Maintaining a lawn care machine is essential for ensuring its longevity and optimal performance. Knowing the intricate layout of its components can greatly enhance the efficiency of repairs and upgrades. A detailed representation of the individual elements not only simplifies the troubleshooting process but also aids in the understanding of the machine’s overall functionality.

In this section, we will explore the various sections and features of the mower, offering insights into the relationships between different parts. By familiarizing yourself with these aspects, you can make informed decisions regarding maintenance and potential replacements, ultimately enhancing your mowing experience.

Whether you are a seasoned user or a newcomer, having a clear visual reference is invaluable. It allows for easier identification of components and helps streamline repair efforts. A comprehensive overview equips you with the knowledge necessary to keep your machine running smoothly and efficiently.

Embracing this understanding can lead to better care of your equipment, ensuring that it performs at its best for years to come.

Understanding Toro Timecutter Z4200

This section provides insights into a popular riding mower model, focusing on its design, functionality, and user experience. With robust engineering and innovative features, this equipment is designed to enhance lawn maintenance efficiency.

Key components play a crucial role in its performance, affecting everything from cutting precision to overall durability. Understanding these elements allows users to optimize their mowing tasks.

Maintenance is essential for longevity. Regular checks and timely replacements ensure the machine operates at its best, preventing potential issues before they arise.

Ultimately, grasping the intricacies of this mower can lead to improved usability and satisfaction, making it a valuable addition to any landscaping toolkit.

Key Features of the Z4200 Model

This model is designed for optimal performance and ease of use, showcasing a variety of innovative attributes that enhance efficiency and user experience. From its powerful engine to advanced maneuverability, it provides reliable service for lawn care enthusiasts and professionals alike.

