In the realm of pneumatic tools, comprehending the intricate arrangement of elements is crucial for optimal functionality and longevity. A well-organized structure not only enhances performance but also facilitates easy troubleshooting and repairs. This exploration delves into the visual representation of these essential components, providing valuable insights for both enthusiasts and professionals.

For anyone looking to maintain or repair their equipment, a clear illustration of the various components serves as an invaluable resource. Such layouts demystify the relationships between different parts, allowing users to pinpoint issues with precision. By familiarizing oneself with these configurations, one can streamline maintenance processes and ensure that everything operates smoothly.

Whether you are a seasoned technician or a DIY hobbyist, having access to a detailed schematic empowers you to take charge of your tools. This knowledge not only enhances your skill set but also promotes a deeper understanding of how each individual piece contributes to the overall functionality. Embracing this level of awareness transforms maintenance from a daunting task into a manageable endeavor.

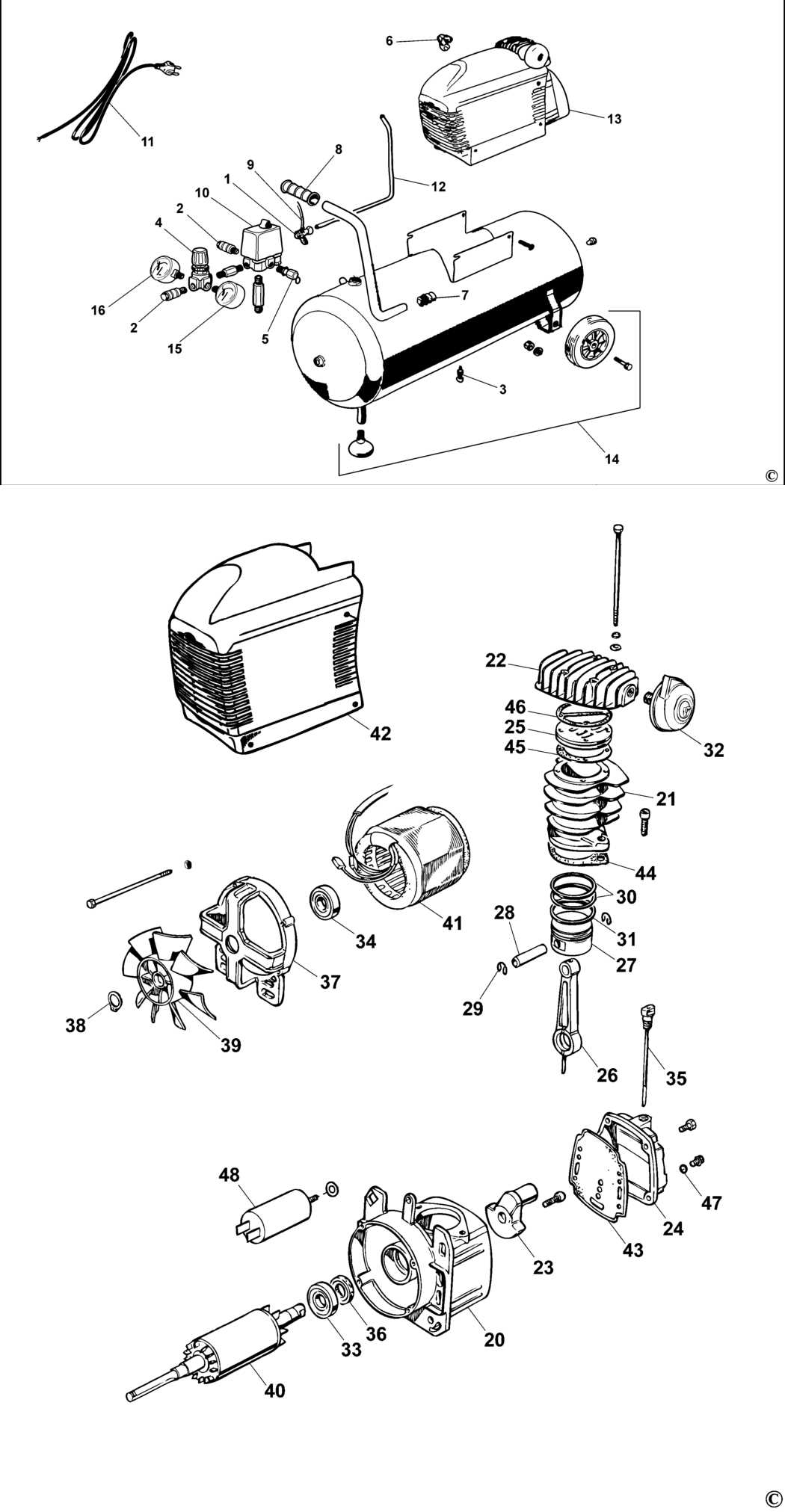

Overview of the Pneumatic Equipment

This section provides a comprehensive insight into a popular type of machinery used for various tasks requiring high-pressure output. Known for its reliability and efficiency, this device is widely utilized in construction, automotive, and home improvement projects. Understanding its components and functionality can greatly enhance user experience and performance.

Key Features

The device offers several noteworthy attributes that contribute to its effectiveness. These include portability, quick recovery time, and ease of use. Many models come equipped with essential safety mechanisms and user-friendly interfaces, making them suitable for both professionals and DIY enthusiasts.

Component Overview

Each unit consists of various crucial elements that work in harmony to deliver optimal performance. Below is a simplified representation of these elements:

| Component | Description |

|---|---|

| Motor | Powers the machinery, providing the necessary force to generate pressure. |

| Tank | Stores compressed air, allowing for sustained operation during tasks. |

| Regulator | Controls the output pressure, ensuring consistent delivery for various applications. |

| Fittings | Connectors that facilitate the attachment of hoses and tools, enhancing versatility. |

| Safety Valve | Prevents over-pressurization by releasing excess air, ensuring safe operation. |

