In the realm of commercial refrigeration, a detailed visual representation of the essential elements is crucial for both maintenance and effective operation. This section aims to provide insights into the various components that make up these machines, allowing users to enhance their understanding of how each part functions together. Familiarity with these components not only aids in troubleshooting but also ensures optimal performance in producing frozen products.

Recognizing the layout and relationships between the different elements within the system can significantly simplify repair processes and parts replacement. Each unit’s efficiency often depends on the precise interaction of its components. By grasping this intricate network, users can better appreciate the importance of regular maintenance and timely interventions when issues arise.

Equipped with this knowledge, operators will find it easier to diagnose problems and make informed decisions regarding repairs and upgrades. A thorough comprehension of the individual elements involved empowers users to keep their machines running smoothly and efficiently, ultimately leading to improved productivity and service delivery.

Importance of Parts Diagrams

Understanding the layout of components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, enabling technicians to identify each element’s location and function. These illustrations simplify complex systems, making it easier to troubleshoot issues and perform necessary replacements.

Benefits of Visual Representations

- Clarity: Clear illustrations help users grasp intricate designs, reducing the likelihood of errors during repairs.

- Efficiency: Quick identification of components leads to faster maintenance and reduced downtime.

- Training Aid: Visual guides serve as valuable resources for training new technicians, ensuring they understand equipment layouts from the outset.

Facilitating Communication

Visual aids enhance communication among team members. When discussing repairs or modifications, referring to these guides ensures everyone is on the same page. This shared understanding is vital for collaborative efforts, particularly in complex projects.

- Promotes teamwork and efficiency.

- Reduces misunderstandings and mistakes.

- Improves overall operational effectiveness.

Common Ice-o-matic Models Explained

This section provides an overview of widely recognized models within the ice-making equipment industry, highlighting their unique features and functionalities. Understanding the various types of these machines can assist users in selecting the right option for their specific needs.

Model A: This variant is known for its compact design, making it ideal for smaller establishments. It efficiently produces a moderate volume of ice, suitable for bars and restaurants where space is limited yet demand is consistent.

Model B: Designed for larger venues, this model excels in high-volume production. Its robust construction ensures durability, while advanced technology optimizes energy consumption, making it a popular choice for busy kitchens.

Model C: This model stands out for its innovative ice-making process that minimizes waste. It is particularly favored by businesses focused on sustainability, as it balances efficiency with environmental responsibility.

Model D: Featuring a sleek design, this option is often incorporated into high-end dining establishments. It not only delivers quality ice but also complements the aesthetic of modern kitchens.

By exploring these different models, users can make informed decisions tailored to their operational requirements and preferences.

