Maintaining any machine requires a clear understanding of its core elements and their arrangement. Knowing how each piece fits together can help ensure proper upkeep and identify areas in need of attention. In this section, we will explore the vital sections of a popular mower model, offering insights into its structural layout.

Each component plays an important role in the overall performance of the device. From the engine to the blades, every part has its own function and contributes to a smooth operation. Learning the arrangement of these elements can help users navigate potential issues and ensure long-lasting use.

By familiarizing yourself with the internal and external structure, you can streamline maintenance tasks, improve efficiency, and ensure that the machine operates at its best. Regular inspections and a clear understanding of the setup will also help in replacing worn or damaged pieces when necessary.

Comprehensive Overview of the Toro TimeCutter 50

When considering high-performance equipment for efficient lawn care, this model stands out as an excellent choice for both residential and professional use. It combines precision, speed, and durability, making it suitable for various tasks.

The design is engineered to enhance productivity, ensuring smooth operation and minimal maintenance. Its intuitive interface and robust components contribute to ease of use while delivering superior cutting quality.

- Efficient cutting mechanisms for consistent performance.

- Durable materials built to withstand tough conditions.

- User-friendly controls designed for maximum comfort.

Whether for large properties or smaller areas, this model excels in providing a reliable and efficient solution, ensuring a neat and well-maintained lawn with minimal

Main Components and Their Functions

Understanding the core elements of this equipment is essential for efficient operation and maintenance. Each component plays a unique role, contributing to the overall performance and functionality. Below, we explore the key parts and their specific purposes to provide a clearer insight into how these systems work together.

| Component |

Function |

| Engine |

Responsible for powering the system, converting fuel into mechanical energy. |

| Transmission |

Facilitates the control of speed and direction, ensuring smooth operation during use. |

| Cutting Deck |

Houses the blades and ensures a precise cutting width for consistent performance. |

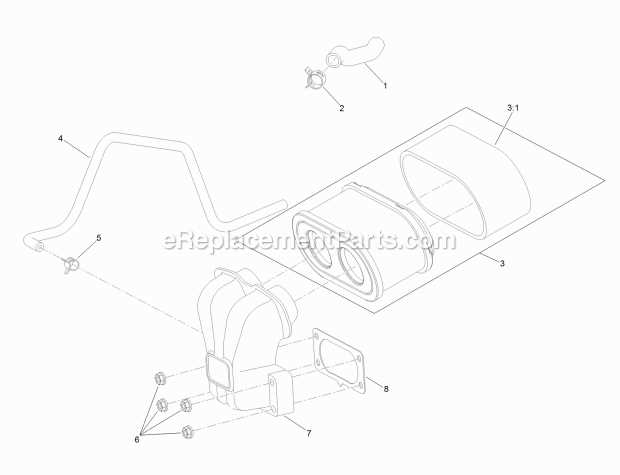

Cutting Deck Structure and Maintenance

The overall framework of the cutting deck is essential for the functionality of the equipment, ensuring efficient performance during operation. The structural design supports various components that work together to achieve clean and precise cuts. Regular upkeep of this section is vital to maintain its longevity and reliability in different working conditions.

Key components of the deck require periodic checks, as they are exposed to wear and tear. Blades, spindles, and belts should be inspected frequently to ensure they are in optimal condition. Keeping these elements clean and properly aligned will help avoid malfunctions during use.

Moreover, cleaning and lubricating moving parts will extend the life of the equipment. It’s recommended to remove debris after each use to prevent damage. Additionally, adjusting the height and angle settings correctly will improve cutting accuracy and reduce strain on the system.

