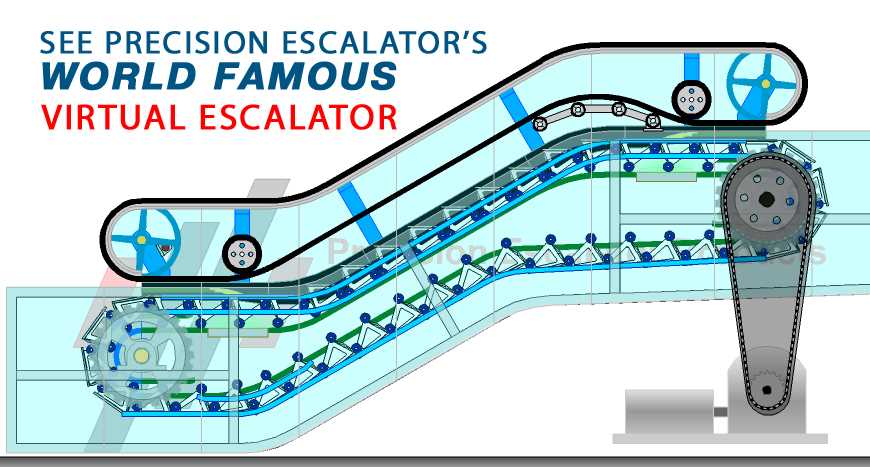

In the realm of vertical transportation systems, comprehending the various elements and their interactions is crucial for ensuring efficient operation and safety. This section delves into the intricate layout and essential elements that constitute these systems, offering insights into their structure and functionality.

Identifying key components plays a vital role in maintenance and troubleshooting. By examining the configuration and relationships among these elements, one can better appreciate their individual functions and contributions to the overall system. Understanding how these components work together fosters a deeper awareness of their significance in daily operations.

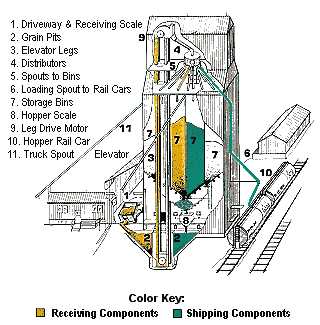

Furthermore, visual representations can greatly enhance comprehension. By providing a clear overview of how different elements are organized, these illustrations aid in recognizing potential issues and implementing effective solutions. A thorough grasp of the system’s configuration not only promotes operational efficiency but also reinforces safety protocols.

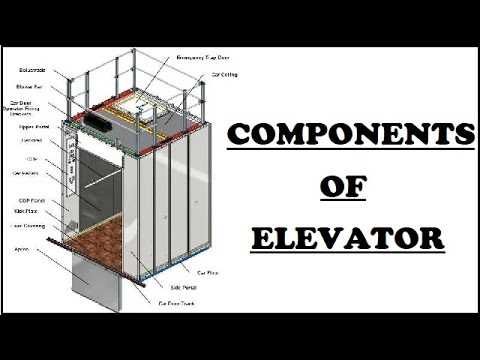

Overview of Elevator Components

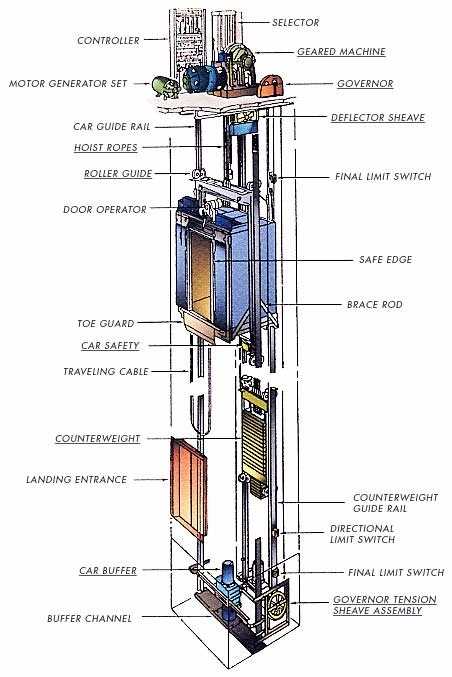

The intricate system that facilitates vertical transportation within buildings comprises various essential elements, each contributing to its functionality and efficiency. Understanding these components is crucial for maintaining optimal operation and ensuring safety in high-rise structures.