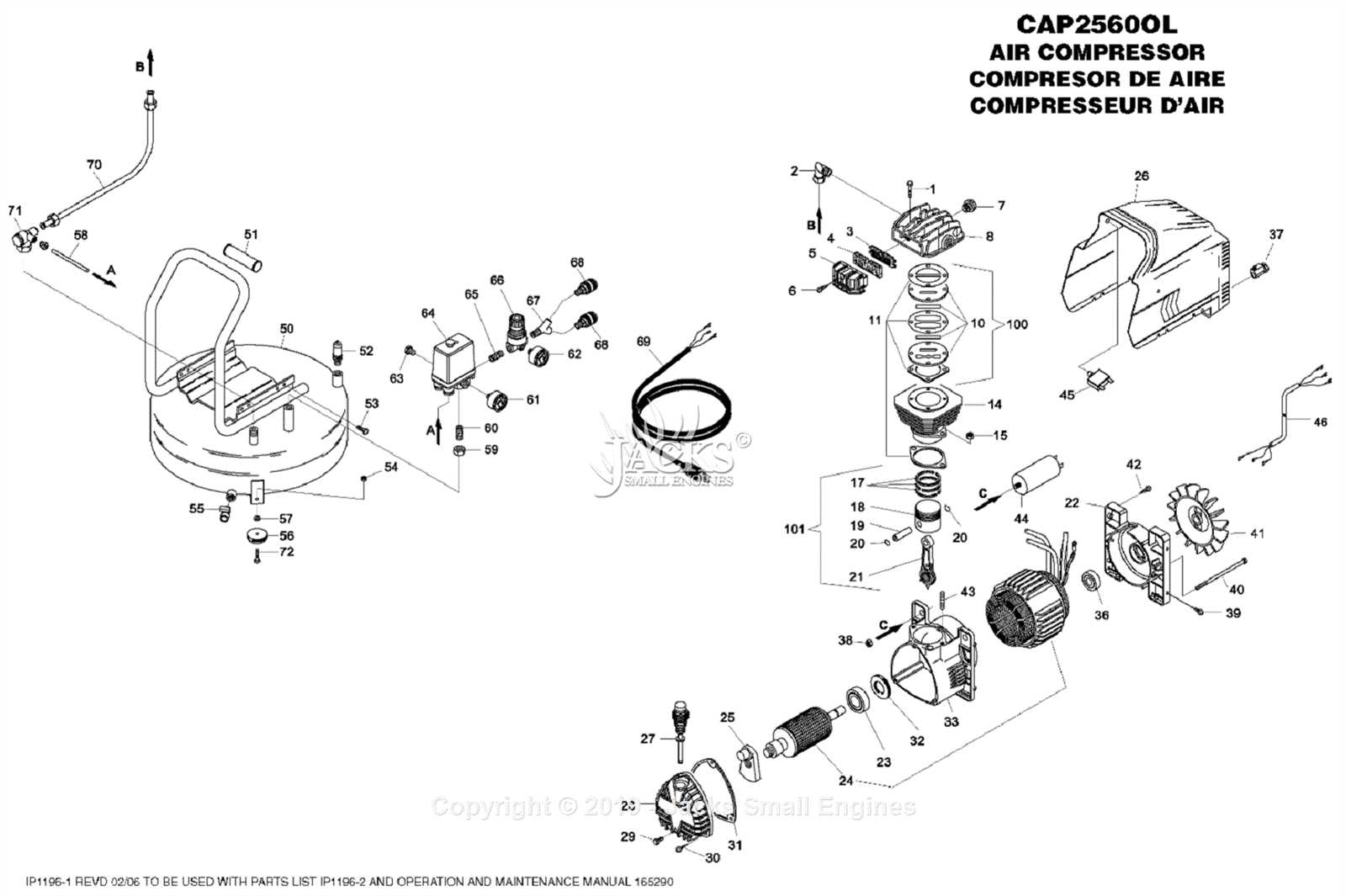

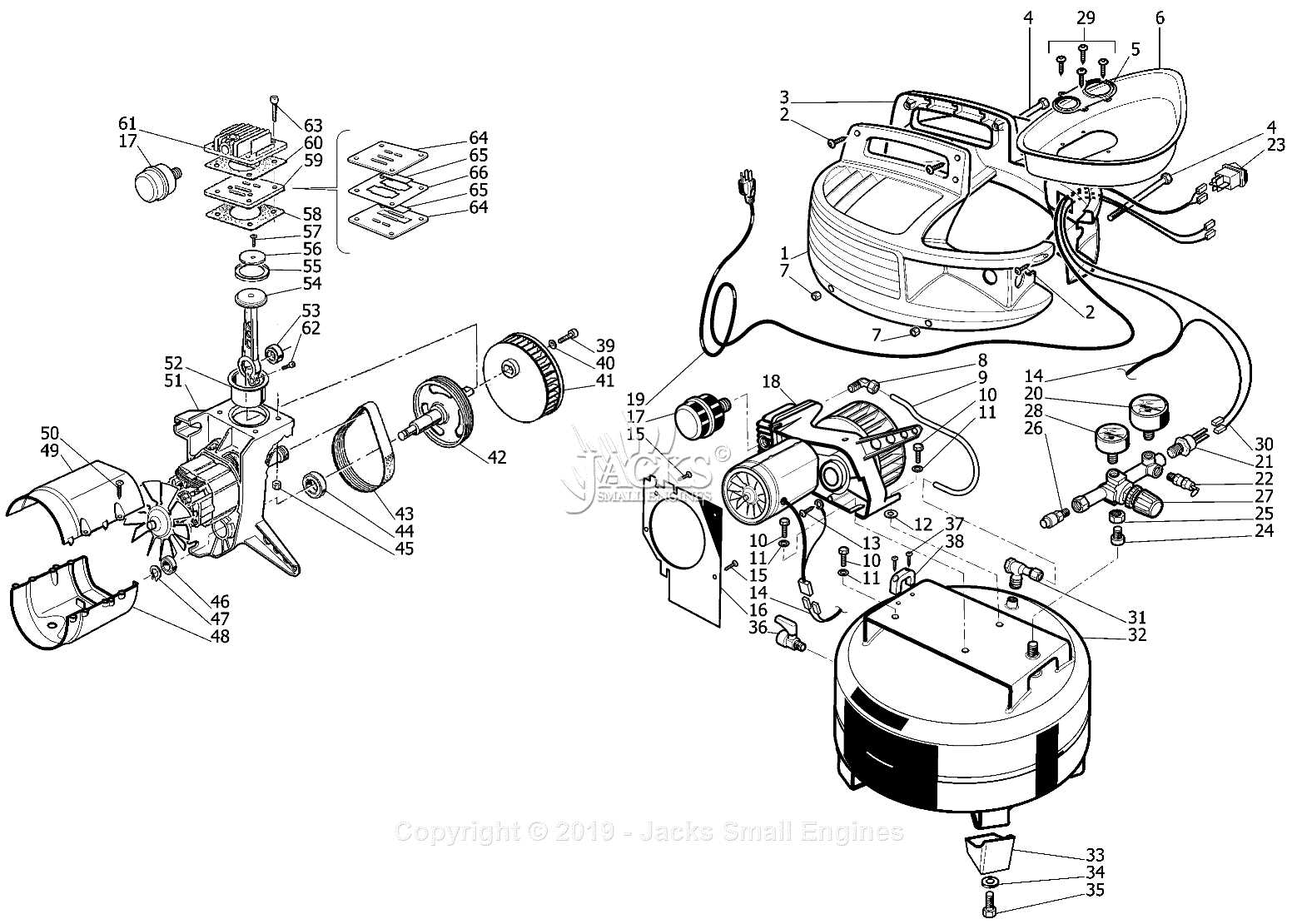

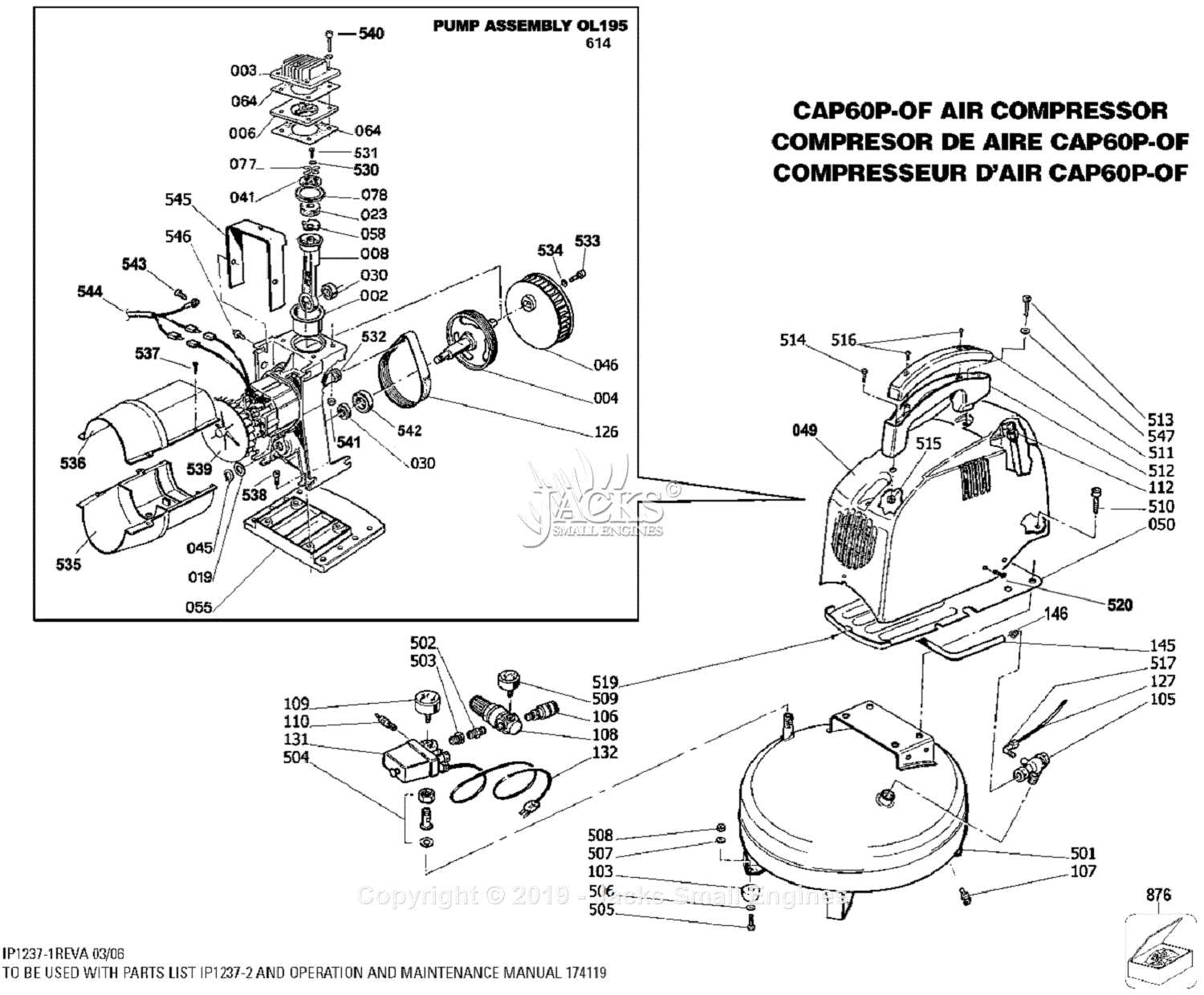

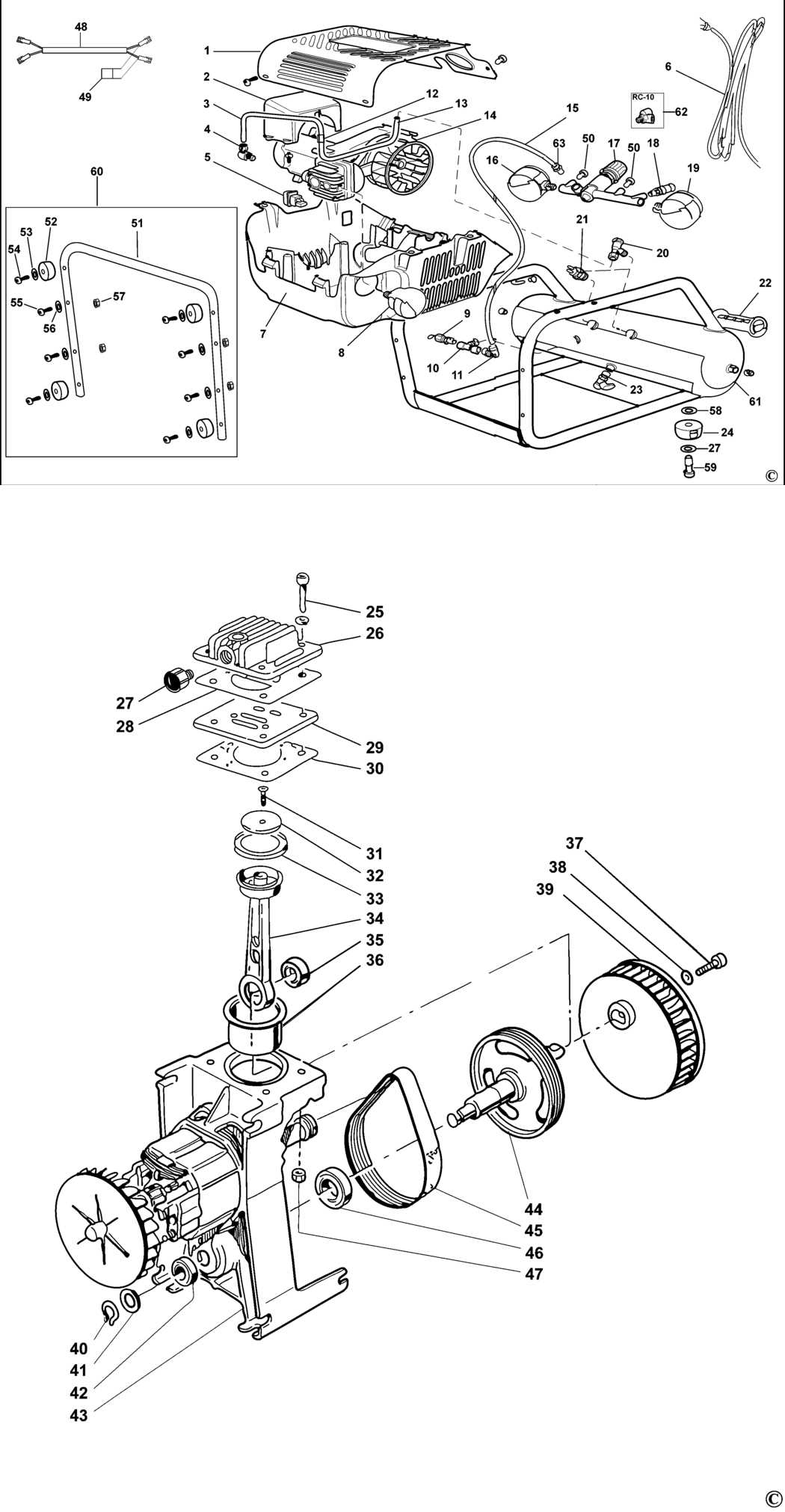

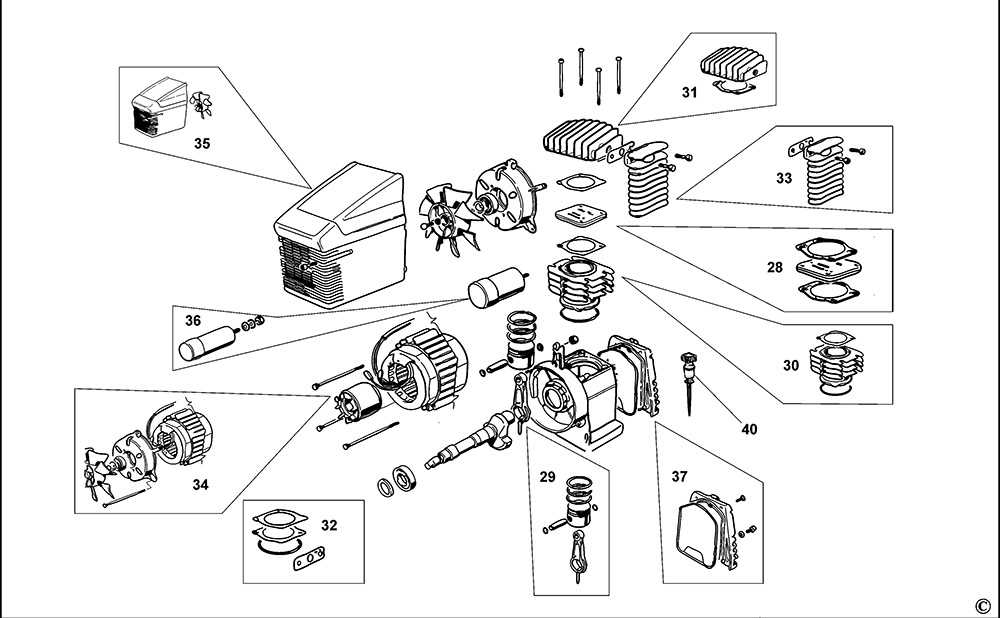

Essential Components of Bostitch Compressors

Understanding the crucial elements of these devices is vital for optimal functionality and longevity. Each component plays a specific role in ensuring the efficiency and reliability of the system, allowing users to achieve their desired outcomes with ease.

