In the realm of modern farming, the efficiency and precision of your machinery play a crucial role in ensuring a successful harvest. Whether you are a seasoned professional or a newcomer to the agricultural world, having a clear grasp of your equipment’s components is essential for optimal performance. This guide aims to illuminate the intricacies of a particular model, providing insights that can enhance your operational workflow.

Familiarizing yourself with the various elements of your machinery not only aids in maintenance but also empowers you to troubleshoot potential issues before they escalate. Each component serves a specific function, contributing to the overall effectiveness of the equipment in the field. Understanding these parts allows for informed decisions, especially when it comes to repairs or upgrades.

Additionally, having access to visual references can greatly enhance your comprehension of how everything fits together. A clear representation of the assembly can help clarify any uncertainties regarding the setup or operation. This knowledge fosters greater confidence, enabling you to maximize the potential of your farming tools and ensure a productive season ahead.

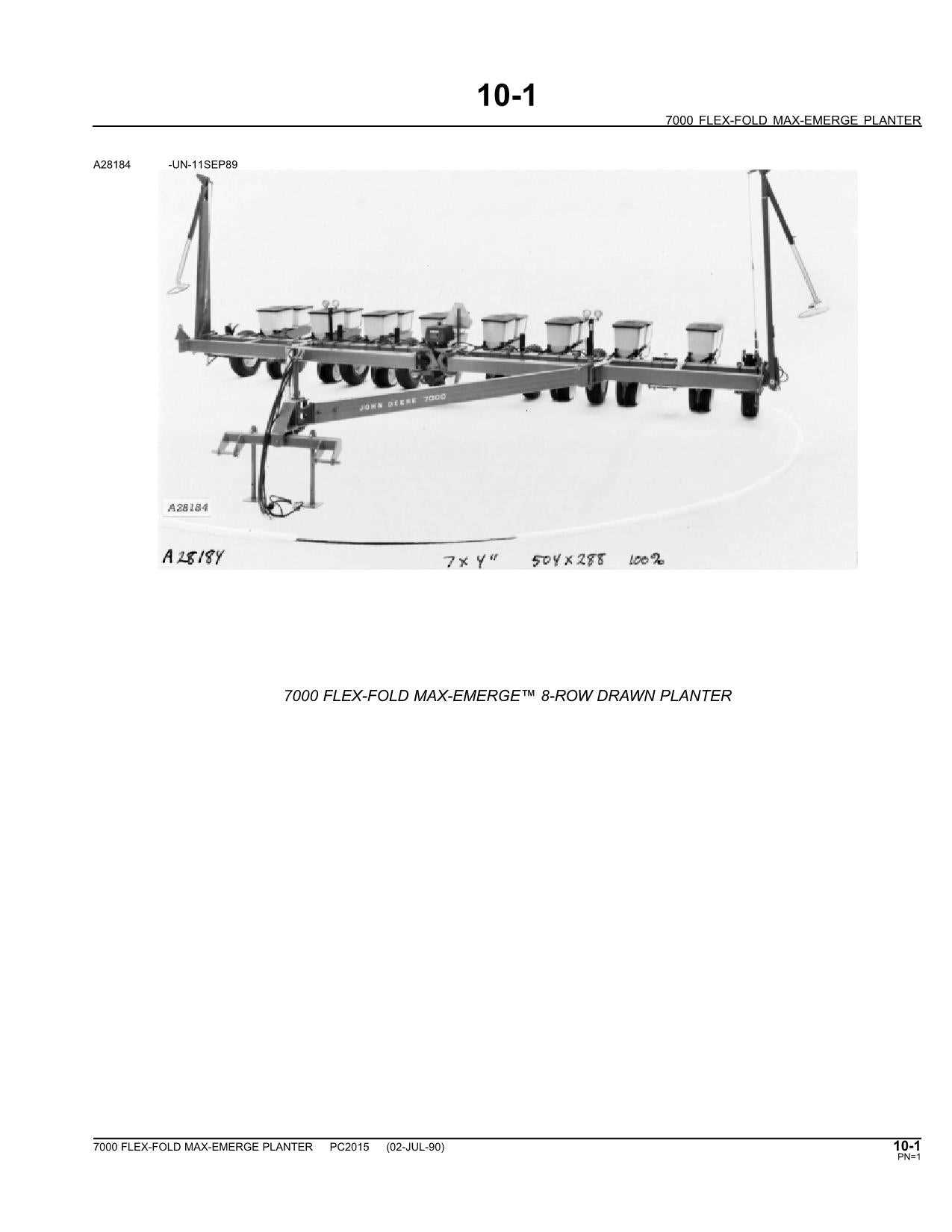

Understanding JD 7000 Planter Basics

This section provides an overview of a well-known agricultural implement designed for efficient seeding. Understanding its fundamental components and functionalities is essential for optimizing performance in the field. The aim is to equip users with the knowledge necessary to enhance their planting operations and achieve better crop yields.

Key Components

- Seed Distribution System: Responsible for the accurate placement of seeds in the soil, ensuring uniform spacing.

- Frame Structure: Provides stability and support, allowing the machine to navigate various terrains.

- Depth Control Mechanism: Regulates the depth at which seeds are planted, critical for optimal germination.

- Furrow Openers: Creates trenches in the soil to facilitate seed placement.

Operating Principles

- Preparation: Ensure the implement is properly calibrated for the specific crop type.

- Seeding: Engage the system to begin the distribution process while monitoring performance.

- Maintenance: Regular checks and adjustments are vital to keep the implement functioning efficiently.

By understanding these essential aspects, users can maximize the effectiveness of their seeding operations, leading to improved agricultural productivity.

Key Components of the JD 7000

The effectiveness of agricultural machinery relies heavily on its essential elements. Each component plays a vital role in ensuring optimal performance, enhancing efficiency, and facilitating seamless operation in various field conditions. Understanding these crucial elements can greatly improve the management and upkeep of the equipment.