Powerful Engine

- High horsepower output for efficient cutting

- Durable construction ensuring longevity

- Quick start system for convenience

Exceptional Maneuverability

- Compact design allows for easy navigation in tight spaces

- Responsive steering for precise control

- Enhanced stability on uneven terrain

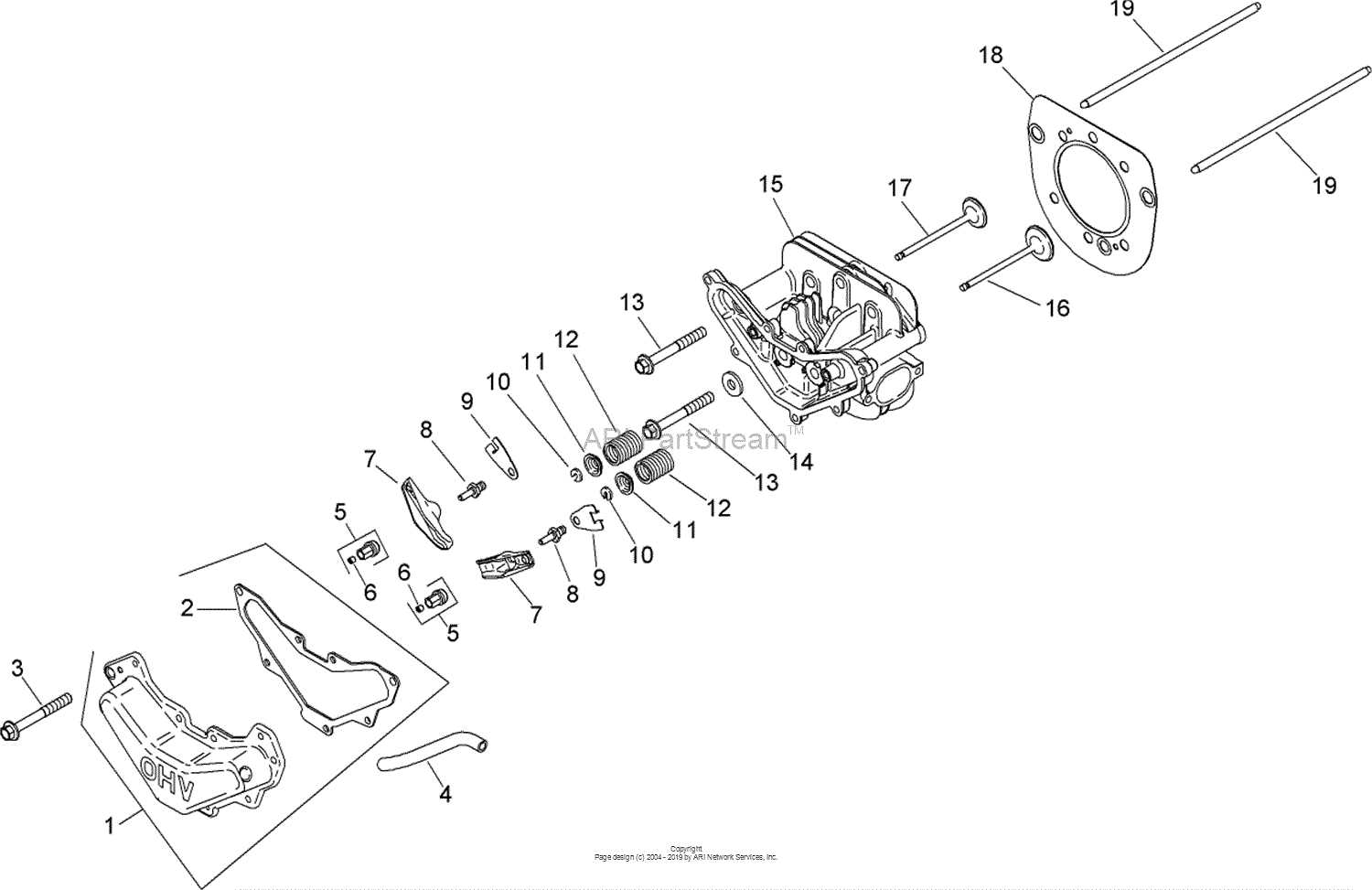

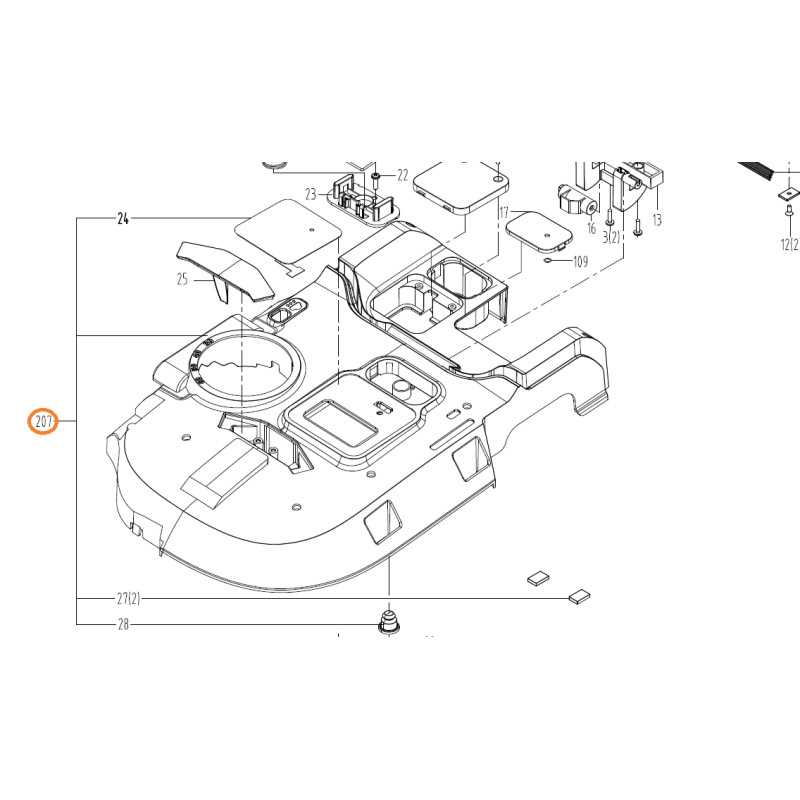

Essential Parts Overview

Understanding the key components of your lawn maintenance machine is crucial for optimal performance and longevity. Each element plays a specific role in ensuring that the equipment operates smoothly, allowing for efficient mowing and maintenance tasks. This overview highlights the fundamental elements that contribute to the functionality and reliability of your machine.

