The realm of aerial machinery is both fascinating and complex, encompassing various mechanisms that enable users to access heights safely and efficiently. Within this landscape, a thorough comprehension of each element’s function and relationship to the overall system is crucial for optimal operation and maintenance.

Having a clear visual representation of these elements can significantly enhance one’s ability to troubleshoot and perform necessary repairs. By exploring the intricate layout of these components, operators can ensure that their equipment remains in peak condition, minimizing downtime and maximizing productivity.

In this discussion, we will delve into the essential features that constitute these specialized devices. Understanding how each piece interconnects not only aids in effective usage but also fosters a deeper appreciation for the engineering behind these remarkable machines.

Nifty Lift Parts Overview

This section provides a comprehensive examination of the various components essential for efficient operation and maintenance of aerial work platforms. Understanding these elements is crucial for ensuring safety and optimal functionality.

| Component | Description |

|---|---|

| Hydraulic System | Enables the movement and stability of the structure during use. |

| Chassis | The base framework that supports the entire system and provides mobility. |

| Platform | Where operators stand while performing tasks at height, designed for safety and accessibility. |

| Control System | Allows users to operate the machinery efficiently and safely. |

| Safety Features | Includes mechanisms such as guardrails and emergency stop buttons to enhance operator security. |

Understanding Nifty Lift Components

Grasping the intricacies of aerial work platforms involves an appreciation for their essential elements. These components work in harmony to ensure safe and efficient operation, allowing users to access elevated spaces with confidence. A thorough understanding of each element enhances both maintenance and functionality.

Power Source: The energy source is crucial, providing the necessary force to operate the machine. Common options include electric and diesel engines, each suited for different environments and applications.

