Maintaining and troubleshooting your lawn care equipment requires a clear understanding of its assembly. This guide focuses on visual aids that illustrate the arrangement and function of various elements, making it easier for users to identify and resolve issues effectively.

By examining detailed illustrations of these components, you can gain insights into how each part interacts within the overall system. This knowledge not only simplifies repairs but also enhances the ability to perform regular maintenance, ensuring optimal performance during operation.

In this section, we will explore an informative representation that serves as a valuable reference for those looking to deepen their comprehension of their machinery’s inner workings. Whether you’re a seasoned technician or a novice user, familiarizing yourself with these visuals will empower you to tackle any challenges that arise.

Kubota ZD331 Overview

This section provides an insight into a specific model designed for efficiency and performance in lawn maintenance. It combines innovative technology with user-friendly features, making it a popular choice for both professionals and enthusiasts.

Key Features

The machine boasts a powerful engine that ensures smooth operation and excellent cutting capabilities. Its ergonomic design allows for comfortable handling, while the compact structure facilitates maneuverability in tight spaces.

Performance and Maintenance

With its robust build, this model is not only reliable but also easy to maintain. Regular upkeep can significantly enhance longevity and operational efficiency, ensuring that users can achieve the ultimate results in landscaping.

Importance of Deck Parts

Understanding the components that contribute to the functionality of lawn care equipment is crucial for maintaining performance and ensuring longevity. Each element plays a vital role in the overall operation, affecting efficiency, safety, and the quality of the final result.

| Component | Function |

|---|---|

| Blade | Responsible for cutting grass evenly and efficiently. |

| Spindle | Supports the blade and enables its rotation. |

| Chassis | Provides structural integrity and support for all other elements. |

| Wheel Assembly | Facilitates movement and maneuverability on various terrains. |

Neglecting any of these crucial components can lead to decreased performance and potential damage, making regular maintenance and understanding their functions essential for optimal operation.

