The maintenance and functionality of a lawn care machine greatly depend on the knowledge of its individual elements. Each component plays a vital role in ensuring the smooth operation and longevity of the equipment. A clear visualization of these parts can significantly enhance the understanding and efficiency of any repair or upkeep task.

In this section, we will explore a comprehensive representation of various elements found in these machines. By familiarizing oneself with the specific roles and interconnections of these components, operators can more effectively troubleshoot issues and carry out necessary adjustments. Understanding these intricate details not only aids in effective repairs but also contributes to the overall performance and durability of the equipment.

For anyone looking to enhance their expertise in lawn care machinery, delving into the specifics of each element is essential. This knowledge empowers users to take proactive measures, ensuring that their equipment remains in optimal condition and continues to perform at its best.

This section delves into the significant attributes and technical specifications of the machine, highlighting its essential capabilities and performance characteristics. Understanding these features is vital for users aiming to maximize efficiency and functionality in their operations.

Core Characteristics

- Robust engine power for efficient operation

- Compact design for easy maneuverability in tight spaces

- Durable construction materials ensuring longevity

- Advanced cutting technology for a clean finish

- Adjustable cutting height to suit various lawn types

Technical Specifications

- Engine Type: Gasoline-powered

- Cutting Width: 42 inches

- Drive System: Hydrostatic transmission

- Fuel Capacity: 3 gallons

- Weight: Approximately 500 lbs

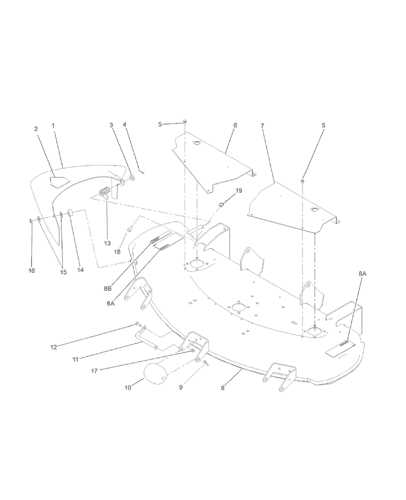

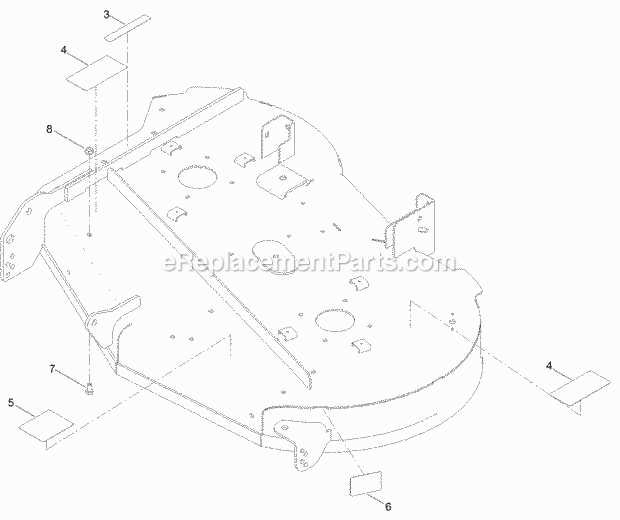

Understanding the Parts Diagram

Grasping the assembly layout is crucial for effective maintenance and repair tasks. This visual representation allows users to identify components and their interconnections, facilitating a smoother troubleshooting process. By familiarizing oneself with the arrangement, one can efficiently address issues that may arise during operation.

In-depth knowledge of each component’s role is essential for ensuring optimal functionality. Each element plays a specific part in the overall performance, and recognizing these roles can help prevent potential malfunctions. Moreover, understanding how various elements interact aids in making informed decisions regarding replacements and upgrades.

Regular consultation of the assembly outline can greatly enhance the user’s ability to perform routine checks and maintenance. By keeping this reference at hand, one can swiftly locate any part that requires attention, thereby extending the lifespan of the equipment and ensuring its reliable performance.

