Maintaining your lawn care equipment is essential for optimal performance and longevity. A thorough understanding of the individual elements that contribute to its operation can enhance your ability to troubleshoot issues and perform necessary repairs. This section aims to provide clarity on the various components that make up the cutting apparatus, allowing for more informed maintenance decisions.

Identifying the Key Elements is crucial for ensuring your machine operates smoothly. By familiarizing yourself with the specific parts and their functions, you can effectively diagnose problems and identify the correct replacements when needed. This knowledge not only helps in maintaining efficiency but also extends the lifespan of your equipment.

Furthermore, having access to a detailed illustration of the assembly allows for easier reference during repairs and servicing. Such resources empower you to take a proactive approach to equipment upkeep, ensuring that each component is functioning as intended. In the following sections, you will find essential information that guides you through understanding and caring for your mower’s cutting assembly.

Toro Timecutter Overview

This section provides a comprehensive look at a popular line of riding mowers designed for efficient lawn care. These machines are built for both residential and commercial use, offering reliability and ease of operation.

- Powerful engine options for optimal performance

- Compact design for maneuverability in tight spaces

- Durable construction for long-lasting use

- Advanced features for user comfort and convenience

With a focus on functionality, these mowers ensure a clean and precise cut, making them ideal for maintaining a beautiful lawn.

Understanding the 50-Inch Deck

When it comes to maintaining your outdoor space, the efficiency of your cutting mechanism plays a vital role. The 50-inch width offers a balance between maneuverability and coverage, making it suitable for various lawn sizes. This segment will explore the components and features that contribute to its performance and longevity.

Key Components

Several essential elements work together to ensure optimal operation. Each component contributes to the overall functionality, making it important to understand their roles.

| Component | Function |

|---|---|

| Blades | Provide the cutting action necessary for an even trim. |

| Spindles | House the blades and facilitate their rotation. |

| Deck Shell | Supports the entire assembly and protects components. |

| Wheels | Assist in maneuvering the unit across varying terrains. |

Maintenance Tips

Regular upkeep is essential for maintaining the effectiveness of your cutting equipment. Periodic checks on blade sharpness, lubrication of moving parts, and cleaning of debris are crucial steps. Staying proactive with maintenance can extend the lifespan and ensure optimal performance during each use.

Key Components of the Mower

Understanding the essential elements of a mowing machine is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance and longevity, contributing to the overall efficiency of the equipment.

The cutting blades are vital for achieving a clean and even trim, while the engine provides the necessary power for operation. The chassis supports all components and influences maneuverability. Additionally, the drive system, including belts and wheels, is responsible for motion, enabling the machine to navigate various terrains effortlessly.

Moreover, the fuel system ensures that the engine runs smoothly, while the control mechanisms allow the operator to steer and adjust settings with ease. Regular inspection of these key components can prevent issues and enhance the ultimate functionality of the mower.