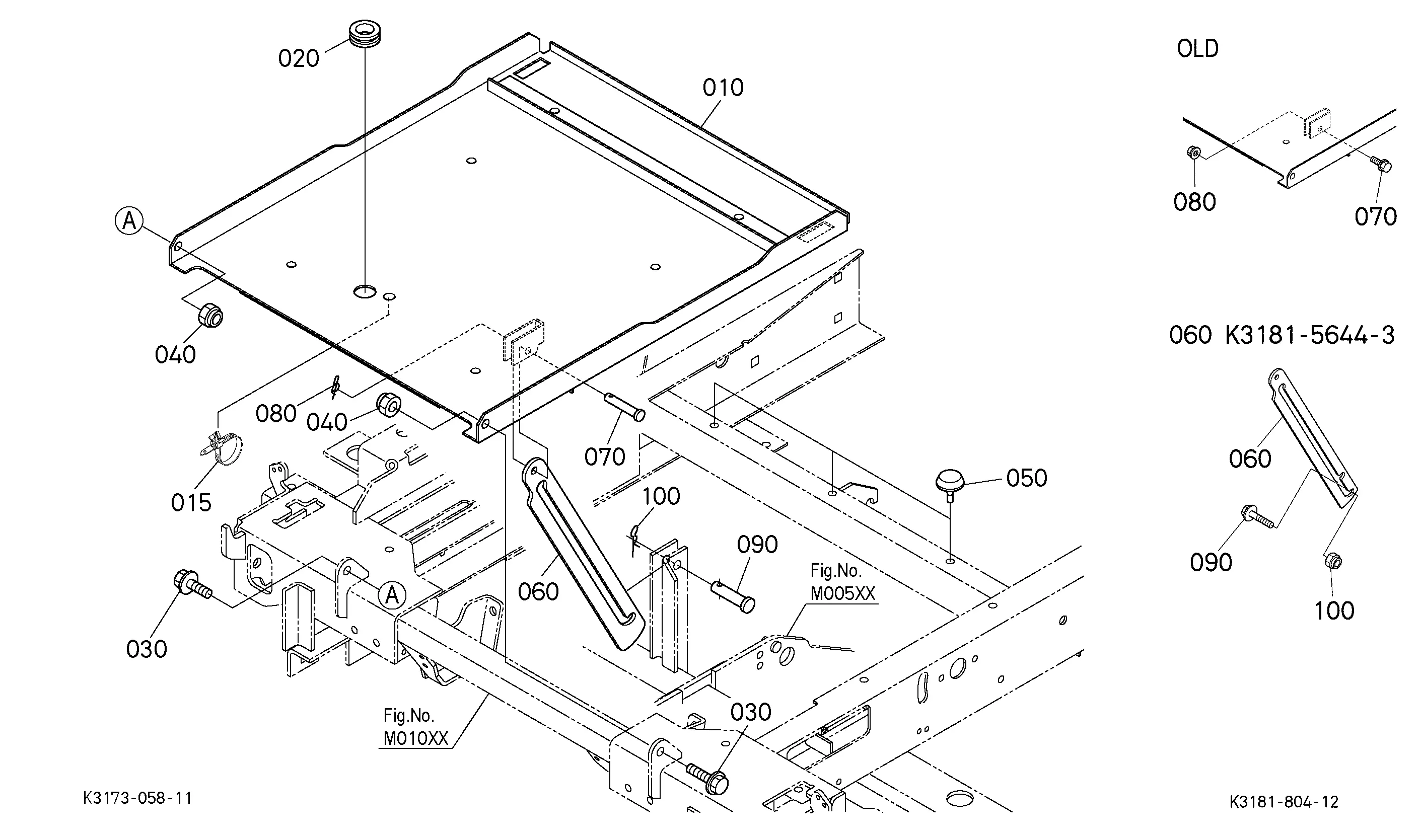

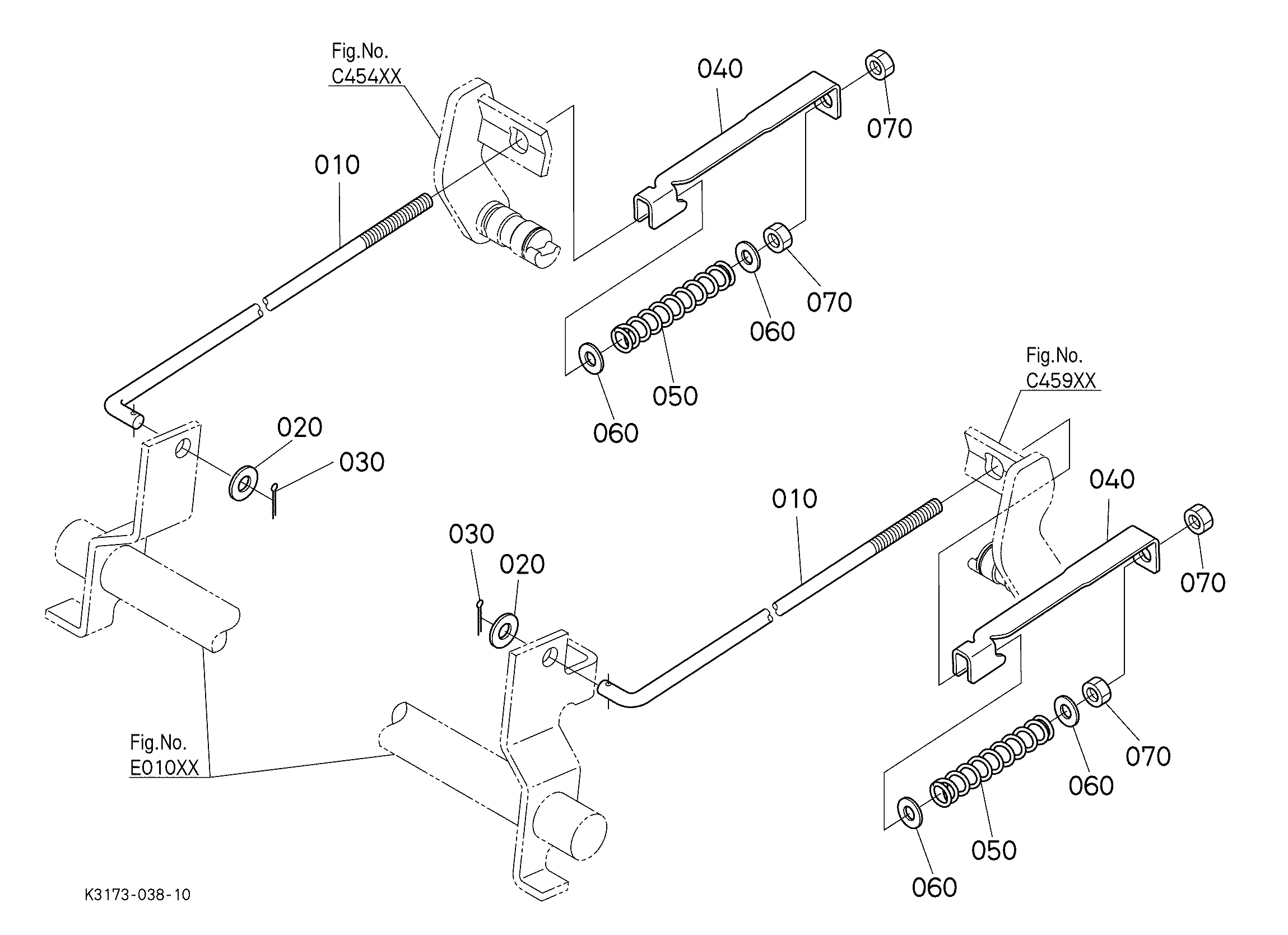

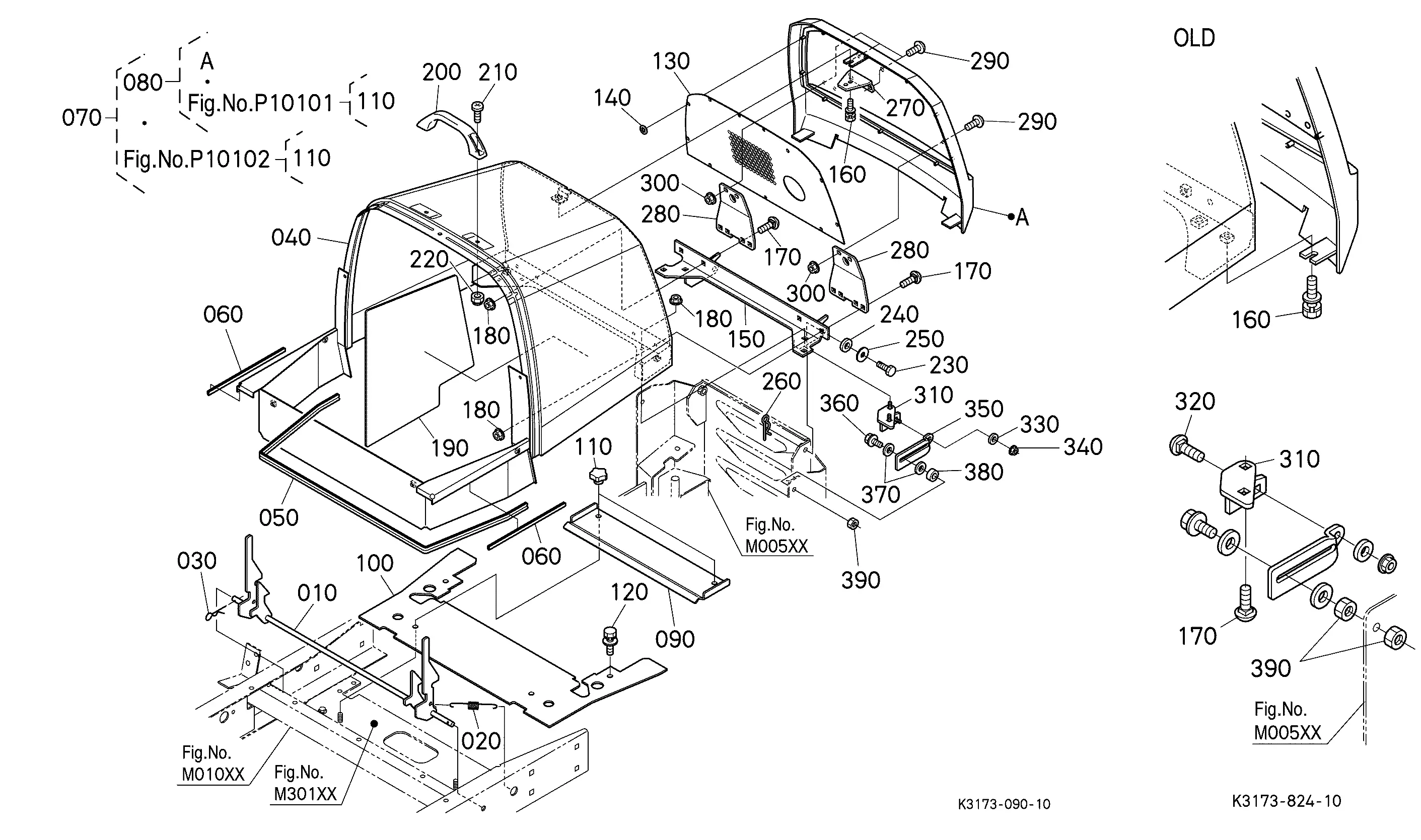