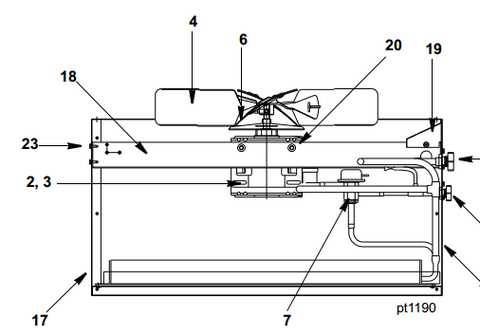

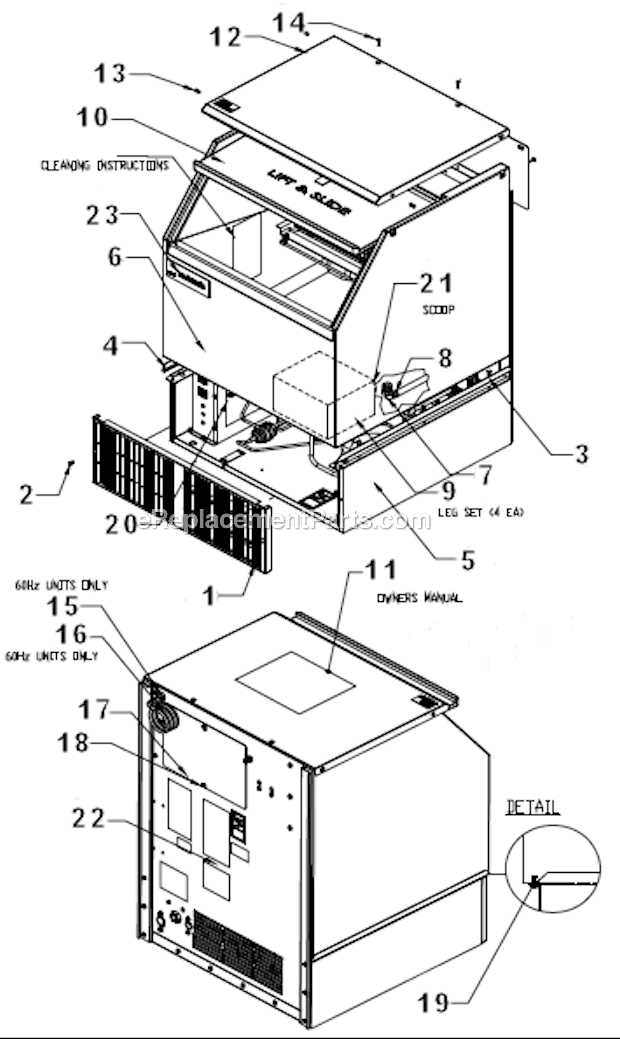

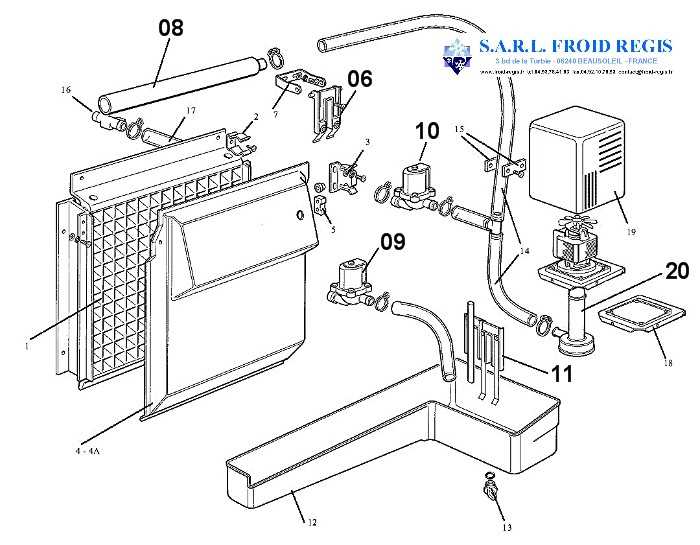

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repairs. These visual guides provide essential information, enabling users to identify components, comprehend their relationships, and facilitate the assembly or disassembly process.

Key Elements to Consider

- Labels and Annotations: Look for clear identifiers next to each component. These can include numbers, letters, or brief descriptions that indicate the part’s function or location.

- Visual Representation: Pay attention to how each element is portrayed. Different shapes or colors might signify various types of components or materials.

- Connection Points: Observe how parts are interconnected. Lines or arrows often indicate the manner in which elements fit together or interact.

Steps for Effective Interpretation

- Familiarize yourself with the key components and their designations.

- Identify the sequence of assembly or disassembly by following the visual cues provided.

- Consult the accompanying documentation for additional context and clarification on any complex aspects.

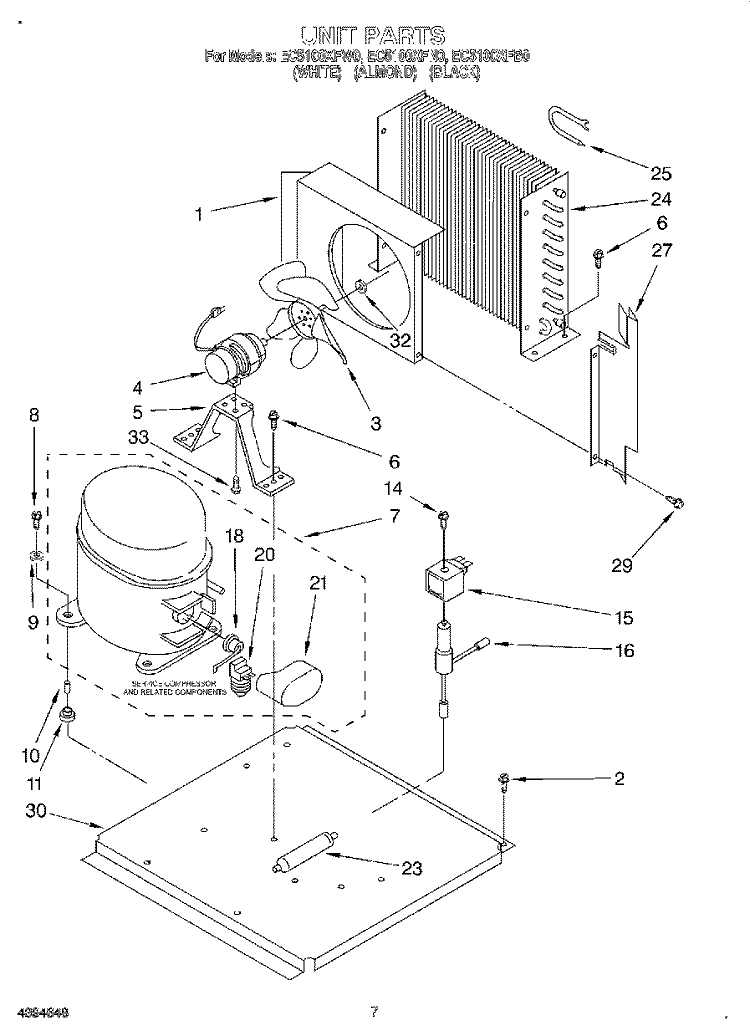

Identifying Key Components and Functions

Understanding the essential elements and their roles is crucial for effective maintenance and troubleshooting. Each component plays a significant part in the overall operation, contributing to efficiency and performance. Recognizing these elements can facilitate timely repairs and ensure optimal functionality.