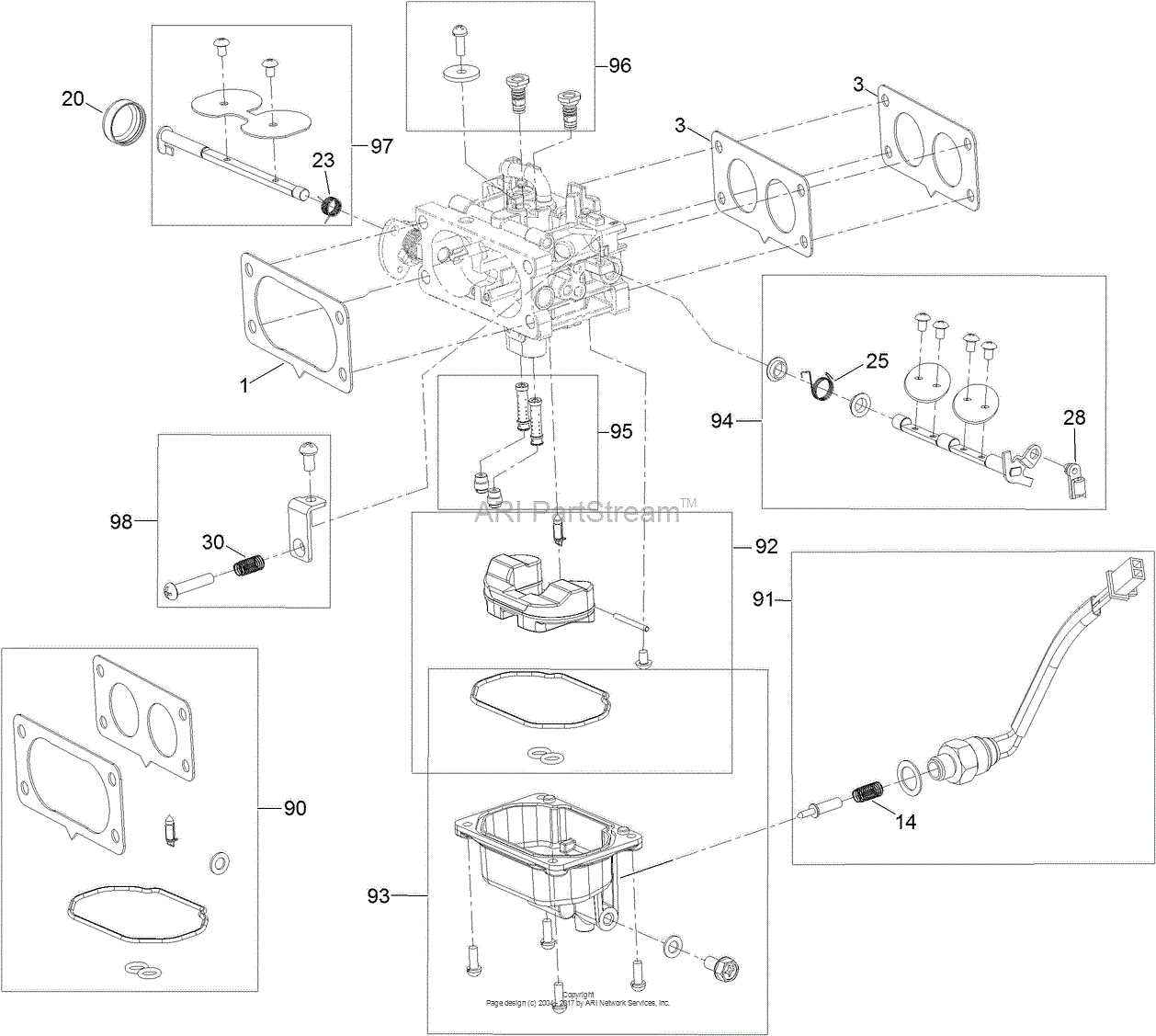

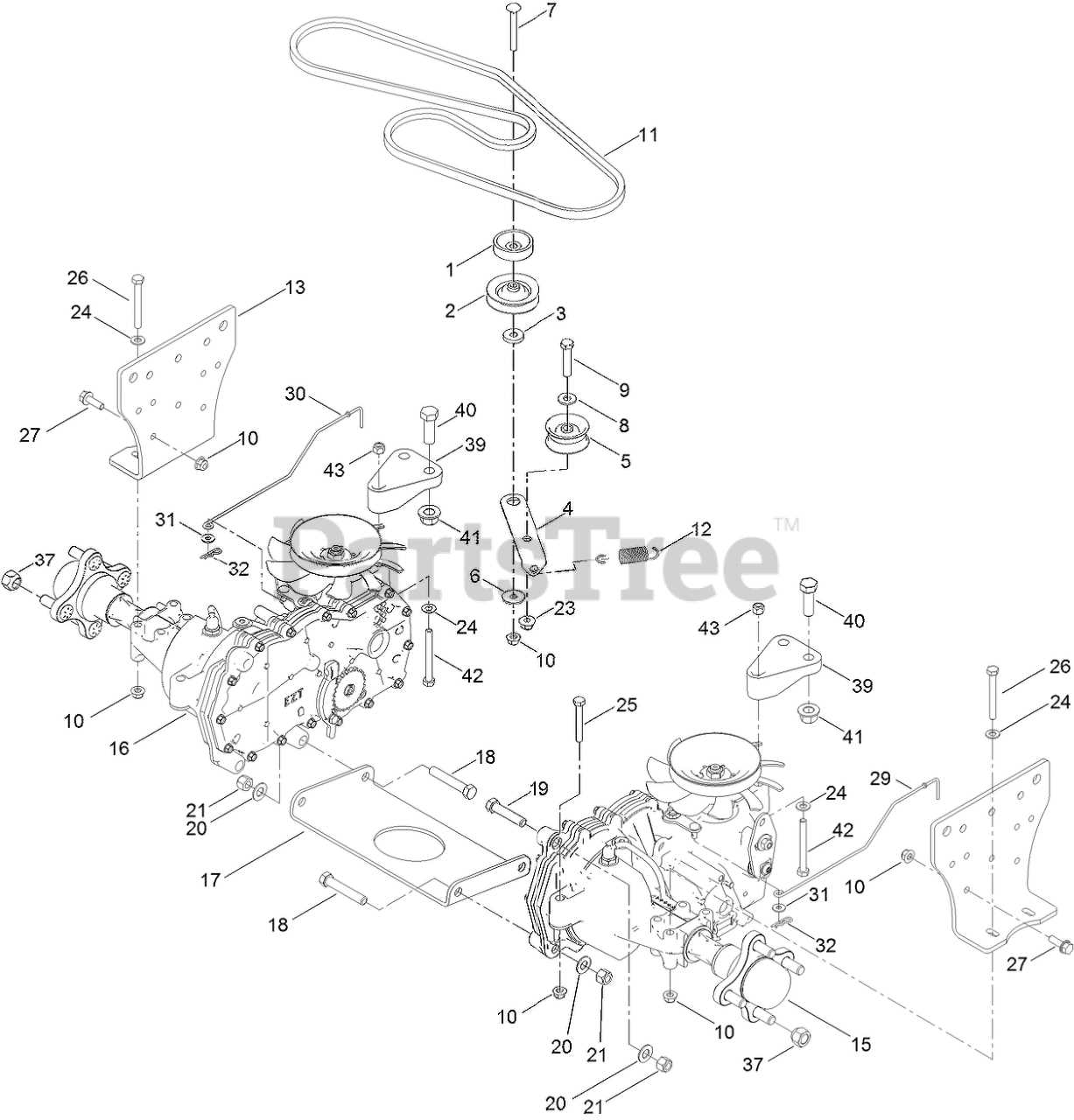

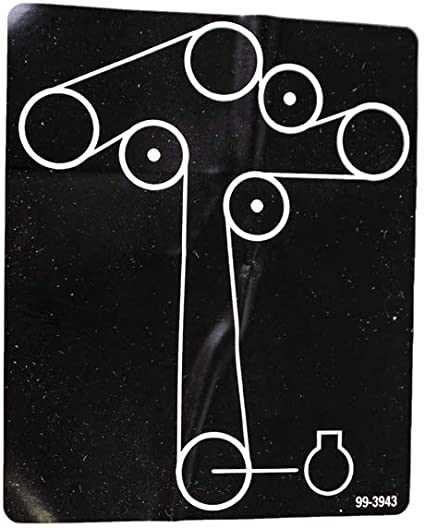

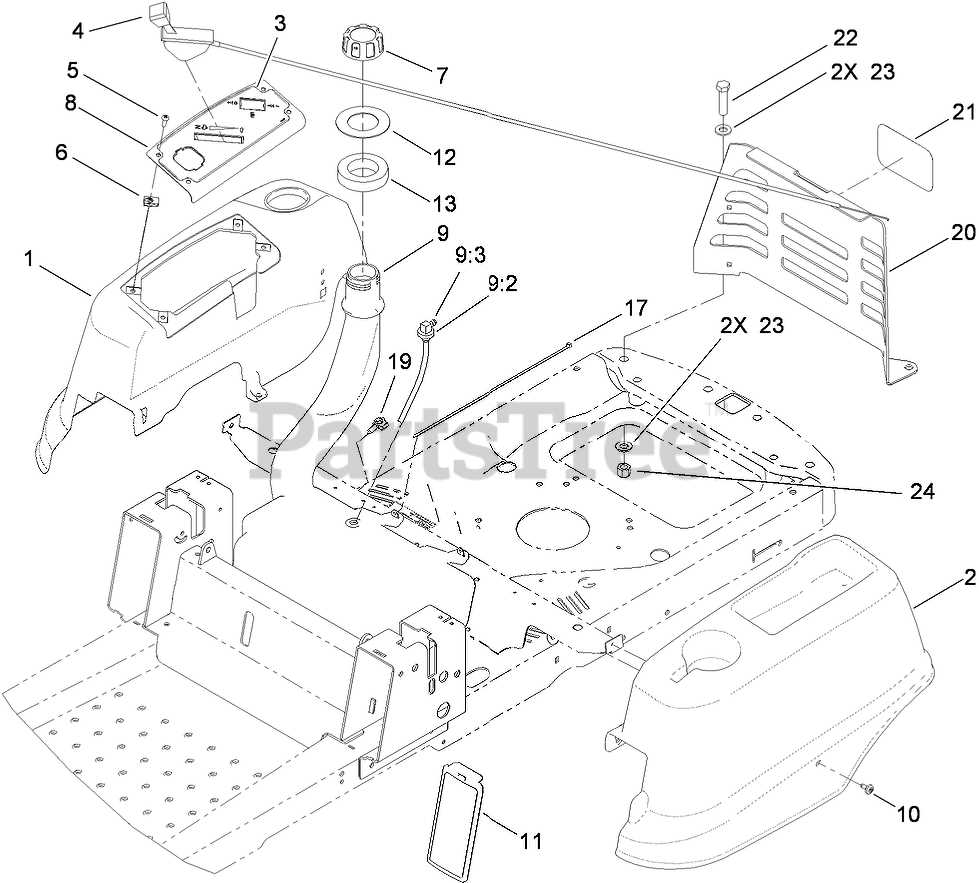

