Maintaining a high-performing lawn tractor requires a comprehensive grasp of its inner workings. The intricate system of mechanisms that contribute to its functionality can often be overwhelming. However, having a clear visual representation of these elements can significantly simplify the process of identification and repair.

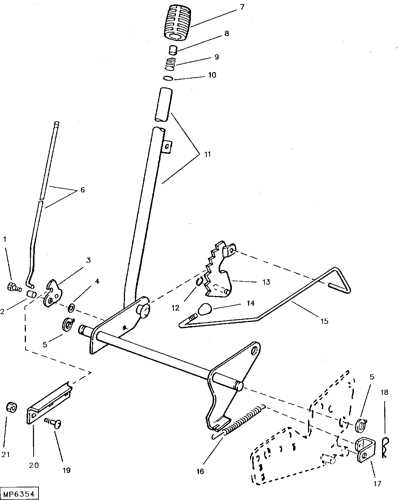

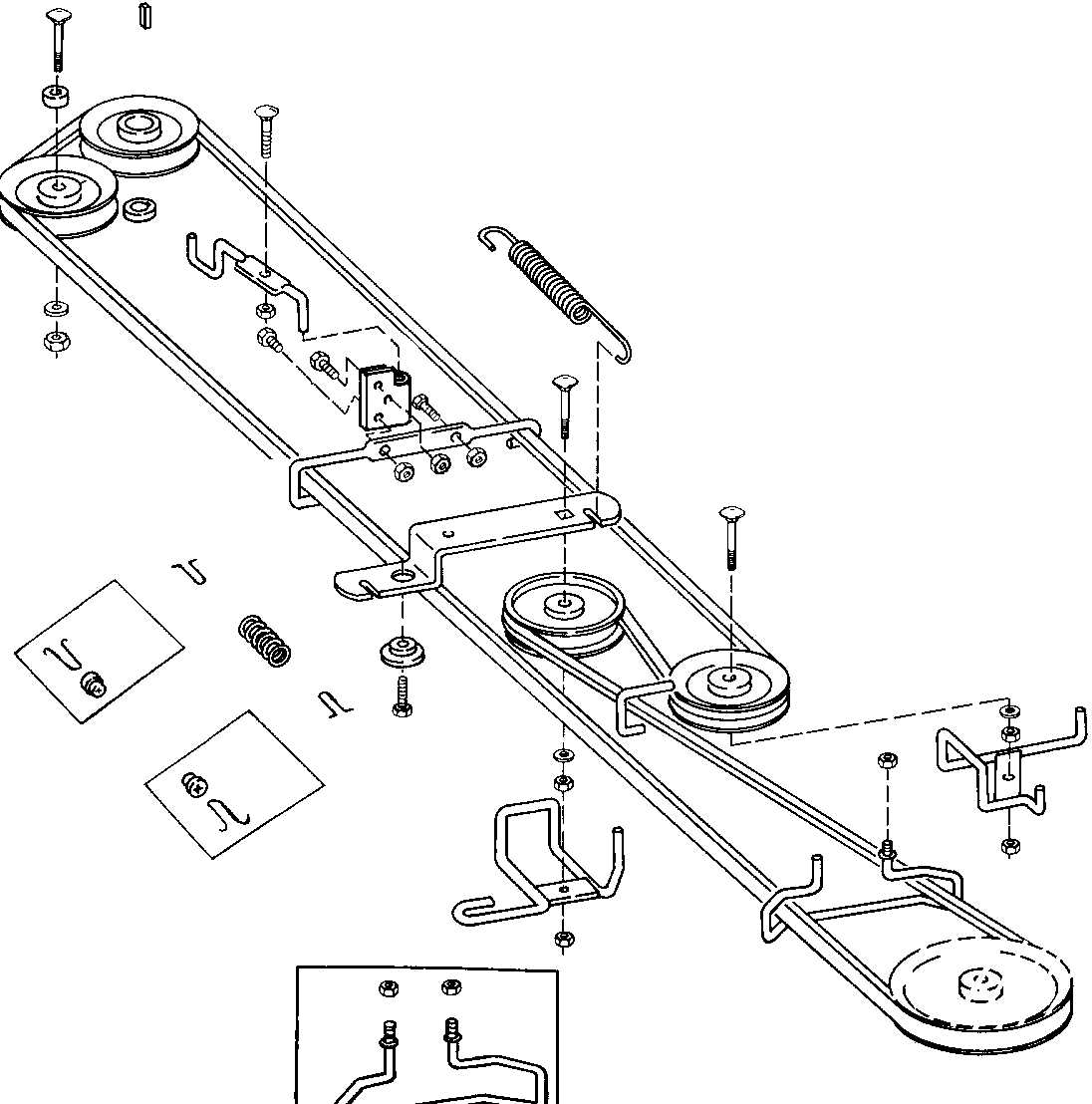