Primary Elements

Among the most significant parts are those responsible for seed placement and soil interaction. These elements are engineered to ensure precision and consistency, allowing for effective planting across diverse terrains. Regular maintenance and familiarity with these components can lead to better crop yields and reduced downtime.

Supporting Structures

In addition to the core functionalities, various supporting structures provide stability and maneuverability. These components contribute to the overall durability of the machinery, ensuring it can withstand the rigors of fieldwork. Proper knowledge of their function and maintenance is essential for sustaining long-term reliability and efficiency.

Importance of Maintenance for Planters

Regular upkeep is crucial for the longevity and efficiency of agricultural machinery. Consistent maintenance not only ensures optimal performance but also significantly reduces the risk of unexpected breakdowns during critical planting seasons. By prioritizing routine checks and repairs, farmers can enhance productivity and safeguard their investment.

Enhancing Efficiency

Well-maintained equipment operates at peak efficiency, leading to better seed placement and soil management. This precision directly impacts crop yields, making it essential to address wear and tear promptly. Timely inspections can identify potential issues before they escalate, ensuring that every component functions harmoniously.

Cost Savings

Investing time and resources into maintenance can result in significant long-term savings. Neglecting minor repairs often leads to more extensive damage, requiring costly replacements. By establishing a maintenance schedule, farmers can minimize downtime and unexpected expenses, ultimately enhancing their bottom line.

Identifying Common Parts Wear Issues

Understanding the wear patterns of various components is crucial for maintaining optimal performance in agricultural machinery. Over time, these elements can experience degradation due to regular use, environmental factors, and operational stresses. Recognizing the signs of wear early can prevent costly repairs and ensure the efficiency of the equipment.

One of the most frequent issues is the erosion of cutting edges, which can lead to uneven soil preparation and reduced planting accuracy. Inspecting blades regularly for nicks or dullness is essential to ensure they function effectively. Additionally, any signs of cracking or warping in structural components should be addressed promptly to avoid failures during critical operations.