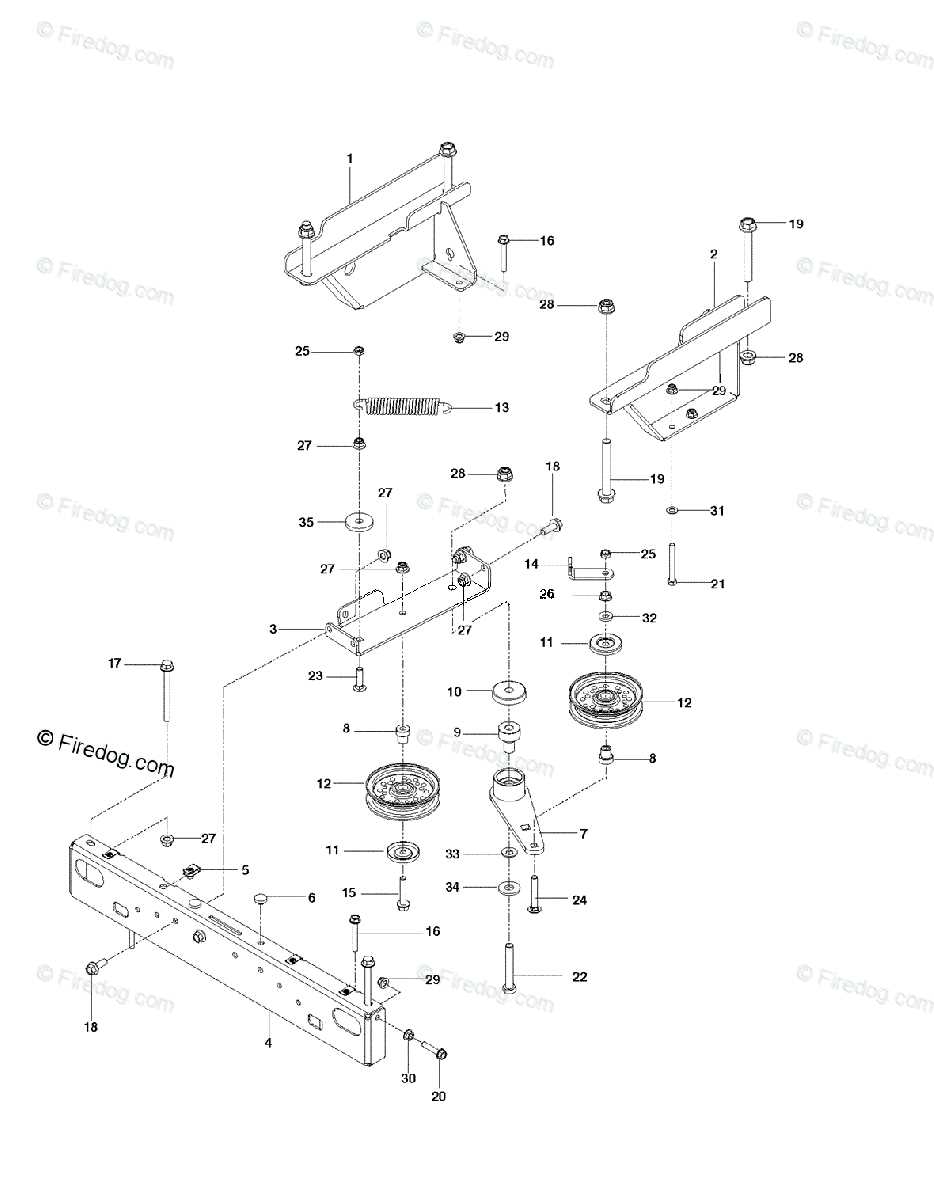

Parts Diagram Explained

Understanding the layout of components is essential for effective maintenance and repair. A visual representation serves as a valuable tool, enabling users to identify each element and its function. This clarity aids in troubleshooting and ensures that all necessary parts are accounted for during servicing.