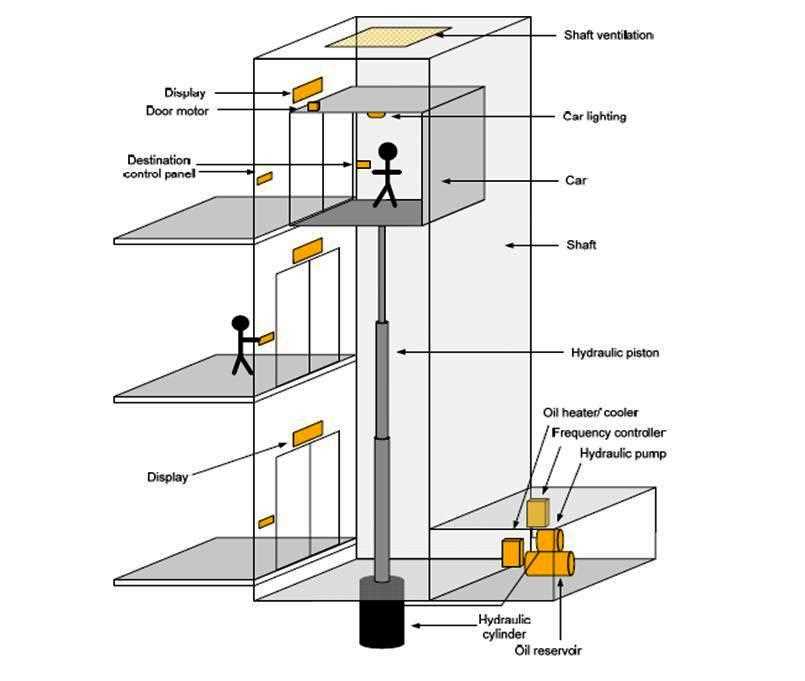

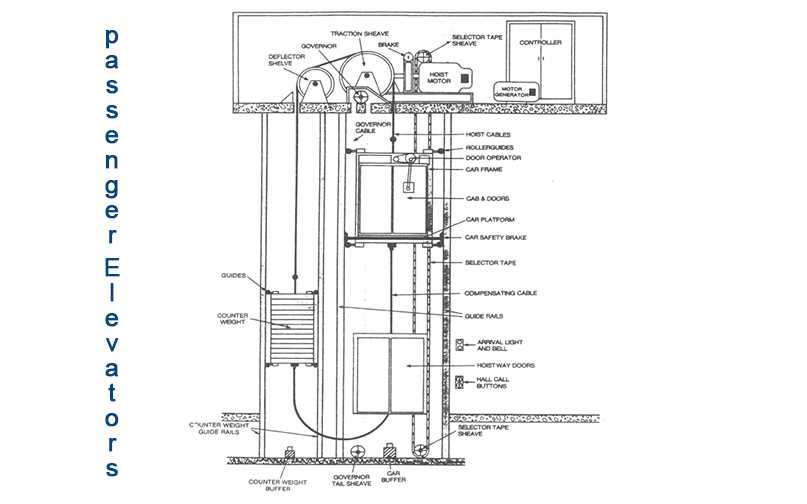

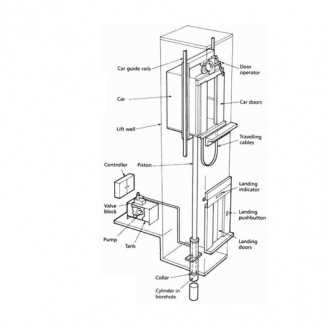

At the core of this mechanism lies the cab, which serves as the passenger compartment, designed to provide a comfortable and secure environment during transit. The hoistway acts as the vertical shaft that houses the cab and supports its movement, while the drive system provides the necessary force for ascent and descent. This system typically includes an electric motor, pulleys, and cables, which work together to facilitate smooth travel.

Additionally, the control panel is vital for user interaction, allowing passengers to select their desired floors. It integrates various safety features to prevent accidents, including emergency brakes and door sensors, which ensure the safe operation of the entire system. Lastly, the counterweight plays a crucial role in balancing the load, enhancing energy efficiency by reducing the amount of force required from the motor.

In summary, each element within this transportation system is interrelated, functioning collaboratively to create a reliable and efficient means of moving individuals between different levels of a building.

