The intricate mechanics of lawn care equipment play a vital role in maintaining the beauty and health of outdoor spaces. Familiarity with the various elements involved in these machines can significantly enhance their performance and longevity. This section aims to provide insights into the essential constituents that make up a renowned mower model.

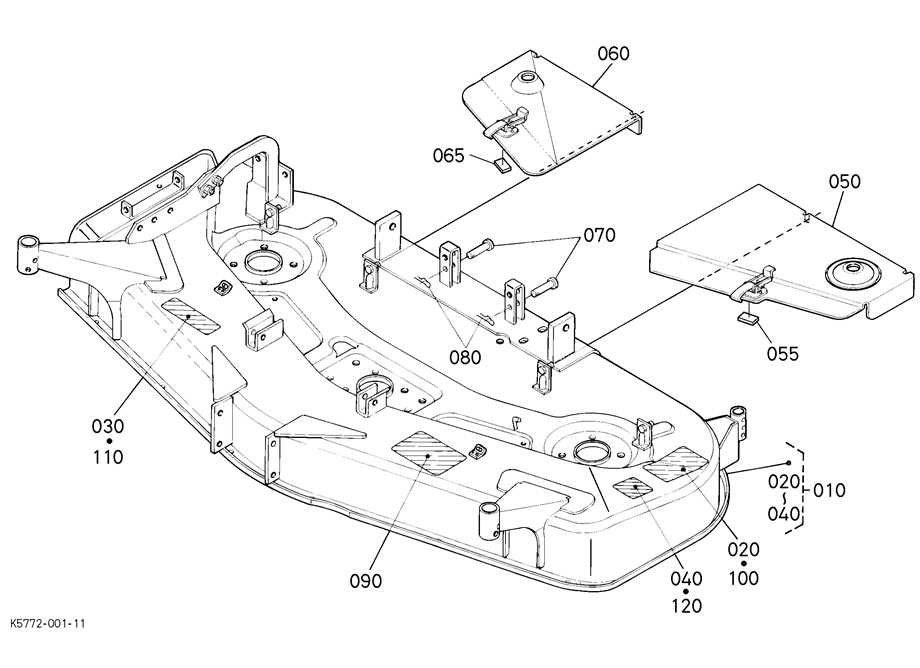

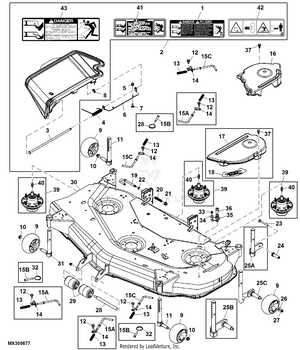

Having a clear visual representation of the individual components allows users to navigate through repairs and maintenance with greater ease. By exploring this intricate layout, one can ultimately improve efficiency and ensure the machinery operates at its best. Emphasizing the importance of understanding each part leads to more informed decision-making for both enthusiasts and professionals alike.

Additionally, recognizing how each piece fits into the larger system encourages a deeper appreciation for engineering excellence. This guide serves as a resource to delve into the specifics of maintenance and repair, empowering users to tackle challenges confidently and effectively.

Understanding the John Deere X324

This section provides a comprehensive overview of a popular garden equipment model designed for optimal performance and user-friendly operation. It highlights key features and functionalities that make this machine a favorite among homeowners and landscapers alike.

Known for its robust construction and advanced technology, this equipment ensures reliable operation across various tasks, from mowing to towing. Its ergonomic design and intuitive controls enhance the user experience, making maintenance and operation straightforward.

With a focus on efficiency and versatility, this model incorporates innovative components that contribute to its durability and effectiveness. Understanding the layout and function of each element can significantly aid in proper care and troubleshooting, ultimately extending the lifespan of the equipment.

In summary, familiarity with the intricacies of this machine not only aids in its operation but also enhances the overall gardening experience, ensuring that tasks are completed with ease and precision.