Importance of Visual Representation

A graphical overview simplifies the complex interrelations between various components. By breaking down the assembly into understandable sections, it allows both novice and experienced users to navigate through the system with confidence. This approach minimizes confusion and enhances efficiency in repairs.

Key Components Overview

| Component | Description |

|---|---|

| Blade | Essential for cutting grass, available in different styles for various mowing needs. |

| Spindle | Holds the blade in place, enabling smooth rotation and effective cutting. |

| Chassis | The main frame that supports all other components and provides stability. |

| Wheel Assembly | Enables movement and maneuverability, crucial for navigating different terrains. |

| Engine | Powers the entire system, with various specifications depending on performance needs. |

Common Issues and Solutions

This section addresses frequent challenges encountered with lawn maintenance equipment, offering practical solutions to enhance performance and longevity.

Engine Performance Problems

- Hard Starting: Check the fuel level, battery condition, and spark plug. Replace any faulty components.

- Uneven Power: Inspect the air filter and ensure it’s clean. Clean or replace as needed.

Mowing Efficiency Issues

- Clumping Grass: Adjust the cutting height and ensure blades are sharp.

- Streaking: Regularly check and maintain the blade alignment to ensure even cuts.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your mowing equipment requires regular attention and care. Implementing a routine maintenance schedule can significantly extend the lifespan of your machine and enhance its performance. Here are some essential tips to keep your mower in optimal condition.

- Regular Cleaning: After each use, remove grass clippings and debris from the exterior and undercarriage to prevent buildup and rust.

- Oil Changes: Check and change the engine oil periodically, following the manufacturer’s recommendations, to ensure smooth operation.

- Sharpen Blades: Keep blades sharp for a cleaner cut. Dull blades can tear grass, making it more susceptible to disease.

- Check Air Filters: Clean or replace air filters regularly to maintain optimal airflow and engine performance.

- Tire Maintenance: Ensure tires are properly inflated and in good condition to promote even cutting and reduce wear.

- Inspect Belts and Cables: Regularly check for wear and tear. Replace any damaged components to prevent breakdowns.

- Store Properly: When not in use, store the equipment in a dry, sheltered area to protect it from the elements.

By following these maintenance practices, you can maximize the efficiency and lifespan of your mowing equipment, ensuring a well-groomed lawn for years to come.

Where to Find Replacement Parts

Locating suitable components for your machinery can be crucial for maintaining optimal performance. Understanding where to search for reliable resources can save you time and ensure you get the right items for your needs.

Authorized Dealers

One of the most dependable options is to visit authorized retailers. They typically offer a wide selection of genuine components, ensuring compatibility and quality. Additionally, these sellers often provide expert advice to assist with your selection.

Online Marketplaces

Another convenient avenue is to explore online platforms. Websites specializing in machinery supplies frequently have extensive catalogs, often including user reviews and ratings. This information can help you make informed decisions when purchasing.

Installation Guide for New Parts

Installing new components can greatly enhance the performance of your machinery. This guide provides essential steps to ensure a seamless replacement process, allowing you to maintain optimal functionality and longevity.

Step 1: Before starting, gather all necessary tools and components. Ensure your workspace is clean and well-lit to avoid any mishaps during the installation.

Step 2: Disconnect the power source to ensure safety while working on the equipment. This step is crucial to prevent any accidental starts during the replacement.

Step 3: Carefully remove the old components by following the manufacturer’s guidelines. Take note of the arrangement and positioning for accurate reassembly.

Step 4: Position the new components as per the guidelines. Ensure that all fittings are secure and that no parts are left loose, which can lead to malfunctions.

Step 5: Once everything is in place, reconnect the power source. Perform a test run to verify that the installation was successful and that everything operates smoothly.

By following these steps, you can ensure that your machinery remains in excellent working condition, ready to tackle any task with ultimate efficiency.

Benefits of Regular Upkeep

Consistent maintenance is crucial for ensuring the longevity and efficiency of your equipment. By prioritizing upkeep, you can enhance performance and prevent unexpected failures that could lead to costly repairs.

Improved Performance: Regular checks and adjustments help maintain optimal functionality, allowing machinery to operate at its best.

Cost Efficiency: Investing time in routine maintenance can reduce long-term expenses by avoiding major breakdowns and repairs.

Safety Assurance: Keeping your equipment in top shape minimizes the risk of accidents, providing a safer working environment.

Increased Lifespan: Well-maintained machinery tends to last longer, maximizing your investment and productivity over time.