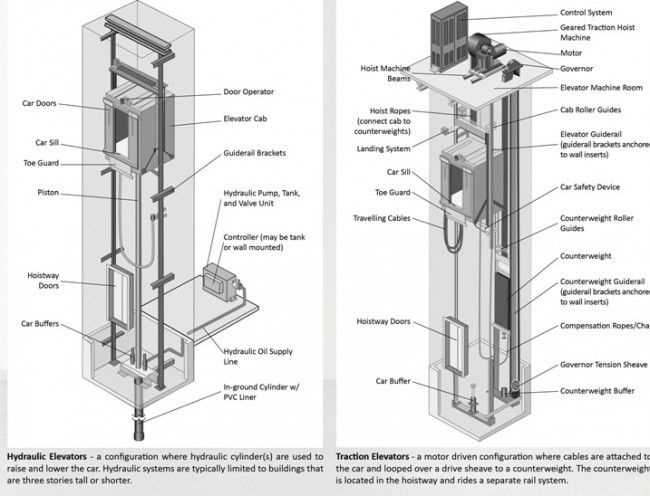

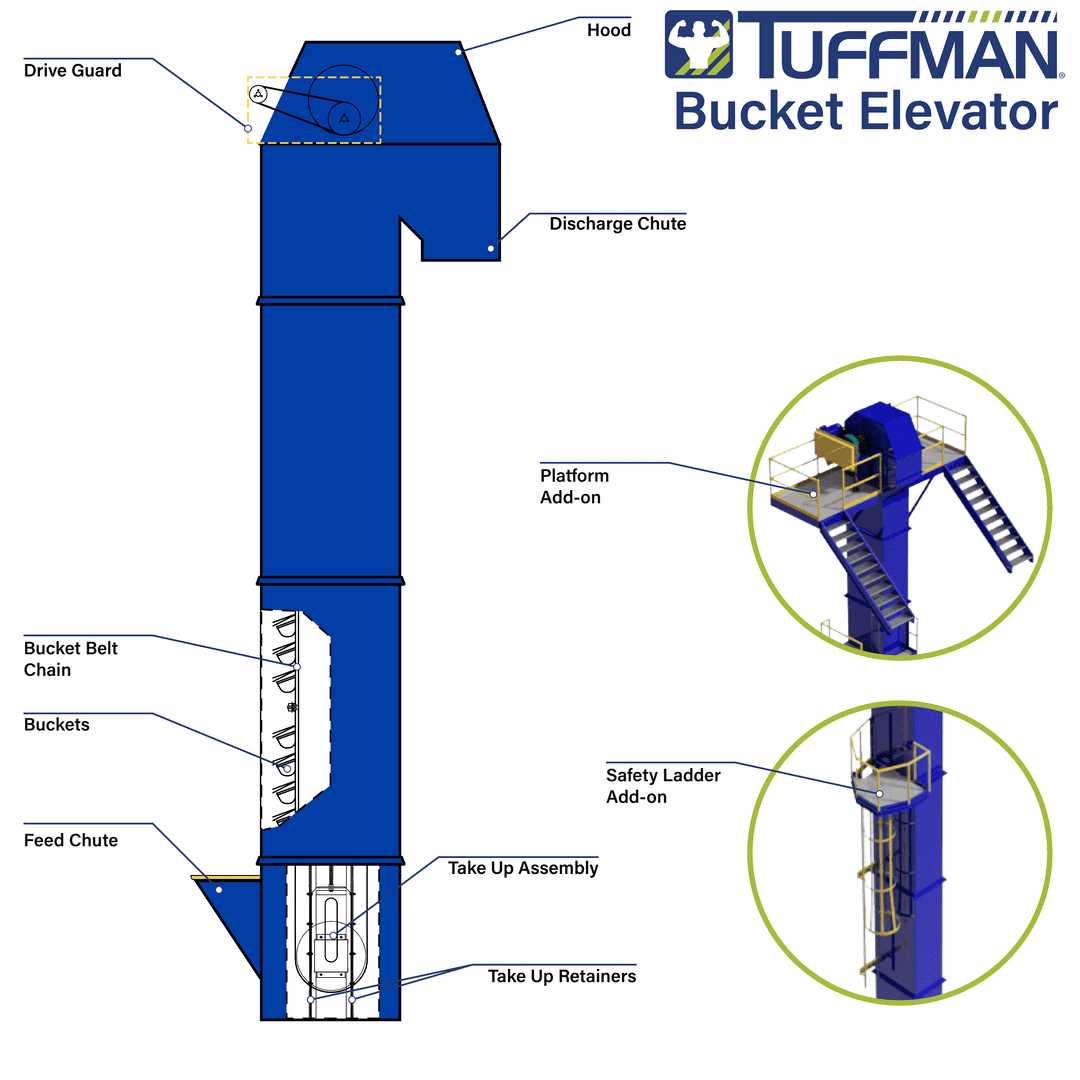

Types of Elevators and Their Parts

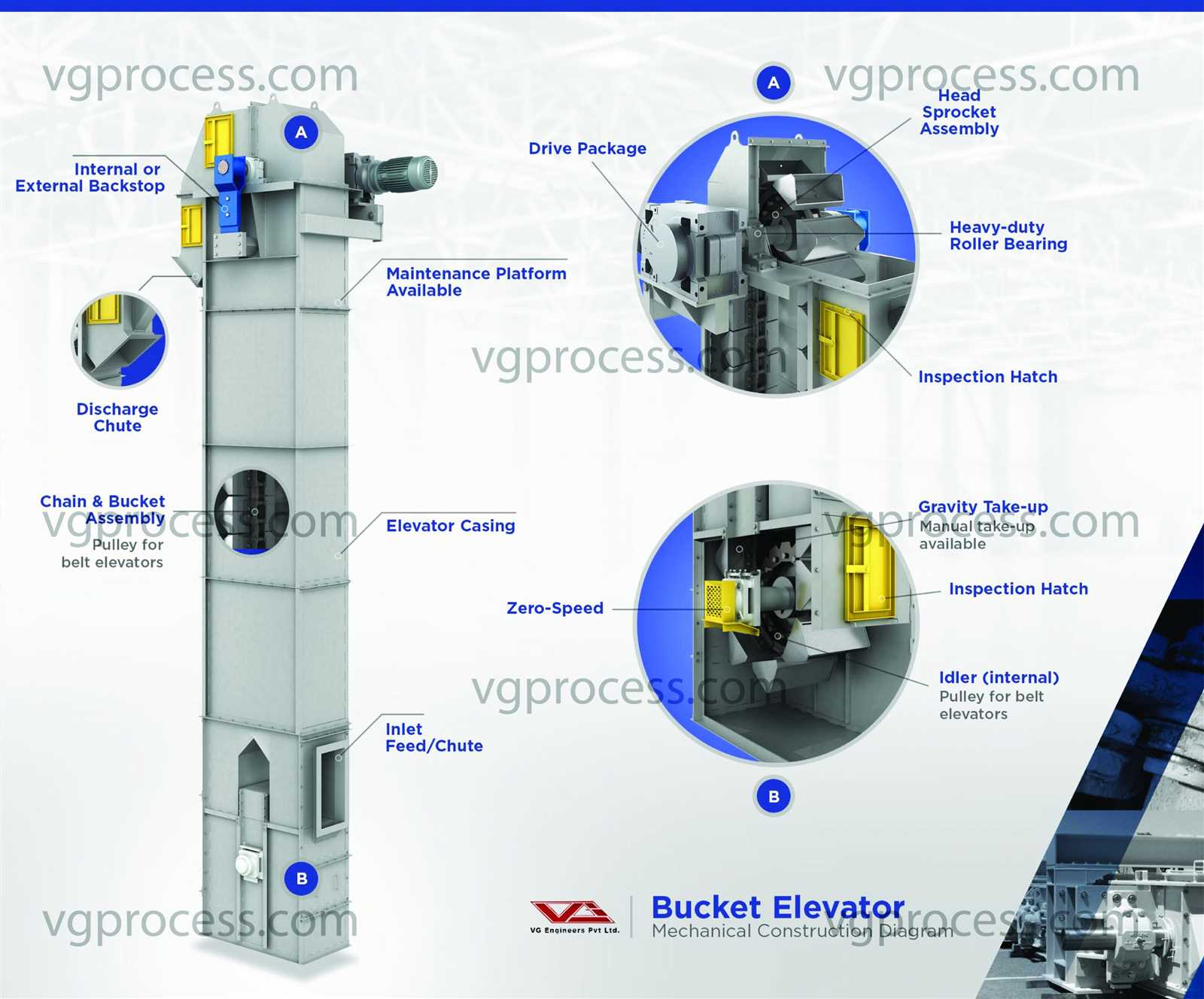

This section delves into various mechanisms designed for vertical transportation, exploring their unique features and components. Understanding these systems is essential for selecting the appropriate type for specific building requirements, as well as for maintenance and repair considerations.

Mechanical Systems

Mechanical systems are widely utilized in commercial and residential settings. These conveyances are characterized by their reliance on cables and pulleys for movement. The design and materials used in these units can vary significantly, leading to diverse functionality and capacity.