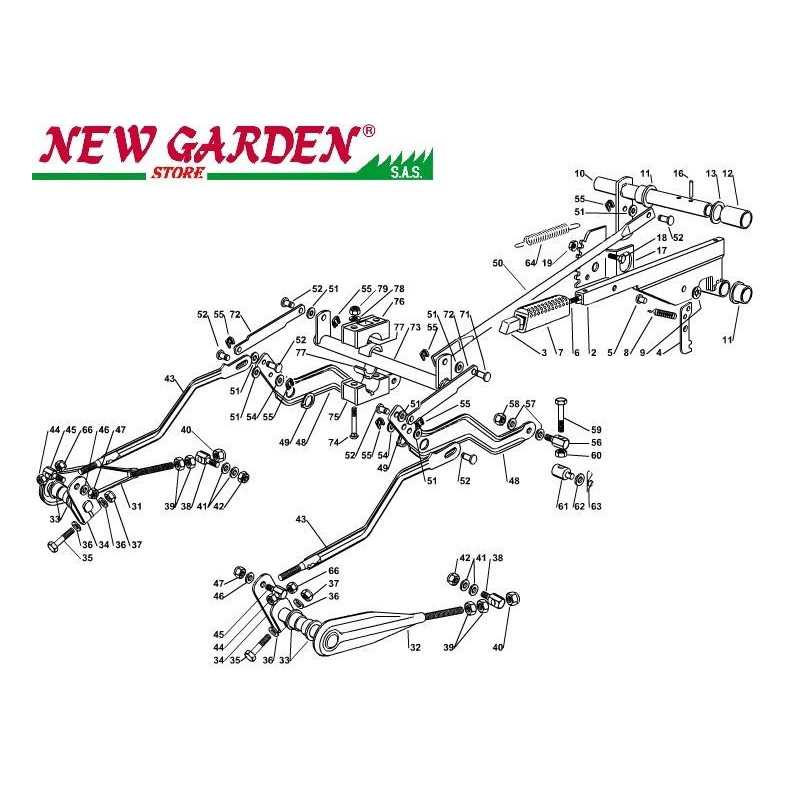

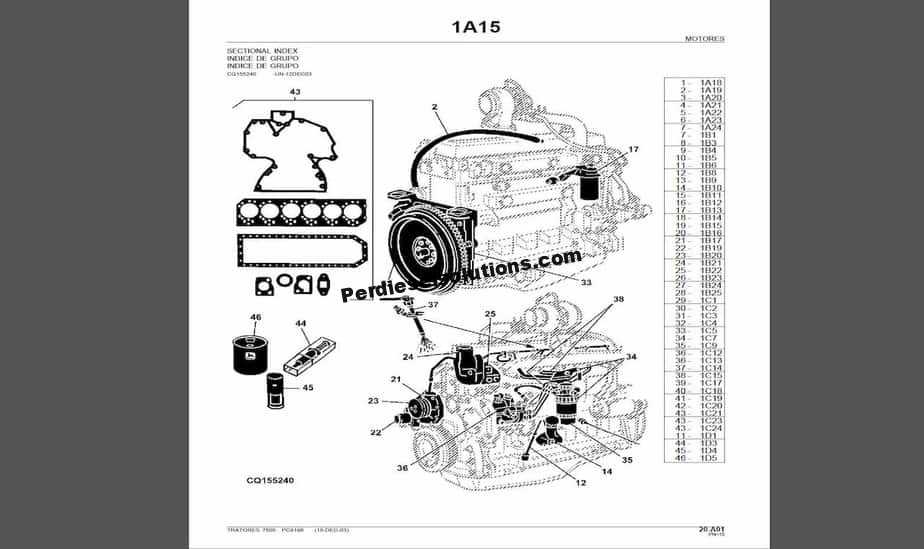

In this guide, we will explore the various segments that make up this essential outdoor machinery. From the driving system to the mowing assembly, understanding the layout of these components is crucial for effective maintenance and troubleshooting. Familiarity with the arrangement not only aids in repairs but also enhances overall operational efficiency.