Key Elements

- Motor: Powers the unit, converting electrical energy into mechanical energy.

- Pump: Compresses the air, creating the necessary pressure for various applications.

- Tank: Stores the compressed air, allowing for a steady supply during operation.

- Pressure Switch: Regulates the pressure, automatically turning the motor on and off as needed.

- Regulator: Controls the output pressure, providing consistent performance for tools.

- Hoses: Connects the unit to tools, facilitating the movement of compressed air.

Maintenance Considerations

- Regularly check for leaks to maintain efficiency.

- Ensure the motor and pump are well-lubricated to prevent wear.

- Inspect the tank for any signs of rust or damage.

- Clean or replace filters as needed to ensure optimal air quality.

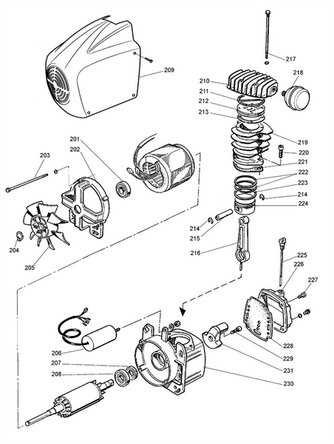

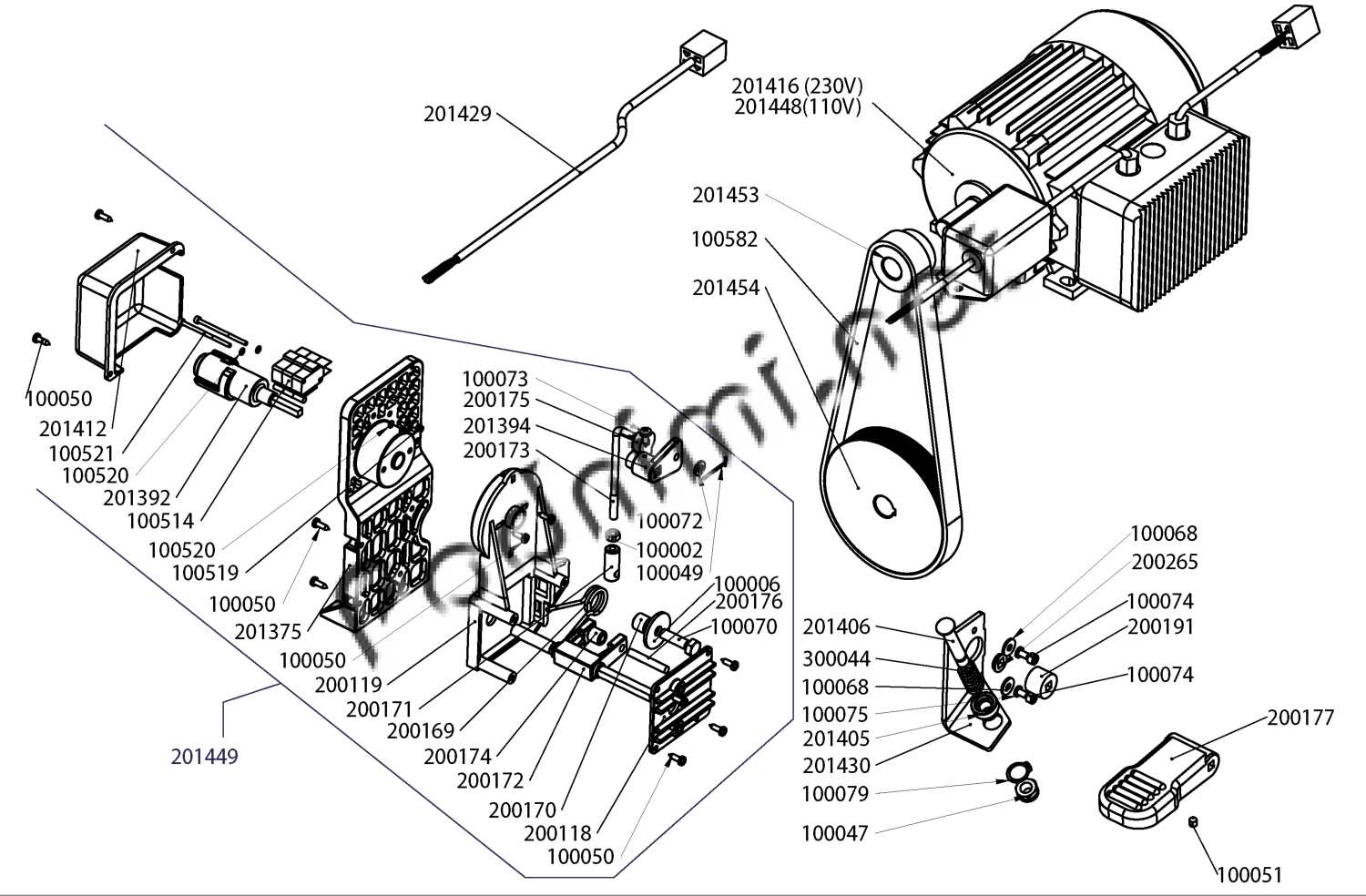

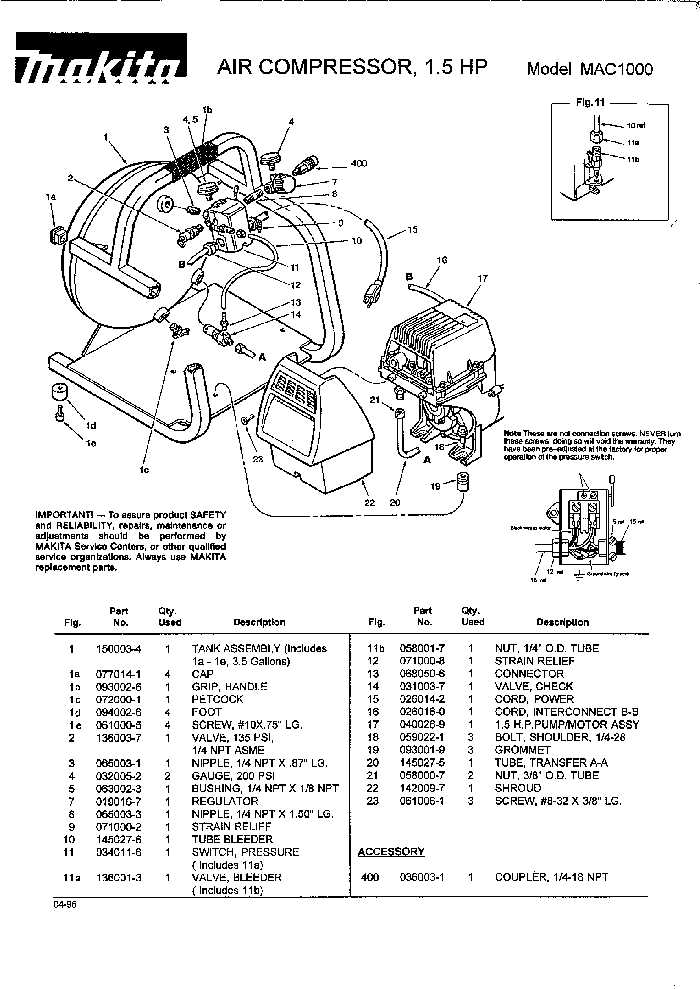

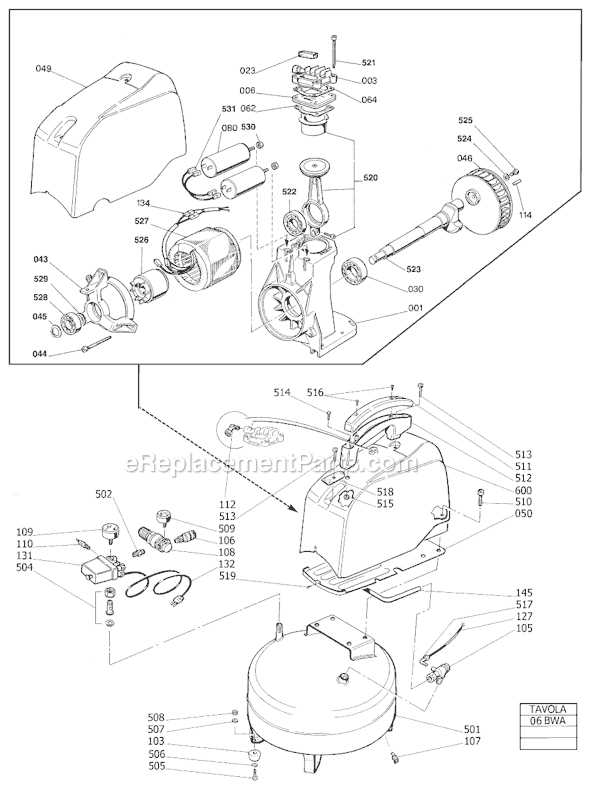