Essential Elements Overview

Various parts work together harmoniously, each serving a distinct purpose. Familiarity with these components allows users to diagnose issues more accurately and perform necessary maintenance. Below is a summary of some key components along with their primary functions:

| Component | Function |

|---|---|

| Compressor | Circulates refrigerant, helping to maintain optimal temperatures. |

| Condenser | Removes heat from the refrigerant, enabling it to condense into liquid. |

| Evaporator | Absorbs heat from the environment, causing the refrigerant to evaporate. |

| Expansion Valve | Regulates the flow of refrigerant, allowing for pressure reduction and temperature control. |

| Fan | Enhances airflow, facilitating efficient heat exchange. |

Importance of Component Awareness

Awareness of each element’s function is vital for troubleshooting. Users can pinpoint the source of a malfunction more effectively, leading to quicker resolutions. Regular checks and familiarity with these components can prevent extensive downtime and ensure continued performance.

Maintenance Tips for Ice-o-matic Units

Regular upkeep is essential for ensuring the longevity and efficiency of your refrigeration equipment. By following a few straightforward practices, you can enhance performance and prevent potential issues. This section outlines crucial maintenance recommendations that can help keep your unit operating smoothly.

Regular Cleaning and Inspection

Consistent cleaning is vital to prevent the buildup of debris and residue, which can hinder functionality. Focus on areas such as the condenser coils and water reservoir, as these spots are prone to accumulation. Conduct routine inspections to identify any signs of wear or damage early, allowing for timely repairs.

Monitoring Performance

Pay attention to the unit’s performance indicators. Unusual noises, fluctuations in temperature, or changes in ice production can signal underlying problems. If you notice any discrepancies, it’s advisable to address them promptly to avoid more significant issues later.

Implementing these maintenance strategies will not only extend the lifespan of your equipment but also ensure it operates efficiently and reliably.

Where to Find Replacement Parts

Finding suitable components for your equipment can significantly enhance its longevity and efficiency. Various avenues can be explored to source the necessary items, ensuring you can restore functionality without hassle.

Here are some effective methods to locate the required components:

- Manufacturer’s Website: Check the official website for a dedicated section on replacement items, often featuring catalogs or search tools.

- Authorized Dealers: Reach out to certified distributors who may offer genuine products along with expert guidance on selection.

- Online Marketplaces: Explore platforms such as Amazon, eBay, or specialized websites where you can find a wide range of offerings from various sellers.

- Local Repair Shops: Visit nearby maintenance centers that may stock or order the specific items you need.

- Forums and Community Groups: Engage with online communities related to your equipment; members often share resources and recommendations for sourcing components.

By utilizing these resources, you can efficiently find the necessary items to ensure your equipment operates at its best. Be sure to verify compatibility and quality before making a purchase.

Common Issues and Solutions

When operating a commercial ice-making system, users may encounter various challenges that can affect performance and efficiency. Understanding these common complications and their corresponding solutions can significantly enhance the longevity and functionality of the equipment.

Frequent Complications

Several issues can arise during the use of an ice production unit. These can include inadequate ice production, unusual noises, and inconsistent ice quality. Identifying the root causes of these problems is essential for effective troubleshooting.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Insufficient ice production | Clogged water filter or low water supply | Check and clean the water filter; ensure adequate water supply. |

| Noisy operation | Worn-out compressor or loose components | Inspect and tighten loose parts; consider replacing the compressor. |

| Inconsistent ice quality | Dirty evaporator or improper water temperature | Clean the evaporator; monitor and adjust water temperature. |

Preventive Measures

To minimize the likelihood of experiencing these issues, regular maintenance and inspections are crucial. Implementing a routine maintenance schedule can help detect potential problems early, ensuring reliable operation and optimal ice production.

Resources for Further Learning

Enhancing your understanding of equipment maintenance and operation can be greatly facilitated by exploring a variety of resources. Whether you’re seeking in-depth manuals, instructional videos, or community forums, a wealth of information is available to aid your learning journey. Utilizing these resources can help you troubleshoot issues and optimize the performance of your machinery.

Online Manuals and Guides

Many manufacturers provide detailed manuals and guides on their official websites. These documents typically cover setup instructions, maintenance tips, and troubleshooting advice. Additionally, third-party websites often host a range of user-created content that can further complement your understanding.

Video Tutorials

Video platforms are rich with content that visually demonstrates various techniques and processes. Engaging with these tutorials can offer practical insights and real-world applications, making complex tasks easier to grasp. Channels dedicated to equipment and tool education often feature expert advice that can enhance your skill set.