Whether you are a seasoned technician or a casual user, a detailed illustration of these elements will empower you to tackle any issues that may arise. By familiarizing yourself with the layout, you will be better equipped to keep your equipment running smoothly and efficiently, ensuring a well-manicured lawn all season long.

Understanding the John Deere 185 Hydro

This section explores the key elements and components that contribute to the functionality of a renowned riding mower model. By breaking down the essential features, users can appreciate the engineering behind its performance and maintenance requirements.

Key Features

The model boasts an innovative transmission system that enhances maneuverability and responsiveness. Additionally, its robust design ensures durability, making it suitable for various terrains and lawn sizes.

Maintenance Considerations

Key Features of the John Deere 185

This exceptional piece of machinery offers a multitude of features designed to enhance performance and efficiency in various tasks. From its robust construction to its innovative technology, this model stands out as a reliable choice for those seeking high-quality equipment for landscaping and maintenance.

Powerful Engine: Equipped with a high-performance engine, this unit delivers impressive torque and acceleration, allowing for smooth operation even in challenging conditions. Its design ensures longevity and consistent performance over time.

Advanced Transmission: The incorporation of a state-of-the-art transmission system facilitates effortless maneuvering. Operators can easily shift gears, providing greater control and responsiveness, making it ideal for both novice and experienced users.

Ergonomic Design: Comfort is paramount, and the thoughtful design of the operator’s station ensures ease of use. The adjustable seat and intuitive controls minimize fatigue during extended periods of operation, enhancing the overall experience.

Versatile Attachments: This model supports a wide range of attachments, significantly increasing its functionality. Whether it’s mowing, plowing, or hauling, the adaptability of this equipment makes it a valuable asset for various tasks.

Durability: Constructed with high-quality materials, this equipment is built to withstand rigorous use. Its robust frame and protective features ensure reliability, reducing maintenance needs and prolonging its lifespan.

Efficient Cutting System: The cutting mechanism is designed for optimal performance, providing clean and precise results. This feature not only enhances aesthetics but also promotes healthy growth in landscaped areas.

Overall, this machine exemplifies excellence in design and functionality, making it an indispensable tool for anyone involved in outdoor maintenance and landscaping activities.

Common Issues with Hydrostatic Systems

Hydraulic drive systems play a crucial role in various machinery, offering smooth operation and efficient power transfer. However, like any mechanical system, they can encounter a range of challenges that may hinder performance. Understanding these common issues is essential for maintenance and troubleshooting.

One prevalent problem is fluid contamination, which can arise from debris or moisture entering the system. Contaminated fluid can lead to poor performance and even damage to internal components. Regularly checking and changing the hydraulic fluid is vital to prevent such issues.

Another frequent concern is pressure loss, which can result from leaks or worn seals. When the system cannot maintain the required pressure, it affects the overall efficiency and responsiveness of the machinery. Identifying and addressing leaks promptly can help maintain optimal function.

Overheating is also a common issue, often caused by excessive load or insufficient fluid circulation. High temperatures can degrade hydraulic fluid and damage components, leading to costly repairs. Ensuring proper cooling and monitoring operational loads can mitigate this risk.

Finally, noise and vibrations may indicate underlying issues, such as air trapped in the system or worn parts. These symptoms can impact performance and indicate a need for inspection. Regular maintenance and attention to these signs can help keep hydraulic systems running smoothly.

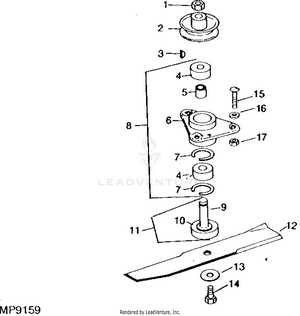

How to Access the Parts Diagram

Accessing the visual breakdown of components for your machinery can greatly enhance your understanding and maintenance efforts. This guide will outline the steps to obtain this valuable resource efficiently.

Step-by-Step Instructions

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Search for the model you own in the provided search bar.

- Look for the section dedicated to illustrations or assembly guides.

- Select the appropriate resource to view or download.

Additional Tips

- Ensure you have your model number handy for quicker access.

- Check if a user manual is available for more detailed information.

- Consider joining online forums for shared experiences and tips.

Essential Replacement Parts Overview

Maintaining equipment functionality requires an understanding of key components that may need to be substituted over time. These vital elements ensure optimal performance and longevity, contributing to a seamless operational experience.