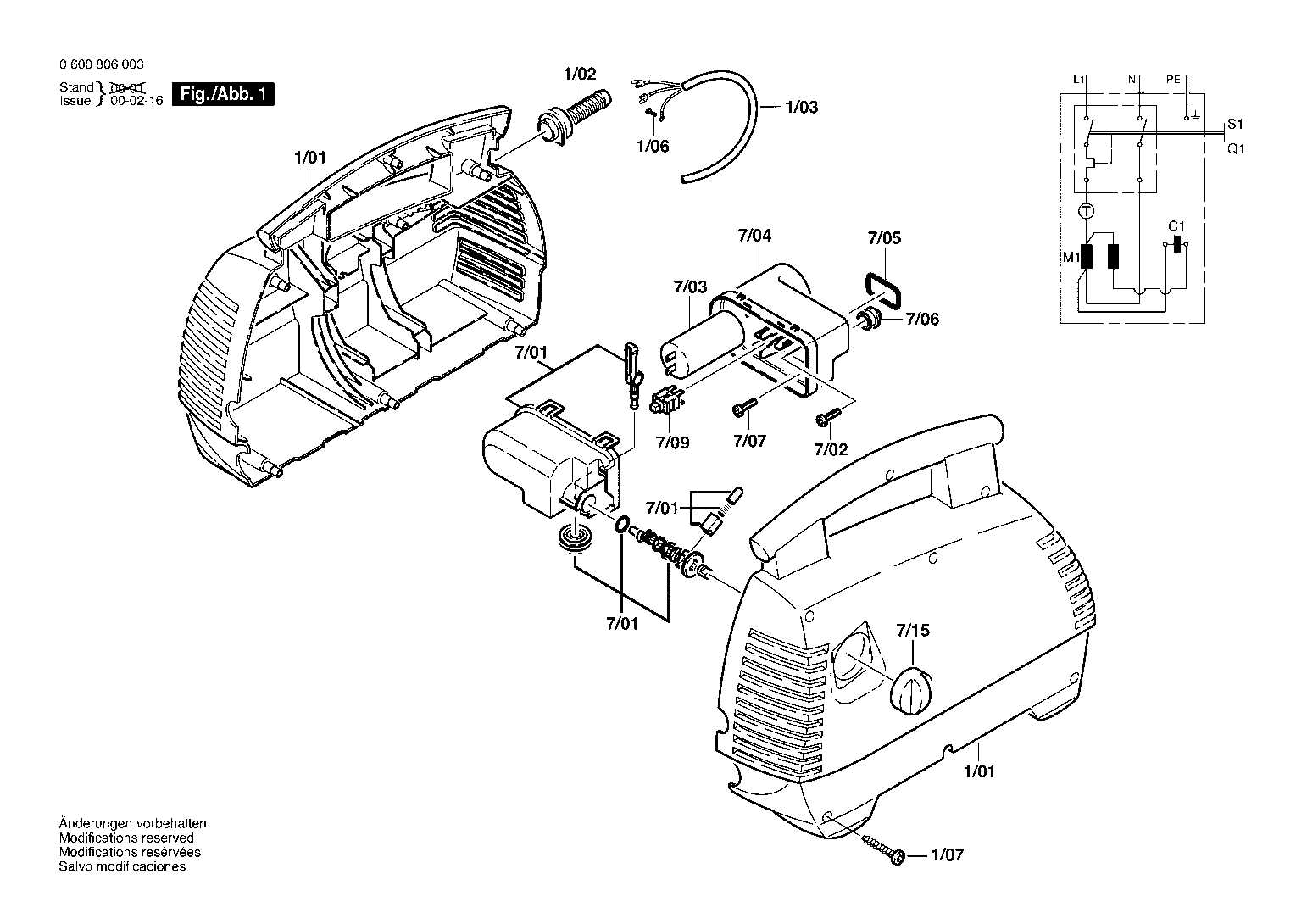

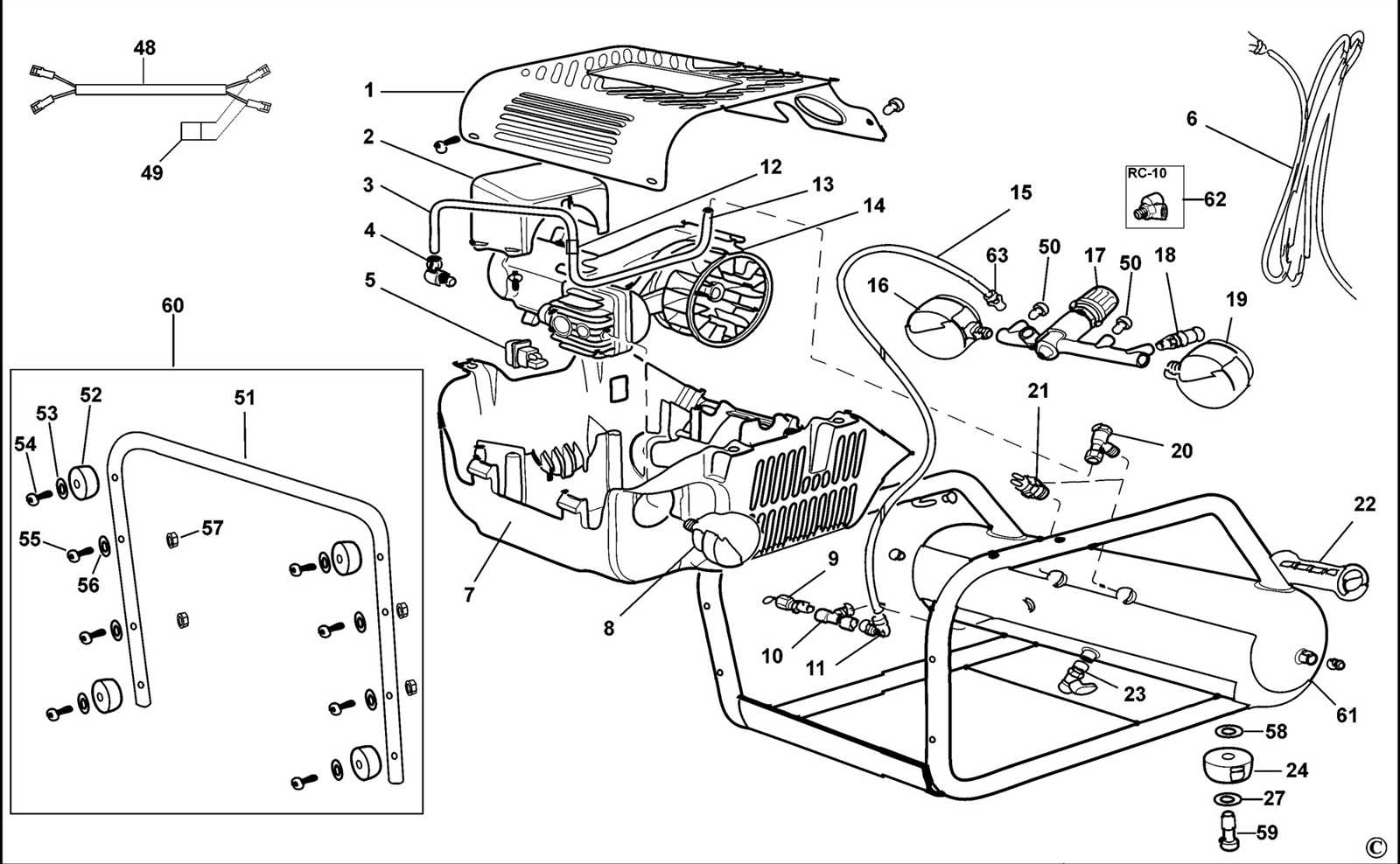

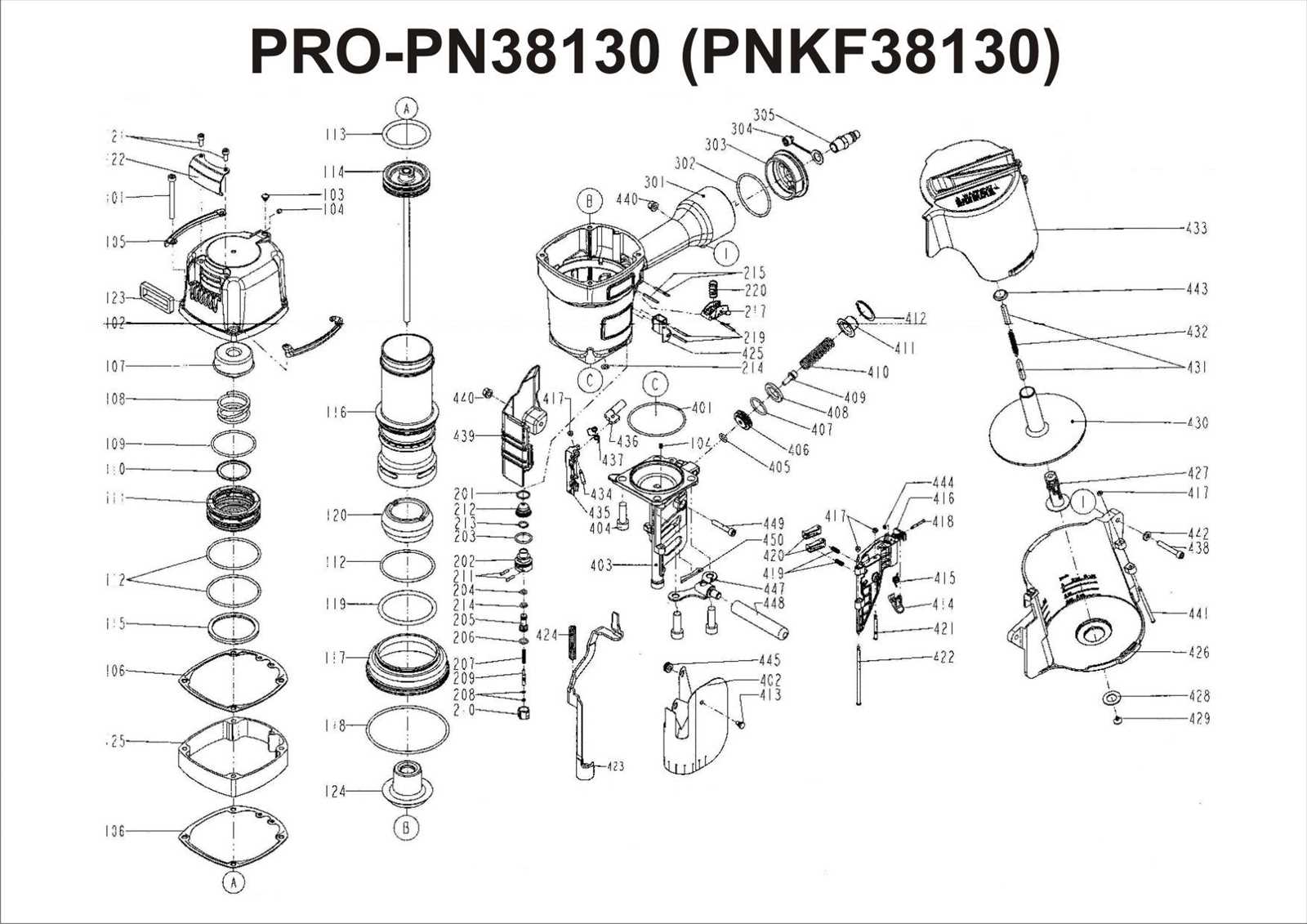

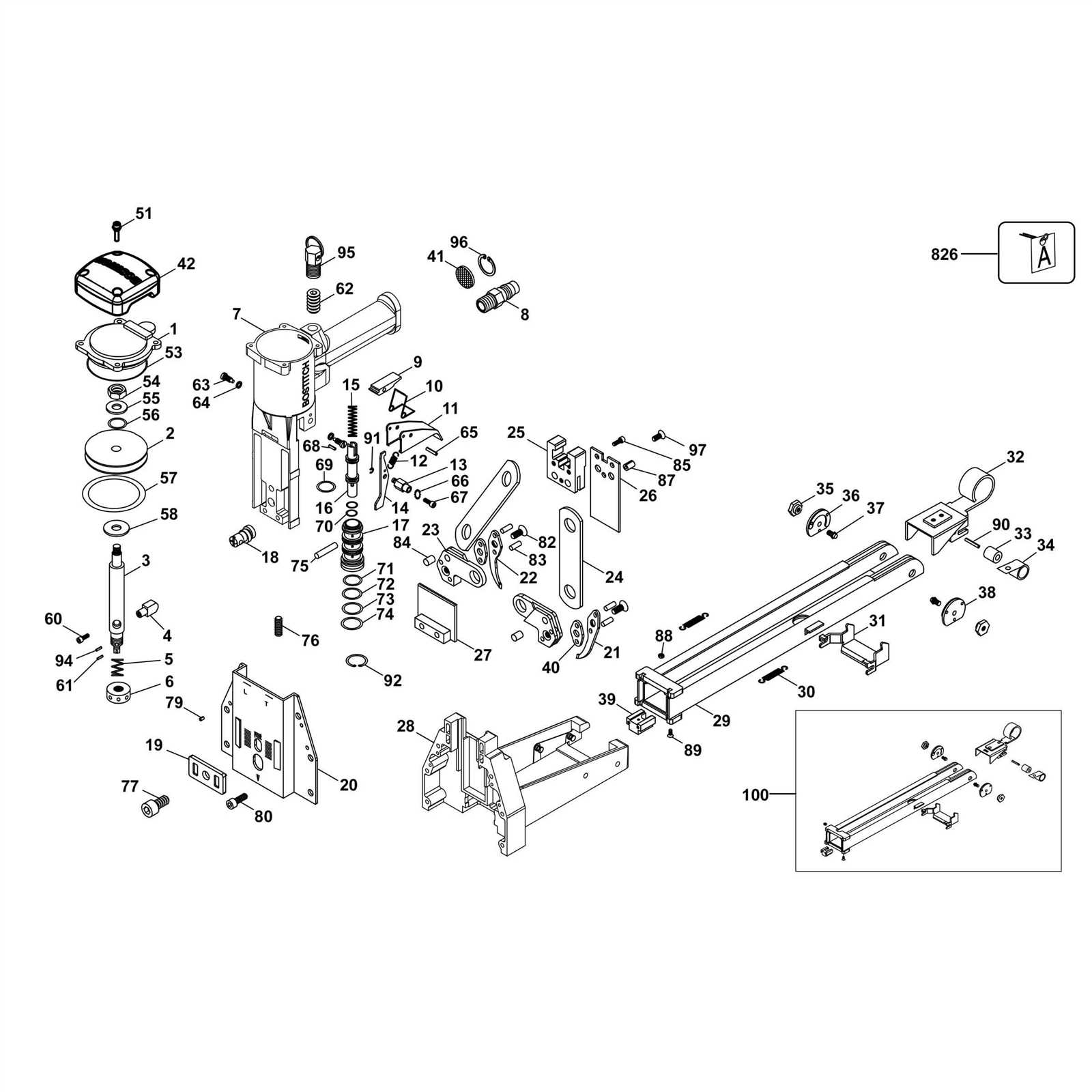

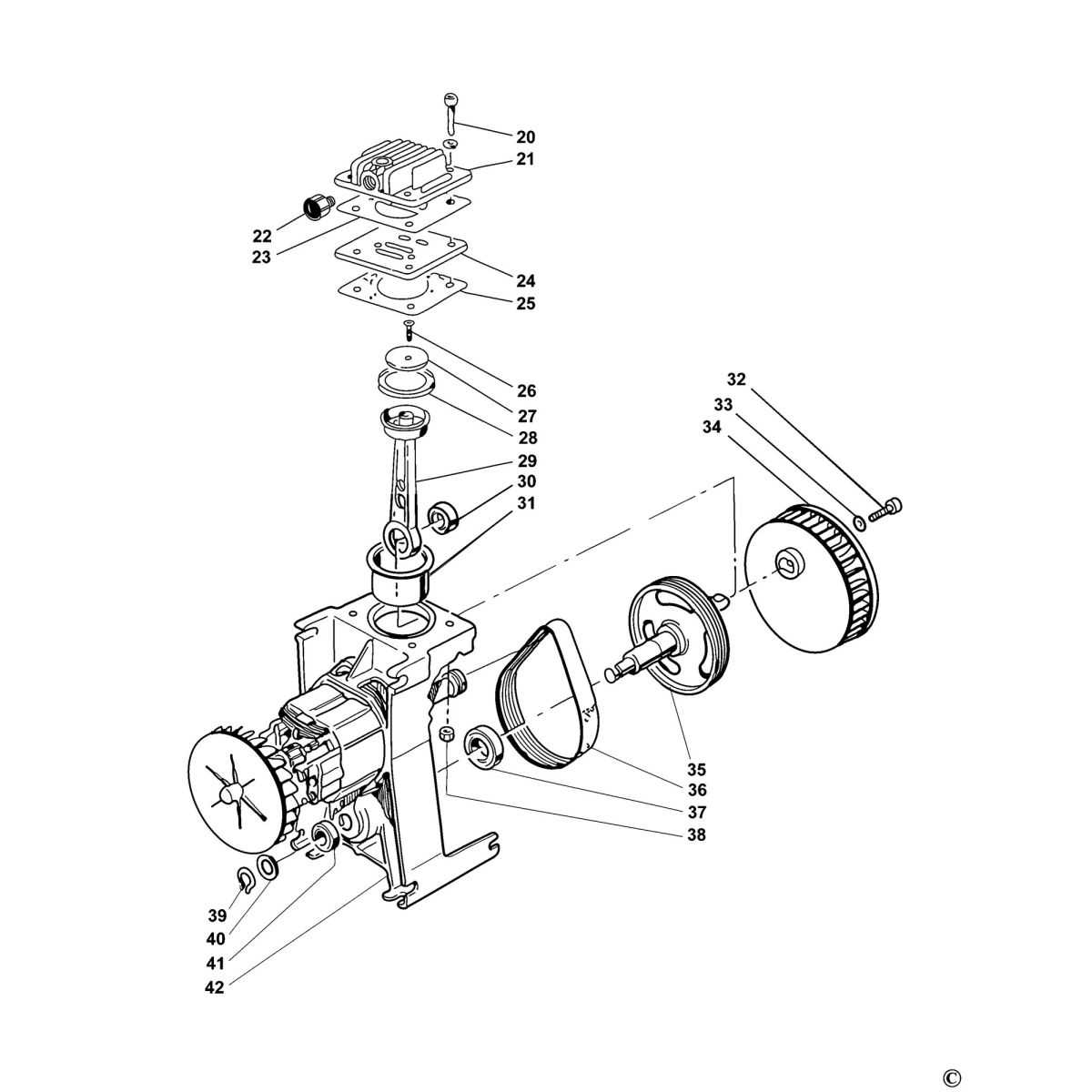

Understanding the Parts Diagram

Grasping the layout of components is essential for anyone looking to maintain or repair equipment efficiently. This visual representation serves as a crucial tool, offering insight into the relationships and functions of various elements within the machine. By familiarizing oneself with the schematic, users can navigate the intricacies of assembly and disassembly with confidence.

Identifying Key Components is a fundamental step. Each segment in the illustration is labeled clearly, allowing for quick reference and easy understanding of where each piece fits. This clarity aids in troubleshooting, making it easier to pinpoint issues and determine the necessary actions for resolution.