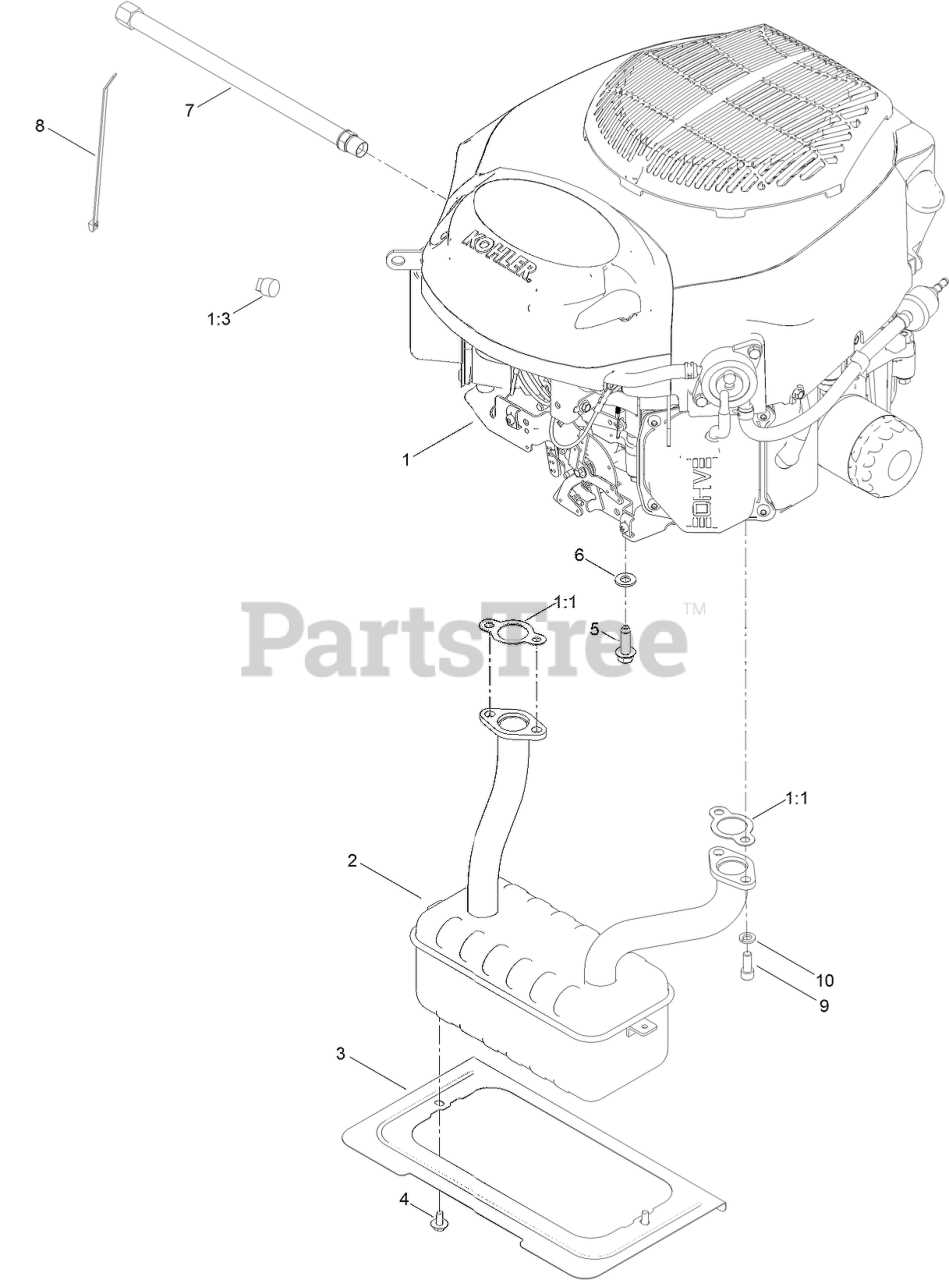

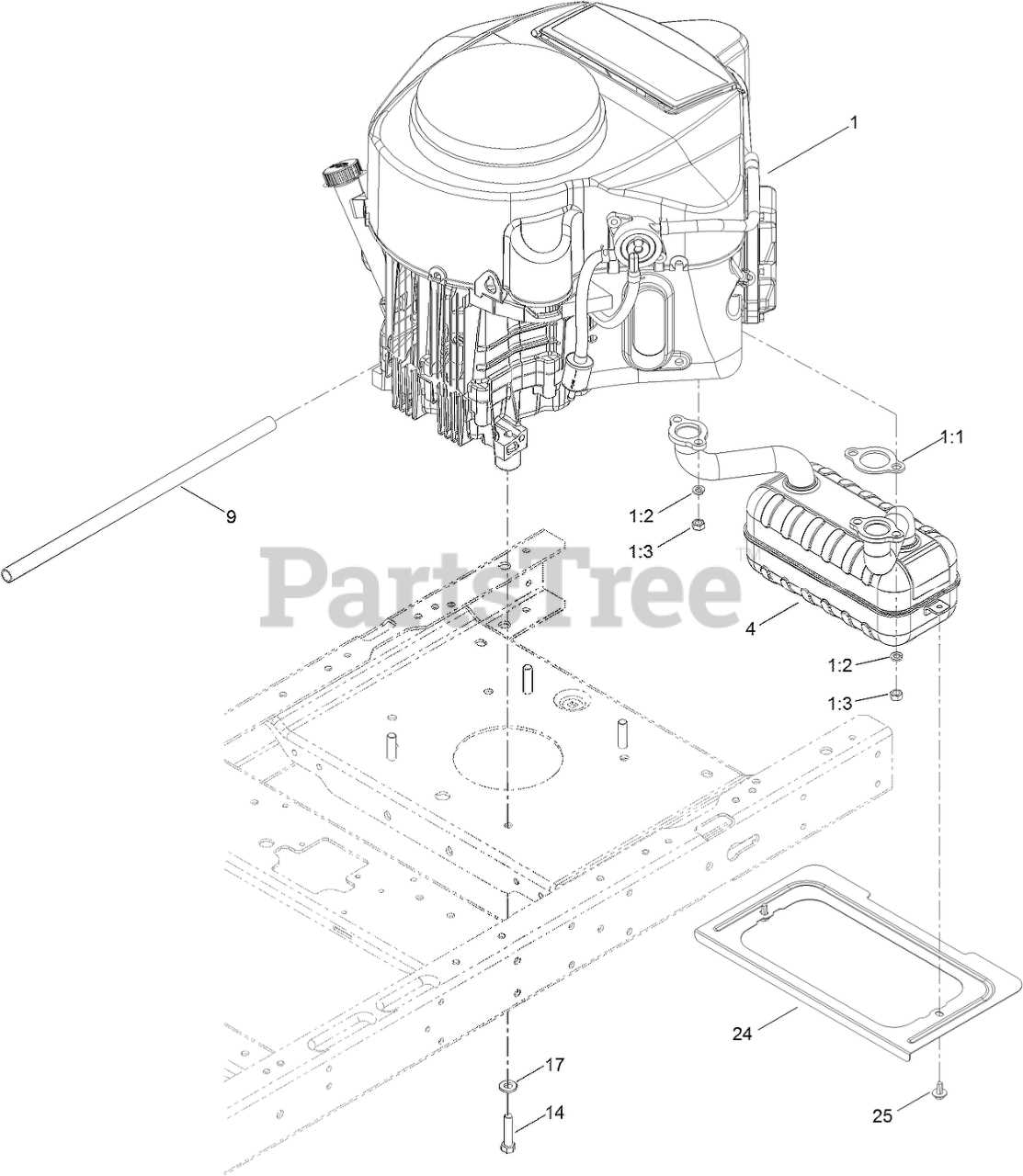

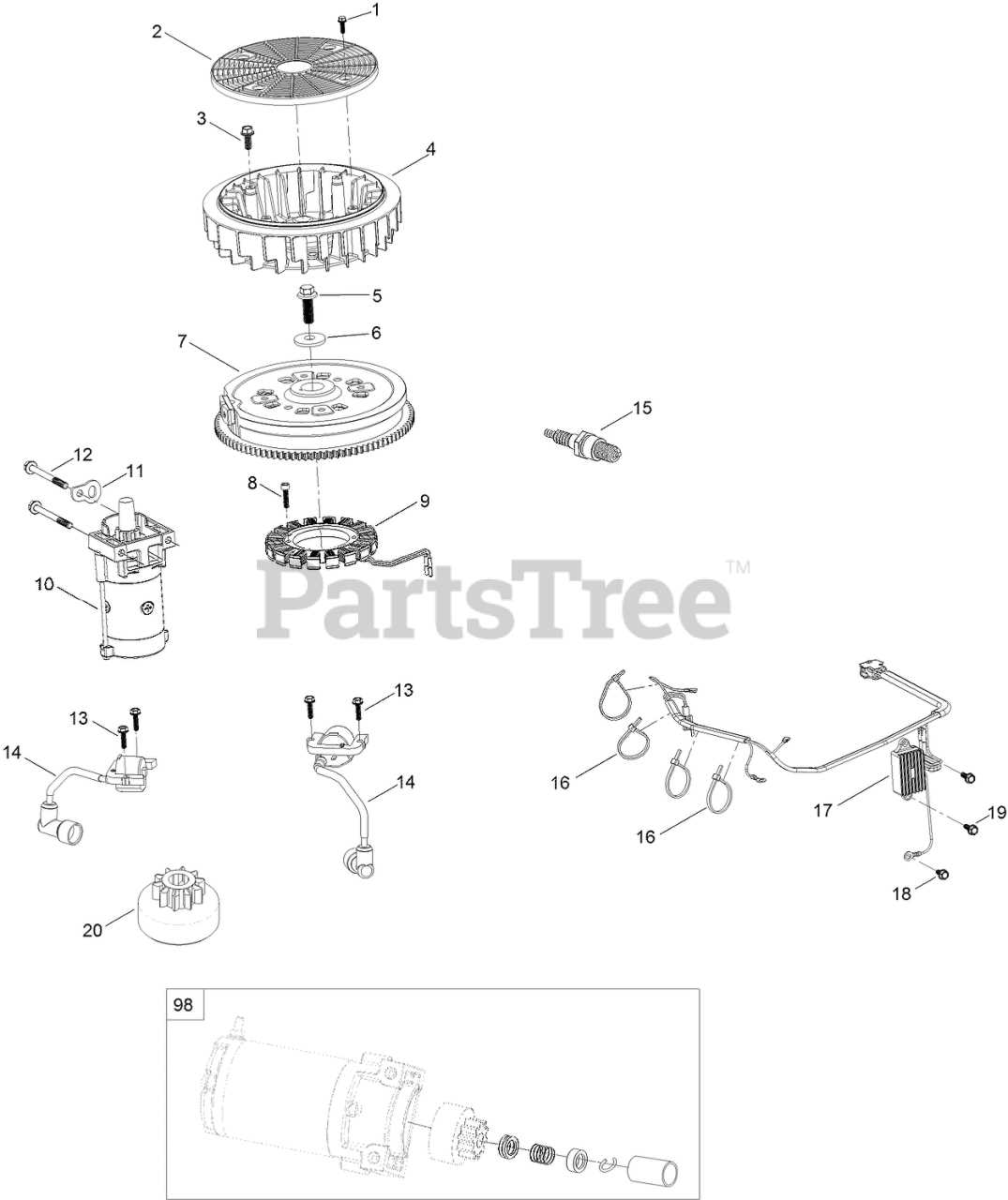

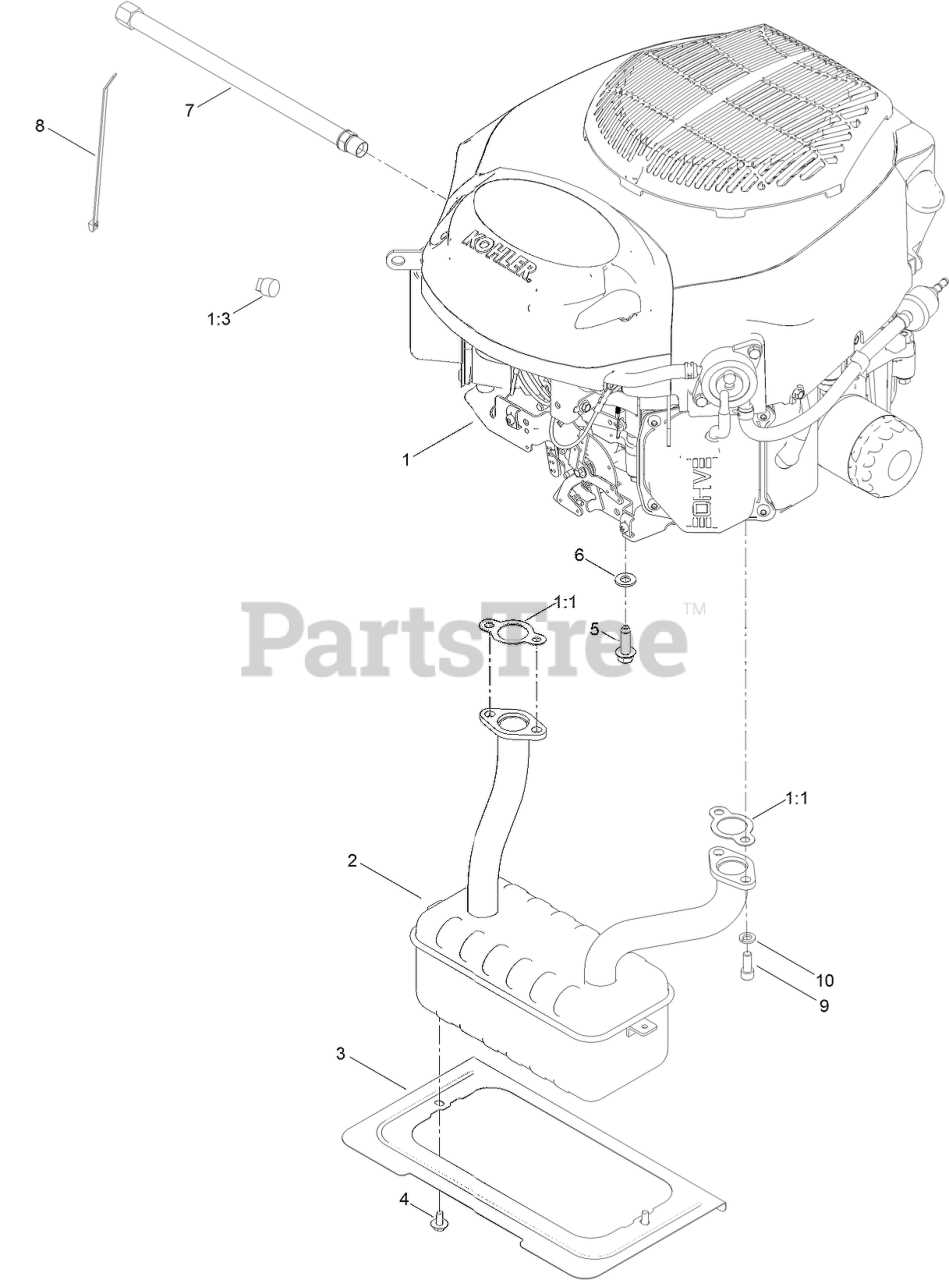

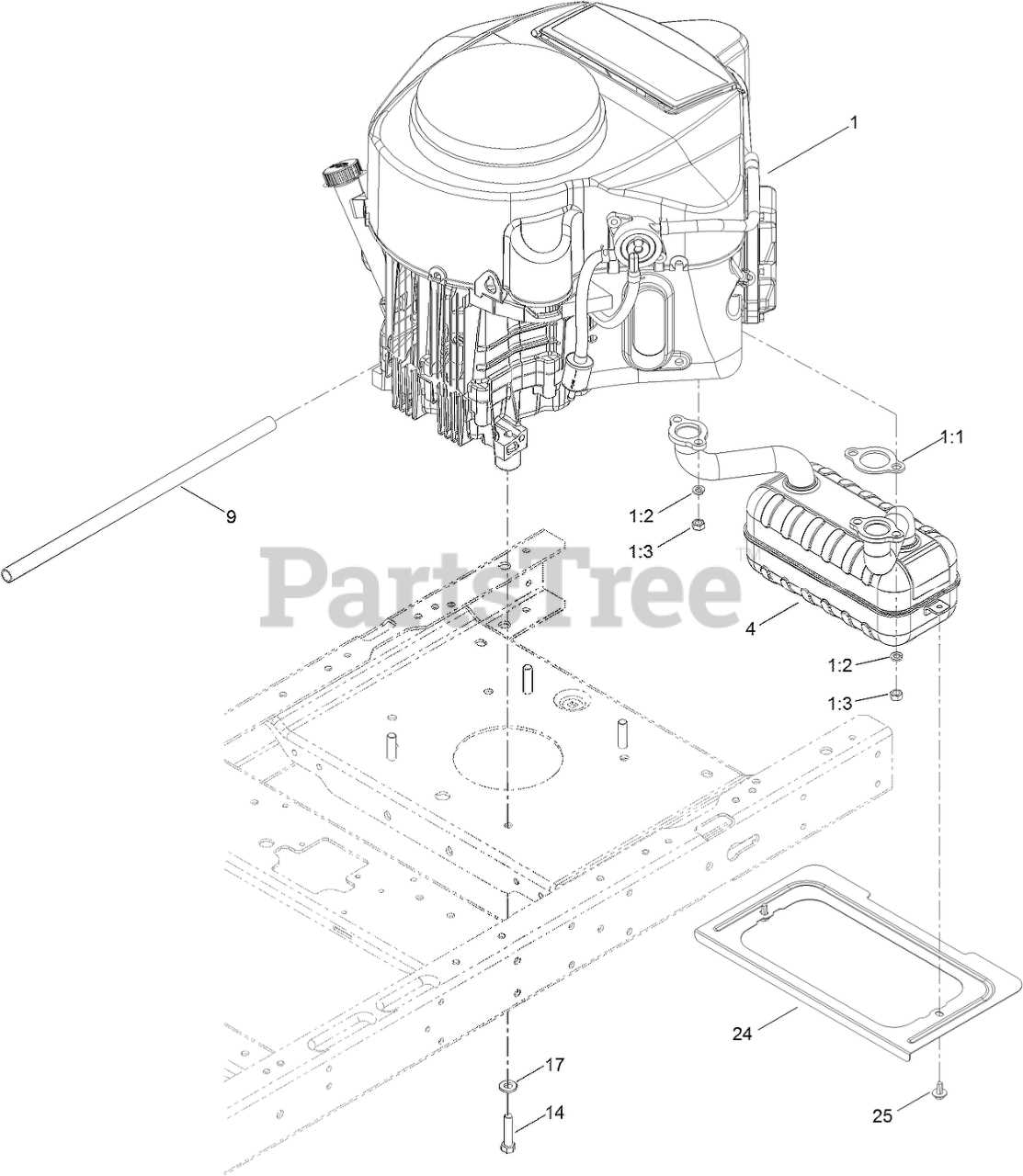

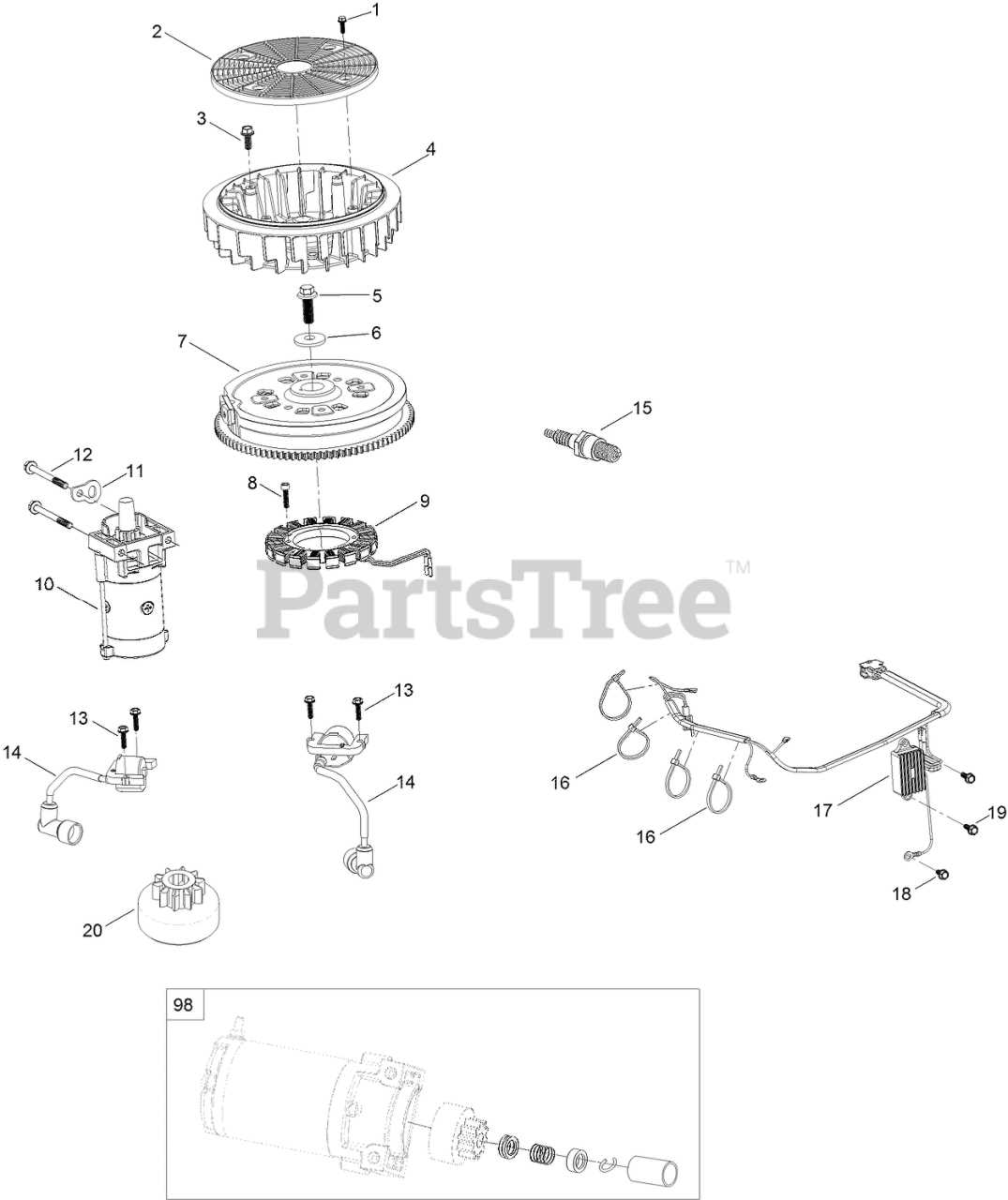

Engine Parts Breakdown and Repair Tips

Understanding the key components of a motor and knowing how to address common issues