Another common concern involves wear in the seed delivery systems. Blockages or irregular seed spacing often indicate that components have lost their integrity. Regular checks for wear on these elements can help maintain consistent planting depth and seed distribution, ultimately enhancing crop yields.

Finally, friction-related wear in moving parts can lead to excessive play or noise, signaling the need for lubrication or replacement. Monitoring these areas will help maintain smooth operation and prolong the lifespan of the machinery. Proactive identification of these issues is key to ensuring reliability and effectiveness in the field.

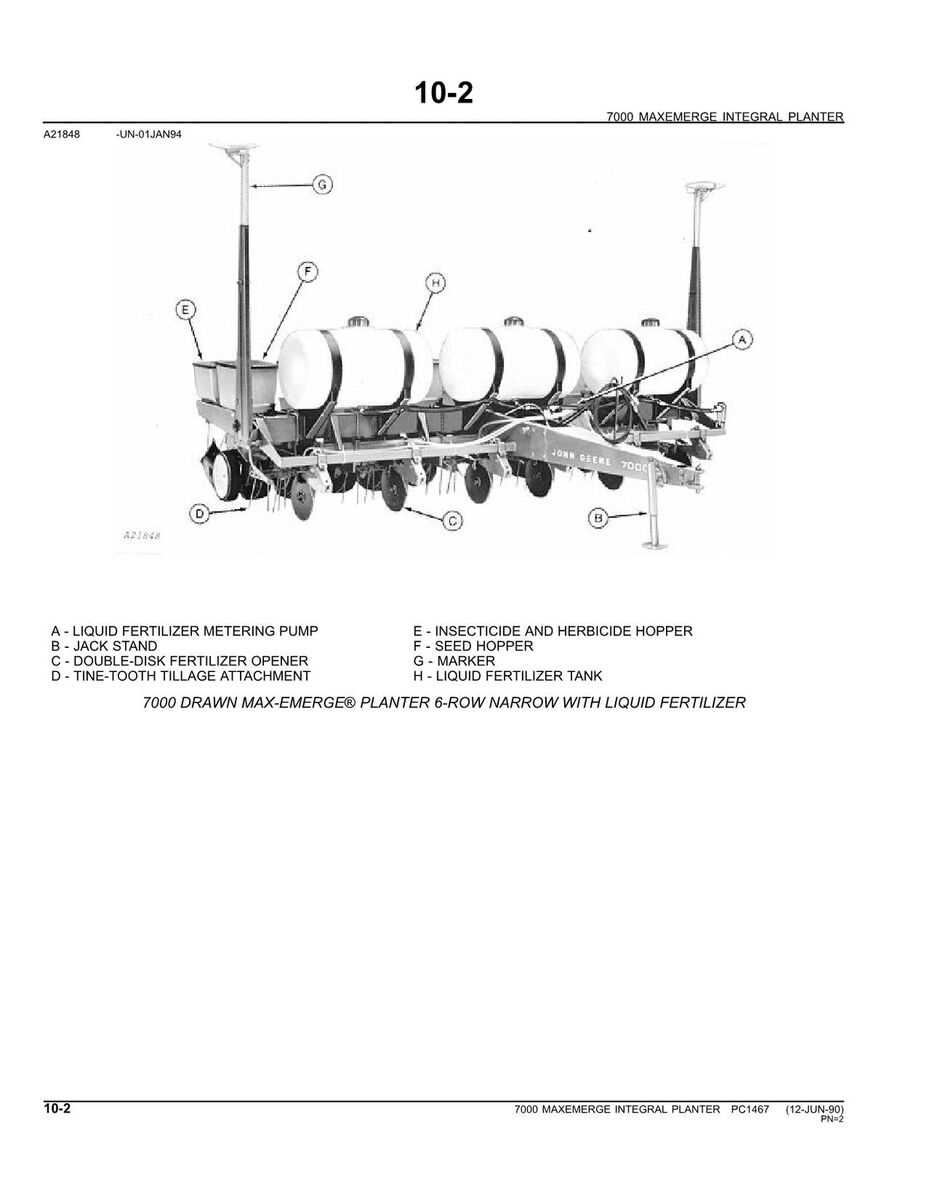

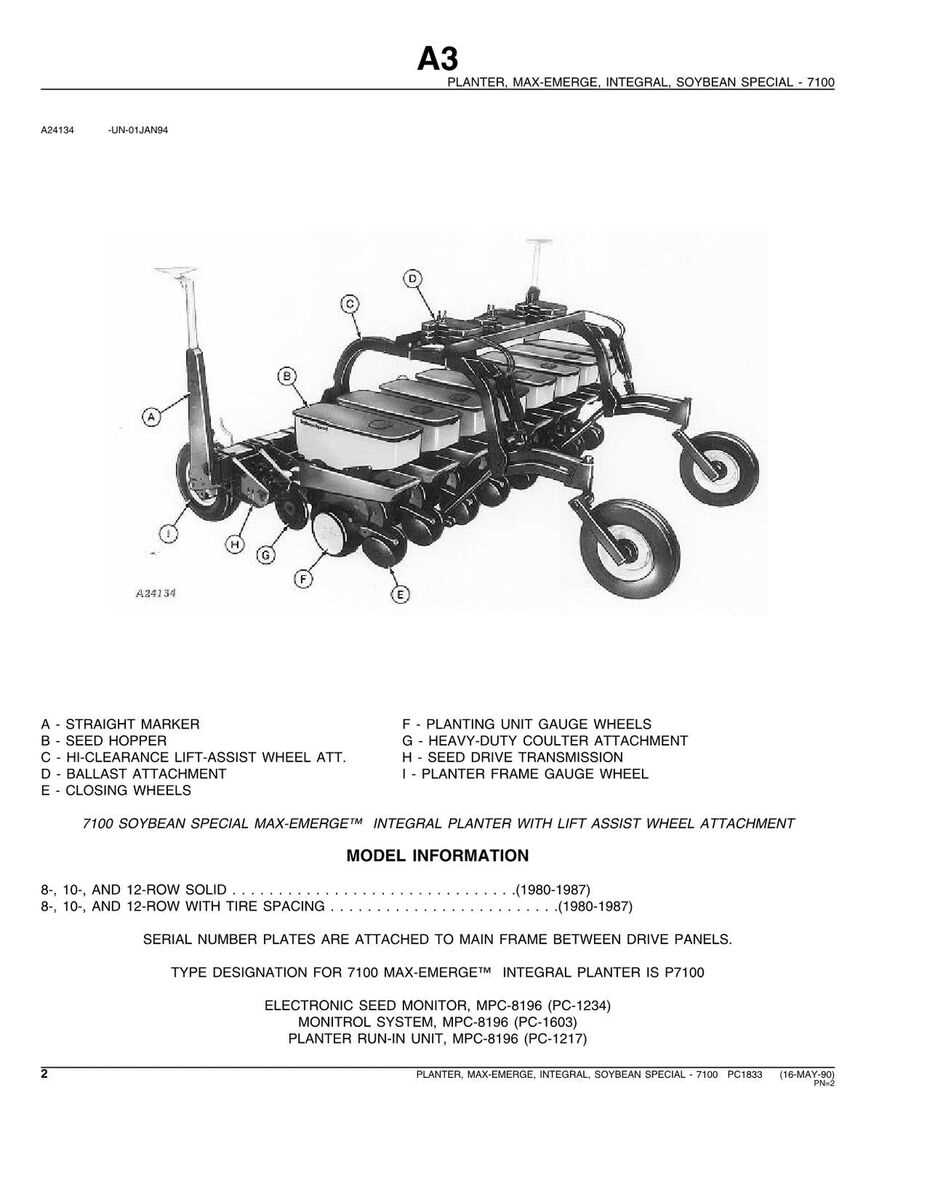

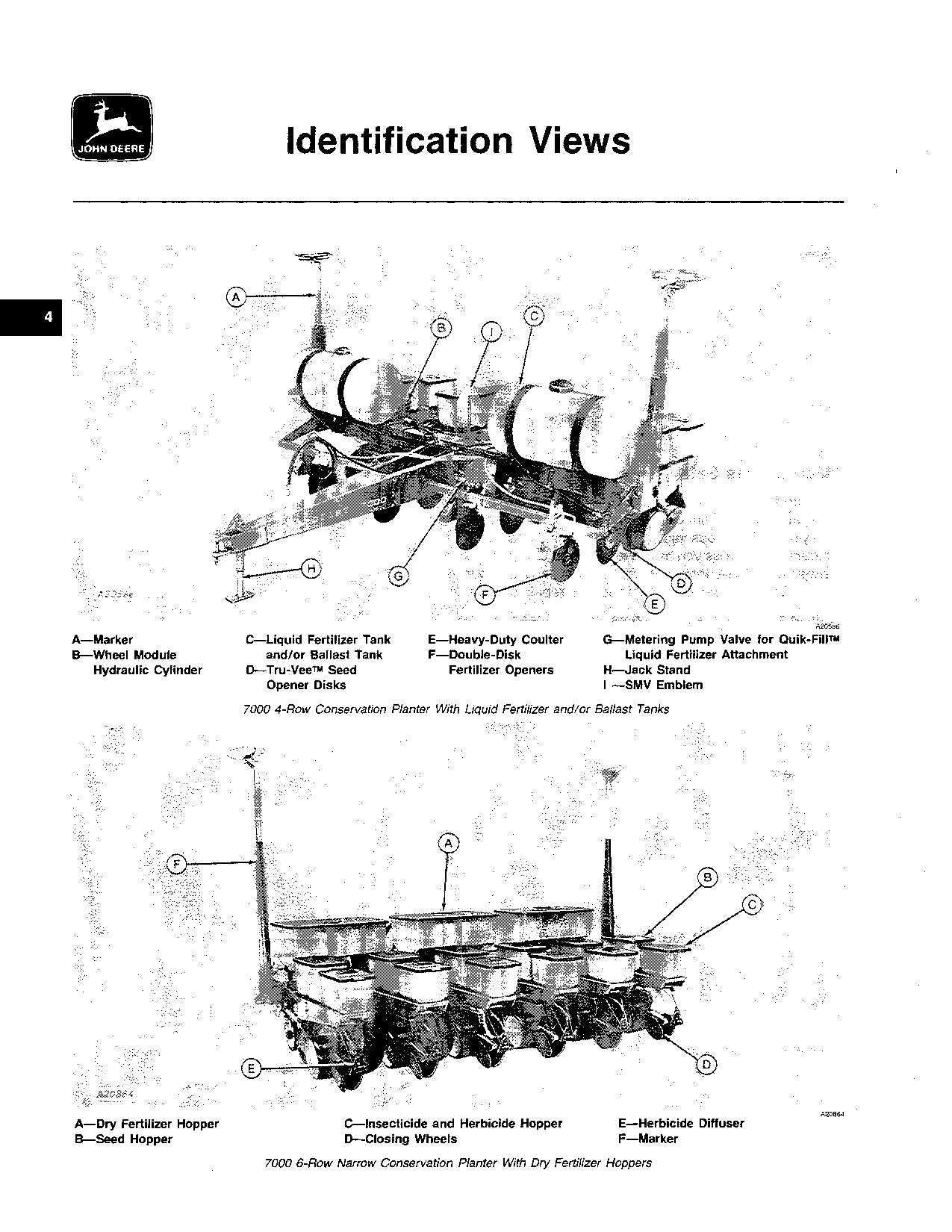

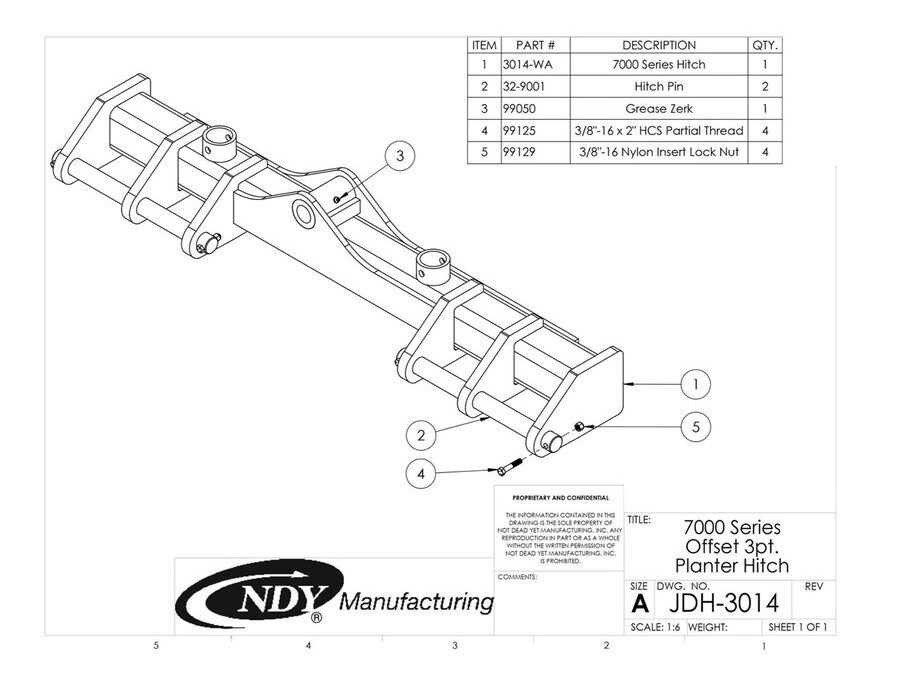