Essential Components of the Mower

Understanding the crucial elements of a lawn care machine is vital for its maintenance and efficient operation. Each component plays a significant role in ensuring optimal performance, durability, and ease of use. Familiarity with these essential parts enables users to make informed decisions regarding repairs and upgrades, ultimately leading to enhanced functionality.

Key Features of the Cutting Mechanism

The cutting mechanism is at the heart of any mowing device, responsible for delivering a clean and even cut. This system typically consists of sharp blades that rotate at high speeds, efficiently trimming grass and maintaining the desired lawn height. Regular inspection and sharpening of these blades are essential to preserve their effectiveness and prolong their lifespan.

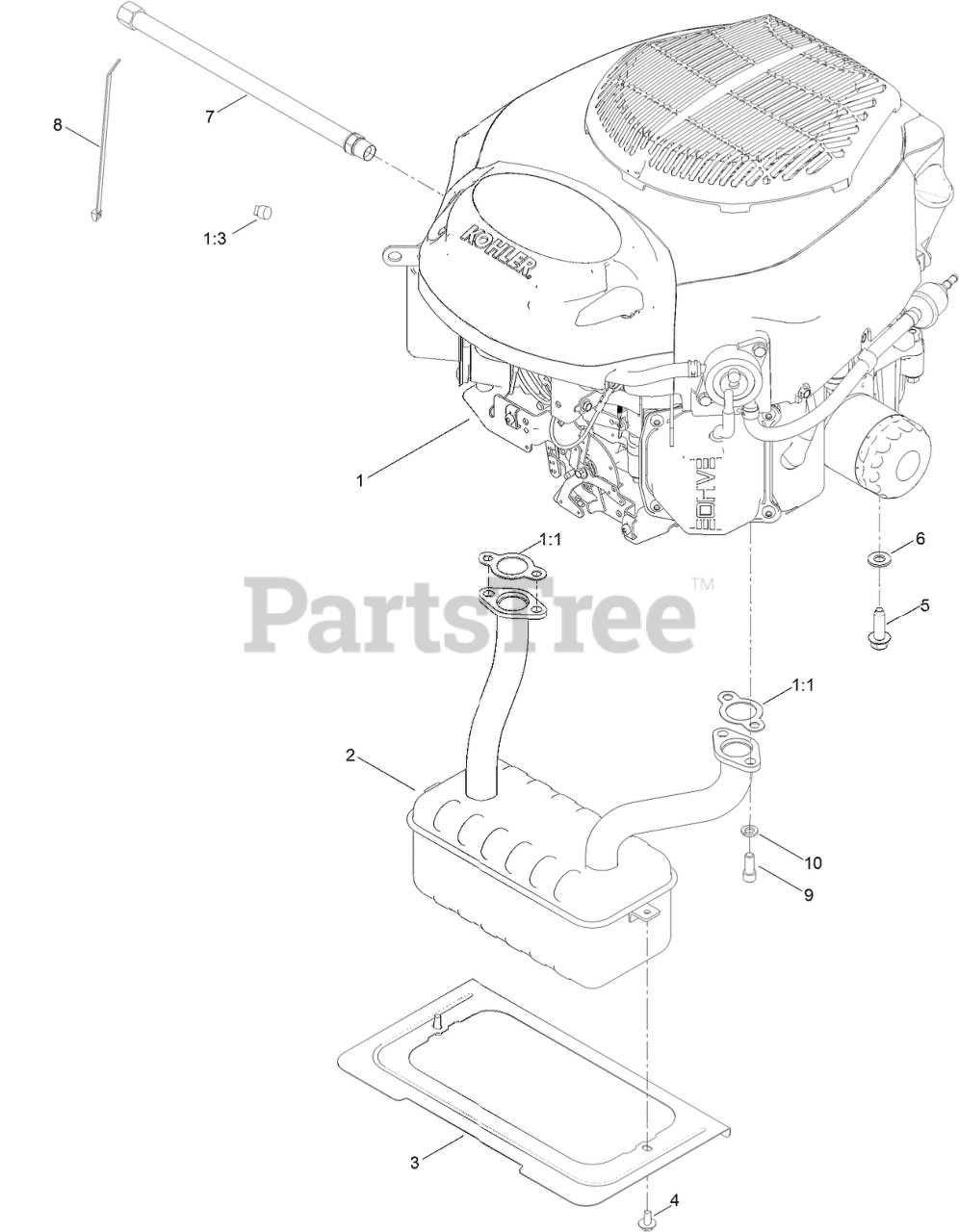

Engine and Power System

The power system drives the machine and ensures it operates smoothly. A reliable engine provides the necessary horsepower, affecting the mower’s performance and speed. Regular maintenance, including oil changes and air filter replacements, is crucial to keep the engine running efficiently and to prevent potential issues during operation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of any machinery. Implementing regular maintenance practices can significantly extend the lifespan of your equipment while enhancing its performance. Here are some vital strategies to consider for optimal care.

Regular Inspection

Frequent examinations of your equipment can help identify potential issues before they escalate into significant problems. Check for any signs of wear and tear, loose components, or unusual noises. Addressing these concerns early can prevent costly repairs and downtime.

Cleaning and Lubrication

Keeping your machinery clean is crucial for preventing debris accumulation, which can lead to mechanical failures. Regularly remove dirt and grime, paying special attention to moving parts. Additionally, ensure all necessary components are properly lubricated to reduce friction and enhance functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect for wear | Monthly | Look for loose parts and signs of damage. |

| Clean exterior | Bi-weekly | Remove dirt and debris. |

| Lubricate moving parts | Every 10 hours of operation | Use appropriate lubricant for best results. |

| Check fluid levels | Weekly | Ensure fluids are at recommended levels. |

Common Issues and Troubleshooting

In the realm of lawn maintenance equipment, users may encounter various challenges that affect performance and efficiency. Identifying these common issues and understanding effective solutions can significantly enhance the overall experience and prolong the lifespan of the machinery.

Frequent Mechanical Problems