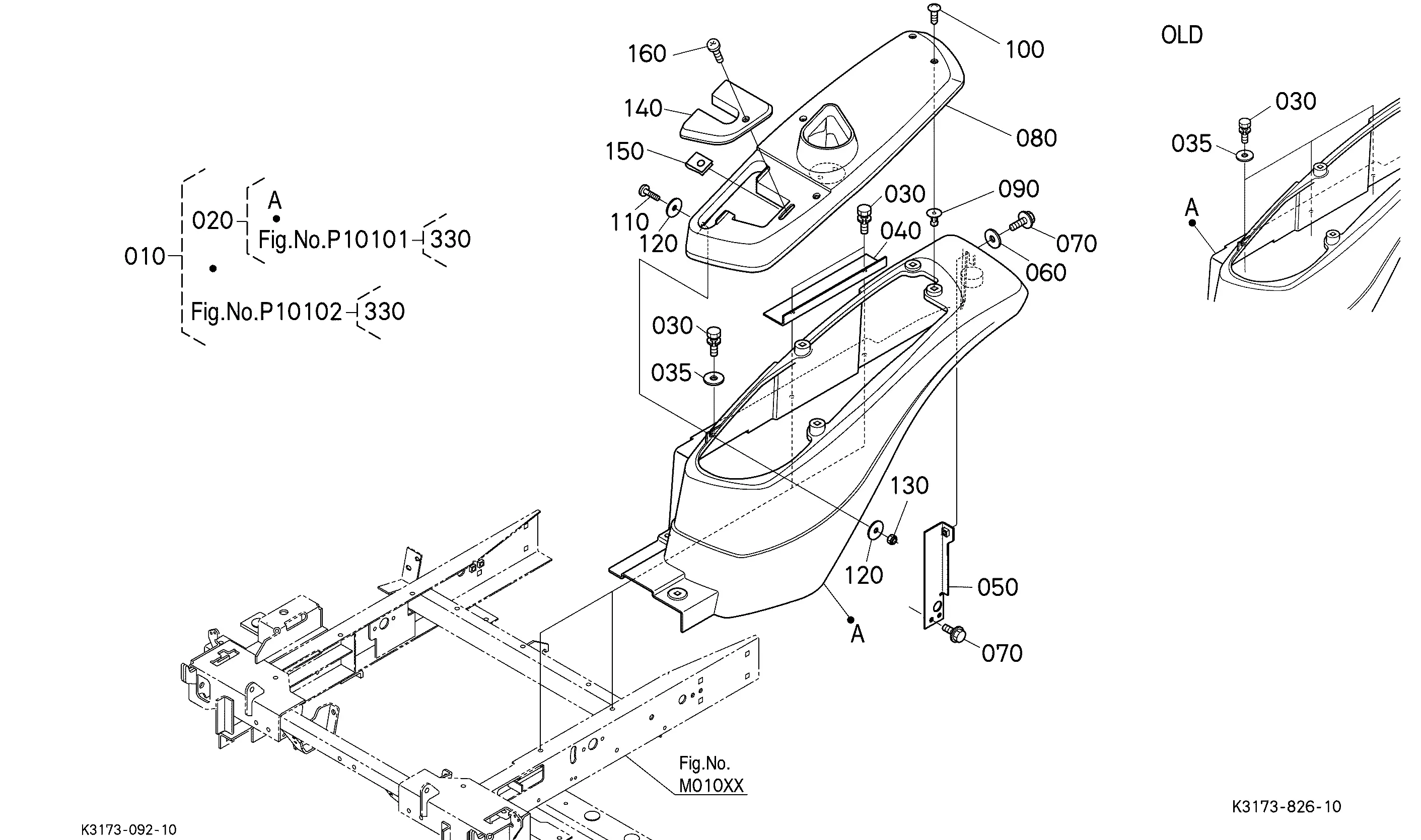

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repair. A clear visual representation allows users to identify each element and understand its function within the overall machinery.