Following the Flow of operations depicted in the schematic is equally important. Understanding how each element interacts within the system enables users to grasp the overall functionality. This knowledge not only enhances repair efforts but also contributes to better operational efficiency.

Lastly, Utilizing the Diagram for Maintenance is invaluable. Regular inspections and timely replacements can be guided by the layout, ensuring the longevity and optimal performance of the equipment. With a solid understanding of the configuration, users are better equipped to carry out preventive measures and avoid potential breakdowns.

Common Issues with Compressor Parts

Understanding frequent complications that arise with these devices is essential for effective maintenance and operation. Various components can experience wear and tear, leading to inefficiencies or malfunctions. Identifying these issues early can help ensure optimal functionality and prolong the lifespan of the equipment.

1. Leaks and Loss of Pressure

One of the most prevalent concerns is the presence of leaks, which can significantly diminish performance. These leaks often occur in seals, hoses, or connections. Regularly inspecting these areas can help in early detection. Addressing any gaps promptly is crucial to maintaining appropriate pressure levels and ensuring that the unit operates efficiently.

2. Overheating Components

Another common problem involves excessive heat generation in various components. This overheating can lead to failure and potentially dangerous situations. Factors contributing to this issue include inadequate lubrication, blockages in airflow, or prolonged usage without breaks. Monitoring the temperature and ensuring proper airflow can mitigate these risks and enhance the overall functionality of the device.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following a systematic maintenance routine, you can prevent premature wear and enhance performance over time. Here are some key practices to consider.