Core Components

The engine serves as the powerhouse, providing the necessary energy for operation. The cutting deck is another vital part, equipped with blades designed to achieve a precise cut while navigating various terrains. Additionally, the transmission system is essential for controlling speed and direction, enabling smooth maneuverability across your lawn.

Supportive Features

Wheels and tires are critical for stability and traction, ensuring that the machine can traverse uneven surfaces without difficulty. The control panel allows for easy operation and adjustment, giving the user command over speed settings and cutting heights. Regular maintenance of these essential components will enhance performance and extend the lifespan of your equipment.

Where to Find Diagrams

Locating visual representations for machinery components can significantly enhance the repair and maintenance process. Understanding the layout and assembly of various elements is essential for efficient troubleshooting. Fortunately, several resources are available to assist in finding these illustrations.

Manufacturer Websites: Most equipment manufacturers provide comprehensive resources on their official websites. These platforms often include downloadable files, offering detailed views of individual parts and their configurations.

Online Forums and Communities: Engaging with online discussion groups dedicated to equipment maintenance can yield valuable insights. Members frequently share resources, including detailed visual guides, and can offer advice based on their experiences.

Retail and Supply Websites: Numerous online retailers specializing in machinery components often feature product manuals that include schematics. These documents are beneficial for identifying specific parts and their arrangement.

Service Manuals: Acquiring service manuals specific to the machinery can be a great asset. These publications typically contain extensive diagrams and step-by-step instructions for repairs and replacements.

Local Libraries and Archives: Many libraries maintain a collection of technical manuals and guides. Accessing these resources can provide in-depth illustrations and detailed information for various models.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your equipment. By adhering to a consistent maintenance schedule, you can ensure optimal performance and reduce the risk of unexpected breakdowns.

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Replace with high-quality oil to keep the engine running smoothly. |

| Blade Sharpening | Every season | Keep blades sharp for cleaner cuts and improved efficiency. |

| Air Filter Check | Monthly | Inspect and clean or replace to ensure proper airflow. |

| Tire Pressure | Every use | Check and maintain the correct pressure for better traction. |

| Belt Inspection | Every 25 hours | Look for wear and replace if necessary to avoid slippage. |

Common Repair Issues Explained

Understanding typical repair challenges can significantly enhance your maintenance skills and ensure longevity for your equipment. Familiarity with frequent problems allows users to troubleshoot efficiently, minimizing downtime and repair costs.

| Issue | Description | Possible Solutions |

|---|---|---|

| Engine Failure | Unexpected stops or inability to start. | Check fuel levels, battery connections, and spark plugs. |

| Deck Damage | Cracks or dents affecting cutting performance. | Inspect for debris, tighten loose parts, and replace damaged sections. |

| Transmission Issues | Slipping gears or loss of power. | Examine fluid levels and look for leaks; consider servicing the transmission. |

| Blade Dullness | Uneven cutting or tearing of grass. | Sharpen blades regularly and replace them if excessively worn. |