Hydraulic Systems

Hydraulic systems employ fluid dynamics to achieve vertical movement. This technology allows for smooth and efficient operation, making it particularly suitable for low-rise buildings. The components of these systems are designed to withstand high pressure while ensuring safety and reliability.

| System Type | Key Features | Common Uses |

|---|---|---|

| Mechanical | Cable-driven, high speed, space-efficient | Commercial buildings, high-rises |

| Hydraulic | Fluid-operated, smooth motion, low rise | Low-rise buildings, warehouses |

| Pneumatic | Air pressure, innovative design, eco-friendly | Residential, small-scale applications |

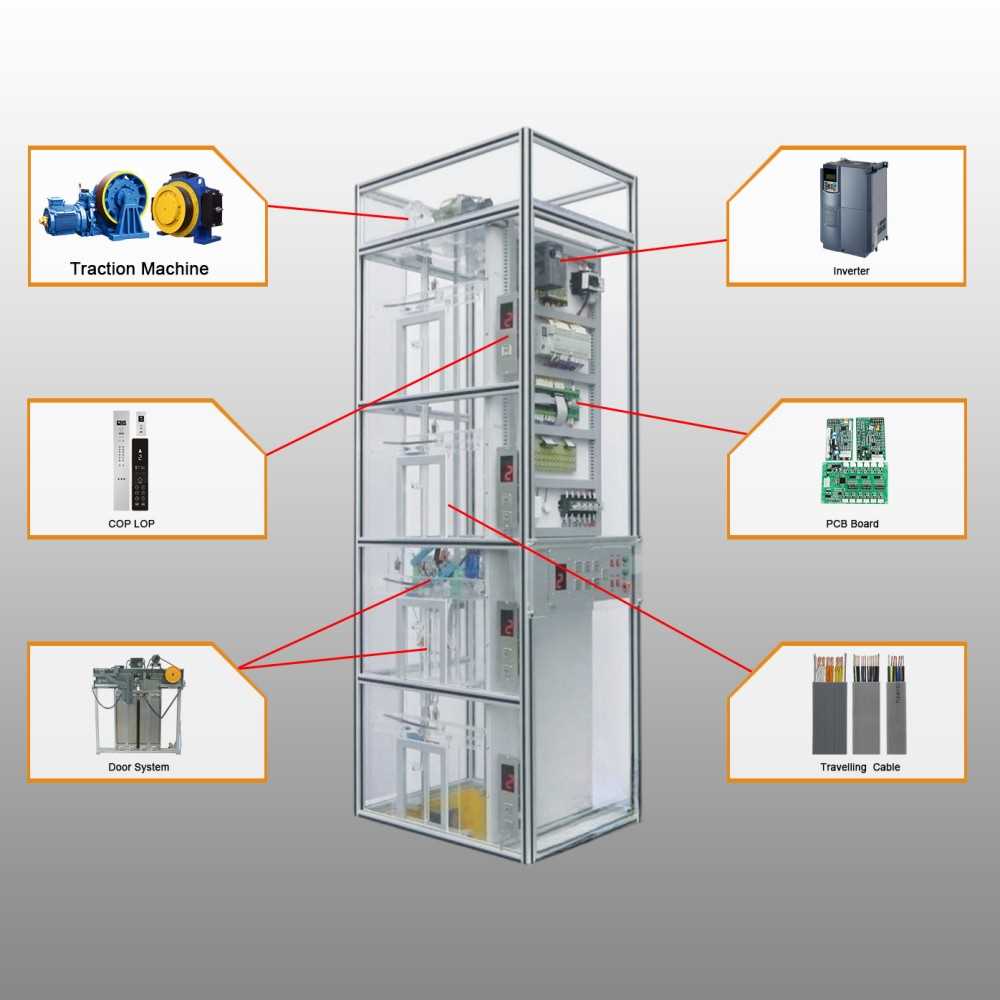

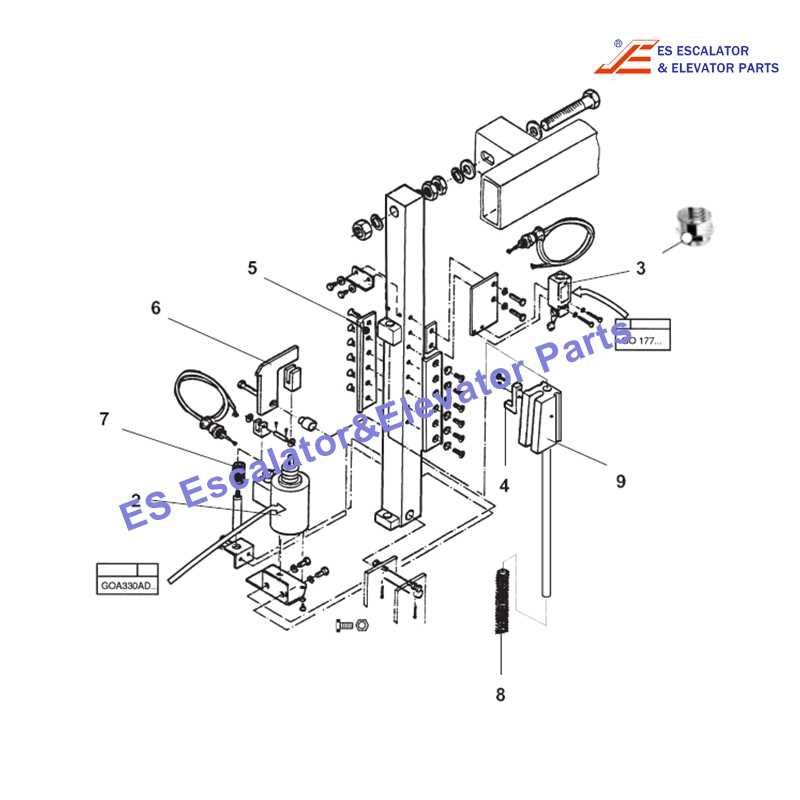

Understanding Elevator Wiring Diagrams

Wiring schematics are essential tools for comprehending the intricate relationships between electrical components within lifting systems. These illustrations provide a visual representation of the connections and functions of various elements, enabling technicians and engineers to diagnose issues and implement effective solutions. By familiarizing oneself with these representations, one can gain insights into the operational framework of these mechanical systems.

Key Components in Wiring Illustrations

In any schematic, several critical components play pivotal roles. These include the control unit, sensors, and power supply. The control unit serves as the brain, managing the system’s operations and facilitating communication between different components. Sensors are vital for detecting positions and ensuring safety measures are met. The power supply provides the necessary energy for the entire setup, making it crucial for effective functionality.

Interpreting Connection Types

Understanding the various types of connections depicted in these schematics is crucial for troubleshooting. Series connections indicate that current flows through each component in a single path, while parallel connections allow for multiple pathways for current flow. Recognizing these differences aids in identifying potential failure points and optimizing system performance. Overall, mastering the interpretation of these schematics enhances one’s ability to maintain and repair these complex systems efficiently.

Common Issues with Elevator Systems

Mechanical transport systems in buildings are essential for facilitating movement between floors. However, like any complex machinery, they can encounter various challenges that affect their functionality and reliability. Understanding these common issues is crucial for maintaining safety and efficiency.

1. Power Supply Interruptions: One of the most frequent problems arises from power outages or fluctuations. These interruptions can lead to sudden stops, leaving passengers stranded or causing delays in operation.

2. Mechanical Wear and Tear: Over time, components such as cables, pulleys, and motors can experience wear and tear. Regular inspections are necessary to identify signs of deterioration and ensure smooth operation.