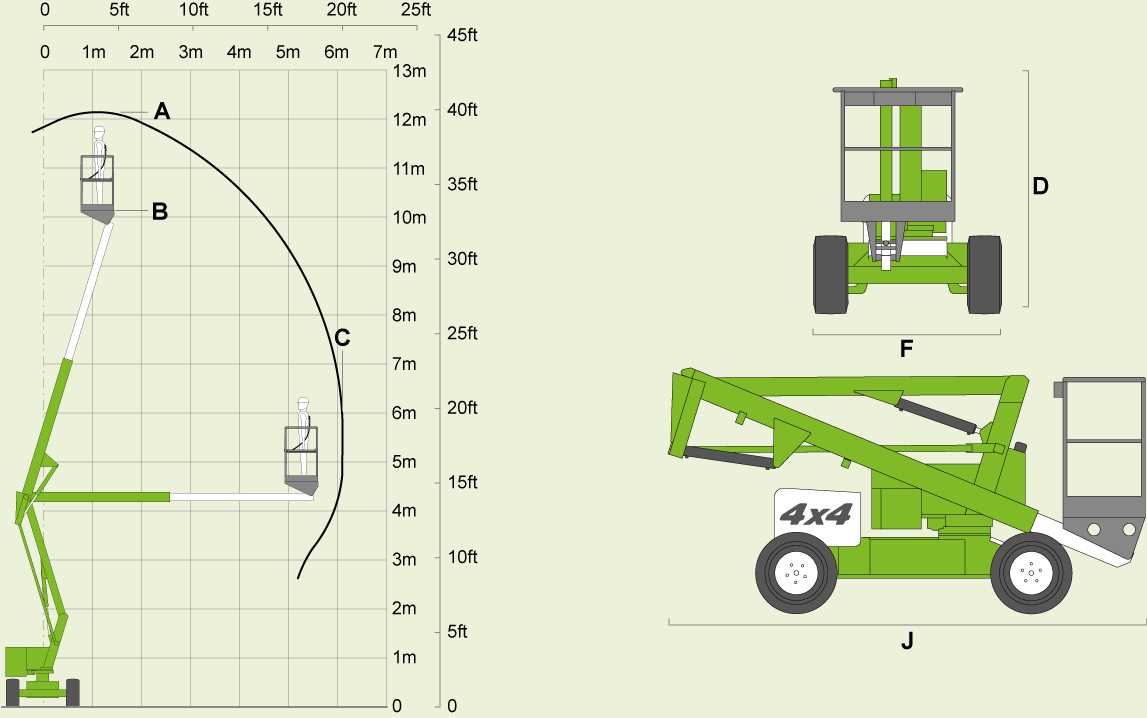

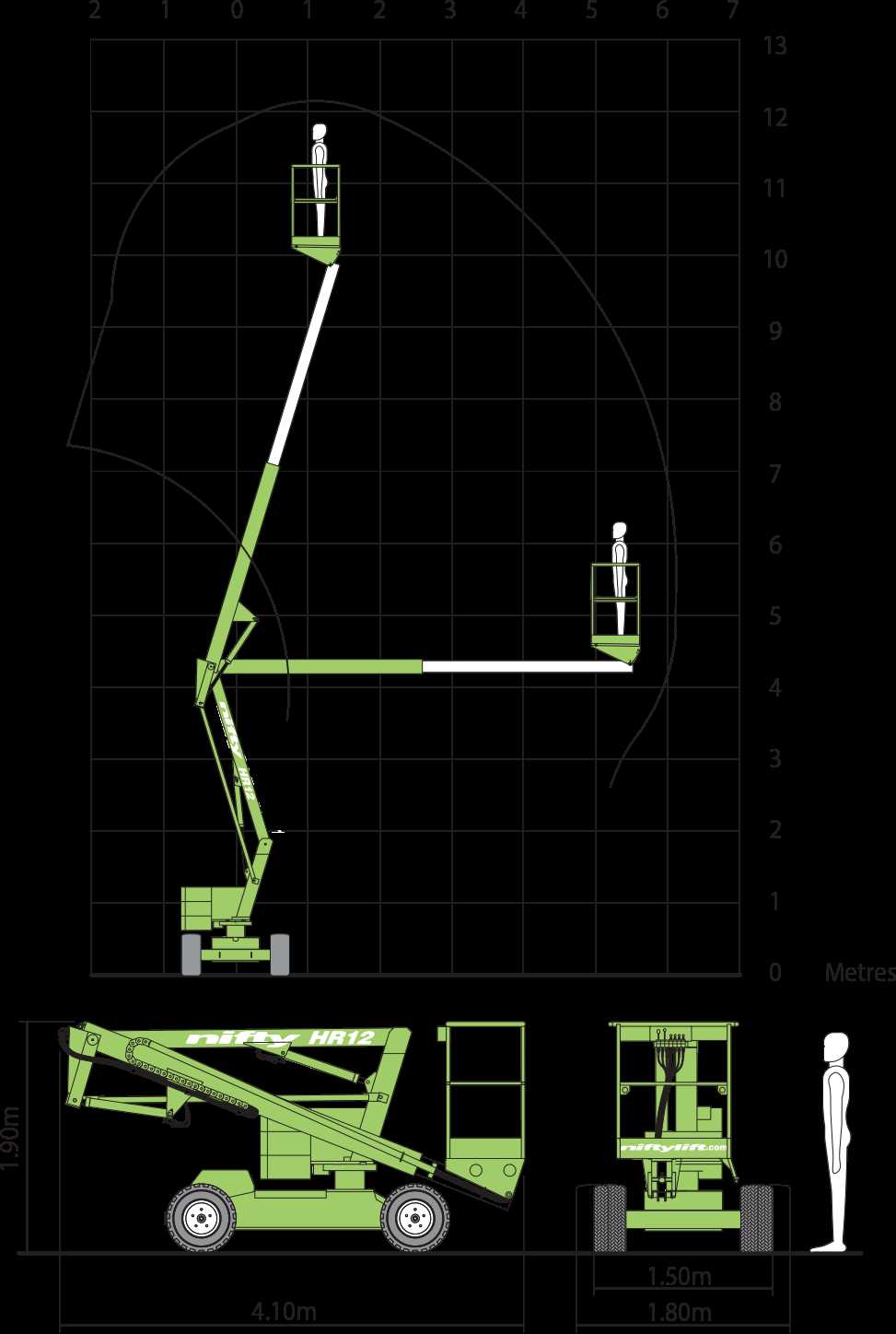

Boom: The extending arm is a vital feature, enabling vertical and horizontal reach. Its design affects the machine’s flexibility and operational height, catering to various job requirements.

Platform: The workspace is where operators conduct tasks. Safety features, such as guardrails and non-slip surfaces, are essential to protect users while they work at height.

Controls: The interface allows for precise maneuvering of the machine. User-friendly controls enhance efficiency and safety, ensuring that operators can easily navigate the platform’s functions.