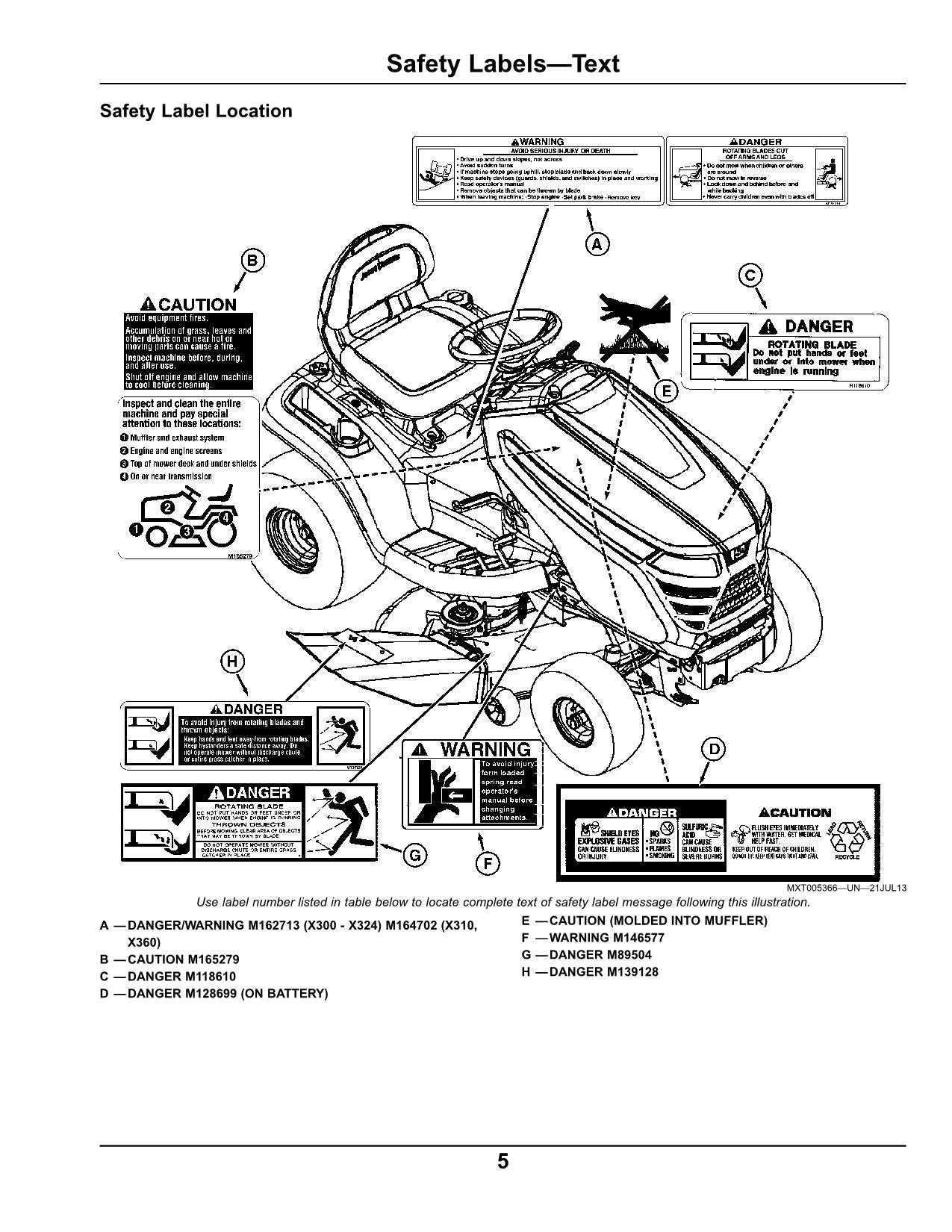

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements provide clarity and assist in identifying specific pieces needed for servicing. By utilizing these illustrative guides, users can ensure that they select the correct items and perform tasks with greater accuracy.

Enhanced Efficiency

When tackling repairs, having a visual reference can significantly reduce time spent searching for the right components. These illustrations streamline the process, allowing for quicker identification and procurement of necessary items. This efficiency translates to reduced downtime and improved productivity.

Improved Understanding

Visual aids also enhance comprehension of complex assemblies. By breaking down intricate structures into easily understandable parts, users can grasp how each element fits into the whole. This deeper understanding not only aids in repairs but also fosters a greater appreciation for the machinery’s functionality.

Common Issues with the X324

When operating a high-performance lawn tractor, several challenges may arise that can impact efficiency and usability. Understanding these common complications can help users maintain their equipment effectively and enhance their overall experience.

Electrical System Problems

One of the frequent issues encountered involves the electrical system. Symptoms may include failure to start or intermittent power loss during operation. These problems can often be traced back to the battery, wiring connections, or the ignition switch. Regular inspection and maintenance of these components can prevent many electrical failures.