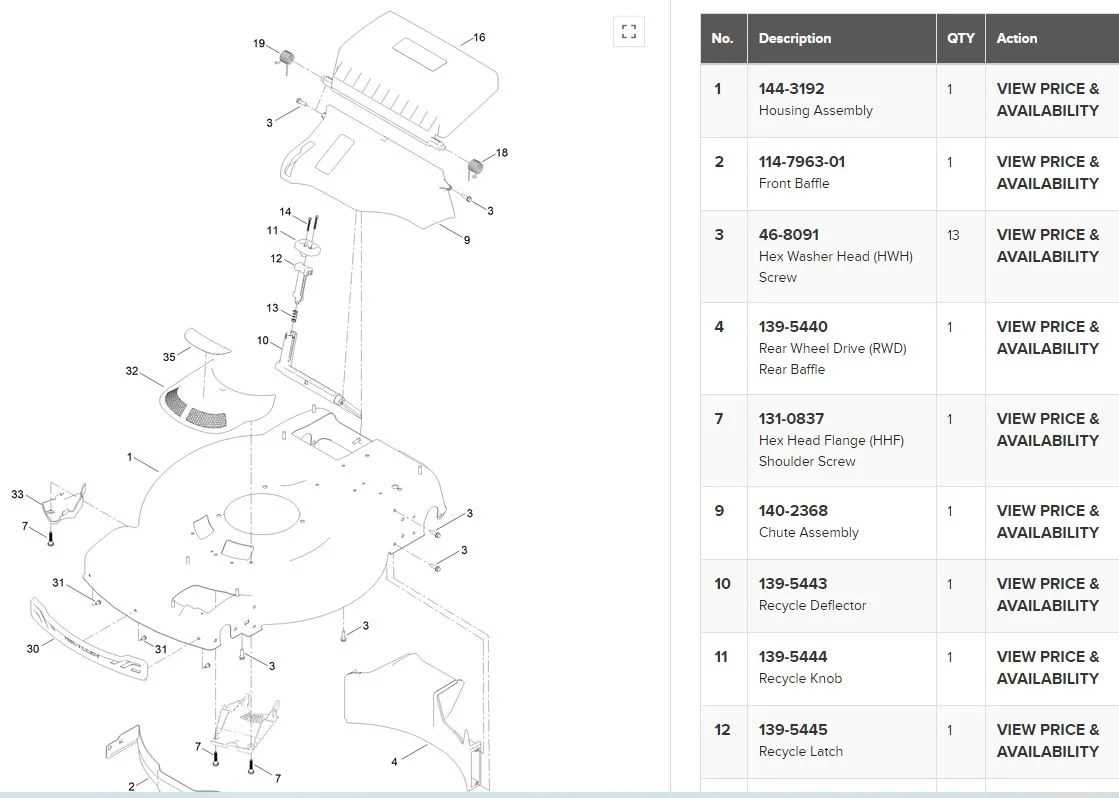

Ordering Replacement Components

When it comes to maintaining your machinery, sourcing the right replacement elements is crucial for optimal performance and longevity. Understanding the process can make this task much more manageable.

- Identify the specific component needed for replacement.

- Consult your user manual for part numbers and specifications.

- Research reputable suppliers that offer genuine or compatible items.

Once you have gathered the necessary information, follow these steps:

- Visit the supplier’s website or contact their customer service.

- Provide the required details, including the part number and model.

- Review shipping options and return policies before finalizing your order.

By following these guidelines, you can ensure a smooth ordering experience and get your equipment back to working order in no time.

Assembly Instructions for DIY Repairs

When tackling home repairs on your equipment, understanding the assembly process is crucial for a successful outcome. This guide provides clear steps to help you reassemble components effectively, ensuring everything functions optimally once put back together.

Preparation Steps

- Gather all necessary tools: screwdriver, wrench set, pliers, and any specific tools required for your model.

- Organize your workspace to keep all parts and tools within easy reach.

- Refer to the manual or an online guide for the specific assembly sequence of your equipment.

Reassembly Process

- Start by laying out all components in the order of assembly to visualize the process.

- Attach the main body parts first, ensuring that all connection points align properly.

- Secure any fasteners, but do not overtighten as this may cause damage.

- Reconnect any wiring or hoses according to the guidance provided in your manual.

- Double-check all connections and fittings before proceeding to the next step.

- Once everything is in place, test the assembly by performing a brief functionality check.

By following these guidelines, you can confidently carry out repairs and maintain your equipment in peak condition.

Maximizing Performance with Upgrades

Enhancing the efficiency of your outdoor equipment can significantly improve its overall functionality and longevity. By focusing on key improvements, users can achieve the ultimate performance tailored to their specific needs.

Consider the following enhancements:

- Engine upgrades for increased power and torque.

- High-performance blades for superior cutting quality.

- Advanced air filters to boost engine efficiency.

- Improved transmission components for smoother operation.

- Upgraded wheels or tires for better traction and stability.

Implementing these modifications can lead to a more productive experience and ensure your equipment remains reliable over time.