Routine Inspection

- Check for leaks regularly. Inspect hoses and connections for any signs of wear or damage.

- Examine filters and replace them as needed to maintain optimal airflow.

- Monitor the condition of all moving parts to catch issues before they escalate.

Proper Storage

- Store the unit in a dry, clean environment to prevent corrosion and dust accumulation.

- Ensure that it is placed on a stable surface to avoid tipping or accidental damage.

- Disconnect power sources when not in use to enhance safety and reduce wear on electrical components.

By implementing these practices, you can significantly extend the lifespan of your equipment and maintain its performance for years to come.

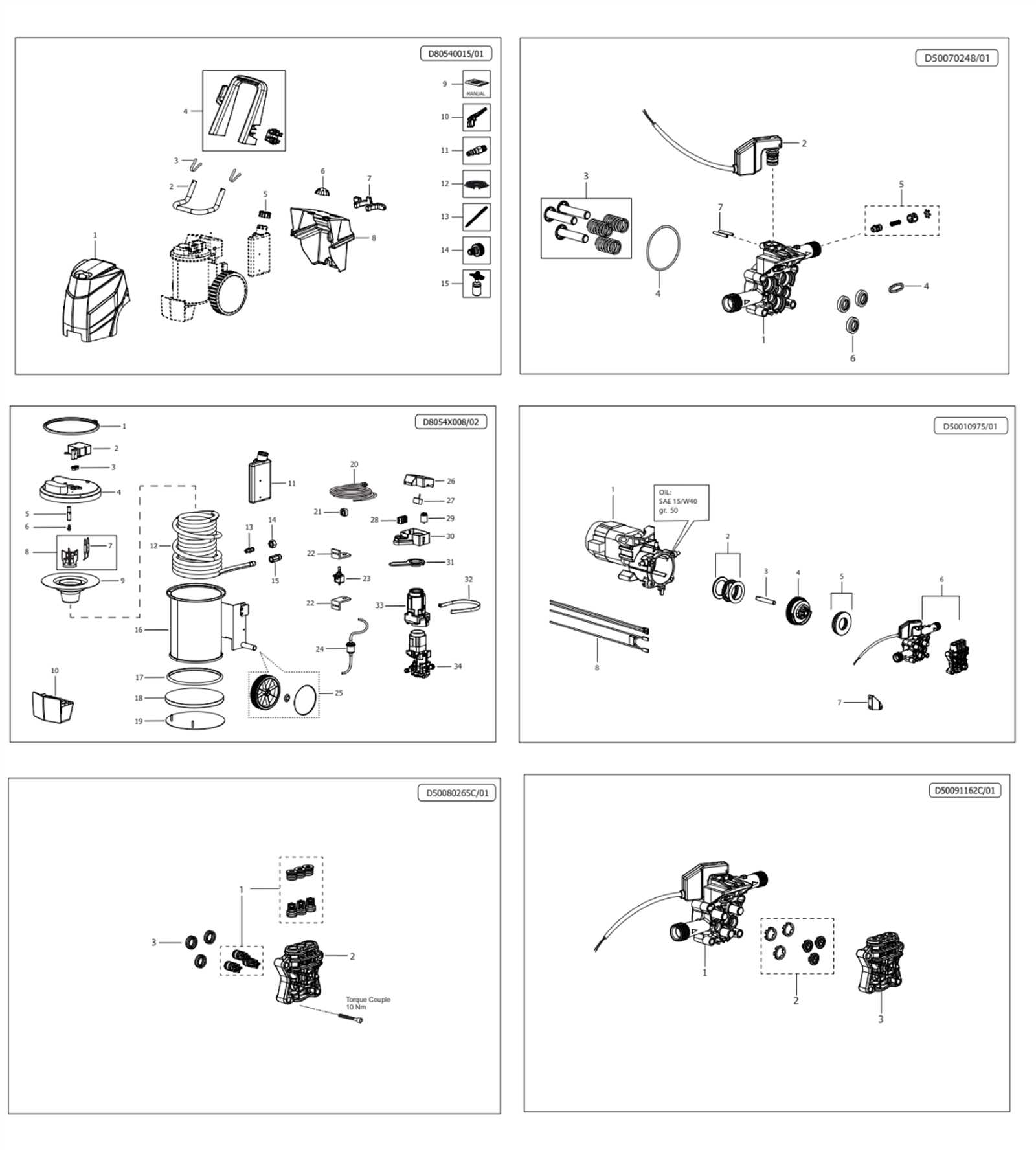

Identifying Replacement Parts Easily

Understanding the components of your equipment is essential for efficient maintenance and repair. By recognizing key elements, you can streamline the process of finding the correct substitutes when needed. This knowledge not only saves time but also enhances the overall performance of your machinery.

Utilizing Reference Materials

Consulting manuals or online resources can significantly aid in identifying the necessary components. These documents typically provide detailed visuals and descriptions, enabling you to pinpoint the exact items required for replacement.

Organizing Your Tools

Keeping your tools and components well-organized can facilitate quick identification. Using labeled containers or sections in your workspace helps in locating the correct substitutes without unnecessary delays.

How to Read the Diagram

Understanding a technical illustration is essential for effective maintenance and repair of equipment. These visual representations convey vital information about the various components and their relationships, allowing users to navigate the assembly with ease. Familiarity with the symbols and layout used in these drawings can significantly enhance comprehension and troubleshooting abilities.

Begin by identifying the legend or key, which explains the symbols and notations utilized within the illustration. Each symbol corresponds to a specific element, providing clarity on function and position. Pay close attention to the connections and flow indicated by arrows, as they illustrate how components interact with one another.

Next, observe the scale of the drawing. Some illustrations may not be to scale, so understanding the relative size and placement of parts is crucial for proper assembly. Look for groupings or clusters of components, as these often indicate how they work together as a system.

Finally, take note of any additional annotations or notes included in the illustration. These can provide insights into specific installation procedures, maintenance tips, or safety precautions, making them invaluable for effective operation and care. By mastering the reading of these technical visuals, users can ensure their equipment remains in optimal working condition.

Upgrading Your Compressor Components

Enhancing the functionality and efficiency of your machinery can lead to improved performance and longevity. Upgrading specific elements within the system can significantly impact its overall output and reliability. As components age or become less effective, investing in modern replacements can bring your equipment back to optimal working condition.

When considering enhancements, focus on essential elements such as motors, tanks, and valves. Modern designs often incorporate advanced materials and technologies that boost efficiency and reduce energy consumption. Replacing outdated components not only ensures compliance with current standards but can also minimize maintenance costs in the long run.

Additionally, evaluating compatibility with existing setups is crucial. Selecting upgrades that seamlessly integrate with your current system can streamline the installation process and reduce downtime. Thorough research on available options will enable you to make informed choices that align with your operational needs.

Ultimately, proactive upgrades will enhance your system’s performance, leading to increased productivity and satisfaction. By keeping your equipment in prime condition, you can maximize its potential and extend its service life.

Where to Buy Genuine Parts

Finding authentic components is crucial for maintaining the efficiency and longevity of your equipment. Using original replacements ensures optimal performance and reliability. This section outlines various options to procure these essential items.

Authorized Retailers

One of the best ways to ensure you are purchasing genuine components is through authorized retailers. These vendors are recognized by the manufacturer and provide verified items.

- Check local hardware stores that specialize in tools.

- Visit online platforms associated with the manufacturer.

- Look for specialized dealers who focus on industrial equipment.

Online Marketplaces

The internet offers a wide array of options for sourcing authentic components. Online marketplaces can provide convenience and a broader selection.

- Search for established e-commerce sites known for tool parts.

- Ensure the seller has a positive reputation and customer reviews.

- Verify the return policy and warranty information before purchasing.