Mechanical Failures

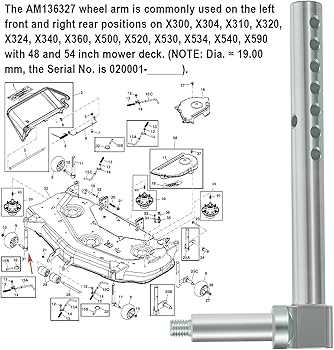

Mechanical breakdowns are another area of concern. Users might experience problems such as uneven cutting or difficulty steering. Such issues can arise from worn-out blades, malfunctioning drive belts, or issues with the transmission system. Timely replacement of worn parts and adherence to maintenance schedules can mitigate these mechanical challenges.

Where to Find Parts Diagrams

Locating detailed illustrations of components for machinery is crucial for efficient maintenance and repairs. These visual aids provide essential information on the arrangement and specifications of each element, ensuring that users can easily identify what they need. Several reliable resources are available to help enthusiasts and professionals find these valuable references.

Official Manufacturer Resources

One of the best places to start is the official website of the manufacturer. Most companies offer an online portal where users can access a variety of materials, including detailed visuals and technical documentation. By entering the model number, individuals can quickly retrieve the necessary resources, making it easier to locate specific elements needed for repairs.

Online Forums and Community Groups

Another effective approach is to explore online forums and community groups dedicated to machinery enthusiasts. These platforms often have dedicated sections for sharing information, including links to illustrations and other useful resources. Members frequently post helpful tips and can assist in finding hard-to-locate references, ensuring that everyone can keep their equipment in top condition.

Benefits of Using Original Parts

Utilizing components that are specifically designed for your equipment ensures optimal performance and longevity. These authentic elements provide superior reliability and compatibility, enhancing the overall efficiency of your machinery.

Enhanced Performance

Original components are crafted to meet precise specifications, leading to improved functionality. By choosing these items, users can expect consistent performance, reducing the likelihood of malfunctions.

Cost-Effectiveness

While initial costs may be higher, the durability of genuine items often results in lower long-term expenses. Investing in quality reduces the frequency of replacements and repairs, ultimately saving money over time.

Maintenance Tips for X324 Owners

Proper upkeep is essential for maximizing the performance and longevity of your lawn care equipment. Regular checks and preventive measures can help you avoid costly repairs and ensure optimal functionality throughout the season.

Start with routine inspections of the engine and electrical systems. Keeping the spark plugs clean and the battery charged will contribute significantly to reliable operation. Additionally, make sure to replace filters and fluids at recommended intervals to maintain efficiency.

Blade sharpness is crucial for a clean cut. Regularly inspect and sharpen the blades, as well as check for any wear or damage. This not only enhances performance but also promotes healthier grass growth.

Don’t forget about the wheels and tires. Ensure they are properly inflated and free from debris, as this will improve maneuverability and reduce wear. Regularly check the belts and cables for signs of wear and replace them as needed.

Lastly, clean your equipment after each use to prevent buildup of grass and dirt, which can lead to corrosion and mechanical issues. Following these simple yet effective maintenance tips will keep your machine running smoothly for years to come.

Upgrades and Modifications Available

Enhancing your machine can significantly improve its performance and functionality. Various upgrades and modifications are available to tailor it to your specific needs and preferences.

- Engine Enhancements: Consider performance kits for increased power.

- Transmission Improvements: Upgrade to a more efficient transmission for smoother operation.

- Attachment Options: Explore various attachments for added versatility in tasks.

- Comfort Features: Add ergonomic seats or improved steering wheels for a better driving experience.

- Lighting Systems: Install upgraded lighting for improved visibility during low-light conditions.

Each modification offers unique advantages, allowing users to delve deeper into maximizing their machine’s capabilities.

Contacting Customer Support for Assistance

When facing challenges with your equipment, reaching out for help can provide the ultimate resolution. Customer support teams are equipped to address inquiries, offer solutions, and guide you through any difficulties you may encounter. It’s essential to know how to effectively communicate your needs to receive the best assistance possible.

Before contacting support, gather all relevant information about your issue. This includes model numbers, descriptions of the problem, and any troubleshooting steps you’ve already taken. Having this information at hand will enable the representatives to assist you more efficiently and swiftly.

Support can typically be reached through various channels, including phone, email, or live chat. Choose the method that best fits your preferences. Many companies also provide online resources, such as FAQs and troubleshooting guides, which can be beneficial before initiating direct contact.

Be patient and courteous during your interaction. Customer support representatives are there to help, and a positive approach can foster a more productive dialogue. Take notes during your conversation to ensure you don’t miss any important details or recommendations they provide.

Lastly, if the initial contact doesn’t resolve your issue, don’t hesitate to follow up. Persistence can lead to a satisfactory outcome, and your feedback helps improve services for everyone.