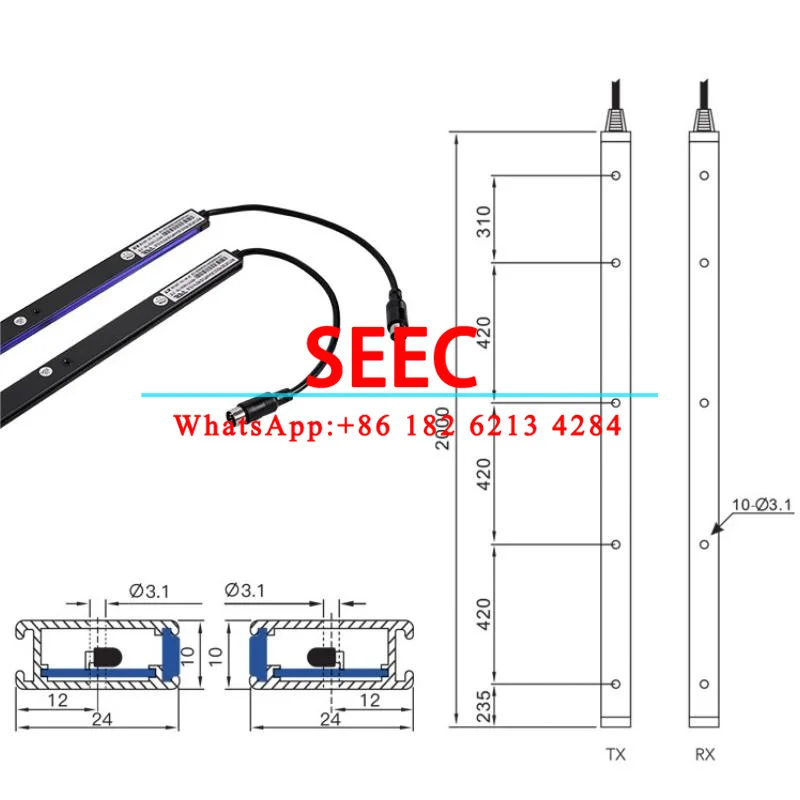

3. Sensor Malfunctions: Many modern systems rely on sensors to detect weight limits and position. If these sensors fail, it can result in erratic behavior, such as not stopping at the correct floor or allowing too many passengers at once.

4. Door Issues: Doors are a critical aspect of safe entry and exit. Problems such as misalignment or faulty sensors can prevent doors from opening or closing properly, posing safety risks to users.

5. Software Glitches: With the increasing reliance on digital controls, software malfunctions can disrupt service. These glitches can lead to incorrect floor selection or communication errors between systems.

6. Emergency System Failures: Effective emergency protocols are vital. Failures in backup systems or alarm notifications can hinder evacuation during emergencies, making it essential to regularly test and update these features.

Addressing these common challenges proactively can enhance the longevity and reliability of mechanical transport systems, ensuring they continue to provide safe and efficient service.

Maintenance Tips for Elevator Parts

Regular upkeep of key components in vertical transportation systems is essential for ensuring their longevity and safe operation. By implementing a routine maintenance schedule, operators can significantly reduce the risk of unexpected breakdowns and enhance performance. This section provides practical advice on how to care for various elements effectively.

Routine Inspections

Conducting frequent evaluations of the system’s critical components can help identify potential issues before they escalate. Pay close attention to mechanisms such as cables, pulleys, and braking systems. Look for signs of wear, corrosion, or misalignment. Documenting each inspection will assist in tracking changes over time and planning for necessary repairs.

Lubrication and Cleaning

Ensuring that moving elements are properly lubricated is vital for optimal function. Use high-quality lubricants suitable for the specific components. Additionally, regular cleaning of control panels and surrounding areas will prevent dust and debris accumulation, which can interfere with operation. Keeping these systems tidy contributes to overall efficiency and safety.