When examining the schematic, attention should be paid to the relationships and connections between various sections. This understanding helps streamline repair processes and enhances efficiency.

| Component | Description |

|---|---|

| Blade | Essential for cutting grass efficiently. |

| Spindle | Holds the blade in place, ensuring stability during operation. |

| Frame | Provides structural support and houses the motor. |

| Wheels | Facilitates mobility across different terrains. |

Utilizing this visual guide can ultimately enhance user knowledge and foster better equipment performance.

Common Issues with Deck Components

Maintaining the functionality of cutting apparatus can present several challenges. Understanding the frequent problems encountered with various components is crucial for ensuring optimal performance and longevity.

Wear and Tear

Over time, essential elements may experience significant wear, leading to decreased efficiency. Blades may dull or chip, while other parts can corrode or crack, impacting overall operation. Regular inspection is vital to identify these issues early.

Alignment Problems

Misalignment of critical components can cause uneven cutting and increased strain on the machinery. Proper adjustment of components is necessary to maintain balance and effectiveness, preventing further damage and enhancing performance.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. Implementing effective maintenance strategies not only enhances performance but also extends the lifespan of your equipment.

Regular Inspections

- Check for wear and tear on components.

- Look for signs of rust or corrosion.

- Inspect fluid levels and filters regularly.

Routine Cleaning

- Remove debris after each use to prevent buildup.

- Clean air filters to ensure optimal airflow.

- Wash exterior surfaces to protect against elements.

By following these practices, you can significantly enhance the reliability and performance of your equipment over time.

Where to Find Replacement Parts

Locating the right components for your machinery can be a straightforward process if you know where to look. Various sources offer a wide range of options to ensure your equipment remains in optimal condition. Understanding these sources will help you find high-quality items efficiently.

Here are some reliable places to consider when searching for replacement components:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in official components, providing assurance of quality and compatibility. |

| Online Marketplaces | Websites like eBay and Amazon feature a variety of sellers offering new and used components, often at competitive prices. |

| Local Repair Shops | These establishments can be valuable resources, often carrying a selection of parts or being able to order them for you. |

| Manufacturer’s Website | Visiting the official website can provide access to a catalog of components along with direct purchasing options. |

| Salvage Yards | For budget-conscious individuals, salvage yards can offer a treasure trove of used components that are still in good condition. |

By exploring these avenues, you can find the necessary components to keep your machinery running smoothly.

Compatibility with Other Models

Understanding the interchangeability of components across various machines is crucial for efficient maintenance and repair. This section explores the compatibility of specific parts, highlighting how certain models may share similarities in design and functionality, thus allowing for the use of identical or equivalent components.

Many operators appreciate the versatility that comes with interchangeable parts, especially when dealing with older or less common models. This compatibility not only simplifies repairs but also reduces costs associated with sourcing unique components.

| Model | Compatible Models | Notes |

|---|---|---|

| Model A | Model B, Model C | Similar design and function |

| Model D | Model E, Model F | Parts are often interchangeable |

| Model G | Model H | Minor modifications may be needed |

By recognizing which models are compatible, users can make informed decisions when sourcing components, ensuring their equipment remains operational and efficient.

Upgrades and Modifications Available

Enhancing performance and functionality can significantly improve the overall experience of your equipment. Various upgrades can optimize efficiency, durability, and user comfort, catering to different needs and preferences.

- Improved Cutting Blades: Upgrade to high-performance blades for a cleaner cut and better longevity.

- Advanced Suspension Systems: Enhance stability and comfort during operation with upgraded suspension components.

- Customizable Seat Options: Opt for ergonomic seating solutions for increased comfort during extended use.

- Fuel Efficiency Kits: Implement modifications that boost fuel economy and reduce emissions.

- Enhanced Lighting Packages: Add LED lighting for improved visibility during early morning or late evening tasks.

These enhancements can ultimately transform the way your machinery performs, making tasks easier and more efficient.