Stabilizers: These elements provide balance, especially on uneven terrain. They are essential for maintaining stability during operation, minimizing the risk of accidents.

Understanding these fundamental components fosters a deeper appreciation for the equipment’s design and enhances operational safety, ultimately leading to more effective work practices in elevated environments.

Importance of Accurate Diagrams

Precise representations are essential in any technical field, serving as vital tools for understanding complex systems. These illustrations not only convey intricate details but also facilitate communication among professionals. By offering a clear visual reference, they enable users to grasp functionality and relationships more effectively.

Clarity is one of the primary advantages of accurate representations. When individuals have access to detailed visuals, it minimizes misunderstandings and errors during assembly or maintenance tasks. This leads to enhanced safety and operational efficiency, as all stakeholders can follow a unified understanding of the system.

Moreover, accurate visuals contribute to effective training and onboarding processes. New employees or technicians benefit significantly from well-crafted illustrations, allowing them to quickly familiarize themselves with equipment or processes. This not only reduces the learning curve but also helps maintain consistency in practices across the organization.

Additionally, the use of reliable visuals can streamline troubleshooting efforts. When problems arise, having a comprehensive reference aids in diagnosing issues swiftly and accurately. This can lead to quicker resolutions, minimizing downtime and associated costs.

In conclusion, the significance of precise representations cannot be overstated. They are indispensable for effective communication, training, and problem-solving within any technical domain.

Common Issues with Nifty Lifts

In the realm of elevated work platforms, users often encounter a range of challenges that can affect performance and safety. Understanding these common complications is crucial for effective troubleshooting and maintenance. This section highlights prevalent problems that operators may face, along with suggested solutions to enhance reliability and efficiency.

Hydraulic System Failures

One of the most significant issues observed involves the hydraulic mechanisms. When these systems malfunction, they can lead to inadequate power or complete loss of functionality. Common signs include leaks, unusual noises, or slow movement.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Fluid Leaks | Worn seals, damaged hoses | Inspect and replace seals and hoses |

| Slow Operation | Low fluid levels, air in the system | Check fluid levels and bleed the system |

| Unusual Noises | Contaminated fluid, mechanical wear | Change the hydraulic fluid and check components |

Electrical Malfunctions

Another frequent complication relates to the electrical systems. Problems in wiring or control panels can lead to operational failures. Indicators include erratic movements or the inability to power on.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Inconsistent Power | Faulty batteries, damaged wiring | Test batteries and inspect wiring for damage |

| Control Failure | Defective switches, poor connections | Examine and replace defective switches |

| Safety Alarm Issues | Malfunctioning sensors, electrical shorts | Check sensors and repair electrical connections |