Engine Components: The heart of any machine, these pieces are critical for power generation and efficiency. Regular inspection and timely replacement can prevent significant downtime.

Transmission Systems: Essential for smooth power transfer, these systems are integral to maneuverability. Keeping them in top condition is paramount for safe operation.

Electrical Units: This category encompasses various switches, batteries, and wiring. Ensuring these are functioning properly is crucial for reliable performance and safety.

Hydraulic Components: These parts play a vital role in controlling movement and functionality. Regular checks and maintenance can help avert major issues.

Cooling Systems: Proper temperature management is key to avoiding overheating. Replacing worn or damaged components can significantly enhance performance and durability.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. By following a few essential maintenance practices, you can extend the lifespan of your machinery and enhance its overall performance. This section outlines key strategies to keep your unit in optimal condition.

Routine Inspections

Regular check-ups are crucial for identifying potential issues before they escalate. Consider the following:

- Inspect belts and hoses for signs of wear and tear.

- Check fluid levels, including oil and coolant, to ensure they are at appropriate levels.

- Examine tires for proper inflation and tread wear.

- Clean air filters regularly to maintain airflow and efficiency.

Proper Cleaning Techniques

Keeping your equipment clean not only enhances its appearance but also prevents damage from debris and corrosion. Here are some cleaning tips:

- Wash the exterior with mild soap and water, avoiding harsh chemicals that can damage paint.

- Remove dirt and debris from hard-to-reach areas using compressed air or a soft brush.

- Store the machine in a sheltered location to protect it from the elements.

- Lubricate moving parts to reduce friction and wear.

By implementing these practices, you can significantly improve the longevity and reliability of your equipment, ensuring it serves you well for years to come.

Finding Quality Aftermarket Components

When seeking replacements for machinery components, it is crucial to prioritize quality to ensure longevity and optimal performance. The aftermarket industry offers a variety of options that can meet or even exceed the specifications of original equipment. However, navigating this market requires careful consideration and research.

Here are some key factors to consider when looking for reliable alternatives:

- Reputation of the Manufacturer: Look for brands that are known for their quality and reliability. Reviews and testimonials from other customers can provide valuable insights.

- Material and Build Quality: Assess the materials used in the components. High-quality materials often lead to enhanced durability and performance.

- Compatibility: Ensure that the components are compatible with your equipment. Mismatched parts can lead to inefficiencies and increased wear and tear.

- Warranty and Support: A good warranty indicates the manufacturer’s confidence in their products. Additionally, reliable customer support can assist with any issues that may arise.

- Price vs. Quality: While it may be tempting to opt for the cheapest option, balance the cost with the quality offered. Sometimes, investing a little more upfront can save money in the long run.

By focusing on these factors, you can confidently select aftermarket components that will enhance the performance and reliability of your machinery.

Comparing Models: 185 vs. 190

This section explores the differences between two popular lawn care machines, focusing on their features, performance, and suitability for various tasks. Understanding these distinctions can help users make informed decisions based on their specific needs.

Key aspects to consider include:

- Engine Performance: Assess the power and efficiency of each model’s engine.

- Transmission Type: Compare the drive systems and ease of use.

- Cutting Width: Analyze the width options and how they affect mowing efficiency.

- Comfort Features: Evaluate the ergonomic design and user-friendly controls.

- Maintenance Requirements: Discuss upkeep and ease of servicing.

By examining these elements, users can delve into the ultimate choice for their lawn care needs.

Customer Reviews and Experiences

When it comes to the performance of machinery, user feedback plays a vital role in understanding its strengths and weaknesses. Customers often share their insights based on personal experiences, which can significantly influence potential buyers’ decisions. This section highlights the diverse opinions of users who have interacted with their equipment, providing valuable perspectives on reliability, ease of use, and overall satisfaction.

Many users express their appreciation for the durability and efficiency of their machines. They highlight how these machines have seamlessly integrated into their daily routines, enhancing productivity and reducing downtime. One reviewer noted that their model has been a reliable companion for years, requiring minimal maintenance while delivering consistent performance.

On the other hand, some customers have shared challenges they faced during ownership. Issues such as part availability and the complexity of repairs can sometimes lead to frustration. A particular user mentioned that while the equipment performs well, finding specific components took longer than expected, impacting their ability to complete tasks promptly.

Overall, the feedback reflects a balance of satisfaction and occasional hurdles, allowing potential buyers to make informed choices based on real-world experiences.