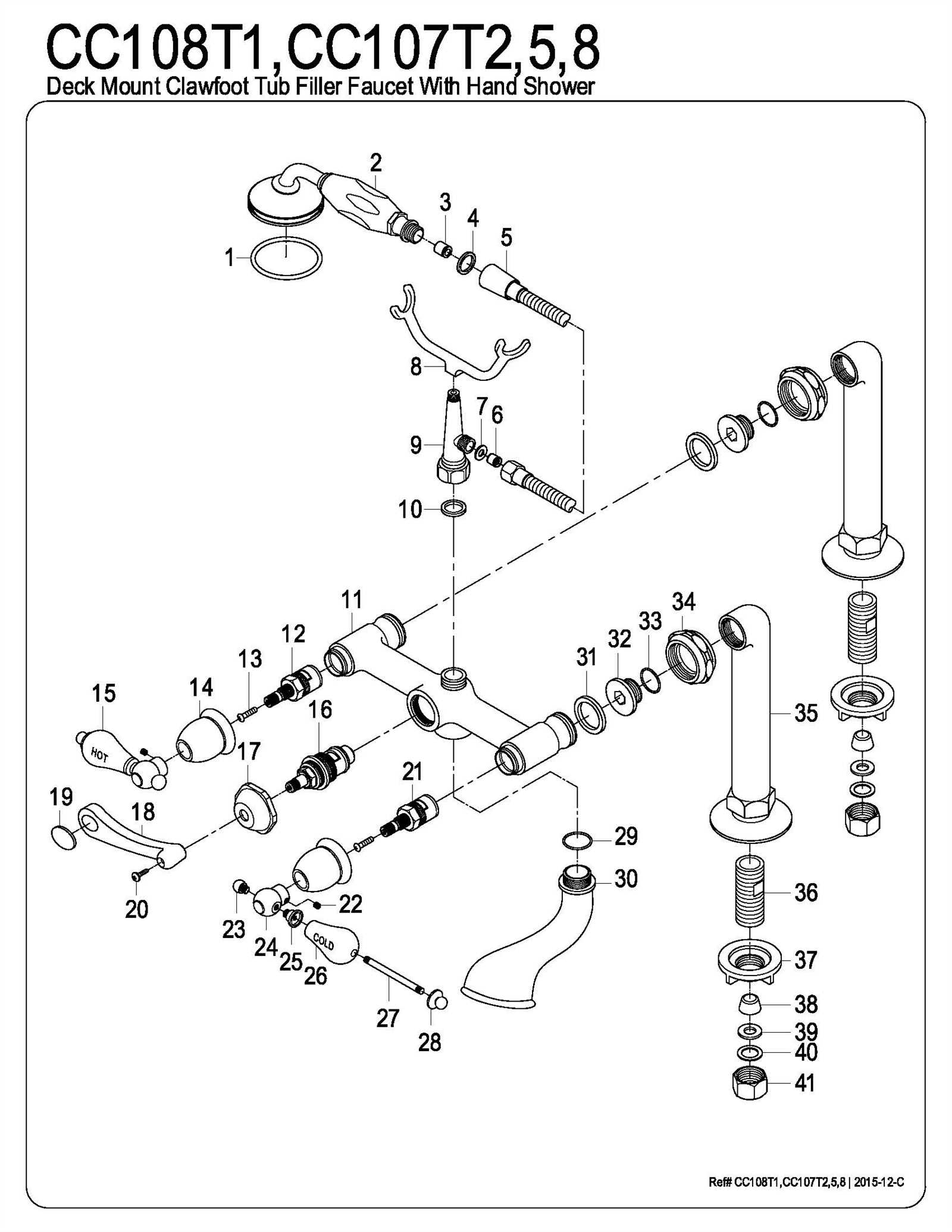

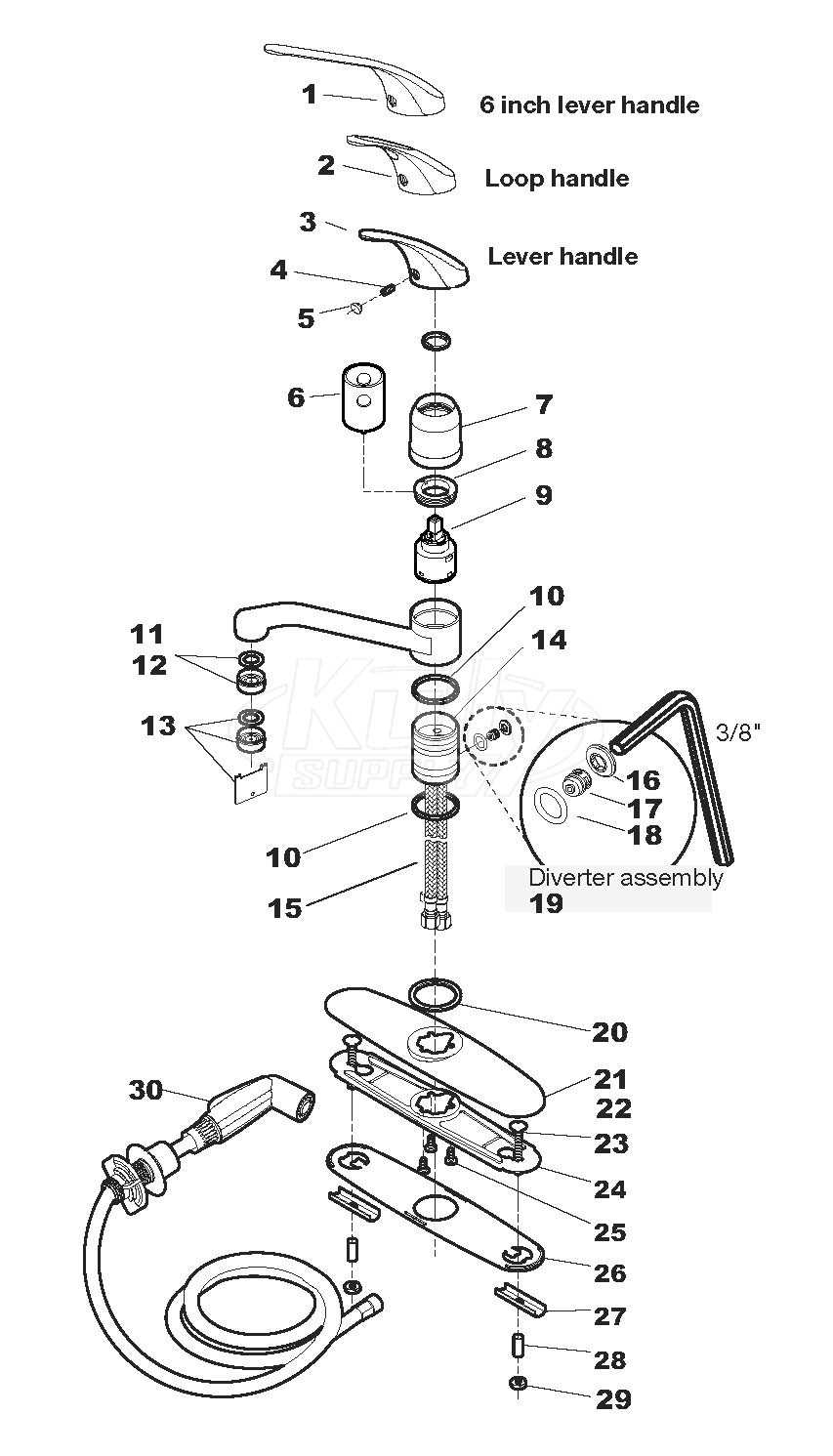

Step-by-Step Guide to Spigot Assembly

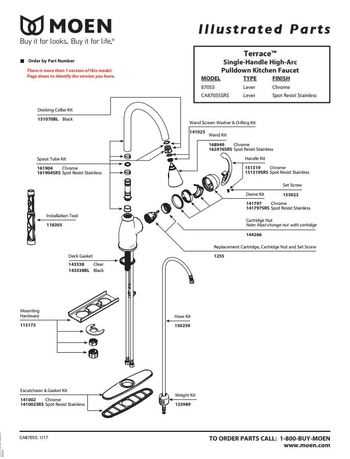

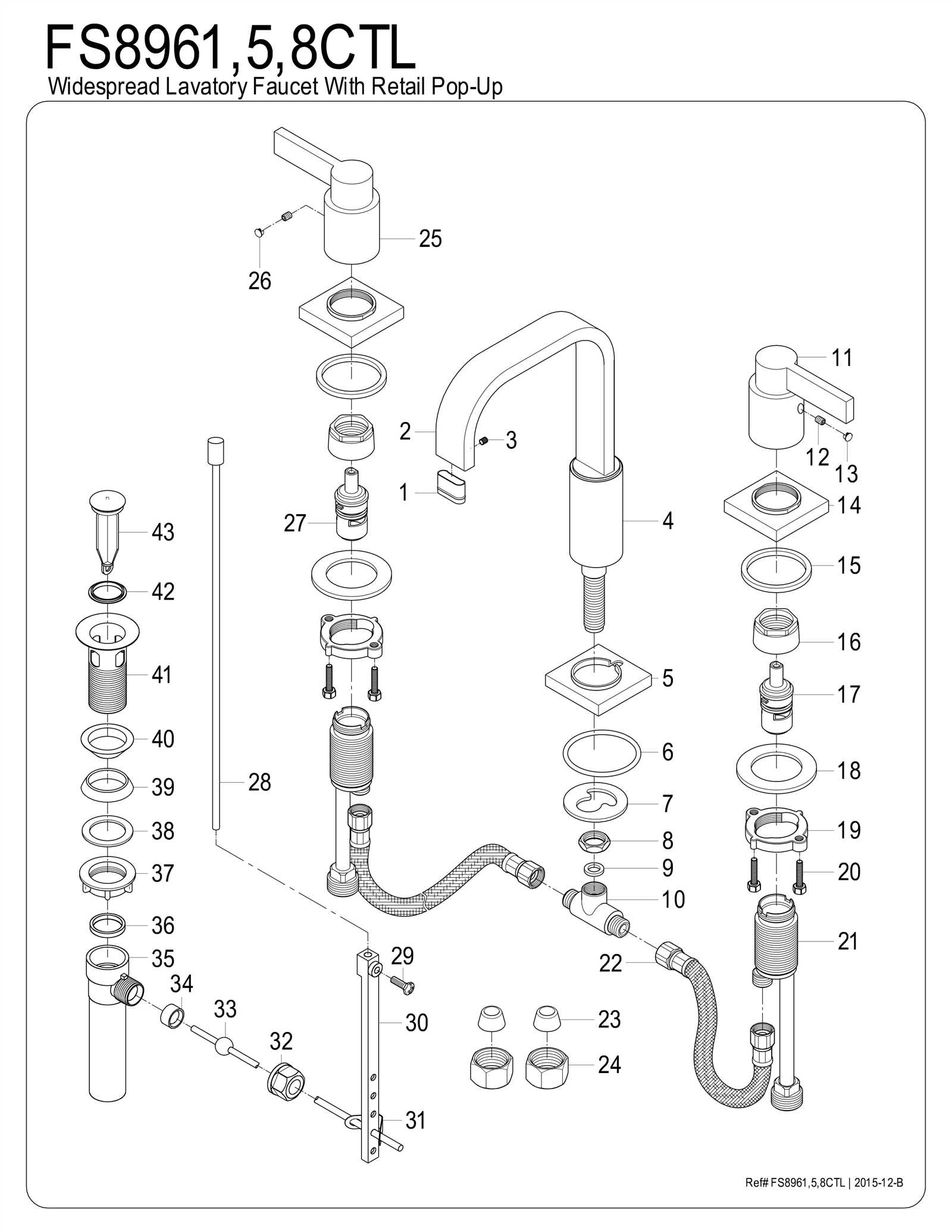

Assembling a faucet or valve system may seem daunting at first, but breaking it down into clear, methodical steps ensures a smooth process. This guide will take you through each stage of the assembly process, providing practical tips and highlighting the key components necessary for proper installation. With the right tools and a step-by-step approach, you’ll be able to assemble the mechanism effectively and with confidence.

Gathering Tools and Materials

Before beginning the assembly, it is essential to ensure that all necessary components and tools are on hand. Having everything ready will help avoid unnecessary interruptions during the process. Typically, you will need a wrench, a screwdriver, sealing tape, and the individual elements that make up the assembly kit.

Assembly Procedure

Begin by carefully reviewing the components and identifying each piece. Ensure that all items are in good condition and free from damage. Start by securing the main body and attaching the various fittings according to the manual’s instructions. Tighten all screws and joints properly to prevent leaks or malfunction. It is recommended to apply sealing tape to the threaded areas to ensure a secure and watertight connection.

| Step | Action | Tools Required |

|---|---|---|

| 1 | Check all parts for completeness and condition | Visual inspection |

| 2 | Secure the main housing to the base | Wrench |

| 3 | Connect and tighten all additional fittings | Screwdriver, sealing tape |

| 4 | Test the assembly for leaks and functionality | Water source |

Once the assembly is complete, conduct a final test to check for proper functionality. Ensure that there are no leaks and that the system operates smoothly. If necessary, make adjustments to the connections or tightening. Following these steps will help ensure a successful assembly and a fully functional unit.