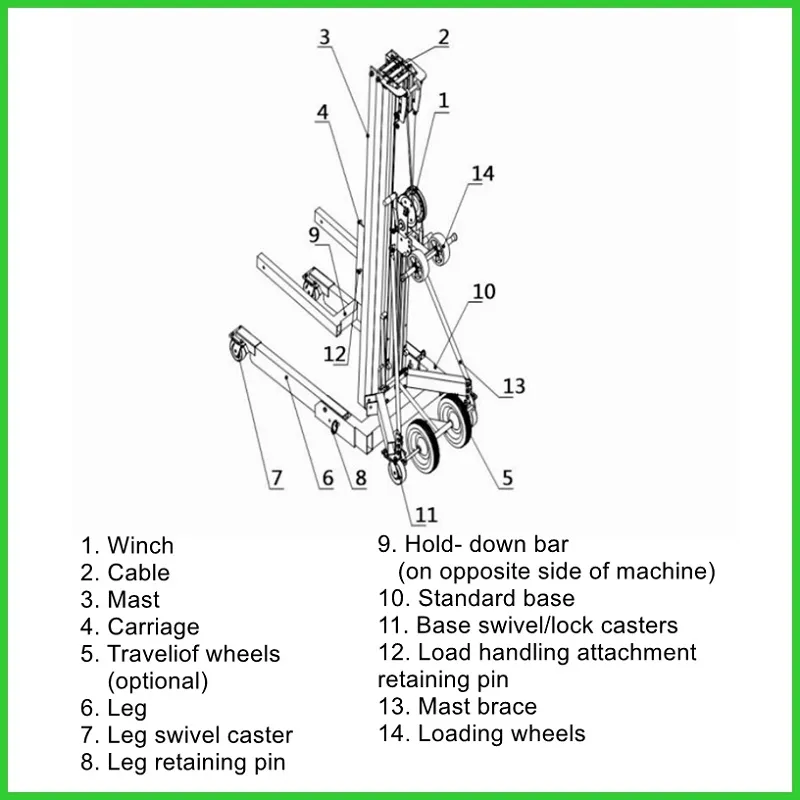

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations offer a clear view of components, allowing users to identify individual elements and their interconnections. Mastering how to interpret these illustrations can enhance troubleshooting efficiency and facilitate smoother assembly processes.

Familiarizing with Symbols and Notations

Each illustration uses specific symbols and notations to convey information about various elements. Before diving into the details, take time to familiarize yourself with the legend or key that explains what each symbol represents. This will serve as your roadmap and ensure that you accurately interpret the information presented.

Identifying Key Components

Once you understand the symbols, focus on identifying key elements within the illustration. Pay attention to the labels and numbers that correspond to parts lists or catalogs. This cross-referencing can help you locate the correct components quickly, saving valuable time during repairs or maintenance tasks.

Finding Replacement Parts Efficiently

Locating the necessary components for maintenance or repair can often be a daunting task. Understanding the various resources available and employing effective strategies can significantly streamline the process. Whether you are a professional technician or a DIY enthusiast, knowing where to look and how to approach your search is essential for timely and cost-effective solutions.

Utilizing Online Resources

The internet provides a wealth of information that can aid in your search for components. Various websites specialize in supplying a wide range of items, often accompanied by detailed specifications and user reviews. Engaging with forums and communities dedicated to your specific equipment can also yield valuable insights and recommendations.

Organizing Information

When searching for items, keeping your findings organized can save time and effort. Creating a list with key details about each required component will help you track your progress and avoid duplication. Below is a sample table to illustrate how to document your search effectively:

| Component Name | Model Number | Supplier | Price | Availability |

|---|---|---|---|---|

| Hydraulic Cylinder | HC-123 | Supplier A | $150 | In Stock |

| Control Module | CM-456 | Supplier B | $200 | Pre-Order |

| Safety Switch | SS-789 | Supplier C | $75 | In Stock |

By adopting these practices, you can enhance your ability to find essential components quickly and efficiently, ensuring that your projects remain on track.

Maintenance Tips for Nifty Lifts

Ensuring the longevity and optimal performance of your aerial work platform requires regular upkeep and attention to detail. By implementing a few essential maintenance strategies, you can significantly enhance the safety and efficiency of your equipment.

Start with a routine inspection to identify any wear or damage. Check the hydraulic systems for leaks, ensure all connections are secure, and verify that safety features are fully operational. Pay special attention to the control systems, as any malfunction can lead to operational hazards.

Regularly clean the machinery to prevent dirt and debris buildup, which can affect performance. Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and prolong component life.

Additionally, schedule periodic professional servicing to address any underlying issues that may not be visible during routine checks. Keeping an accurate maintenance log can also help track service intervals and ensure that all necessary tasks are completed on time.

Lastly, educate all operators on proper usage and safety protocols to reduce the likelihood of misuse and potential damage. A well-informed team is key to maintaining the functionality of your equipment.

Resources for Parts and Support

When it comes to maintaining and servicing your equipment, having access to reliable resources is crucial. This section aims to provide you with essential information for sourcing components and obtaining support for your machinery.

Here are some key resources to consider:

- Manufacturer Websites: Many companies offer comprehensive online platforms where you can find technical specifications, maintenance manuals, and contact information for customer service.

- Authorized Dealers: Connecting with certified distributors ensures you receive genuine components and expert guidance tailored to your needs.

- Online Forums: Engaging with communities of professionals can provide invaluable insights and recommendations for troubleshooting and sourcing supplies.

Additionally, consider exploring the following options:

- Local Service Centers: These establishments often have trained technicians who can assist with repairs and provide advice on best practices.

- Parts Catalogs: Detailed catalogs can help you identify the specific components you require for efficient replacements.

- Support Hotlines: Many manufacturers offer dedicated support lines for immediate assistance, ensuring you can resolve issues quickly.

By utilizing these resources, you can enhance the longevity and performance of your machinery, ensuring smooth operation for years to come.