can greatly enhance its longevity and performance. By focusing on each section of the engine, it becomes easier to diagnose potential problems and implement effective solutions.

- Cylinder and Piston Maintenance: Regularly check the condition of the cylinder and piston. Clean debris and ensure there is no wear or scoring, which can affect the engine’s efficiency.

- Fuel System Inspection: Inspect the fuel lines and filter for clogs or damage. Replace the filter if necessary to maintain smooth fuel delivery.

- Ignition System Check: Make sure the spark plug is in good condition. Clean or replace it if fouled, as a clean spark plug is essential for

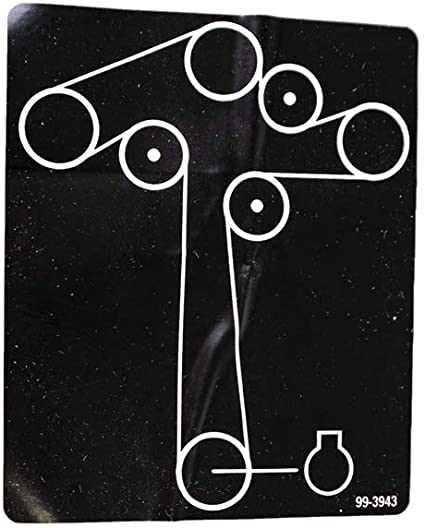

Steering System Diagram and Troubleshooting

The steering mechanism plays a crucial role in ensuring smooth and controlled movement. Understanding how this system operates is key to identifying potential issues and performing necessary maintenance. By familiarizing yourself with its layout, you can efficiently diagnose and resolve common problems that may arise during operation.

Key Components and Their Functions

The steering system consists of several interconnected parts that work together to guide the equipment. Key elements include the steering wheel, linkages, and pivot points. These components enable directional changes and precise control, ensuring stability and ease of use. Proper alignment and regular lubrication are essential for preventing wear and tear.

Troubleshooting Common Steering Issues

If the steering feels unresponsive or stiff, several potential causes can be addressed. Start by inspecting the linkages for damage or misalignment. Loose connections may lead to erratic steering, while worn bearings can cause increased resistance. Regular checks and timely adjustments help maintain optimal performance and extend the lifespan of the equipment.