Common Issues with Spigot Parts and Fixes

In any system involving fluid transfer, various components can encounter issues that affect functionality and efficiency. Understanding these common problems and their solutions can help maintain optimal performance and prevent costly repairs.

| Issue | Symptoms | Possible Fixes |

|---|---|---|

| Leakage | Water pooling around the base, dripping noises | Inspect seals and gaskets; replace damaged components |

| Blockage | Poor flow or no flow at all | Clear any obstructions; use a cleaning agent to dissolve buildup |

| Corrosion | Discoloration, flaking surfaces | Apply protective coatings; replace corroded elements |

| Noise | Unusual sounds during operation | Check for loose fittings; tighten as necessary |

| Worn Out Components | Inconsistent performance, leaks | Schedule regular maintenance; replace worn items |

Choosing the Right Spigot for Your Needs

When it comes to selecting the ideal faucet for your requirements, several factors come into play that can significantly influence your decision. Understanding the specific applications and functionalities you need is crucial for ensuring optimal performance and convenience in your daily activities.

First, consider the intended use. Are you looking for a model for gardening, cooking, or perhaps for industrial purposes? Each application demands different features, such as flow rate and durability. Choosing a model designed for its specific use will enhance efficiency and longevity.

Next, think about the materials involved. Options range from stainless steel to plastic, each with its unique benefits and drawbacks. Stainless steel offers robustness and resistance to corrosion, while plastic can be lighter and more affordable. Evaluate which material aligns best with your environment and usage patterns.

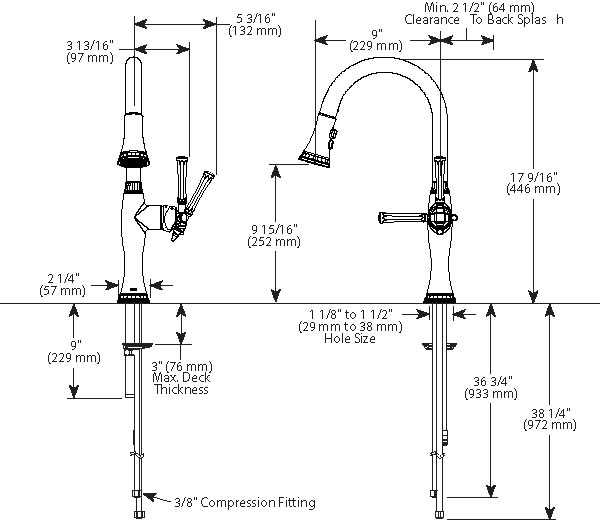

Another important aspect is installation and compatibility with your existing plumbing system. Some models may require specific fittings or tools for installation. Ensure that the chosen option can be easily integrated into your setup to avoid additional costs and complications.

Lastly, always keep in mind the aesthetic appeal. A visually appealing faucet can enhance the overall look of your space, whether it’s in your home, garden, or workplace. Choose a design that complements your surroundings while fulfilling your functional requirements.

By carefully considering these factors, you can select a fixture that not only meets your needs but also provides long-lasting satisfaction and reliability.

Spigot Maintenance Tips for Longevity

Ensuring the longevity of your water dispensing device requires regular attention and care. By following a few simple guidelines, you can prevent common issues and enhance performance, ultimately saving time and resources in the long run.

Regular Cleaning: Keep the exterior and interior surfaces clean to prevent buildup of grime and mineral deposits. Use mild soap and water for cleaning, and avoid harsh chemicals that could damage the material.

Inspect Seals and Gaskets: Regularly check the integrity of seals and gaskets. Replacing worn or damaged components promptly can prevent leaks and ensure efficient operation.

Avoid Extreme Temperatures: Protect your unit from extreme heat or cold. Excessive temperatures can lead to material degradation and affect functionality. Store in a climate-controlled environment whenever possible.

Regular Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure you use lubricants that are compatible with the materials of your device.

Check for Wear: Periodically inspect all components for signs of wear and tear. Early detection of potential issues can help you address them before they become major problems.