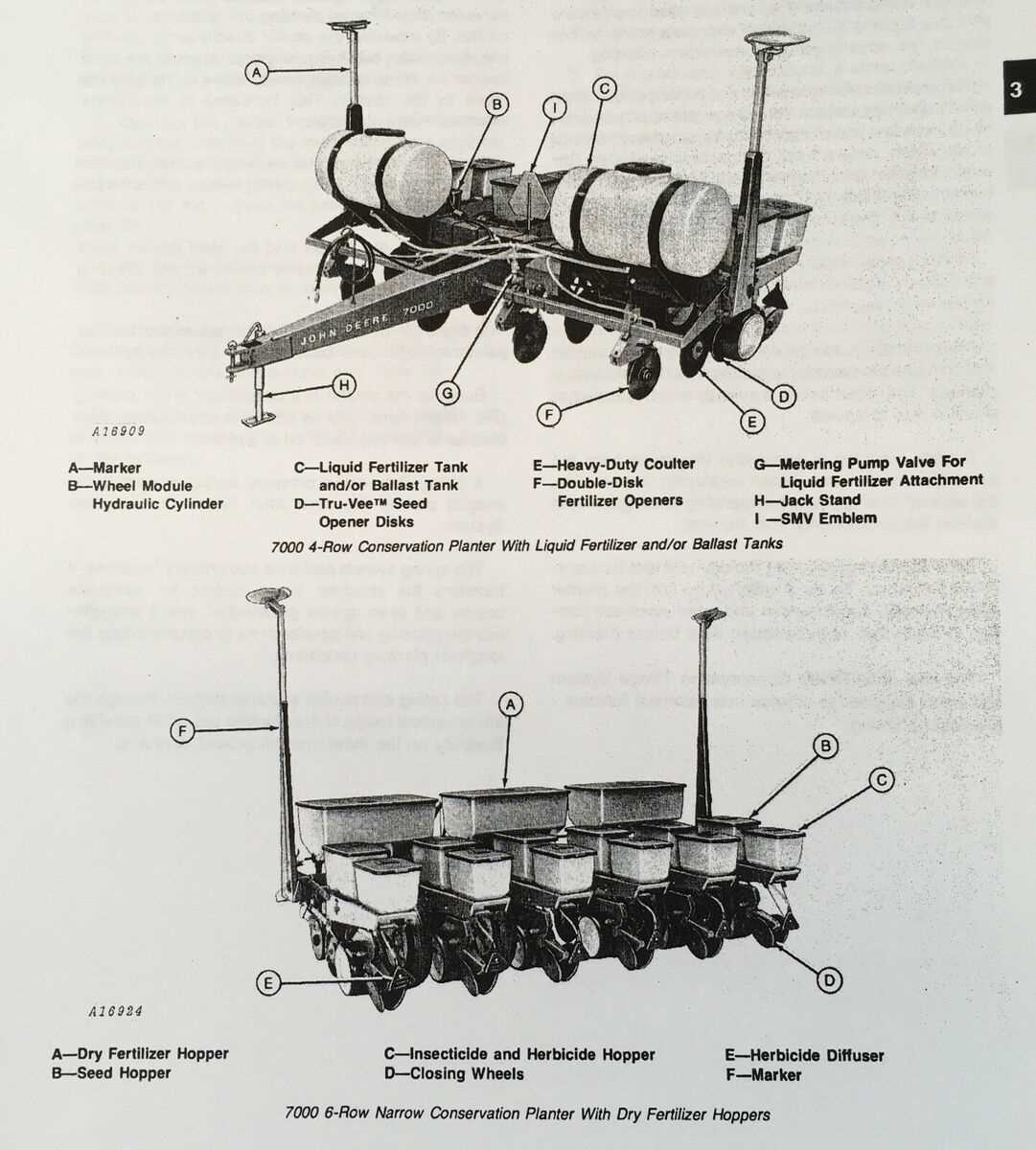

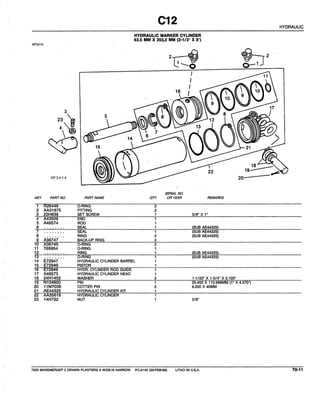

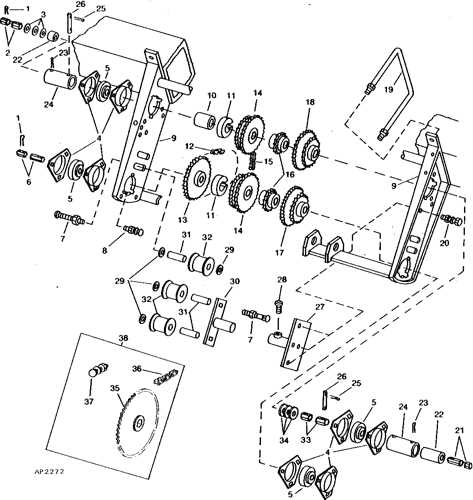

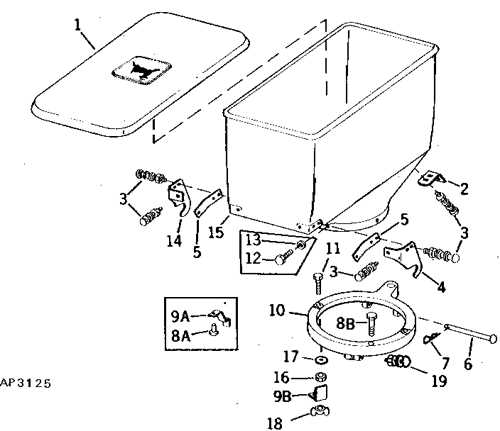

How to Read the Parts Diagram

Understanding a technical illustration is essential for effective maintenance and repair. These visual guides provide a comprehensive overview of various components, their arrangement, and interconnections. Familiarizing yourself with this information can significantly enhance your troubleshooting skills and enable you to identify parts quickly.