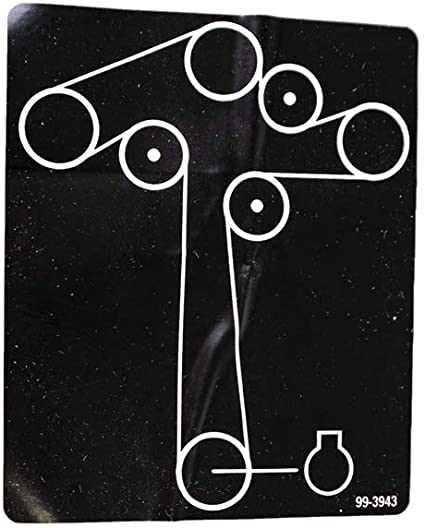

Drive System Overview for Efficient Operation

The functionality and performance of the drive system play a crucial role in maintaining smooth and effective operation. Understanding how the various components interact allows for improved control and extended longevity, ensuring the machinery functions at its best.

Key Components and Their Roles

- Transmission: Responsible for managing power distribution and speed control, this part helps maintain consistent movement and adaptability to different terrain.

- Hydraulic Mechanism: Provides the fluid power necessary to operate the drive system smoothly and efficiently, reducing wear on mechanical components.

- Wheel Drive System: Ensures the vehicle maintains optimal traction, adapting to various surface conditions for enhanced maneuverability.

Maintenance Tips for Prolonged Efficiency

- Regular Inspections: Frequently check the

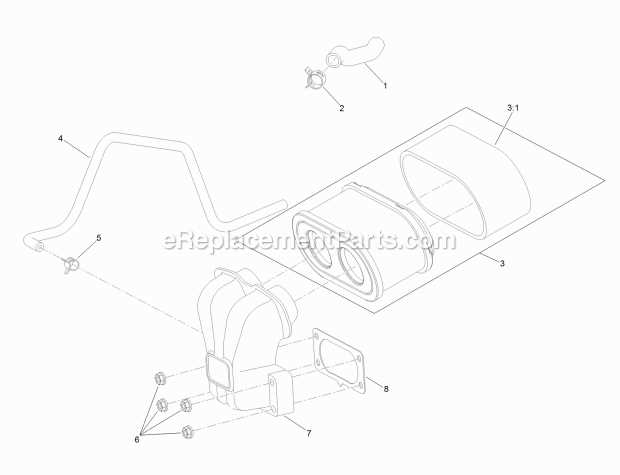

Blades Assembly and Replacement Guide

Maintaining the cutting mechanism in prime condition is essential for effective lawn care. Regular inspection and proper installation of the blades ensure smooth operation and extend the overall lifespan of the equipment. The following instructions provide a clear overview of assembling and replacing the blades to keep the system functioning optimally.

Before starting, it’s important to gather the necessary tools and prepare a clean working area. Safety measures should always be in place during any maintenance process.

- Ensure the machine is securely elevated to access the blades.

- Use the proper wrench to remove the bolts holding the blades in place.

- Carefully detach the worn or damaged blades from the spindle.

- Check the spindle for any signs of wear or damage.

When installing new blades, follow these steps:

- Align the new blade with the spindle, ensuring it sits correctly in

Wiring Diagram for Electrical Components

The structure of electrical connections is essential for ensuring proper functionality and safety of the system. Understanding how different elements interact within this network can greatly assist in troubleshooting and maintenance. A clear representation of the wiring allows users to identify key connections and power flow, enhancing overall efficiency and reducing the chance of errors.

Electrical systems typically include a variety of components such as motors, switches, and circuits. These components need to be arranged in a logical order to support optimal performance. By reviewing the wiring layout, it’s possible to trace the connections and make necessary adjustments when certain components require attention or replacement.

Tips for Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Here are some strategies to ensure you acquire high-quality replacements that align with your specific model.

Utilize Authorized Dealers

One of the most reliable methods to find genuine components is to engage with authorized retailers. These outlets are certified to sell specific brands and guarantee that the items you purchase meet the necessary quality standards.

- Check the manufacturer’s website for a list of authorized dealers.

- Visit local stores known for stocking recognized brands.

- Inquire about warranty and return policies for added security.

Research Online Marketplaces

Many reputable online platforms offer a wide range of genuine components. However, it is essential to conduct thorough research before making a purchase.

- Read customer reviews to gauge the reliability of the seller.

- Look for listings that clearly state authenticity and brand compliance.

- Verify the return and refund policies to safeguard your purchase.