Follow Manufacturer Guidelines: Always adhere to the maintenance recommendations provided by the manufacturer. These guidelines are designed to help you achieve the best performance and extend the life of your equipment.

By implementing these maintenance strategies, you can significantly enhance the durability and efficiency of your water dispensing equipment, ensuring it serves you well for many years.

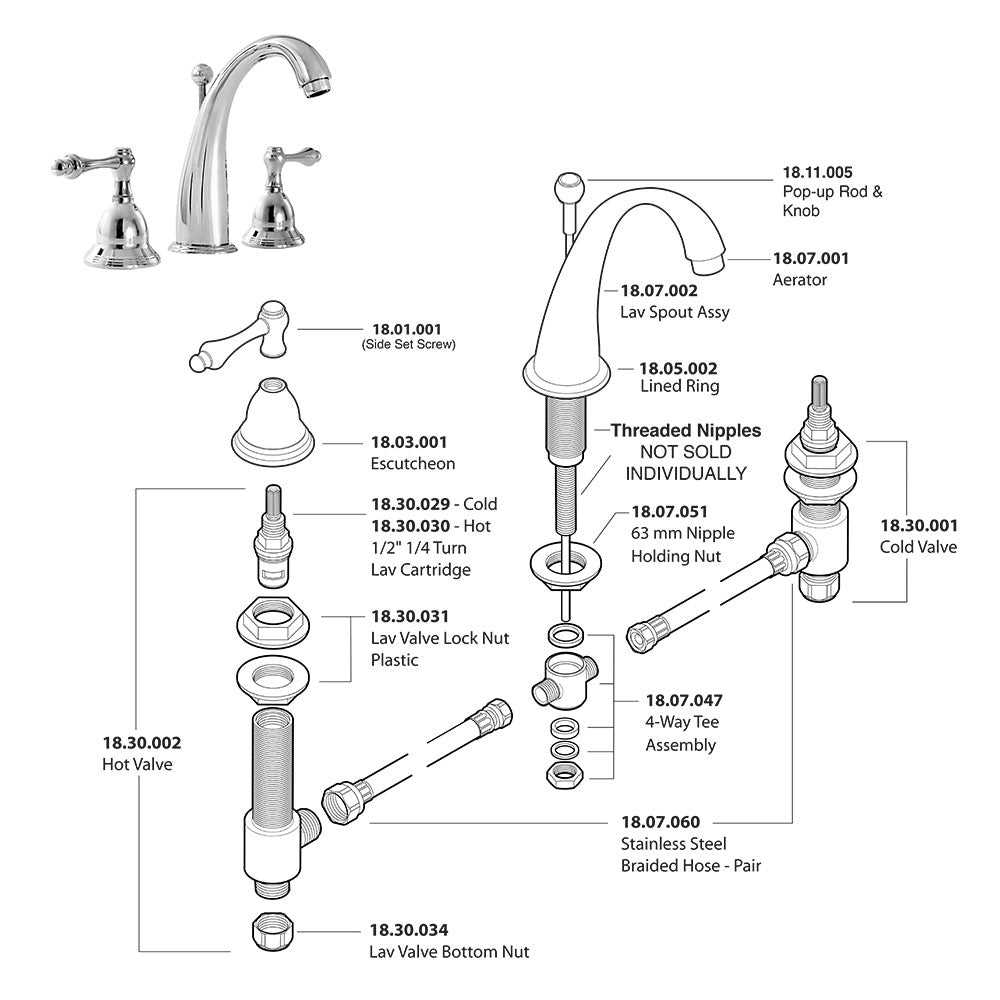

Where to Find Spigot Parts Diagrams Online

Locating detailed illustrations and breakdowns for plumbing fixtures can significantly simplify repair and maintenance tasks. Numerous online resources provide comprehensive visual guides that can assist both professionals and DIY enthusiasts in identifying components and understanding their functions.

Here are some reliable sources to consider when searching for these valuable resources:

| Website | Description |

|---|---|

| Manufacturer’s Website | Official sites often have technical documentation and resources available for specific models. |

| Online Retailers | Major retailers frequently provide manuals and schematic representations alongside product listings. |

| DIY Forums | Community-driven platforms where users share their experiences and often post helpful visuals and guides. |

| Technical Libraries | Some online libraries host a collection of manuals and drawings that can be accessed for free or via subscription. |

Utilizing these resources can greatly enhance your understanding and ability to address any issues related to your plumbing installations.