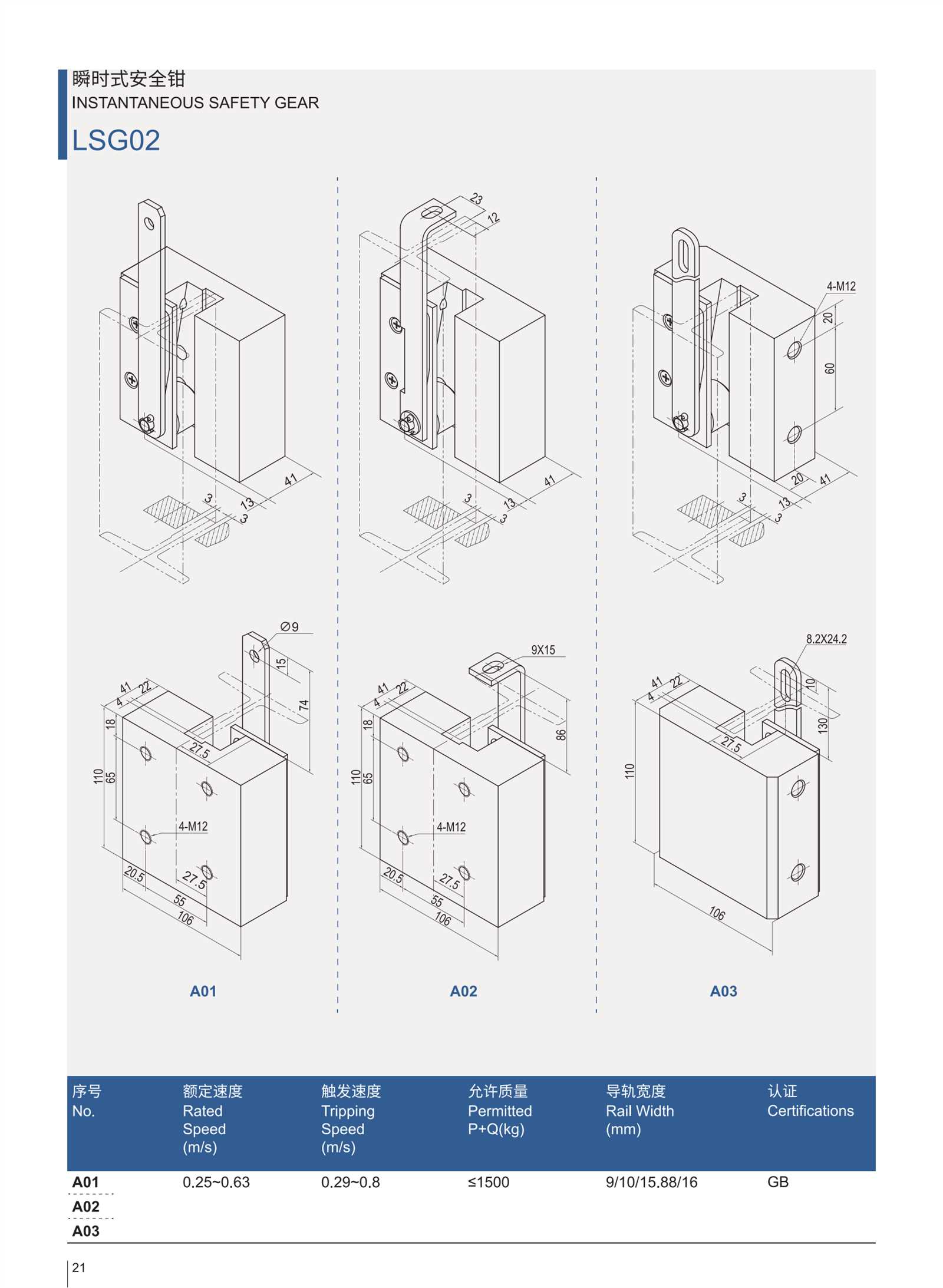

Safety Features in Modern Elevators

Contemporary lifting systems are equipped with a variety of safety mechanisms designed to ensure passenger protection and enhance operational reliability. These innovations play a crucial role in minimizing risks and providing a secure experience for users while traveling between floors. This section explores some of the key features that contribute to the overall safety of these transportation solutions.

Emergency Braking Systems

One of the most critical safety features is the emergency braking system, which activates in case of a malfunction or power failure. This mechanism is designed to halt the movement of the carriage swiftly, preventing any sudden drops and ensuring that individuals remain safe inside. Advanced models employ sensors to detect irregularities in motion, allowing for a rapid response to potential hazards.

Communication Devices

Modern installations also incorporate effective communication devices, enabling passengers to reach help during emergencies. These systems typically include intercoms and alarm buttons located within the cabin, which connect users directly to security personnel or emergency services. The presence of these communication tools fosters a sense of security, assuring riders that assistance is readily available if needed.

Importance of Regular Inspections

Routine evaluations are crucial for maintaining safety and efficiency in any mechanical system. These assessments help identify potential issues before they escalate, ensuring smooth operation and longevity of the equipment. Regular check-ups not only enhance reliability but also foster a culture of proactive maintenance.

Key Benefits

- Safety Assurance: Frequent inspections minimize the risk of accidents, safeguarding users and operators alike.

- Cost Savings: Detecting problems early can significantly reduce repair costs and extend the lifespan of the machinery.

- Regulatory Compliance: Adhering to inspection schedules helps organizations meet legal and safety standards.

Best Practices

- Develop a comprehensive inspection checklist tailored to the specific system.

- Schedule regular evaluations and ensure they are conducted by qualified personnel.

- Document findings and address any issues promptly to prevent further complications.

Upgrades and Innovations in Elevators

The evolution of vertical transportation systems has been driven by advancements in technology, design, and safety standards. These enhancements aim to improve user experience, operational efficiency, and environmental sustainability. As urbanization continues to rise, the focus on modernizing and optimizing these systems has never been more crucial.

Technological Advancements

Recent innovations in this field include the integration of smart technologies, which allow for real-time monitoring and predictive maintenance. With the implementation of IoT (Internet of Things) devices, operators can analyze performance data to reduce downtime and improve reliability. Additionally, features such as touchless controls and advanced user interfaces enhance accessibility and convenience.

Sustainability Initiatives

In response to global environmental concerns, many manufacturers are developing energy-efficient solutions that minimize power consumption. Regenerative drives and efficient motors are becoming standard, contributing to lower operational costs and reduced carbon footprints. Furthermore, the use of eco-friendly materials in construction promotes sustainability throughout the entire lifecycle of these systems.