To effectively interpret the illustration, consider the following steps:

- Identify Key Sections: Start by locating the main areas of interest. Most illustrations are divided into sections, making it easier to focus on specific components.

- Use Labels: Pay close attention to the labels accompanying each component. These annotations often include identification numbers or names that correlate with a parts list.

- Refer to the Legend: Many illustrations include a legend that explains symbols or color codes used throughout. This can provide crucial context for understanding the various elements.

- Follow the Flow: Observe how different parts interact with one another. Understanding the flow of materials or operations can give insight into the overall functionality.

- Check for Updates: Ensure you are referencing the correct version of the illustration. Variations may exist depending on the model or year of manufacture.

By following these guidelines, you will enhance your ability to navigate technical illustrations, making maintenance tasks more efficient and informed.

Upgrading Parts for Enhanced Performance

Improving machinery functionality can significantly boost efficiency and productivity in agricultural operations. By replacing or enhancing specific components, operators can achieve better results, minimize downtime, and ensure a smoother workflow during critical planting seasons.

Benefits of Component Enhancements

Upgrading elements of your equipment leads to several advantages. First and foremost, newer or more advanced components often incorporate the latest technology, resulting in improved accuracy and reduced operational costs. Enhanced materials can also contribute to longer lifespans, allowing for consistent performance over time.

Key Areas for Improvement

Focusing on particular areas can yield remarkable improvements. For instance, seed delivery mechanisms can be upgraded to ensure more precise placement and better germination rates. Additionally, enhancing monitoring systems can provide real-time feedback, helping operators make informed decisions during planting operations.

Resources for JD 7000 Parts

Finding the right components for your agricultural equipment can significantly enhance its performance and longevity. A variety of resources are available to assist you in sourcing these essential items, ensuring your machinery runs smoothly and efficiently. Whether you’re looking for replacements or upgrades, exploring multiple avenues can lead to optimal solutions.

Online marketplaces offer a vast selection of components from various suppliers, providing competitive pricing and convenience. Websites specializing in agricultural machinery often feature catalogs with detailed descriptions and compatibility information, making it easier to locate the exact items needed for your equipment. Additionally, forums and community groups dedicated to farming and machinery can be invaluable for exchanging tips and recommendations on reliable vendors.

Local dealers and distributors remain a crucial resource, as they typically stock commonly used items and can provide expert advice tailored to your specific needs. Moreover, some manufacturers offer direct sales or have official retailers that guarantee authenticity and quality. Always consider reaching out to service centers that specialize in repairs, as they may also have insights into sourcing hard-to-find components.

Finally, keeping an eye on auctions and second-hand marketplaces can yield significant savings while still providing quality items. Networking with fellow farmers and attending agricultural shows can uncover unique opportunities to acquire what you need at competitive prices.

DIY Repairs: Tips and Tricks

Engaging in home repairs can be both rewarding and challenging. Understanding how to troubleshoot issues and implement solutions effectively is key to maintaining your equipment. With a little guidance and the right approach, you can tackle common problems without the need for professional assistance.

Assess the Situation: Before diving into repairs, take the time to evaluate the problem thoroughly. Identifying the source of an issue can save you time and effort later on. Use manuals or online resources to gather information that will aid in your repair process.

Gather Your Tools: Ensure you have all necessary tools at hand before starting. This might include wrenches, screwdrivers, and pliers. Having everything organized will streamline your work and minimize interruptions.

Follow Safety Precautions: Always prioritize safety. Wear appropriate protective gear and ensure your workspace is clear of hazards. Taking these precautions will help prevent accidents during your repair tasks.

Document Your Process: Keep a record of your steps, including any modifications made. This documentation can be invaluable for future repairs or troubleshooting, enabling you to track what has been done and what may need attention later.

Test Thoroughly: After completing repairs, conduct thorough tests to ensure everything is functioning as intended. This step is crucial to confirm that your DIY efforts have resolved the issue effectively.