One of the most prevalent concerns involves the malfunctioning of the cutting system. This may manifest as uneven cuts or the blades failing to engage properly. Regular inspection and maintenance of the blades, along with ensuring they are sharpened and aligned correctly, can mitigate these issues. Additionally, users should check for any obstructions that may hinder blade movement.

Electrical and Engine Troubles

Another area to consider is the power unit. Users might notice difficulties in starting the engine or unexpected stalling during operation. These problems can often be traced back to fuel delivery issues or battery performance. Regular checks of the fuel lines for blockages, along with ensuring the battery is charged and connections are secure, are essential steps to troubleshooting.

Where to Find Replacement Parts

Maintaining the longevity and performance of your equipment often requires sourcing suitable components. Identifying the right outlets for these essentials can significantly impact the upkeep of your machinery.

There are several effective methods to locate the necessary components:

- Authorized Dealers: These establishments typically offer genuine replacements, ensuring compatibility and reliability.

- Online Retailers: Numerous websites specialize in machinery components, providing a wide selection and convenient shipping options.

- Local Hardware Stores: Many community stores stock various essential items, and staff can assist in finding specific solutions.

- Salvage Yards: For those looking to save costs, salvage yards can be a treasure trove of usable items at reduced prices.

- Manufacturer’s Website: Checking the official website of the machinery’s producer can lead to a comprehensive catalog of available components.

When searching for the appropriate elements, consider factors such as quality, warranty, and customer service to ensure a satisfactory purchase experience.

Resources for Repair Guides

Finding the right materials for maintenance and repair tasks can significantly enhance your understanding and efficiency. Various resources are available to assist individuals in troubleshooting and fixing their equipment effectively. Utilizing these guides not only saves time but also promotes the longevity of your machinery.

Online Manuals and Tutorials

Numerous websites offer comprehensive manuals and step-by-step tutorials, providing valuable insights into the maintenance process. These resources often include visual aids, such as diagrams and images, which can make complex repairs more accessible. Utilizing such online platforms can empower users to carry out repairs with confidence.

Community Forums and Support Groups

Engaging with online communities can be an excellent way to gain knowledge and support. Many enthusiasts and professionals share their experiences, tips, and solutions to common issues. Participating in these forums allows individuals to ask questions and receive guidance from others who have faced similar challenges, fostering a collaborative environment for learning.